A Production Schedule Document Sample for Manufacturing Plant outlines the planned sequence of operations, timelines, and resource allocation to ensure efficient workflow and timely product delivery. It serves as a critical tool for coordinating tasks, minimizing downtime, and optimizing labor and machinery usage throughout the manufacturing process. This document enables managers to track progress, adjust schedules as needed, and maintain consistent production quality.

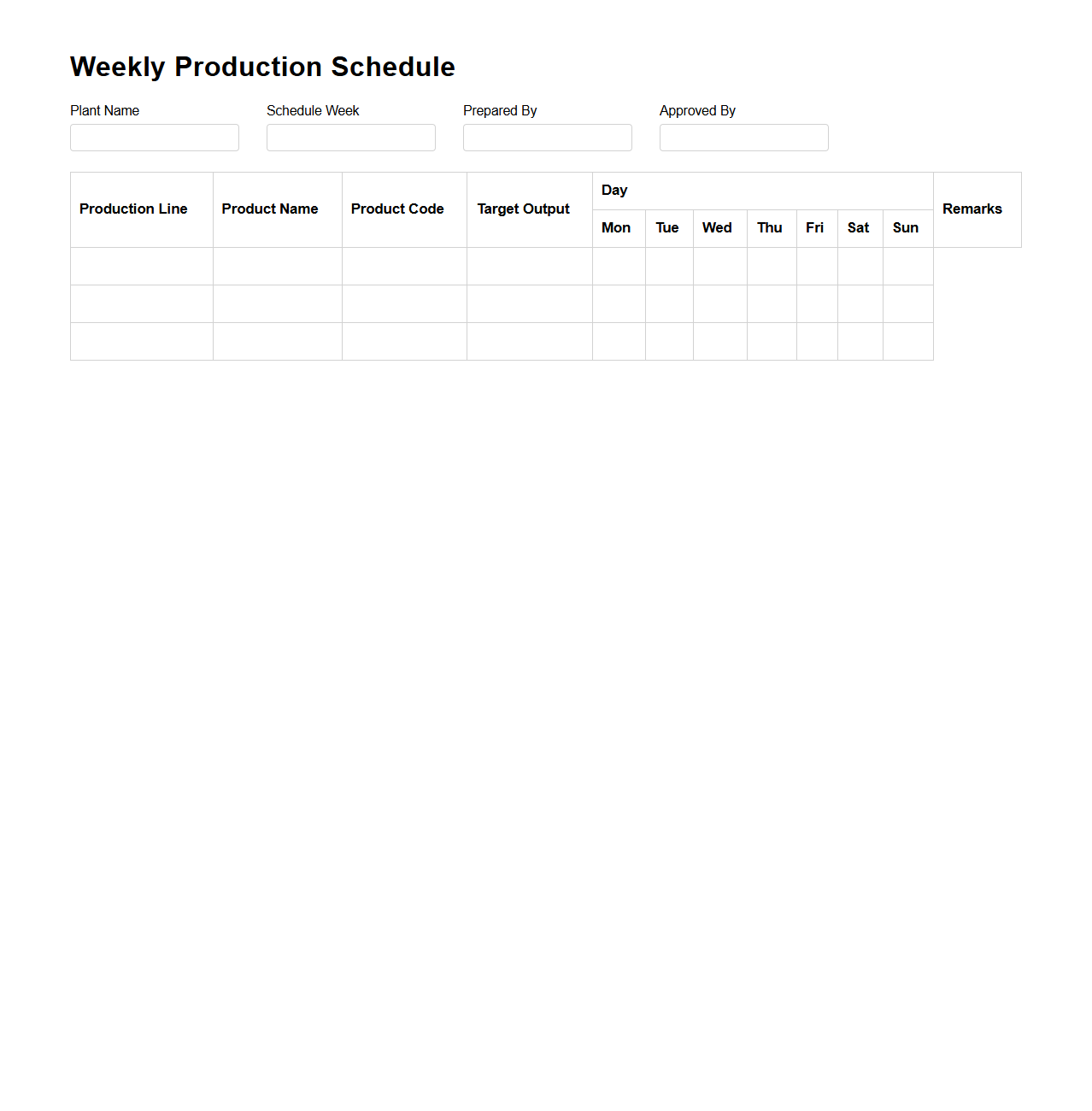

Weekly Production Schedule Template for Manufacturing Plant

A

Weekly Production Schedule Template for a manufacturing plant is a detailed document that outlines the specific tasks, timelines, and resource allocations required to meet production goals within a seven-day period. It helps optimize workflow by coordinating machinery, labor, and material availability, ensuring efficient output and minimizing downtime. This template serves as a critical tool for production managers to track progress, anticipate bottlenecks, and streamline operations.

