The Finished Goods Inspection Document Sample for Quality Assurance ensures that products meet specified standards before shipment. It includes detailed checklists, measurement criteria, and defect classifications to maintain consistent quality. This document helps streamline the inspection process and supports compliance with industry regulations.

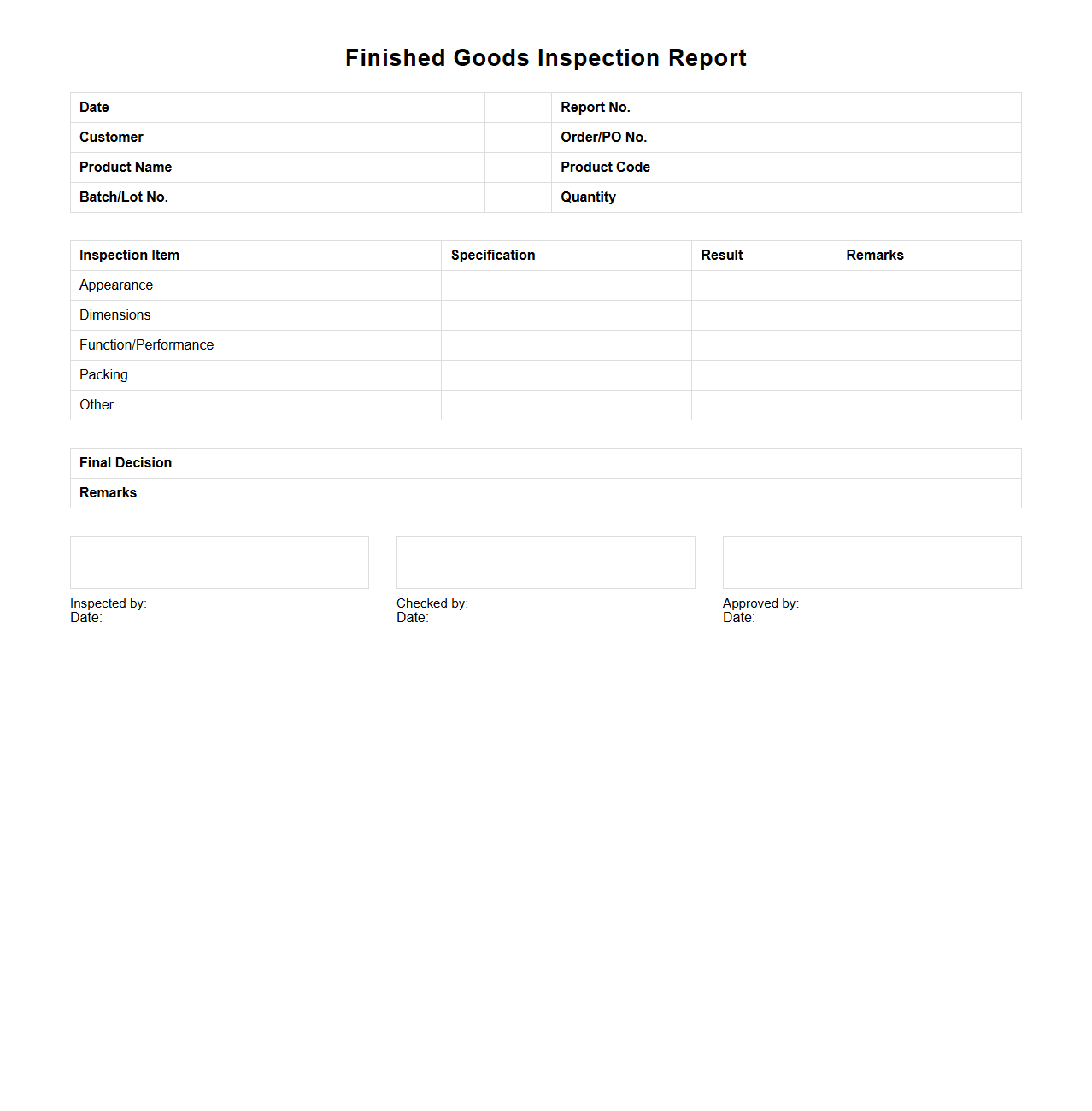

Finished Goods Inspection Report Template

A

Finished Goods Inspection Report Template document is a structured form used to systematically record and evaluate the quality and compliance of final products before shipment or delivery. It includes detailed sections for item descriptions, inspection criteria, defect categorization, and inspector remarks to ensure consistent quality control. This template helps organizations maintain product standards, reduce return rates, and meet regulatory requirements efficiently.

