A Quality Control Checklist Document Sample for Manufacturing ensures that all production processes meet established standards by providing a detailed list of inspection criteria. This document helps identify defects early, maintain product consistency, and enhance overall efficiency in the manufacturing workflow. Using a structured checklist supports compliance with industry regulations and promotes continuous quality improvement.

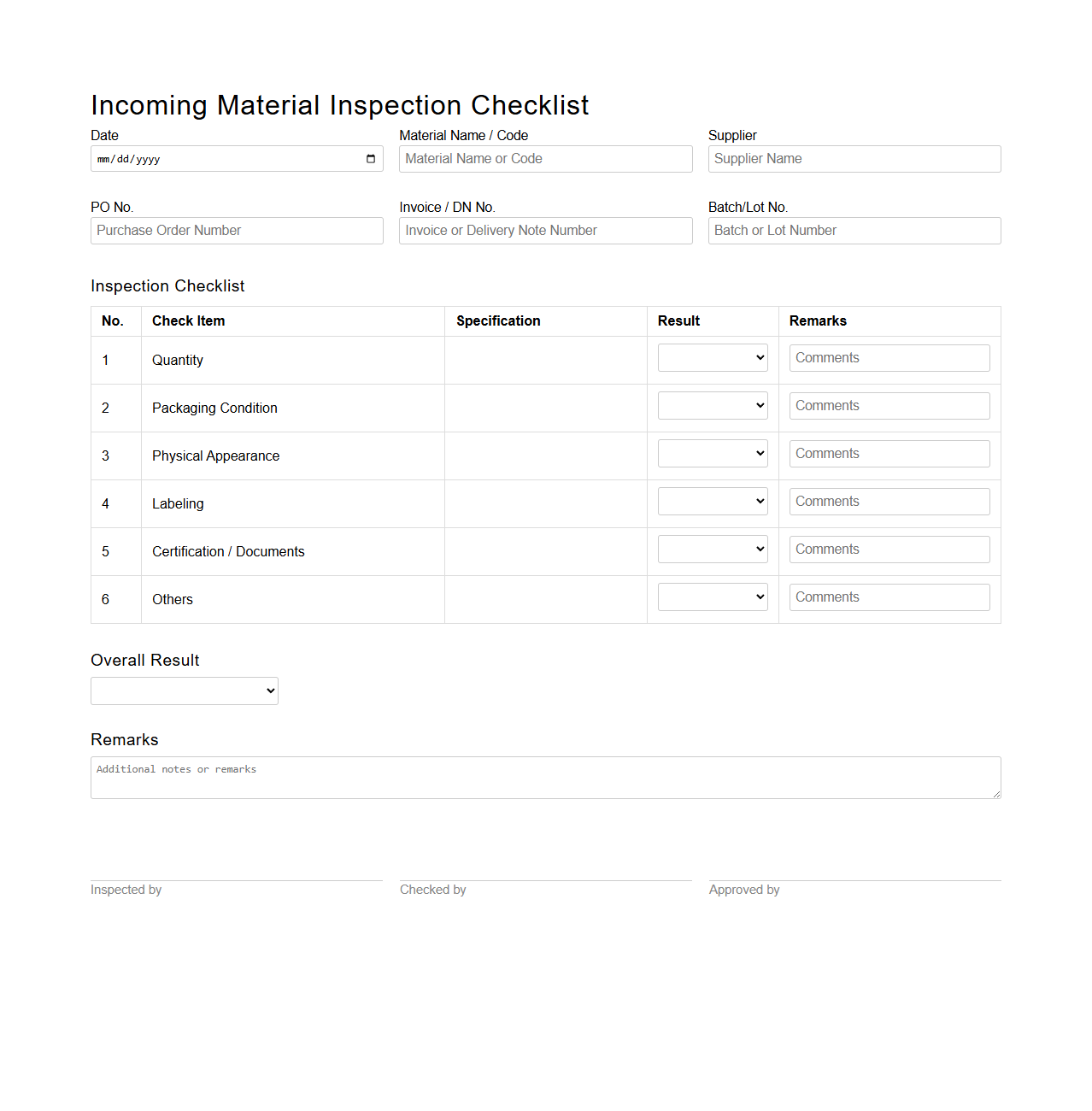

Incoming Material Inspection Checklist for Manufacturing

The

Incoming Material Inspection Checklist for manufacturing document ensures all raw materials meet specified quality standards before entering the production process. It includes detailed criteria for verifying material specifications, dimensions, certifications, and any potential damages or discrepancies. This checklist helps maintain product quality, reduce defects, and streamline manufacturing efficiency by systematically identifying non-conforming materials early.