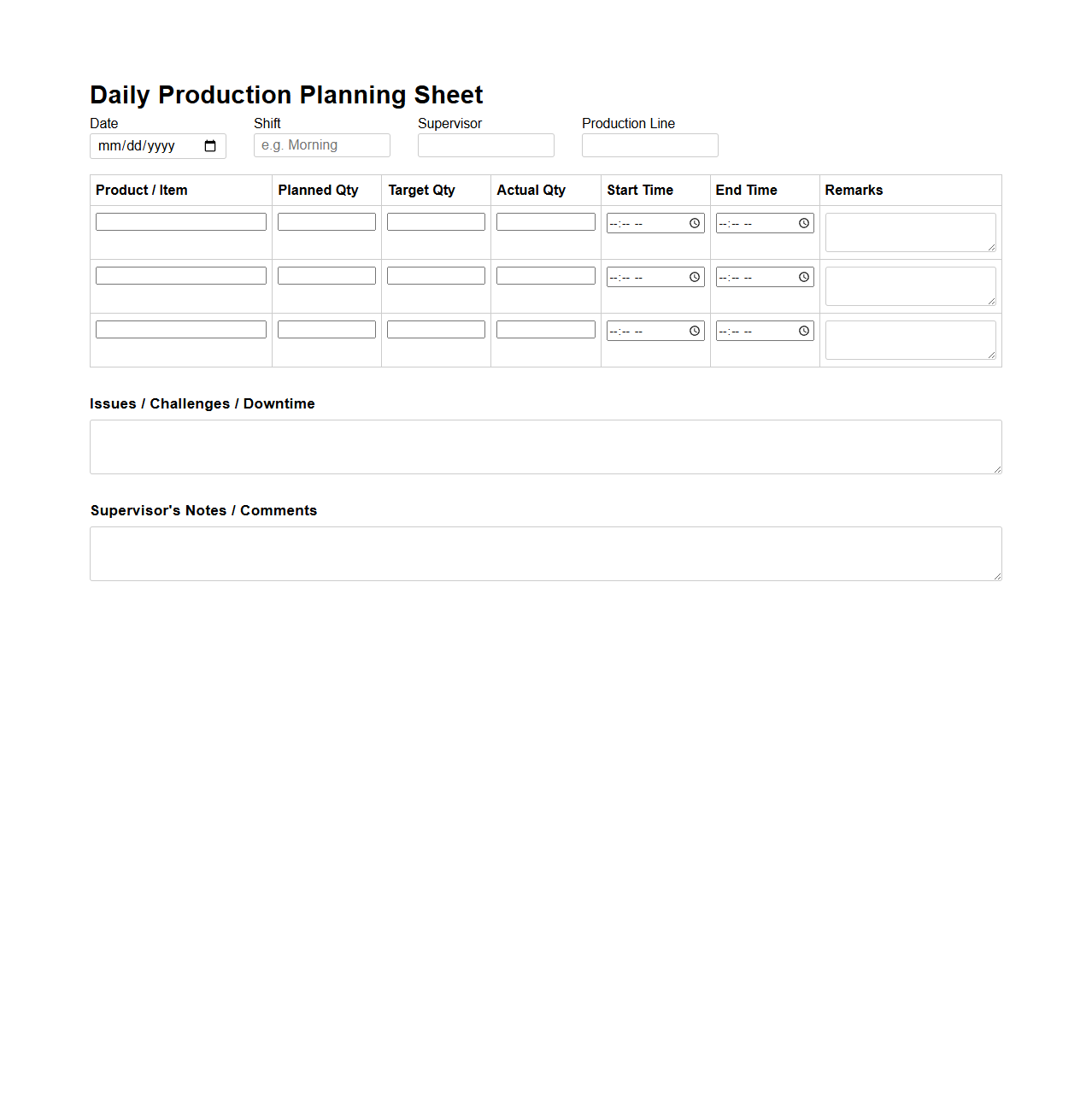

Daily Production Planning Sheet for Manufacturing Operations

A

Daily Production Planning Sheet for manufacturing operations is a detailed document used to organize and monitor the daily workflow on the factory floor. It includes key information such as production targets, assigned tasks, machine allocations, and operator schedules, ensuring efficient resource utilization and timely order completion. This sheet is essential for aligning production activities with demand forecasts and minimizing downtime or bottlenecks throughout the manufacturing process.