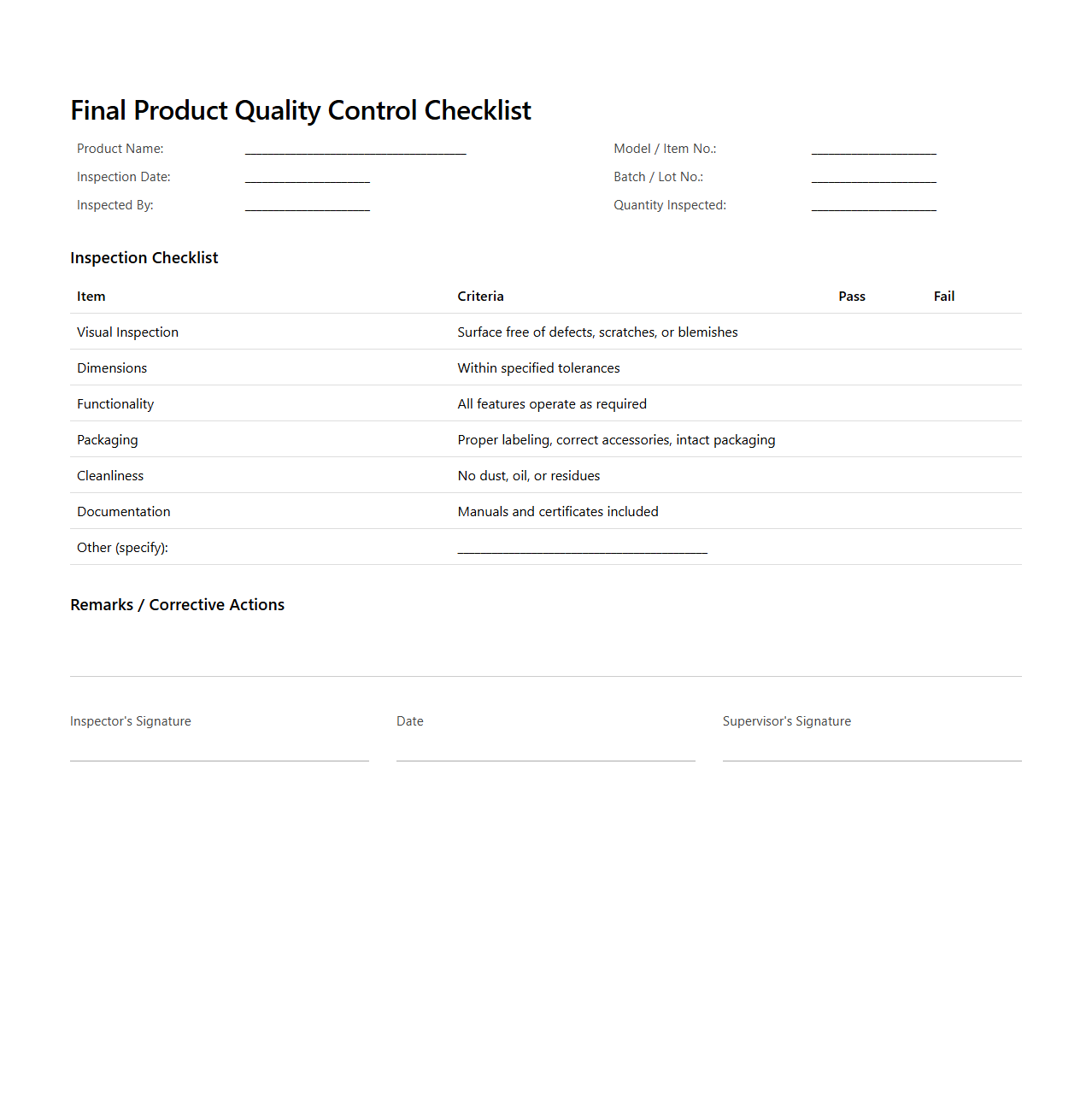

Final Product Quality Control Checklist

The

Final Product Quality Control Checklist document serves as a comprehensive guide to verify that all product specifications and quality standards have been met before shipment or release. It includes critical inspection points such as dimensional accuracy, functional performance, safety compliance, and packaging integrity. This checklist ensures consistent quality assurance, reduces defects, and enhances customer satisfaction by systematically validating the final product against predefined criteria.