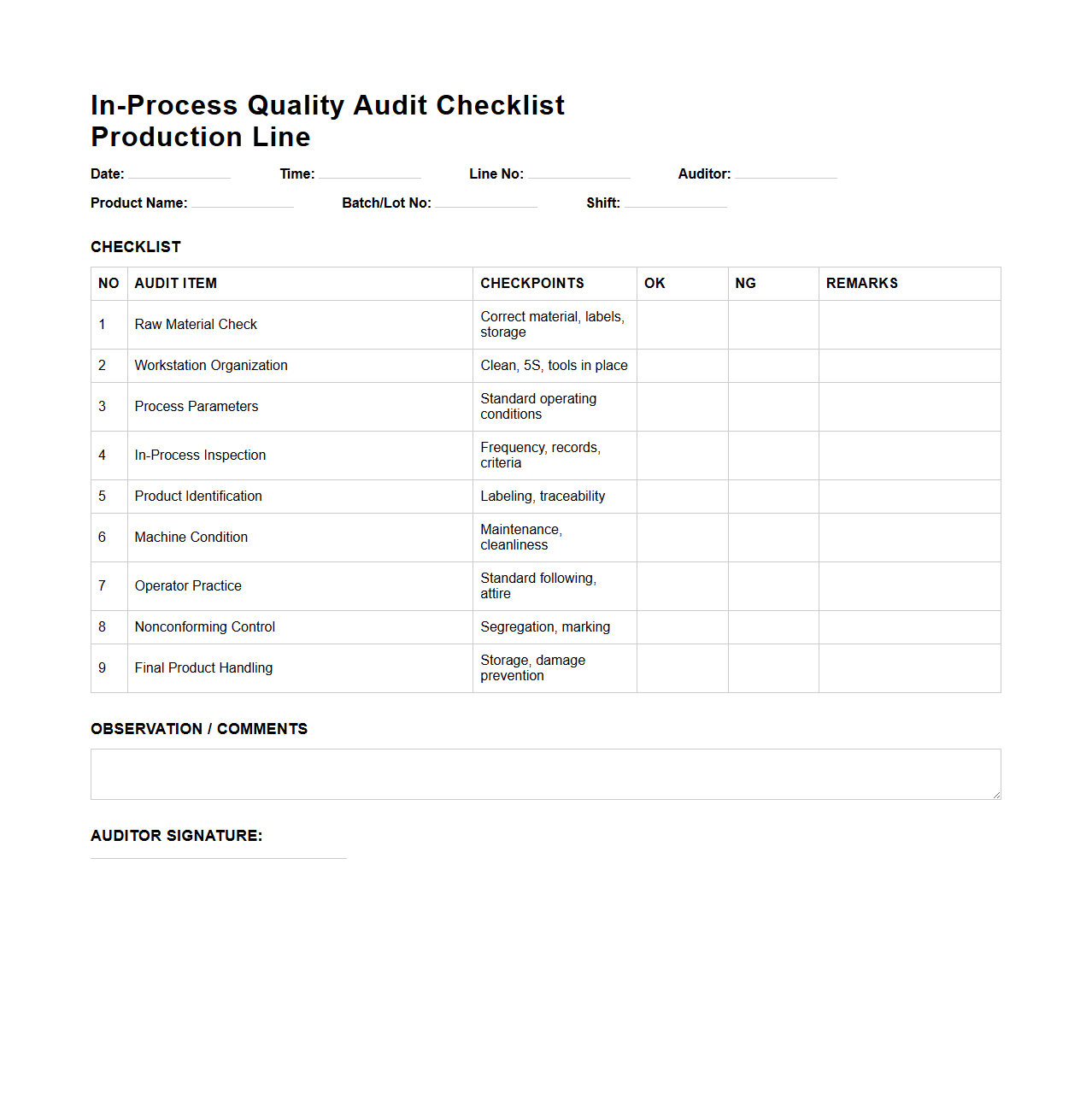

In-Process Quality Audit Checklist for Production Line

The

In-Process Quality Audit Checklist for Production Line document serves as a critical tool for systematically evaluating manufacturing processes to ensure compliance with quality standards and specifications. It enables auditors to verify real-time adherence to operational procedures, identify defects, and implement corrective actions promptly, thereby minimizing production errors and enhancing product quality. This checklist supports continuous improvement by providing actionable insights into process efficiency and effectiveness on the production floor.