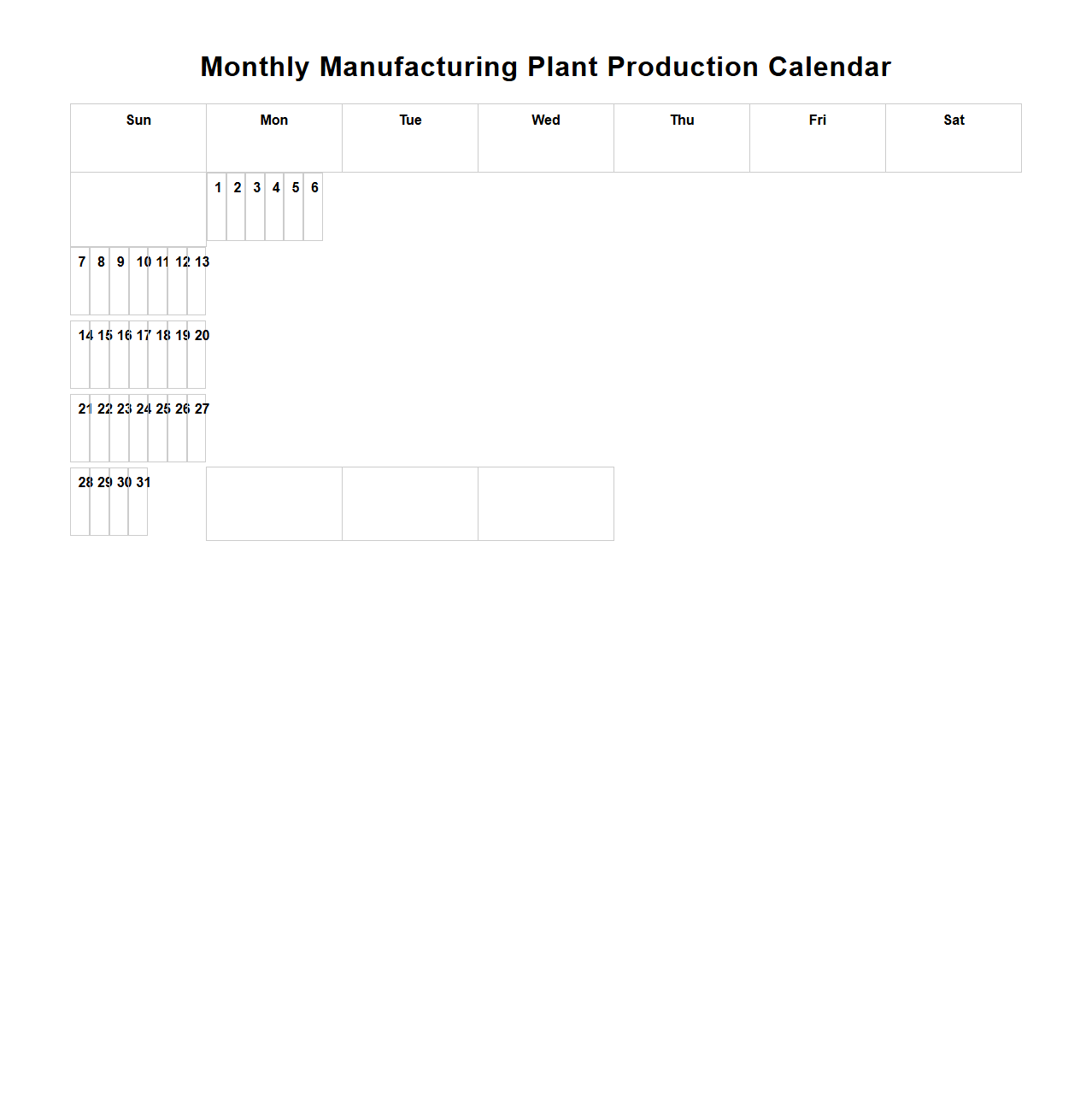

Monthly Manufacturing Plant Production Calendar

The

Monthly Manufacturing Plant Production Calendar document outlines the scheduled production activities, including planned shifts, maintenance, and downtime periods for each day of the month. It serves as a critical tool to coordinate resources, manage inventory, and ensure timely delivery of manufacturing outputs. This calendar helps optimize workflow efficiency and maintain consistent production rates across the manufacturing plant.