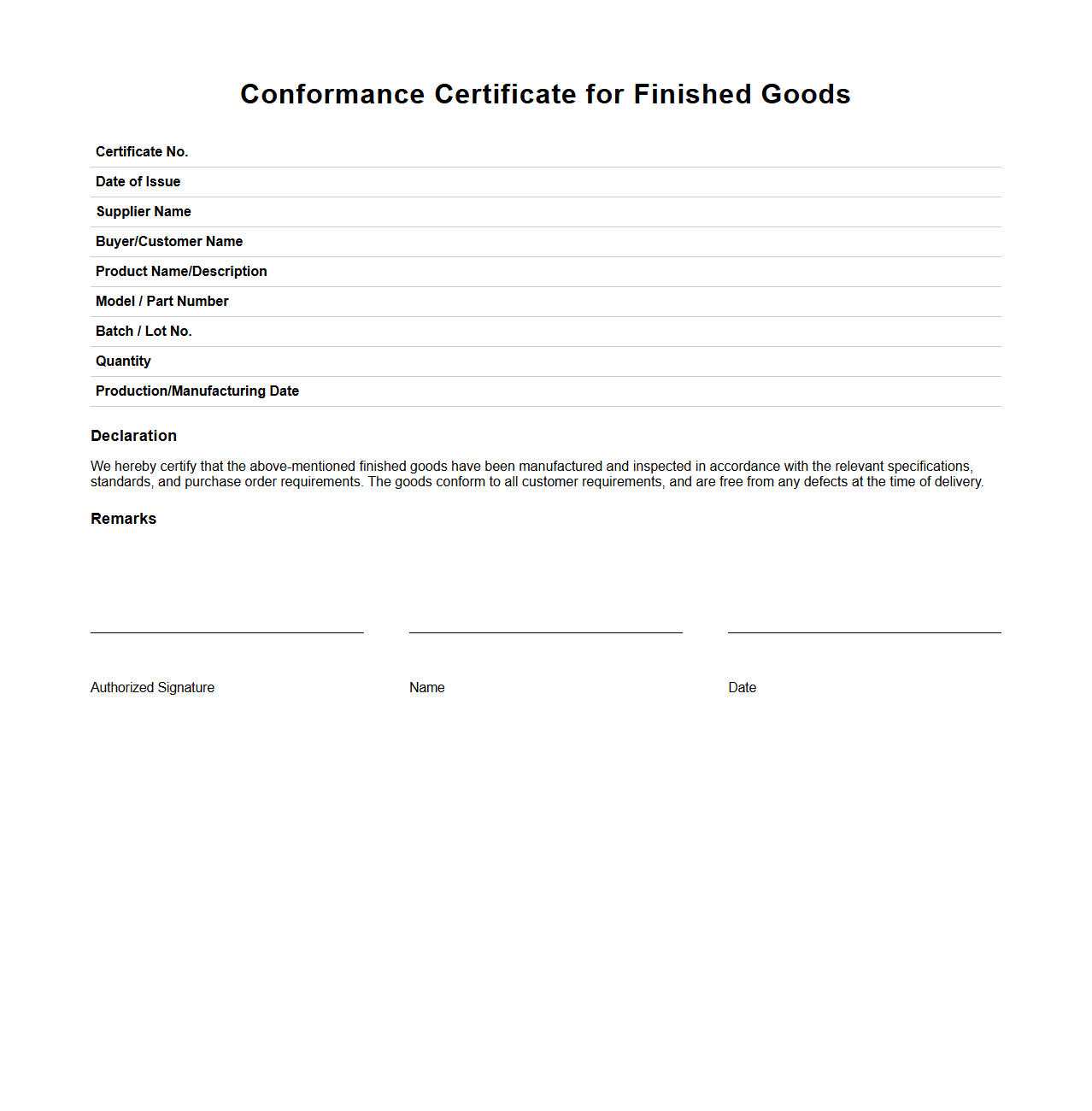

Conformance Certificate for Finished Goods

A

Conformance Certificate for Finished Goods is a formal document that verifies products meet specified standards and requirements established by regulatory authorities or client contracts. It provides assurance that the finished goods comply with quality, safety, and performance criteria, enabling smooth acceptance during inspections or audits. Manufacturers issue this certificate to confirm that each batch or lot adheres to agreed specifications, ensuring trust and accountability in the supply chain.

Finished Goods Acceptance Inspection Form

The

Finished Goods Acceptance Inspection Form document serves as a critical tool for verifying that manufactured products meet specified quality standards before being approved for shipment or storage. It details inspection criteria, test results, and conformity status, ensuring compliance with customer requirements and regulatory guidelines. This form helps maintain product integrity, reduce defects, and facilitate traceability throughout the supply chain.