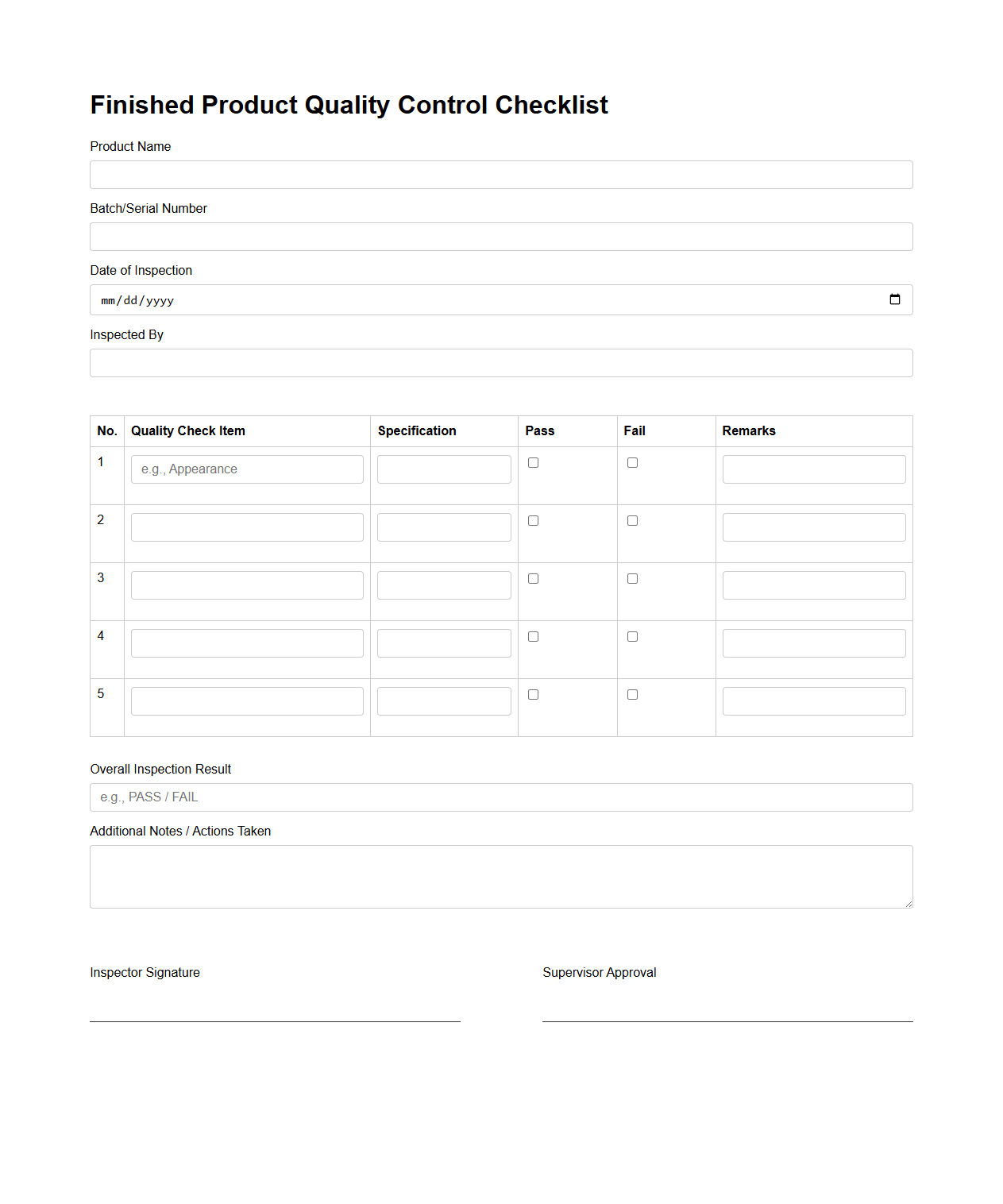

Finished Product Quality Control Checklist for Manufacturing

A

Finished Product Quality Control Checklist for manufacturing is a detailed document used to verify that a product meets all specified quality standards before shipment. It includes inspection criteria such as dimensional accuracy, functionality, appearance, and packaging integrity to ensure compliance with regulatory and customer requirements. This checklist helps manufacturers maintain consistency, reduce defects, and enhance customer satisfaction by systematically evaluating each finished item.

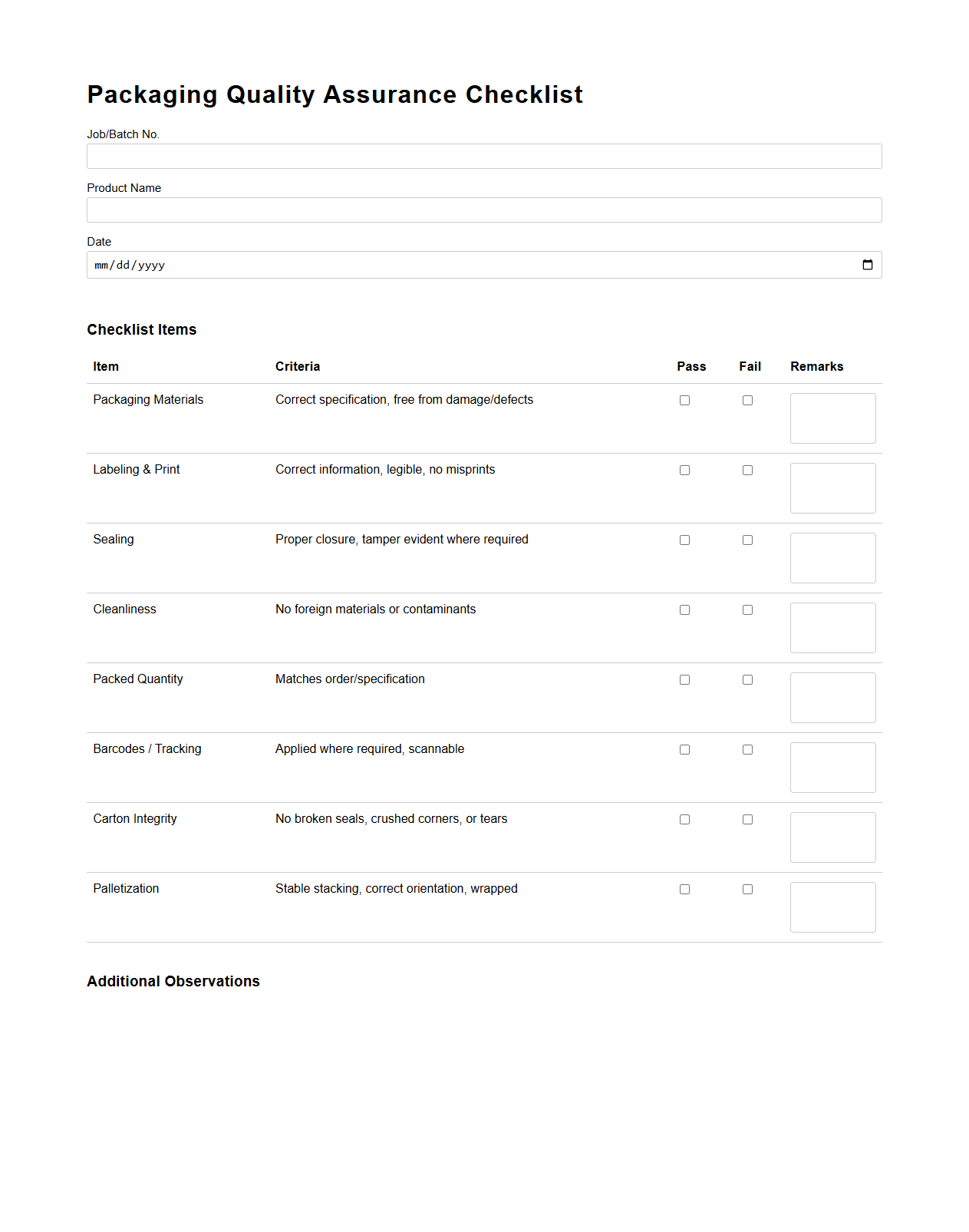

Packaging Quality Assurance Checklist for Manufacturing

A

Packaging Quality Assurance Checklist for manufacturing is a detailed document used to ensure all packaging materials and processes meet predefined quality standards before products reach the market. This checklist typically includes criteria such as material specifications, labeling accuracy, seal integrity, and compliance with regulatory requirements to prevent defects and reduce product damage during transportation. By systematically verifying each packaging aspect, manufacturers can enhance product safety, maintain consistency, and improve customer satisfaction.

