A Equipment Calibration Record Document Sample for Production Machinery provides a detailed log of calibration activities, ensuring machines operate within specified tolerances. This document includes essential information such as calibration dates, equipment identification, technician details, and measurement results. Maintaining accurate calibration records helps optimize production efficiency and comply with quality standards.

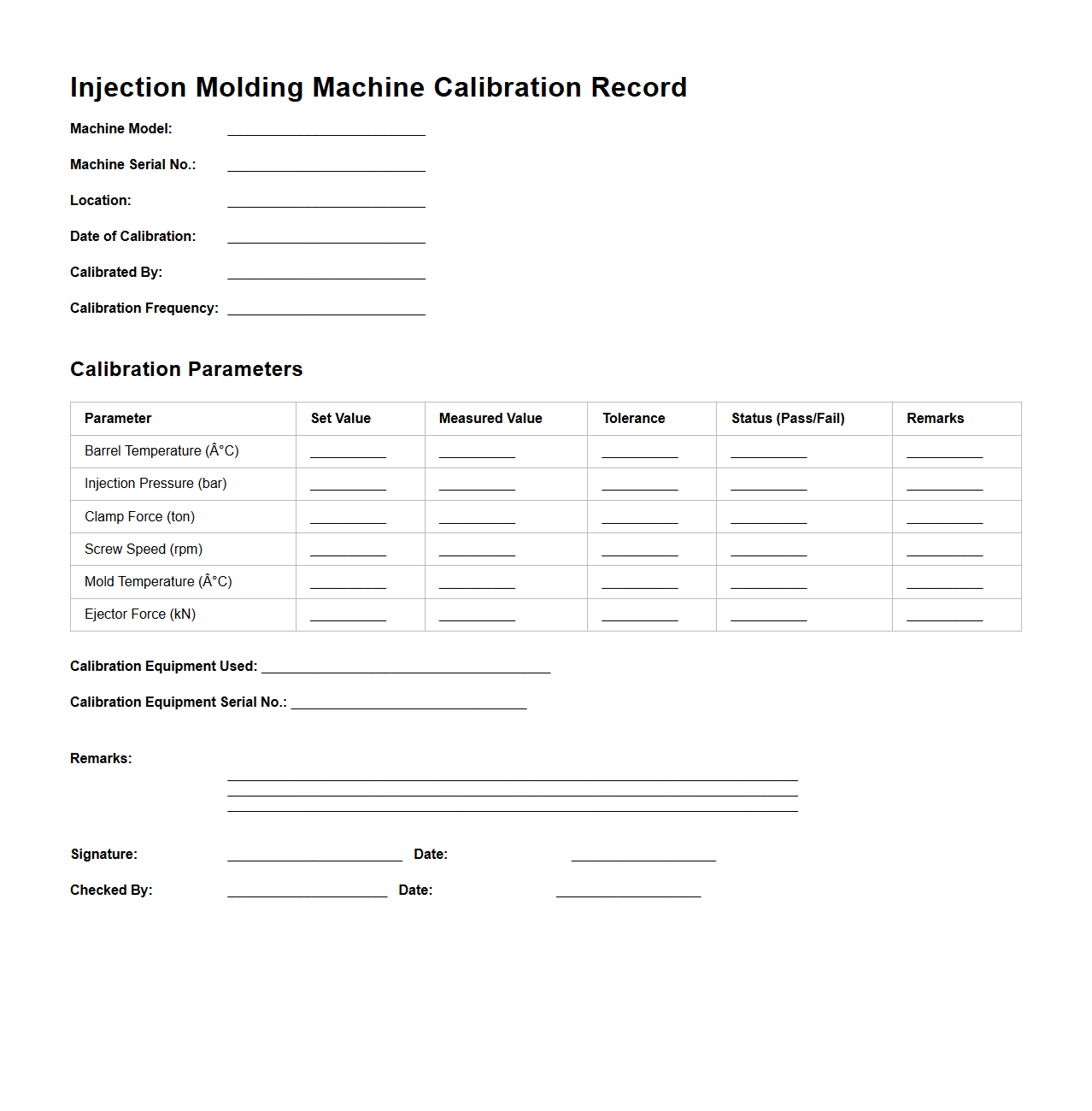

Injection Molding Machine Calibration Record Example

An

Injection Molding Machine Calibration Record Example document is a detailed log that tracks the calibration status and settings of injection molding machines, ensuring precision in manufacturing processes. It includes recorded data such as pressure, temperature, cycle times, and machine parameters, allowing for quality control and maintenance verification. This document helps maintain consistent product quality by providing evidence of machine accuracy and compliance with industry standards.