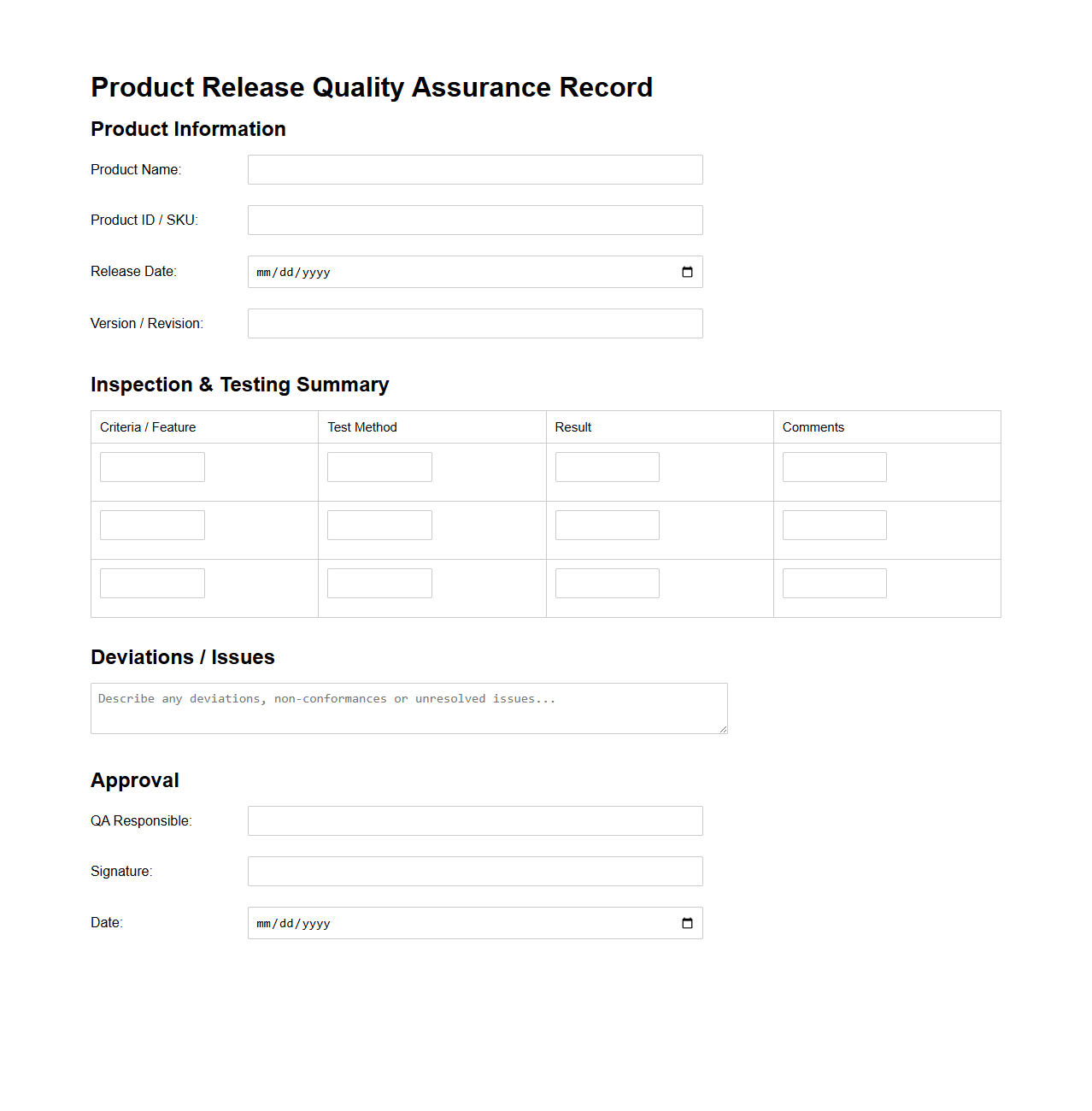

Product Release Quality Assurance Record

The

Product Release Quality Assurance Record document is a critical validation tool used to ensure that a product meets all predefined quality standards before it reaches the market. It compiles detailed test results, inspection reports, and compliance certifications, confirming that every aspect of production aligns with regulatory requirements. This record serves as a verified reference for quality control teams and auditors, guaranteeing product safety, reliability, and customer satisfaction.