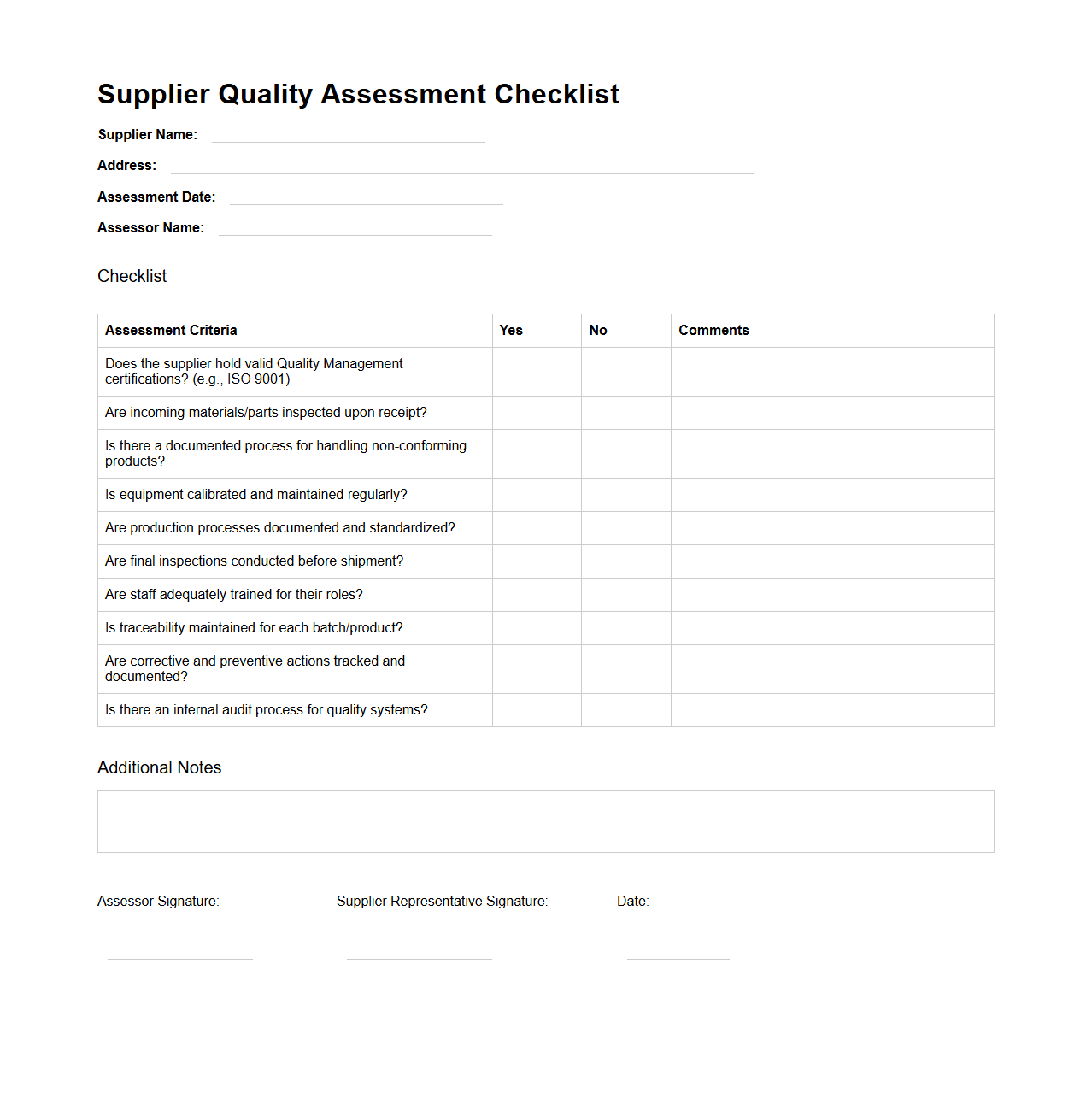

Supplier Quality Assessment Checklist for Manufacturers

The

Supplier Quality Assessment Checklist for manufacturers is a structured document used to evaluate and verify the quality standards of suppliers before engagement. It includes criteria such as compliance with industry certifications, quality management systems, product quality consistency, and delivery reliability. This checklist ensures manufacturers select suppliers that meet strict quality requirements, reducing risk and improving overall supply chain performance.