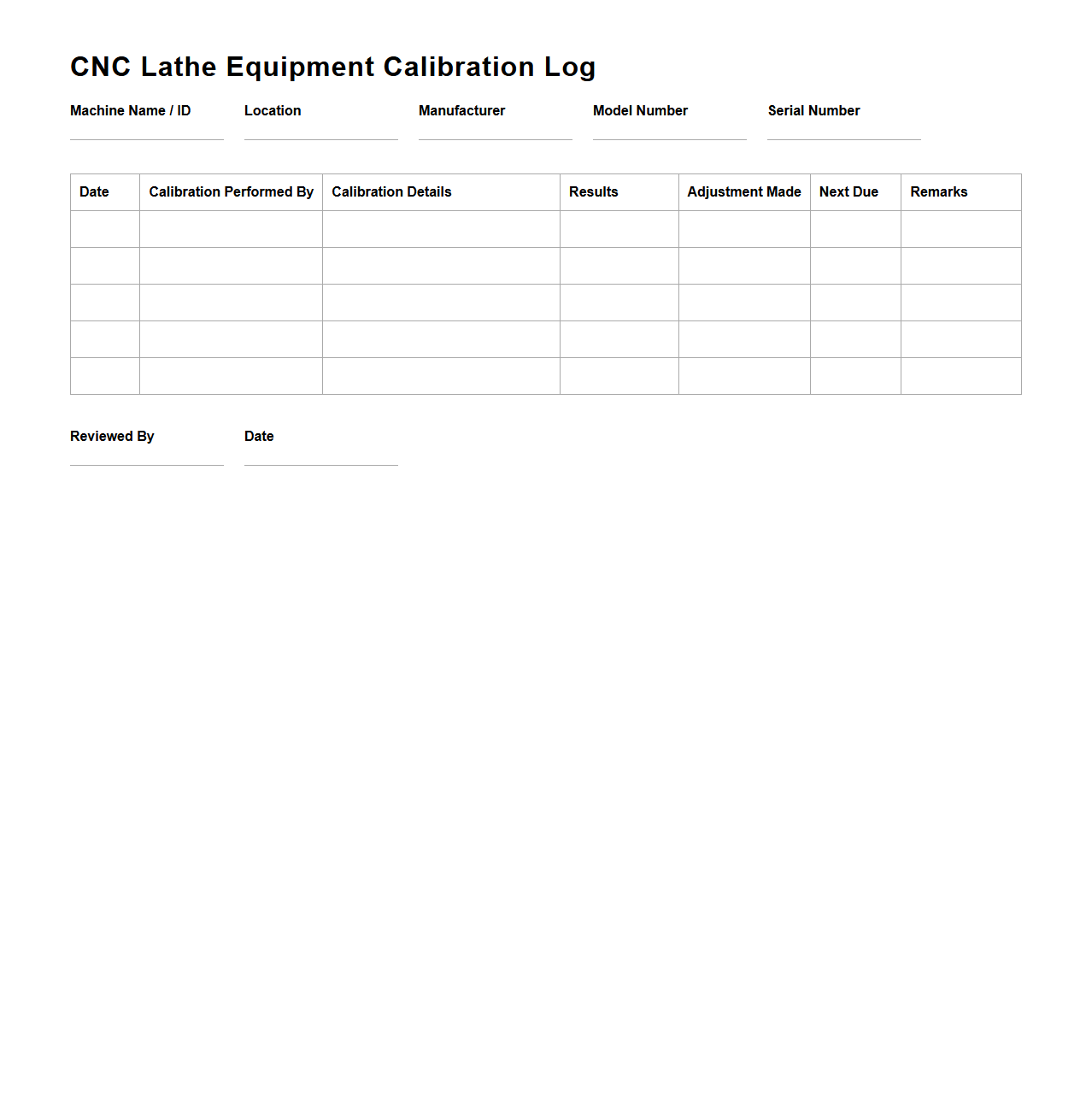

CNC Lathe Equipment Calibration Log Template

A

CNC Lathe Equipment Calibration Log Template document is used to systematically record calibration details for CNC lathe machines, ensuring precision and operational accuracy. It tracks critical data such as calibration dates, technician information, equipment identification, measured values, and compliance with industry standards. This log template is essential for maintaining quality control, minimizing machine errors, and meeting regulatory audit requirements.