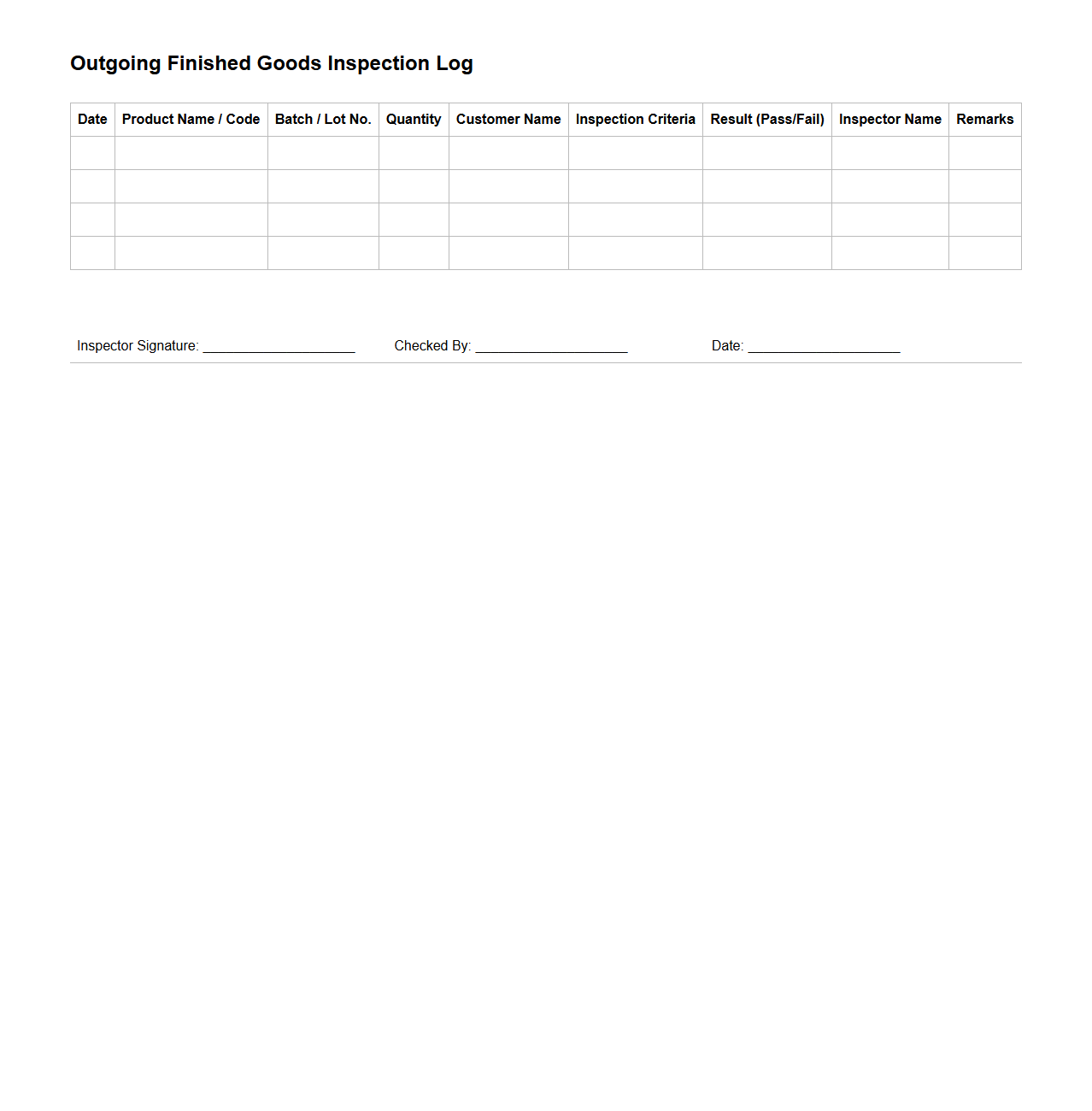

Outgoing Finished Goods Inspection Log

The

Outgoing Finished Goods Inspection Log document records the quality checks and inspections performed on finished products before shipment. It ensures that all items meet specified standards and helps track compliance with regulatory requirements. Maintaining this log enhances product accountability and supports continuous quality improvement processes.

Batch Quality Verification Sheet

A

Batch Quality Verification Sheet is a critical document used in manufacturing and production processes to ensure that each batch of products meets predefined quality standards. It records detailed inspections, test results, and compliance checks for various parameters, helping identify defects or deviations during quality control. This document facilitates traceability, accountability, and continuous improvement in product consistency and safety.