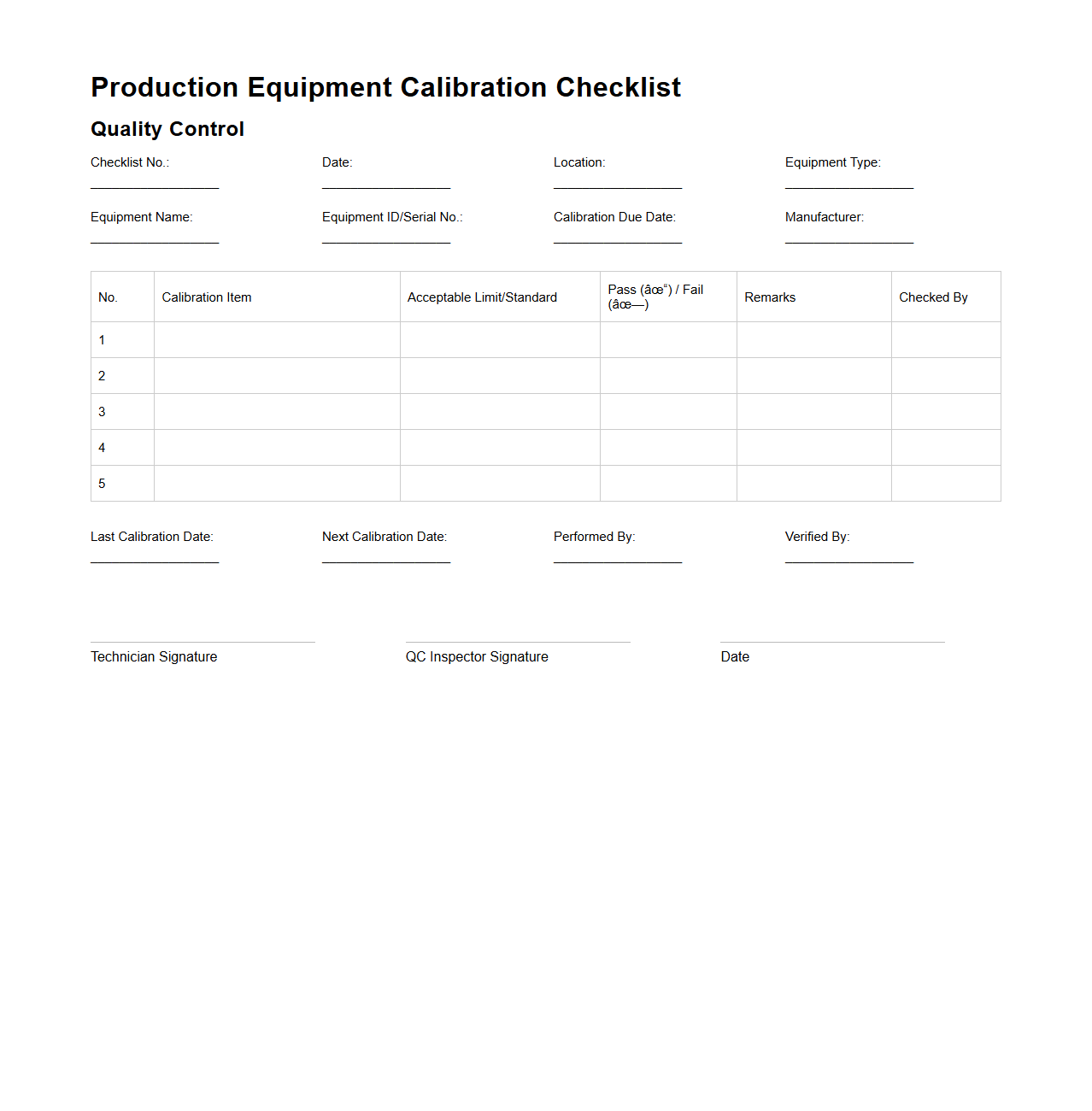

Production Equipment Calibration Checklist for Quality Control

A

Production Equipment Calibration Checklist for Quality Control is a systematic document used to ensure all manufacturing tools and machines are accurately calibrated according to specified standards. It helps maintain equipment precision, reduces errors, and guarantees product consistency in compliance with industry regulations. This checklist typically includes calibration dates, standards referenced, equipment identification, and verification status to facilitate reliable quality assurance.