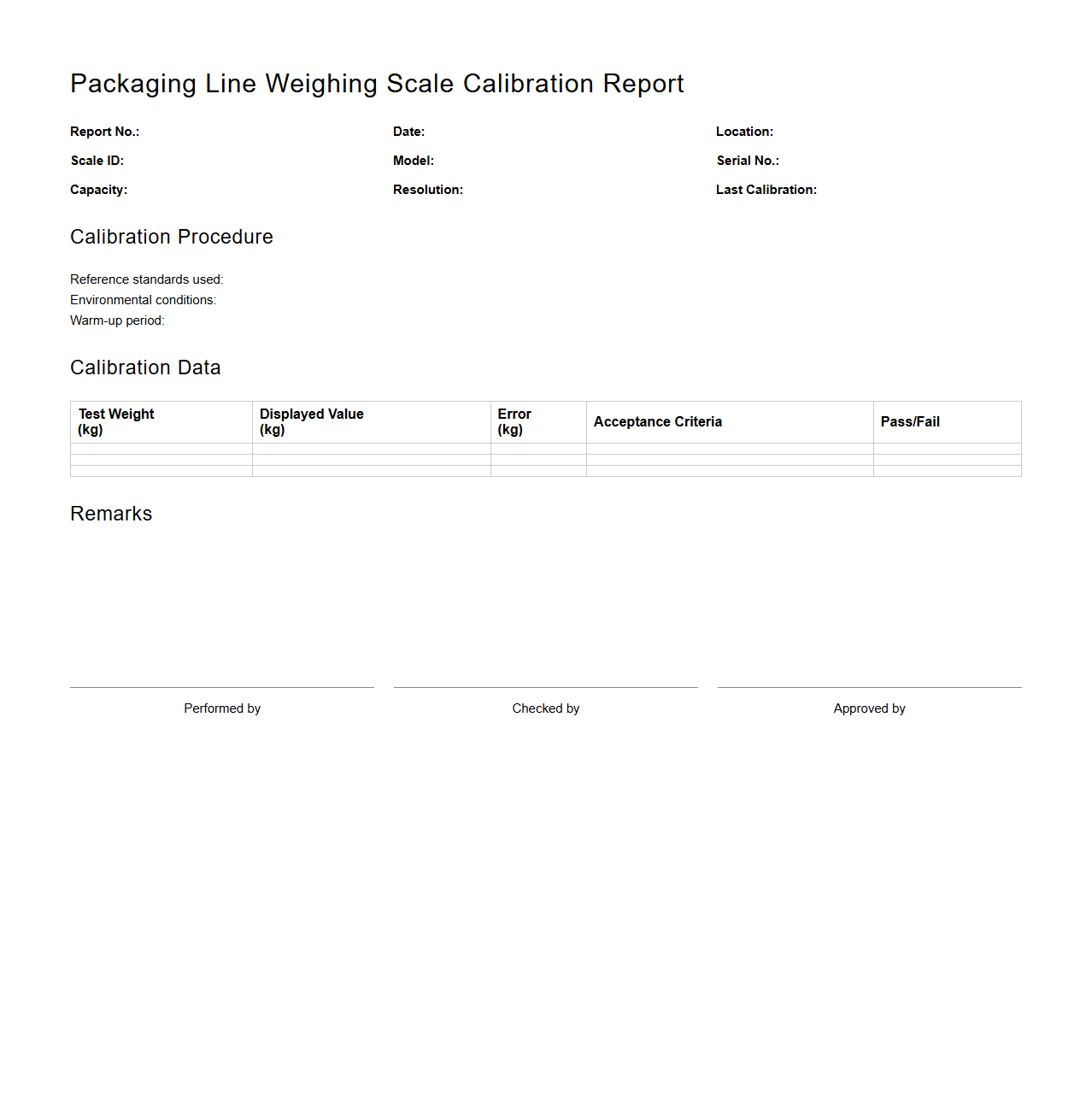

Packaging Line Weighing Scale Calibration Report

A

Packaging Line Weighing Scale Calibration Report document details the precision checks and adjustments performed on weighing scales used in packaging lines to ensure accurate measurements. It includes data such as calibration dates, measurement deviations, correction factors, and verification results to maintain compliance with industry standards. This report is critical for quality control, regulatory audits, and maintaining product consistency throughout the packaging process.

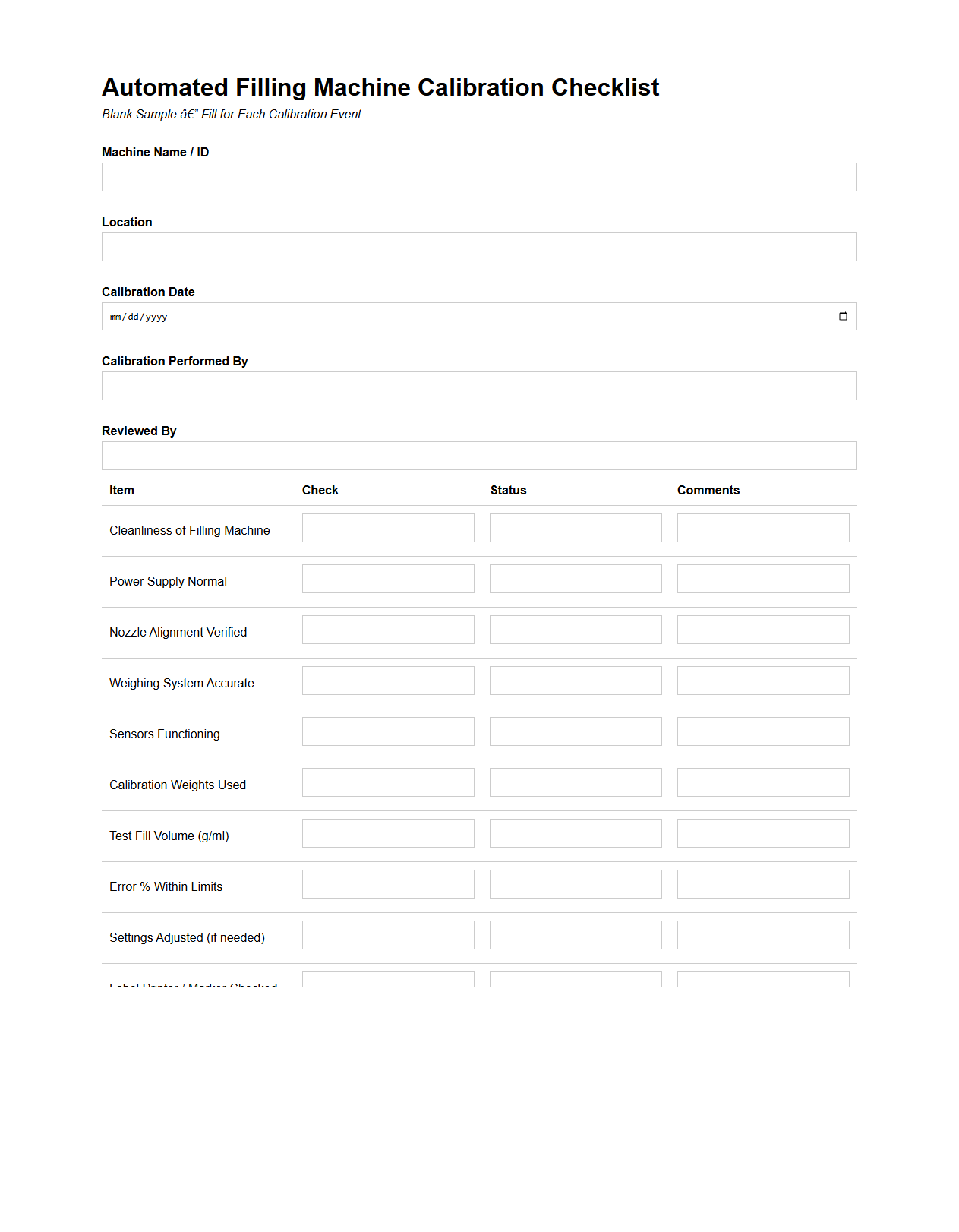

Automated Filling Machine Calibration Checklist

The

Automated Filling Machine Calibration Checklist document serves as a vital tool to ensure precise calibration and consistent performance of automated filling machines. It outlines specific procedures, measurement criteria, and verification steps to maintain accuracy in volume, speed, and alignment during the filling process. Regular use of this checklist helps prevent operational errors, reduces product waste, and complies with industry quality standards.