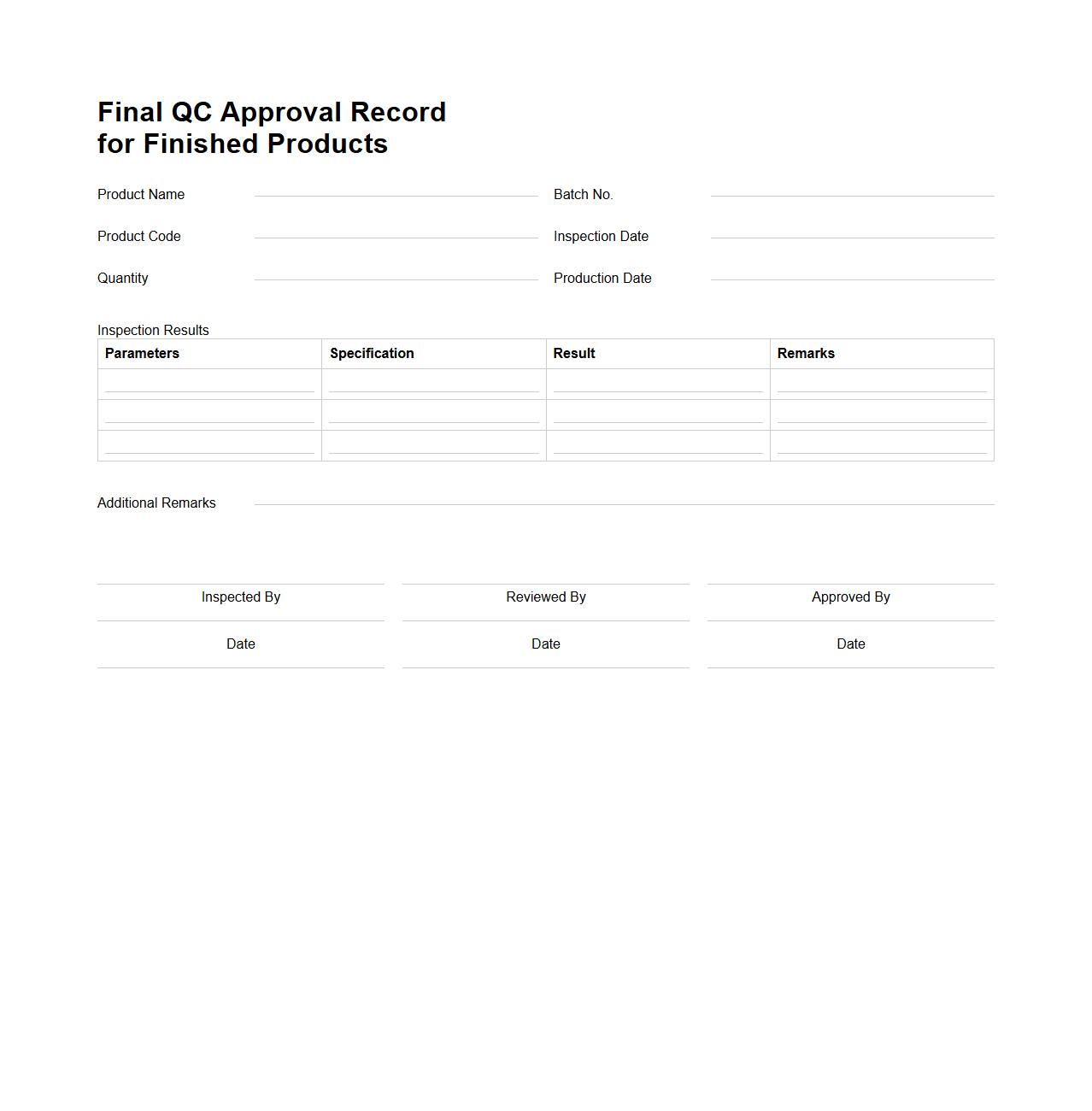

Final QC Approval Record for Finished Products

The

Final QC Approval Record for Finished Products document serves as a verified confirmation that all quality control inspections and tests meet the required standards before the product shipment or release. It includes detailed information such as batch numbers, inspection results, and approval signatures, ensuring traceability and compliance with regulatory requirements. This document is crucial for maintaining product quality assurance and supporting audit processes in manufacturing.