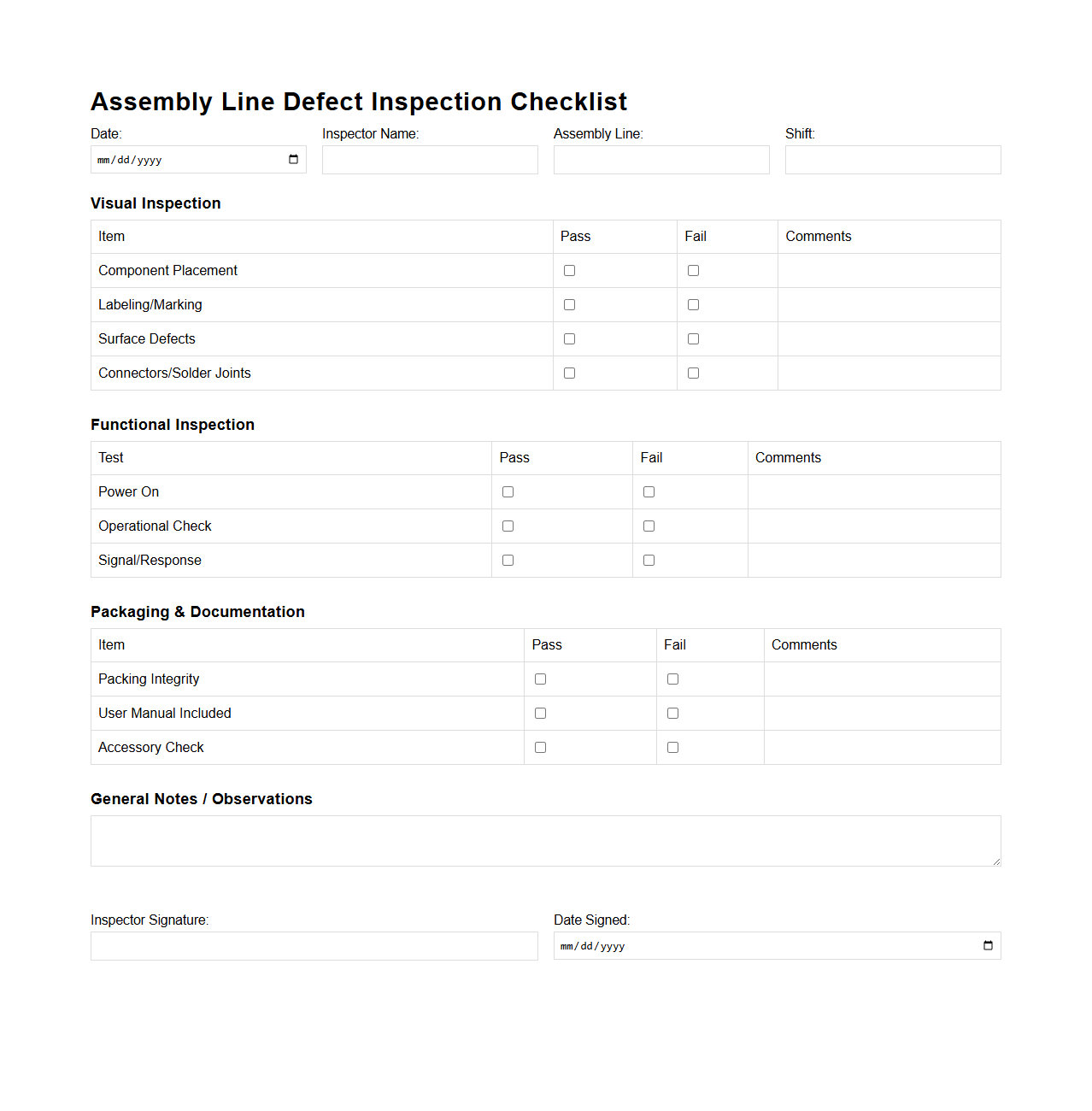

Assembly Line Defect Inspection Checklist

The

Assembly Line Defect Inspection Checklist document serves as a crucial tool for quality control, outlining specific criteria to identify and record defects during the manufacturing process. It ensures consistent inspection standards by detailing defect types, inspection points, and corrective actions, thereby minimizing errors and enhancing product quality. This checklist facilitates efficient communication between inspection teams and production managers, promoting timely resolution of issues on the assembly line.