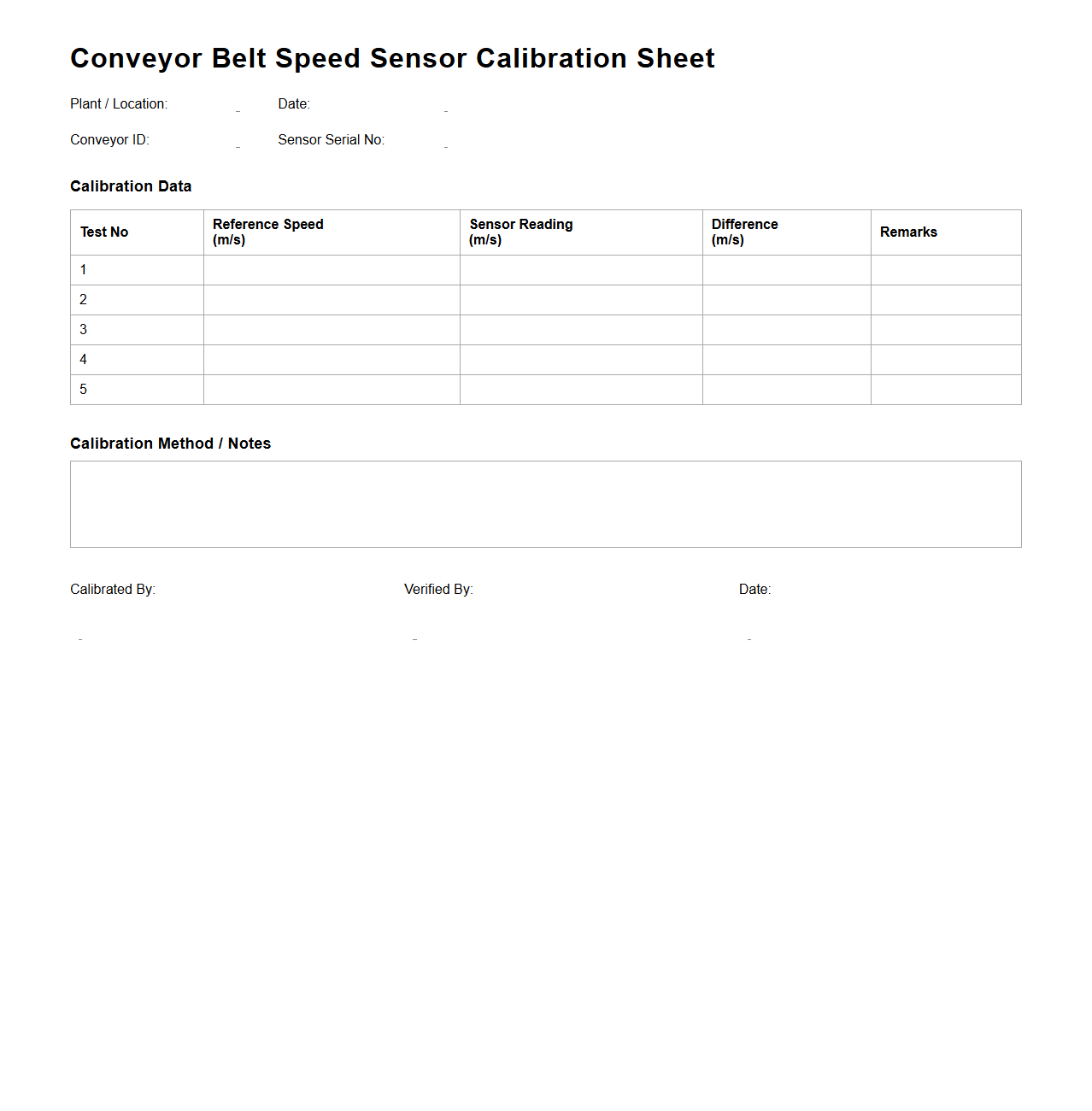

Conveyor Belt Speed Sensor Calibration Sheet

A

Conveyor Belt Speed Sensor Calibration Sheet document records precise calibration data to ensure accurate speed measurement of conveyor belt systems. It includes sensor specifications, calibration dates, measured speed values, and adjustment settings necessary for optimal sensor performance. This sheet is essential for maintaining consistent operational efficiency and preventing process errors in automated material handling.