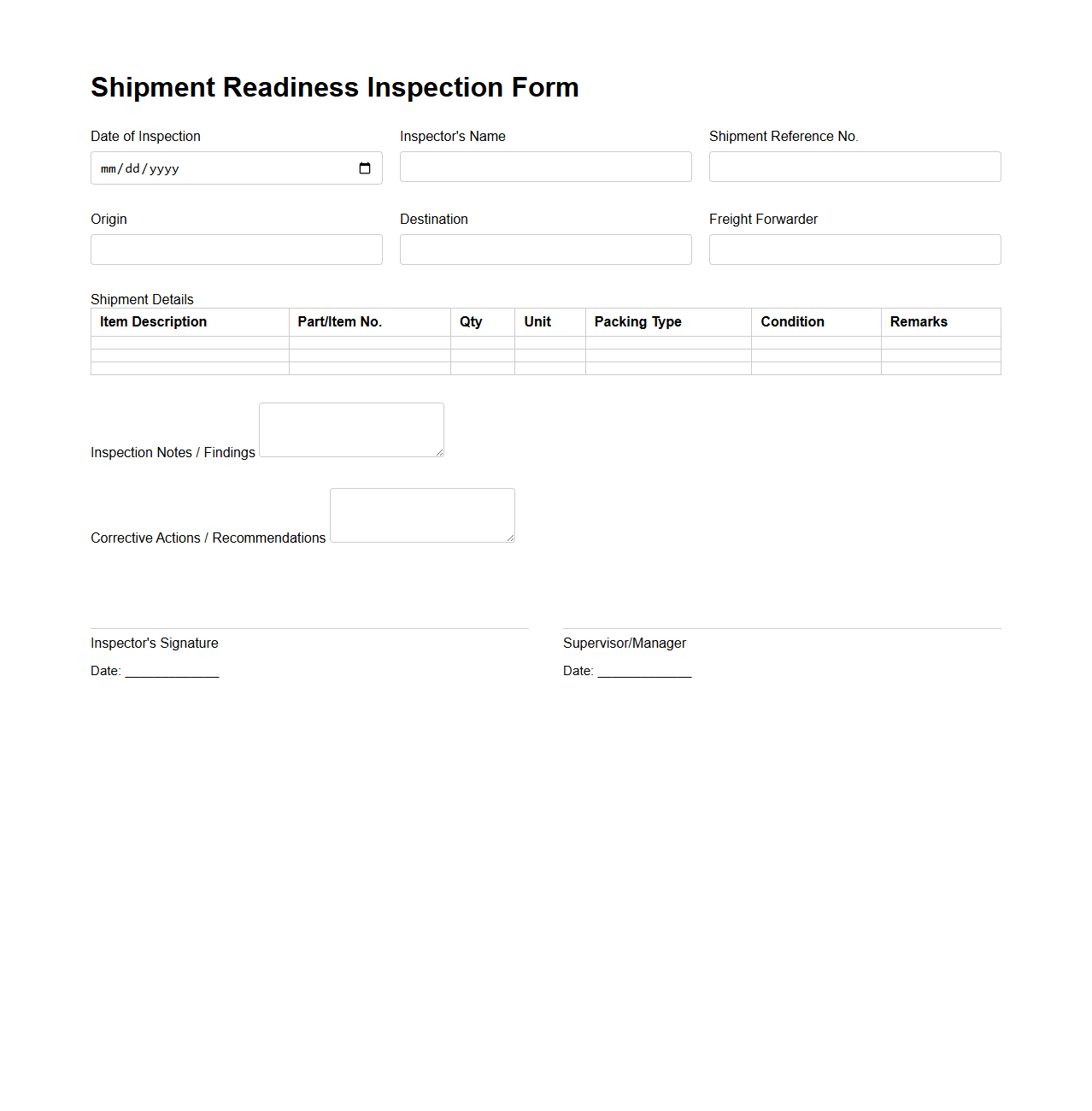

Shipment Readiness Inspection Form

A

Shipment Readiness Inspection Form is a critical document used to verify that all aspects of a shipment meet specified requirements before dispatch. It includes detailed checks of packaging, labeling, quantity, and compliance with regulatory standards to ensure products are prepared for safe transport. This form helps minimize shipping errors, delays, and damages, enhancing overall supply chain efficiency.