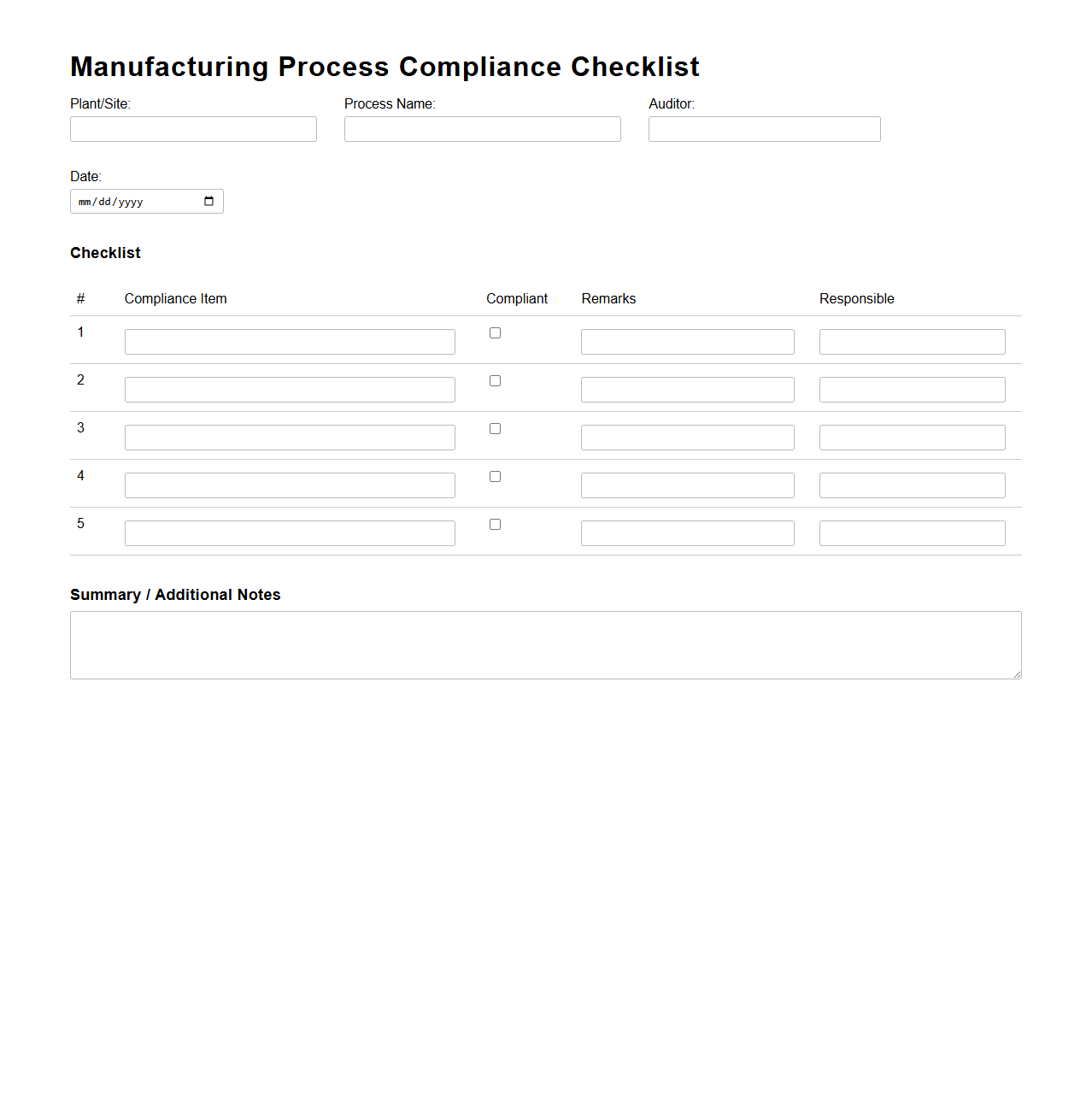

Manufacturing Process Compliance Checklist

The

Manufacturing Process Compliance Checklist document serves as a critical tool to ensure all steps in the production process adhere to established industry standards and regulatory requirements. It systematically verifies key aspects such as equipment calibration, quality control measures, safety protocols, and documentation accuracy to minimize risks and maintain product consistency. Regular use of this checklist supports regulatory audits, enhances operational efficiency, and helps manufacturers achieve consistent compliance throughout production cycles.

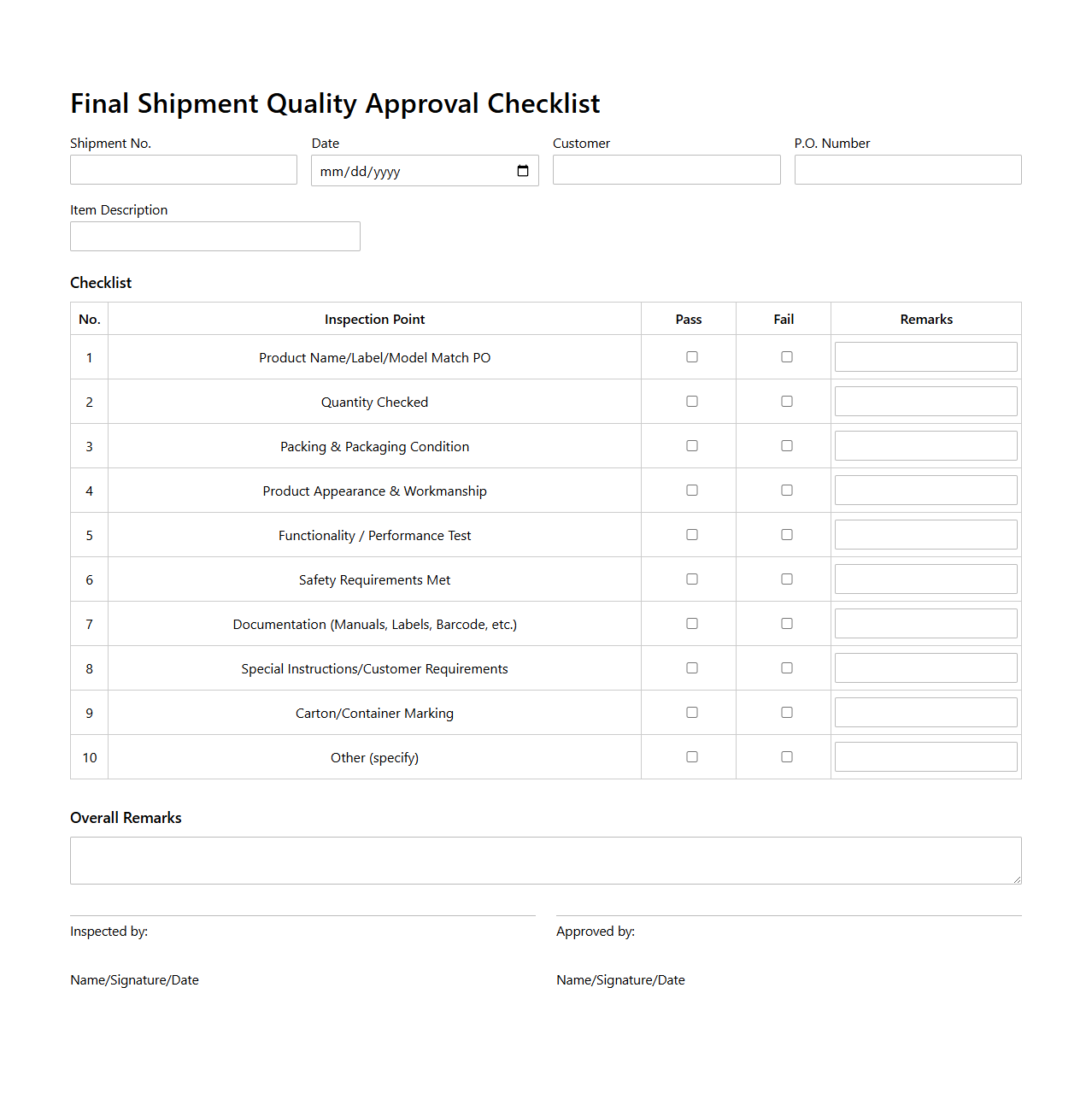

Final Shipment Quality Approval Checklist

The

Final Shipment Quality Approval Checklist document ensures all products meet specified quality standards before dispatch. It verifies compliance with customer requirements, packaging conditions, and shipment integrity to prevent defects or discrepancies during transit. This checklist acts as a critical control tool to maintain product quality and enhance customer satisfaction in the supply chain.