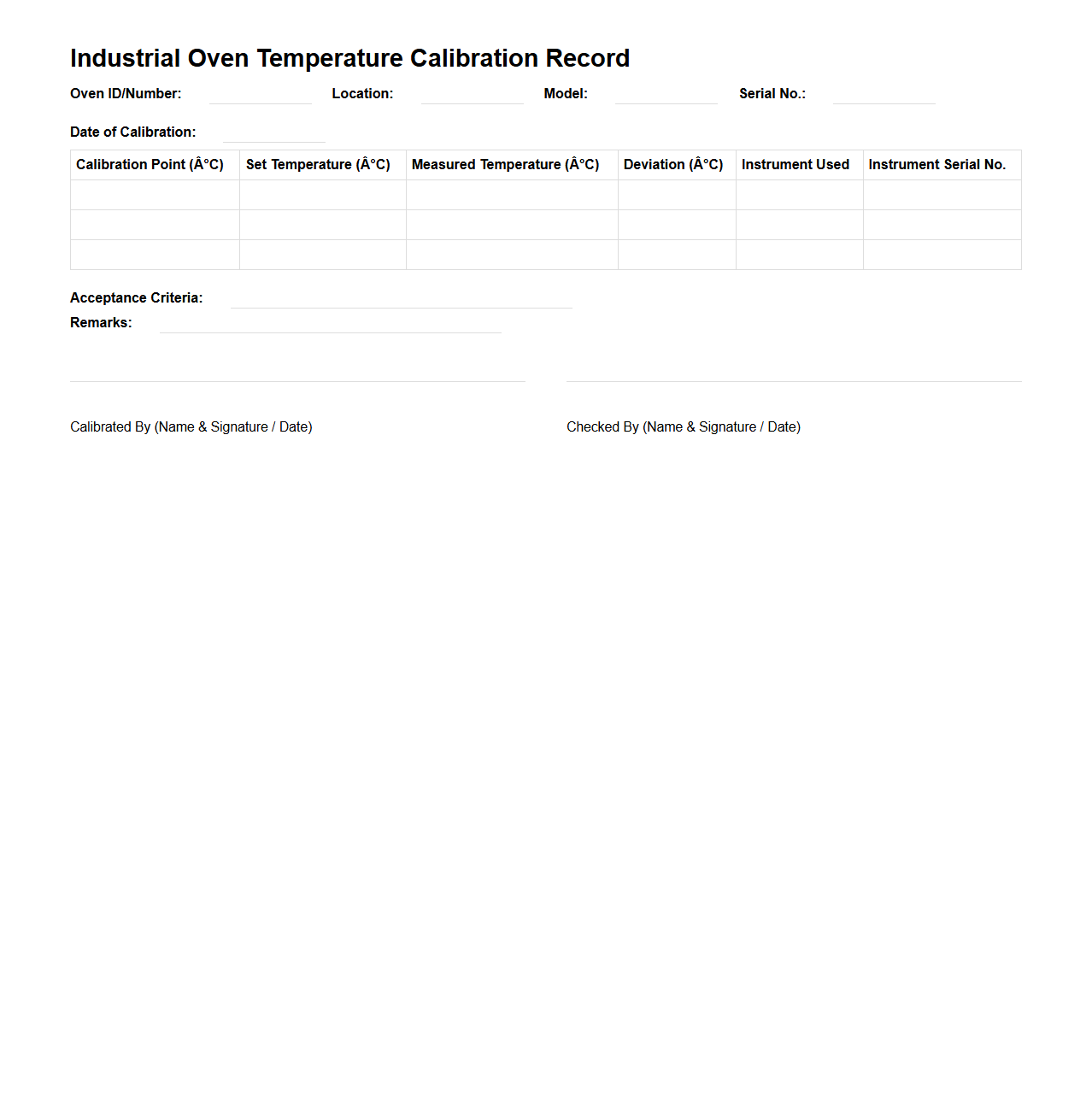

Industrial Oven Temperature Calibration Record

An

Industrial Oven Temperature Calibration Record document is a detailed log used to verify and document the accuracy of temperature settings in industrial ovens. It contains temperature readings taken at specific intervals during calibration processes to ensure that the oven maintains precise temperature control critical for manufacturing quality and safety. These records are essential for compliance with industry standards and audits, helping to maintain consistent product quality and equipment performance.