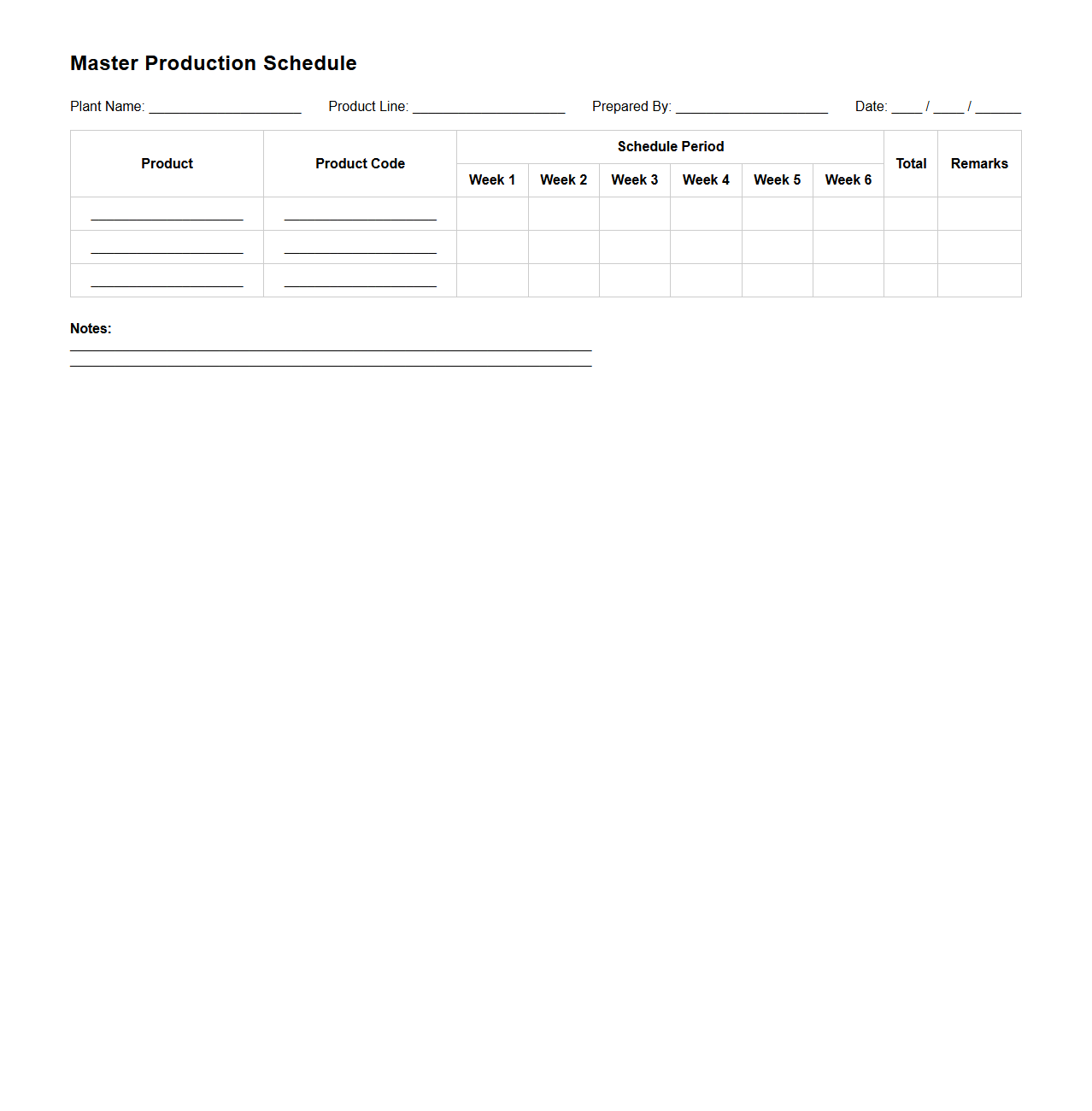

Master Production Schedule Format for Industrial Plants

The

Master Production Schedule (MPS) Format for Industrial Plants document outlines a detailed plan that specifies the quantity and timing of production activities within a manufacturing facility. It serves as a crucial tool for coordinating inventory levels, labor resources, and equipment utilization to meet customer demand efficiently. By clearly defining production targets across specific time periods, this document helps optimize workflow, reduce lead times, and minimize operational costs.