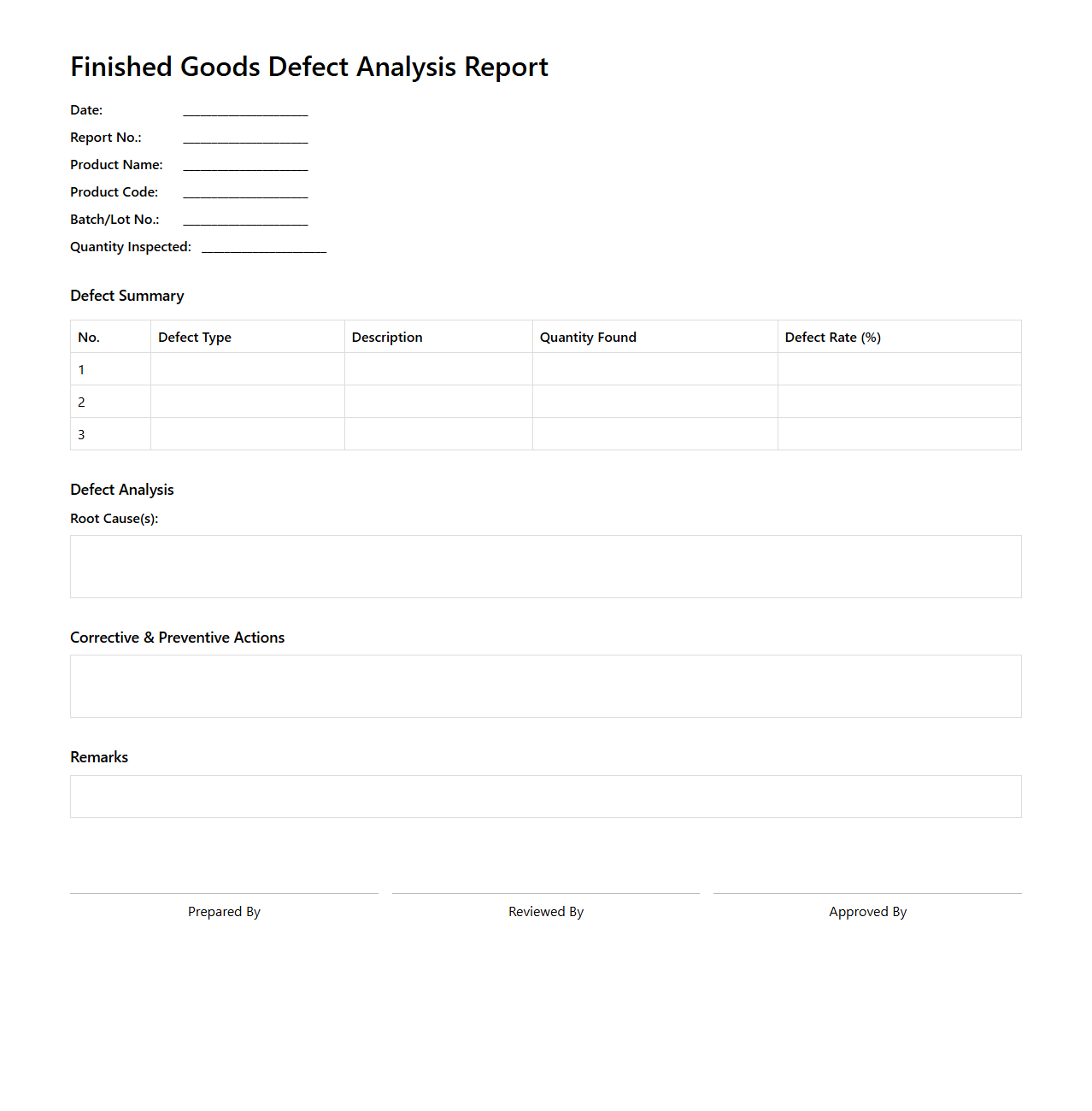

Finished Goods Defect Analysis Report

The

Finished Goods Defect Analysis Report document systematically identifies and evaluates defects found in completed products, aiming to improve quality control and reduce returns. It compiles data on defect types, root causes, and frequencies to facilitate targeted corrective actions and production process improvements. This report is essential for maintaining product standards and enhancing customer satisfaction across manufacturing and supply chain operations.

What key quality criteria are specified for finished goods inspection in this document?

The document specifies dimensional accuracy as a critical quality criterion, ensuring products meet design specifications. It emphasizes product functional performance to verify operational reliability. Additionally, surface finish and appearance standards must be consistently maintained to guarantee aesthetic quality.

Which inspection methods and tools are mandated by the sample document?

The document mandates the use of calipers and micrometers for precise dimensional inspection. It requires visual inspection under standardized lighting conditions to assess surface integrity. Furthermore, functional testing tools are specified to validate product performance against set benchmarks.

What are the required documentation and reporting procedures for non-conforming finished goods?

Non-conforming goods must be documented in a Non-Conformance Report (NCR) detailing the defect nature and location. The report should be promptly submitted to quality control for corrective action review. A traceable record of all inspections and actions taken is mandatory for accountability and continuous improvement.

How does the sample document define acceptance and rejection parameters for finished products?

Acceptance criteria are defined by compliance with all specified dimensions and functional tests. Any deviation beyond established tolerance limits results in rejection. The document includes clear thresholds that distinguish acceptable quality levels from non-compliance.

Which roles and responsibilities are outlined for personnel in the finished goods inspection process?

The document assigns inspection officers the responsibility to perform detailed examinations and record results. Quality assurance managers oversee the compliance and approve final acceptance. Production staff are tasked with immediate reporting of defects to ensure swift resolution.

More Manufacturing Templates