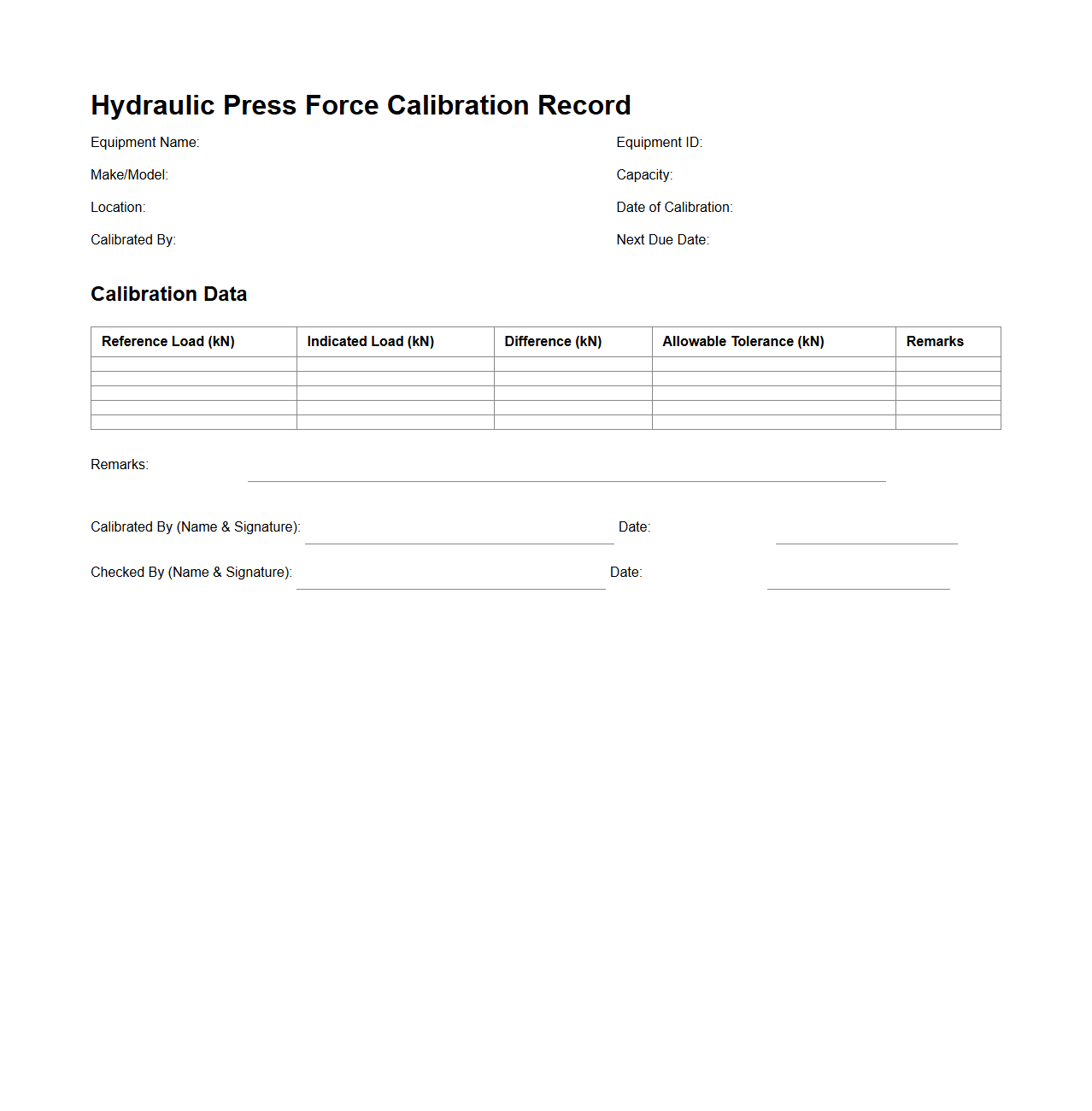

Hydraulic Press Force Calibration Record

The

Hydraulic Press Force Calibration Record document is a detailed log that tracks the calibration of the force exerted by a hydraulic press to ensure accuracy and compliance with industry standards. It includes critical data such as calibration dates, applied forces, measurement results, and the technician's verification, helping maintain the press's performance and safety. Accurate records support quality control processes, prevent equipment failure, and ensure consistent operational output.