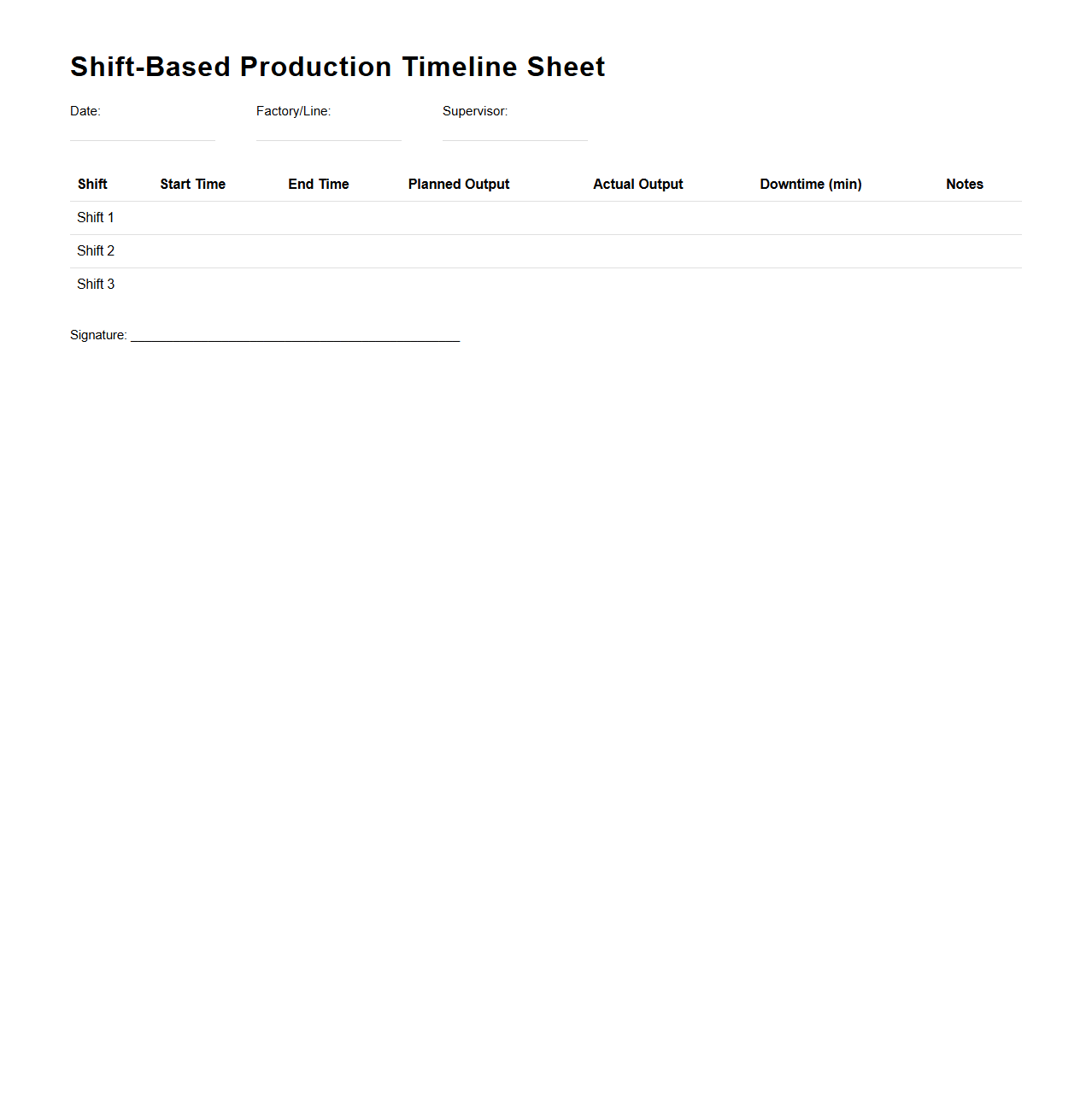

Shift-Based Production Timeline Sheet for Factory Use

A

Shift-Based Production Timeline Sheet is a detailed document used in factories to track and manage production activities across different shifts. It outlines specific tasks, timelines, and responsible personnel for each shift, ensuring smooth workflow and timely completion of manufacturing processes. This sheet enhances operational efficiency by providing real-time visibility into production progress and shift performance.

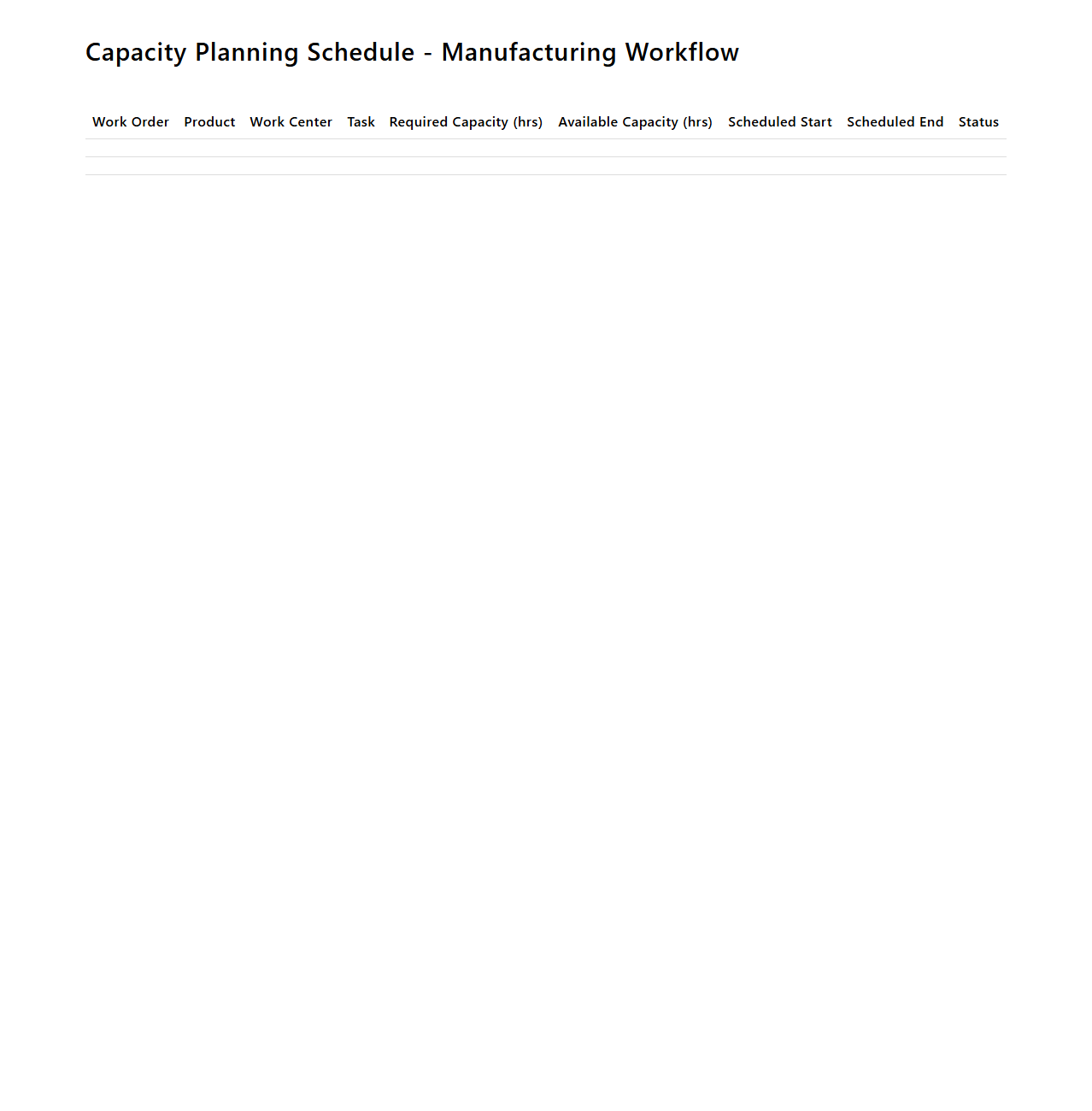

Capacity Planning Schedule for Manufacturing Workflow

A

Capacity Planning Schedule for Manufacturing Workflow is a strategic document that outlines the allocation of production resources over a specific period to meet manufacturing demands efficiently. It details machinery availability, labor shifts, and raw material requirements, ensuring optimal utilization and minimizing bottlenecks. This schedule supports proactive decision-making by forecasting workload distribution and accommodating fluctuations in production volume.