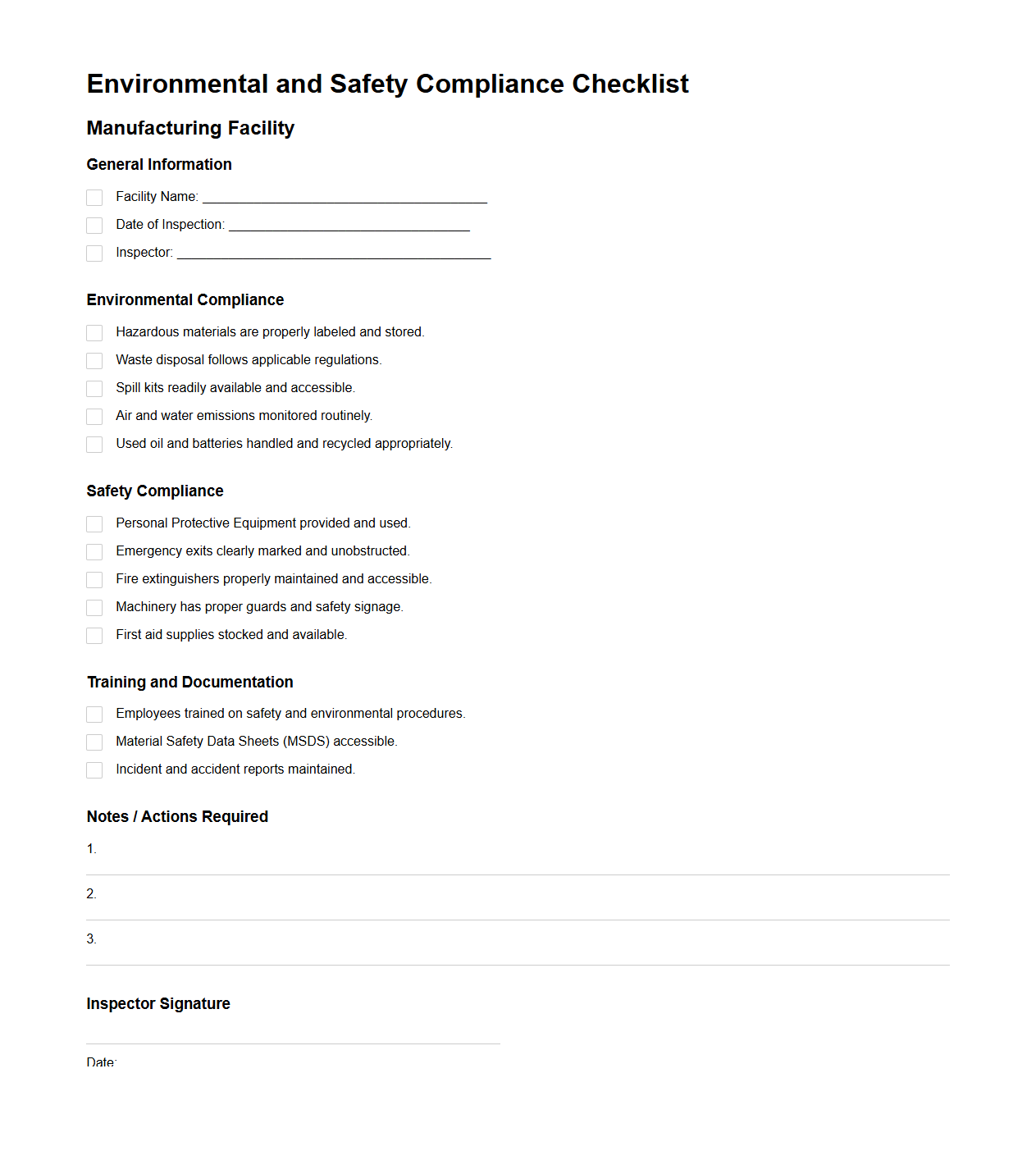

Environmental and Safety Compliance Checklist for Manufacturing

The

Environmental and Safety Compliance Checklist for Manufacturing document is a comprehensive tool used to ensure that manufacturing facilities adhere to regulatory standards and best practices for environmental protection and workplace safety. It systematically evaluates processes, equipment, and procedures to identify potential hazards, waste management issues, and compliance gaps with regulations such as OSHA, EPA, and ISO standards. This checklist helps manufacturers minimize risks, avoid legal penalties, and promote sustainable and safe operational environments.

What key quality attributes must be inspected according to the checklist?

The checklist focuses on inspecting crucial quality attributes such as dimensional accuracy, surface finish, and material integrity. These attributes ensure the product meets all specified industry standards and customer requirements. Strict examination of these factors helps maintain consistent product quality and reliability.

Which stages of the manufacturing process are covered by the checklist document?

The checklist covers multiple manufacturing stages including raw material inspection, in-process monitoring, and final product evaluation. Each stage is critical to identifying and correcting defects early to prevent downstream issues. Comprehensive coverage ensures no aspect of production is overlooked.

What specific criteria determine a pass or fail for each quality control item?

Pass or fail decisions are based on precise acceptance criteria such as tolerance limits, absence of surface defects, and adherence to functional specifications. These criteria are quantified and documented to provide objective quality assessments. Products not meeting these benchmarks are subjected to rework or rejection.

How is traceability of defects or issues ensured in the checklist?

Traceability is maintained by assigning unique identification codes to each batch or unit, recorded within the checklist. Any defects discovered are logged with details about the stage and inspector to enable root cause analysis. This systematic approach supports effective corrective actions and continuous improvement.

What documentation or records must be maintained for audit purposes?

All quality inspection results, including pass/fail outcomes and defect reports, must be stored as part of the audit trail. These records include signed checklists, calibration certificates, and corrective action logs. Proper documentation ensures compliance with regulatory requirements and facilitates external audits.

More Manufacturing Templates