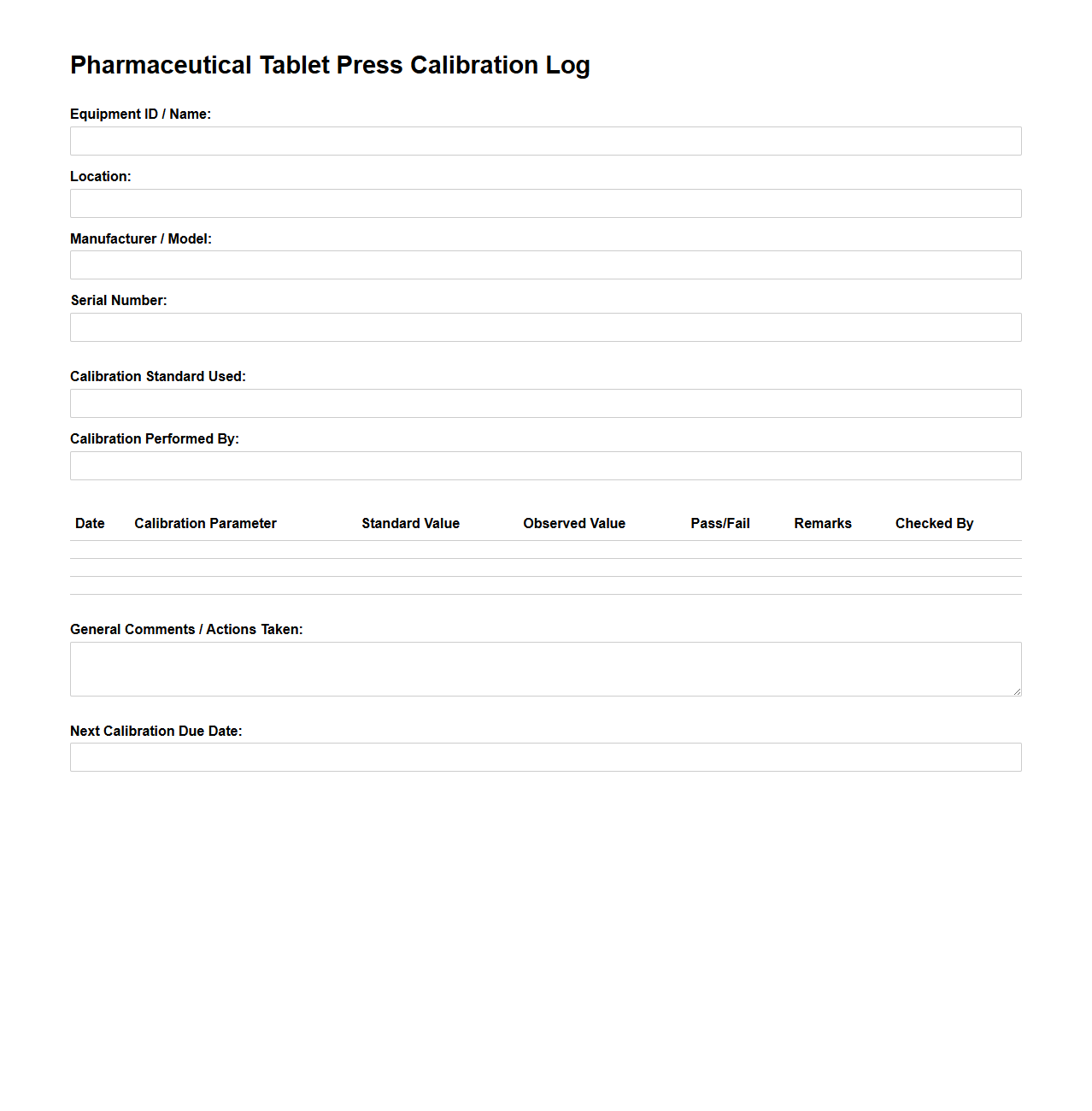

Pharmaceutical Tablet Press Calibration Log

A

Pharmaceutical Tablet Press Calibration Log document records detailed information about the calibration activities of tablet press machines used in drug manufacturing. It ensures compliance with regulatory standards by tracking calibration dates, technician details, machine settings, and measurement results. Maintaining this log is essential for quality control, preventing production errors, and validating equipment performance.

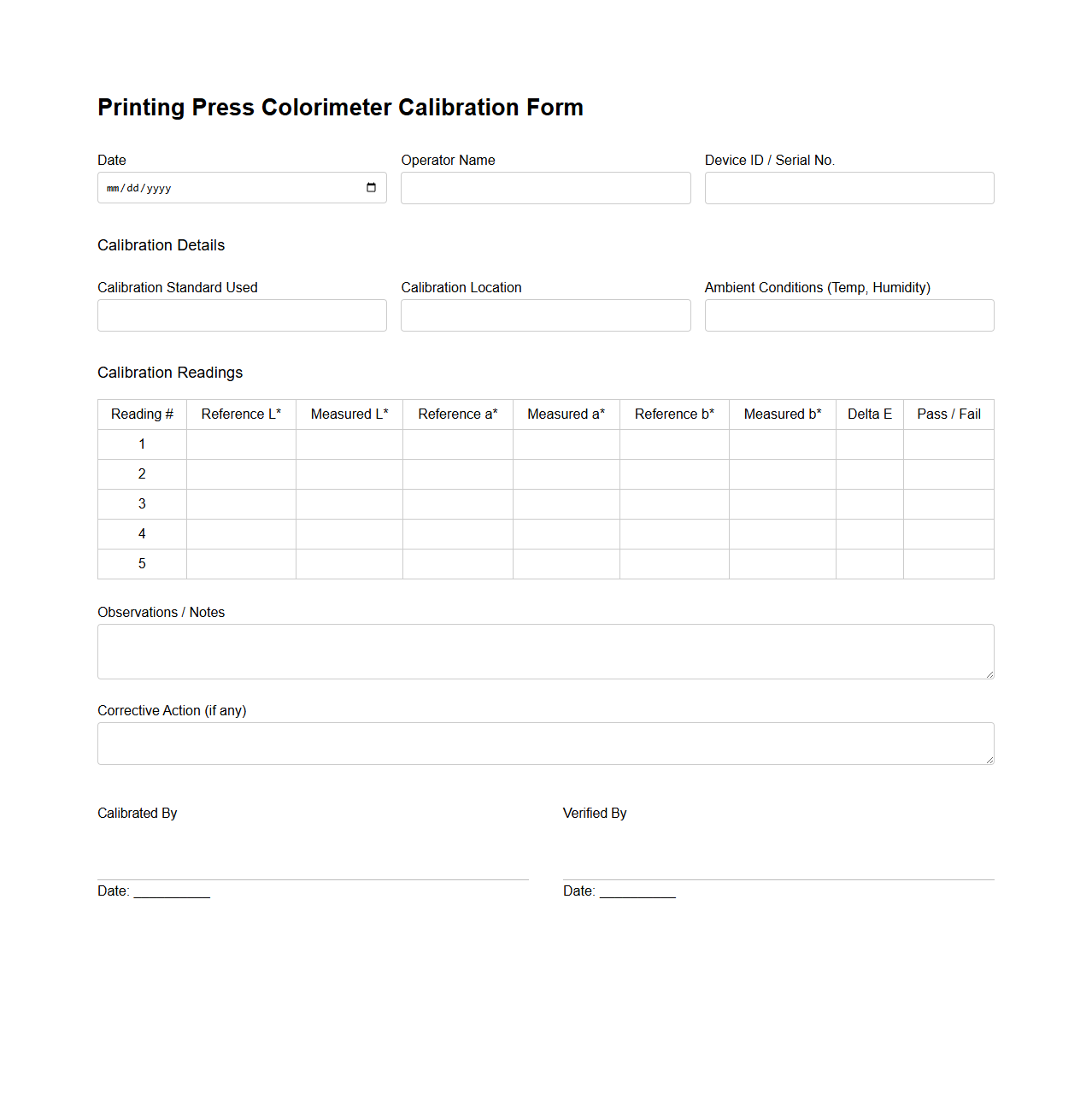

Printing Press Colorimeter Calibration Form

The

Printing Press Colorimeter Calibration Form document is used to record and verify the calibration settings of colorimeters used in printing presses, ensuring accurate color measurement and consistency. This form typically includes fields for device identification, calibration date, reference standards, and measured values against known color patches. Maintaining precise calibration records helps achieve optimal print quality and adherence to industry color standards.