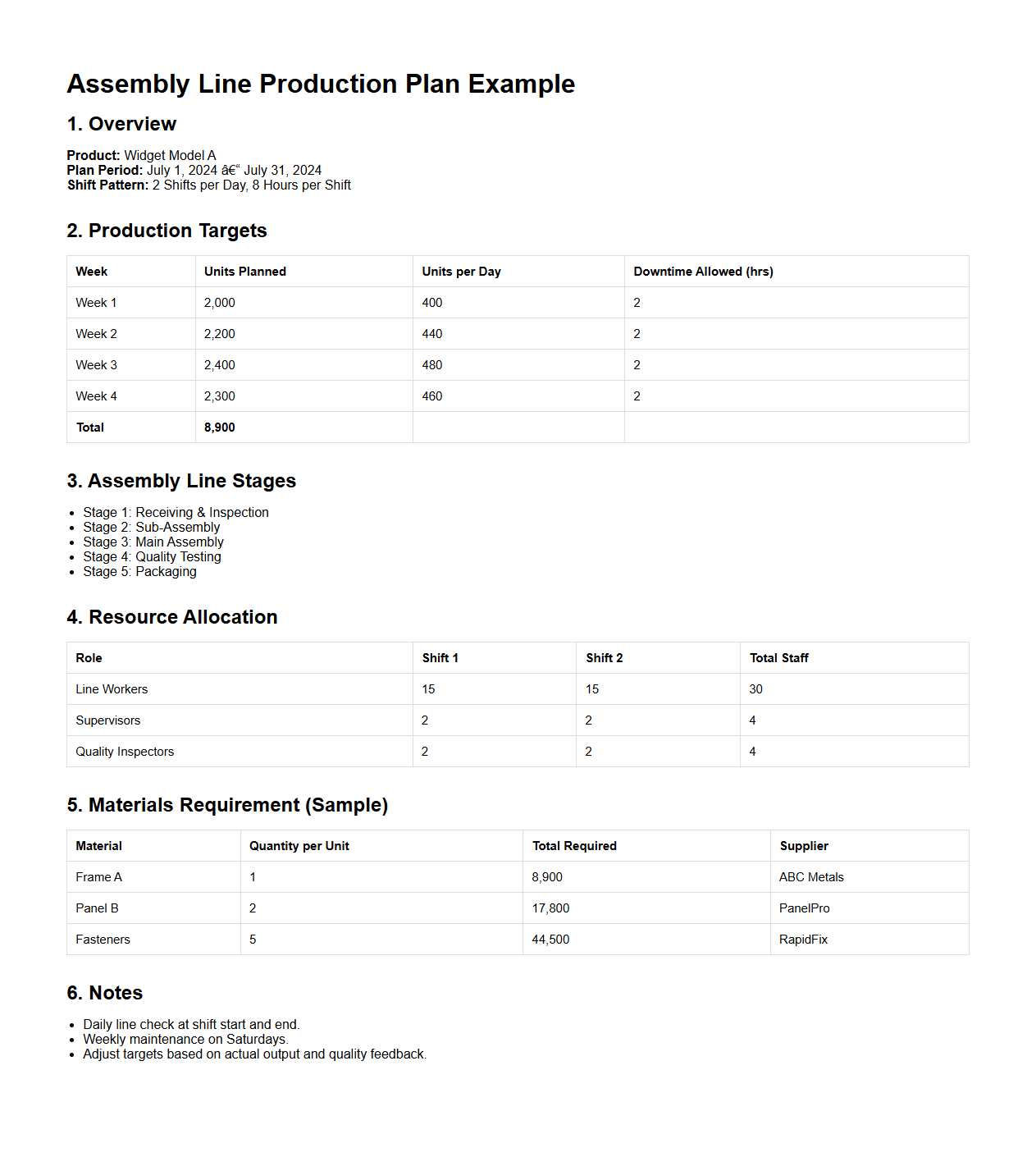

Assembly Line Production Plan Example for Manufacturing

Assembly Line Production Plan Example documents provide a detailed blueprint for organizing manufacturing processes to enhance efficiency and output quality. These plans typically include step-by-step workflows, resource allocation, task sequencing, and time scheduling for each stage of the assembly line. Implementing a well-structured

Assembly Line Production Plan helps manufacturing firms streamline operations, reduce downtime, and optimize labor productivity.

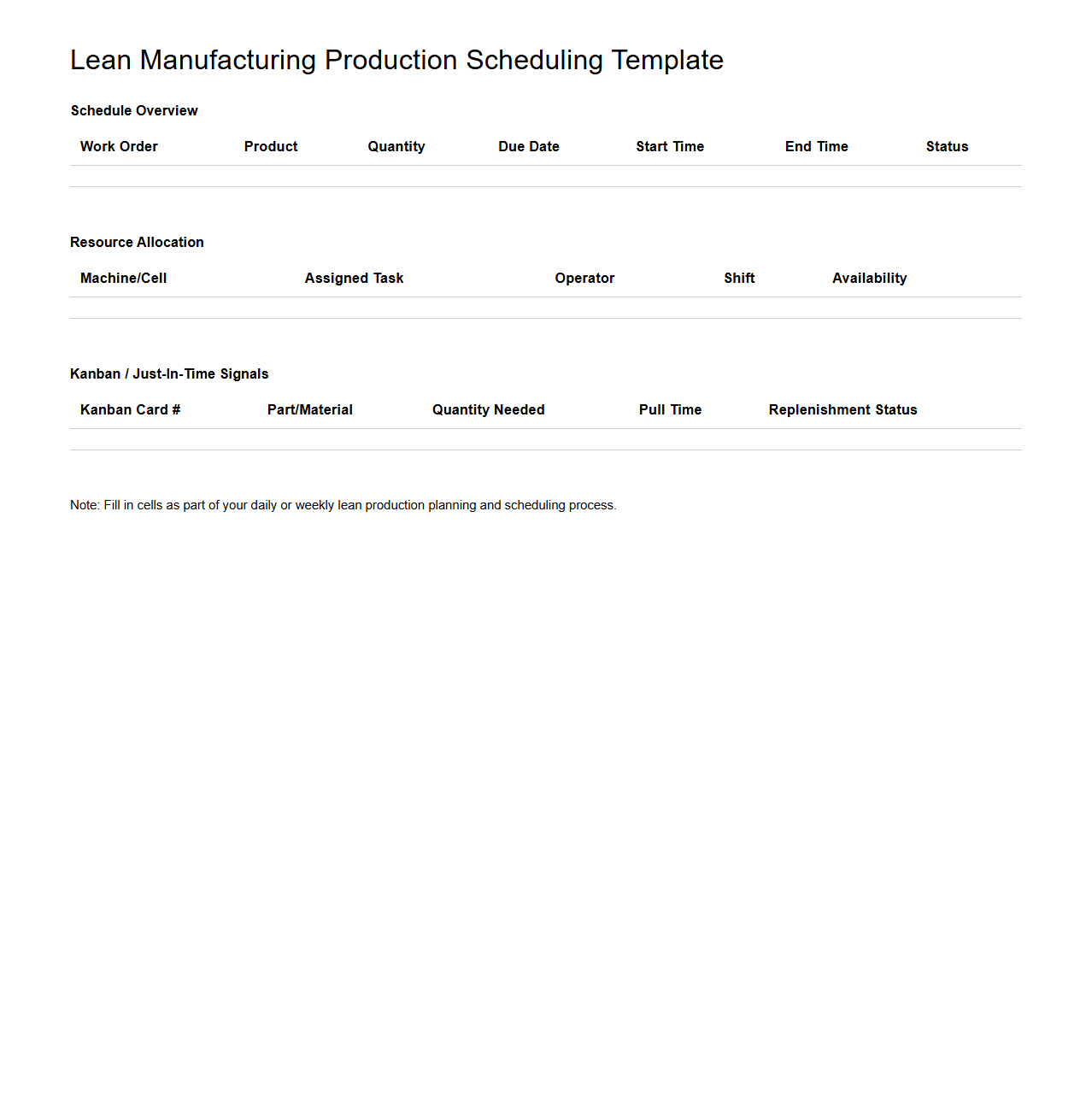

Lean Manufacturing Production Scheduling Template

A

Lean Manufacturing Production Scheduling Template document is a strategic tool designed to streamline production workflows by minimizing waste and enhancing efficiency. It organizes tasks, resources, and timelines, ensuring that manufacturing processes align with lean principles such as just-in-time inventory and continuous improvement. This template supports optimal resource allocation, timely order fulfillment, and reduced lead times, driving overall operational excellence.