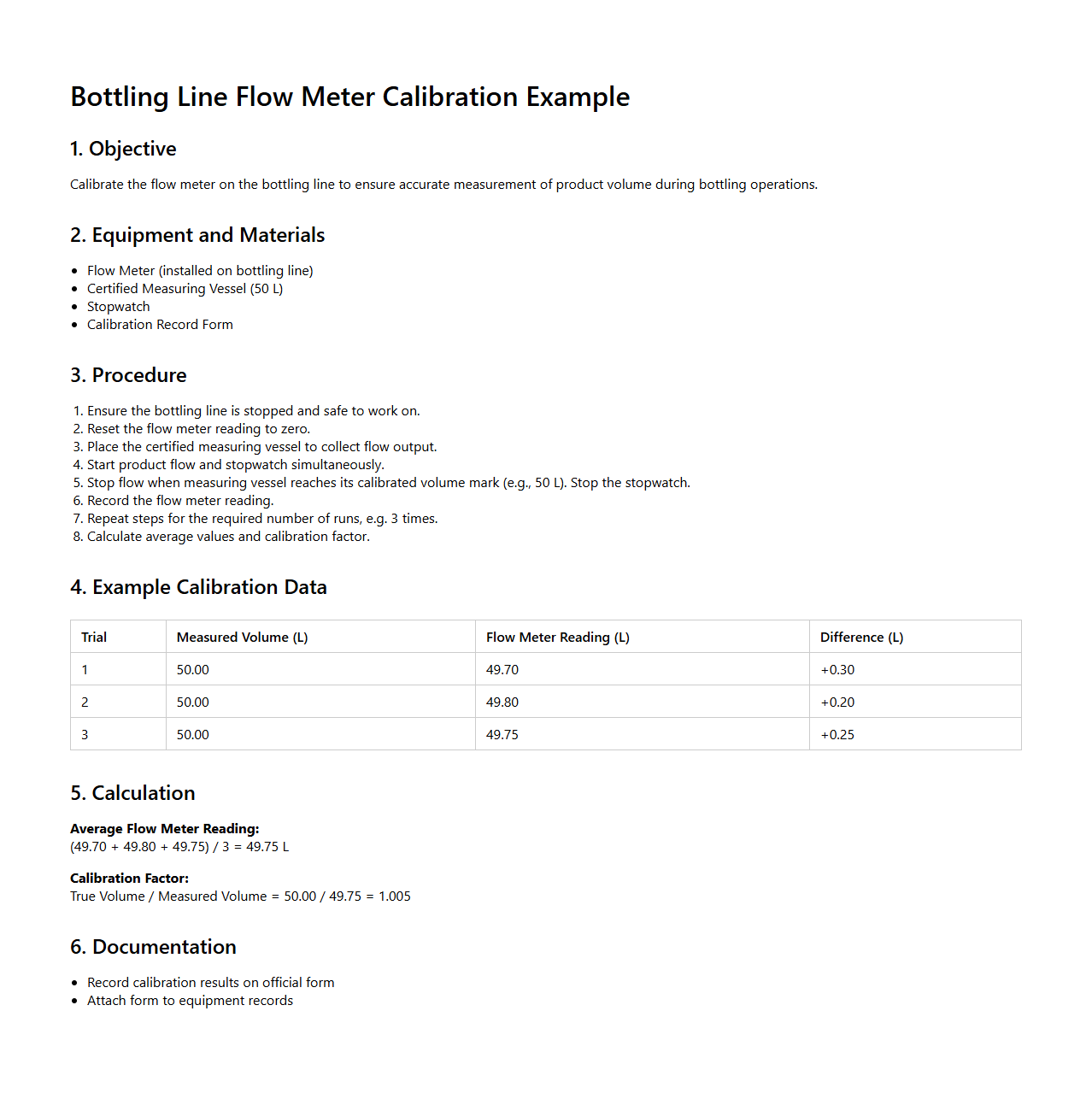

Bottling Line Flow Meter Calibration Example

A

Bottling Line Flow Meter Calibration Example document provides detailed procedures and standards for accurately calibrating flow meters used in bottling lines, ensuring precise measurement of liquid volumes. It typically includes step-by-step instructions, calibration methods, and acceptable tolerance ranges to maintain production quality and regulatory compliance. This document helps technicians verify and adjust flow meter performance, reducing errors and optimizing bottling efficiency.

What specific equipment or machinery is covered by this Equipment Calibration Record document?

The Equipment Calibration Record document covers all critical machinery used within the operational process. This includes measuring instruments, testing devices, and production equipment requiring regular calibration. The document ensures each piece of equipment listed undergoes timely verification for accuracy.

Which calibration standards and procedures are referenced within the document?

The document references internationally recognized calibration standards, such as ISO 17025 and ASTM guidelines. It includes detailed procedures ensuring consistency and reliability during the calibration process. These standards guarantee the equipment meets industry-specific accuracy requirements.

Who is authorized to perform and verify the calibration activities according to the record?

Only qualified and certified personnel are authorized to conduct and verify calibration activities. The document specifies roles including calibration technicians and quality assurance inspectors. Authorization ensures accountability and compliance with quality management systems.

What are the acceptable tolerance limits and calibration intervals specified for each piece of machinery?

The record clearly defines acceptable tolerance limits for each instrument based on manufacturer specifications and industry standards. Calibration intervals are scheduled at regular, predefined periods to maintain accuracy. This systematic approach minimizes errors and ensures operational efficiency.

How and where are non-conformities or calibration failures recorded and addressed in the document?

All non-conformities and calibration failures are logged in a dedicated section of the document. Corrective actions and follow-up procedures are outlined to resolve issues promptly. This process helps maintain calibration integrity and supports continuous improvement.

More Manufacturing Templates