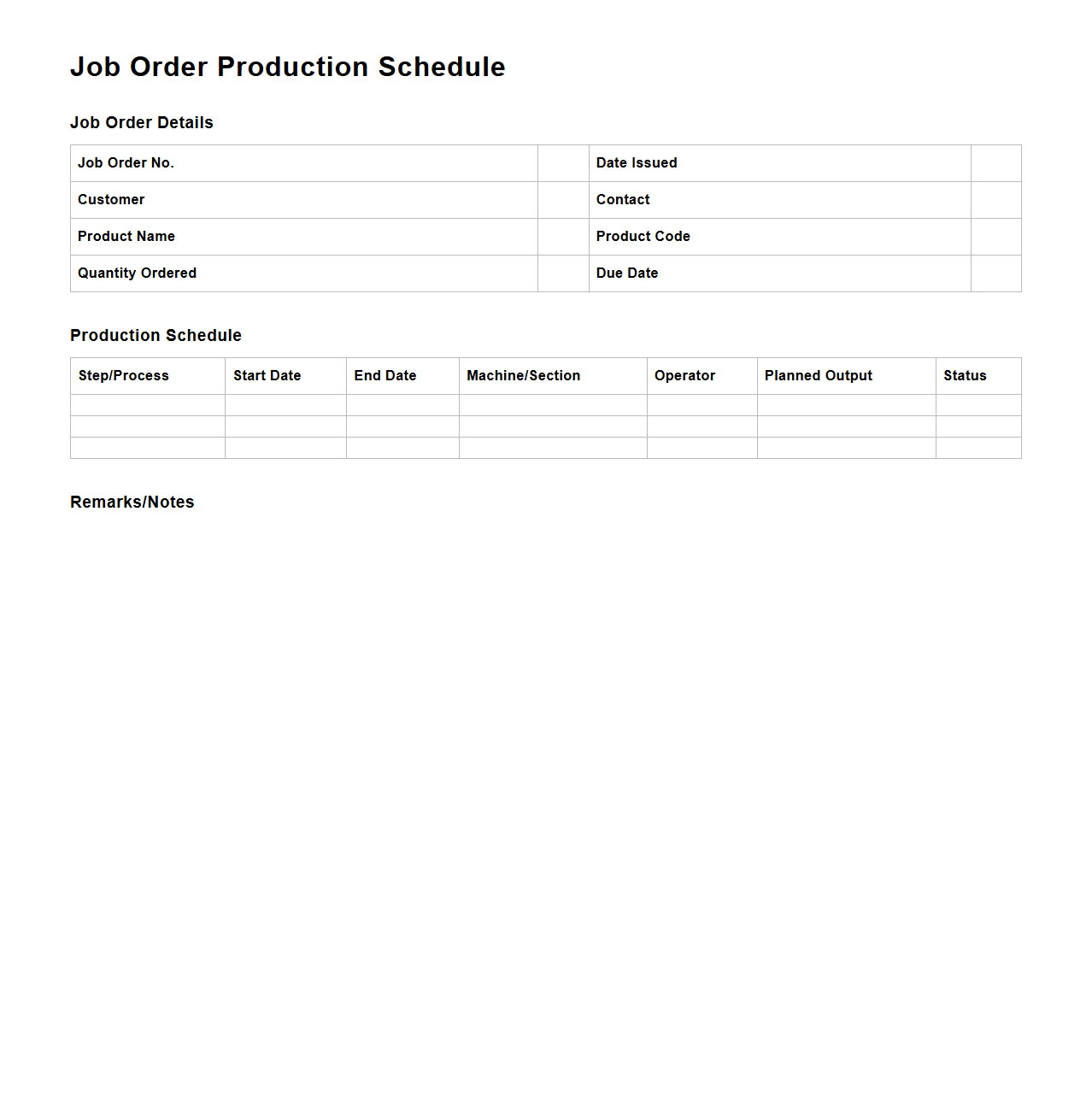

Job Order Production Schedule for Plant Management

A

Job Order Production Schedule for Plant Management is a detailed plan that outlines the timing and sequencing of specific production jobs within a manufacturing facility. This document helps coordinate resources, track job progress, and ensure efficient workflow by scheduling individual orders based on priority, machine availability, and labor capacity. It serves as a critical tool for optimizing production efficiency and meeting delivery deadlines.

Batch Production Tracking Schedule for Manufacturing Facility

A

Batch Production Tracking Schedule for a manufacturing facility is a detailed document that monitors and records the progress of production batches from start to finish. It includes critical data such as batch numbers, production dates, quality control results, and inventory usage to ensure accurate tracking and traceability. This schedule helps streamline operations, maintain compliance with regulatory standards, and improve overall manufacturing efficiency.

What key components should be included in a standard production schedule document for a manufacturing plant?

A standard production schedule document must include key components such as production tasks, timelines, and assigned resources. It should clearly outline start dates, end dates, and quantities for each manufacturing step. Additionally, incorporating task dependencies and priority levels ensures efficient workflow management.

How does the production schedule document align with inventory management and material requirements planning (MRP)?

The production schedule is tightly integrated with inventory management and MRP to synchronize material availability with production needs. It ensures that raw materials and components are ordered and delivered just in time, preventing delays or excess stock. This alignment enhances operational efficiency and reduces carrying costs.

What methods are used to update and communicate the production schedule to relevant departments in the plant?

Production schedules are updated using real-time data inputs through ERP systems or specialized scheduling software. Communication occurs via digital dashboards, emails, or automated alerts to ensure all departments are informed promptly. Regular coordination meetings also support continuous alignment among teams.

How are lead times and production deadlines represented and monitored in the schedule document?

Lead times and deadlines are represented using clearly defined start and finish dates for each production phase. Monitoring tools like Gantt charts or timeline visualizations help track progress against these targets. Alerts and dashboard indicators highlight any deviations requiring immediate attention.

What strategies are in place within the schedule to address production bottlenecks or unexpected machine downtimes?

Schedules typically include buffers and contingency plans to mitigate production bottlenecks and equipment failures. Flexible task reallocations and overtime options are predefined to maintain output levels. Continuous monitoring of key performance indicators allows rapid response and minimizes downtime impact.

More Manufacturing Templates