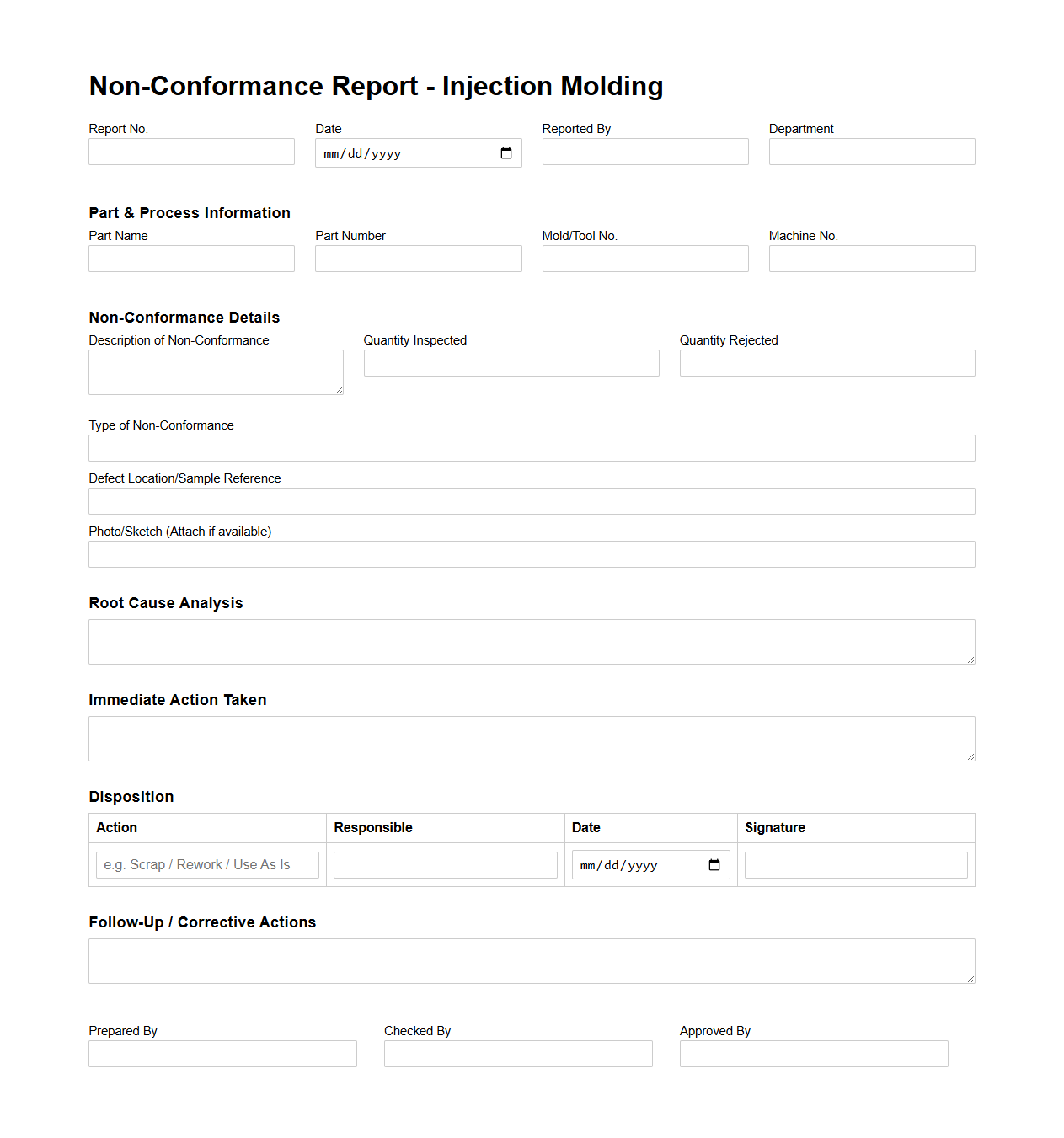

Non-Conformance Report Template for Injection Molding

A

Non-Conformance Report Template for Injection Molding is a standardized document used to identify, record, and address defects or deviations from specifications during the injection molding process. It facilitates systematic tracking of issues such as dimensional inaccuracies, material inconsistencies, or processing errors, enabling quality control teams to implement corrective actions effectively. Utilizing this template helps maintain product quality, ensures compliance with industry standards, and minimizes production downtime.

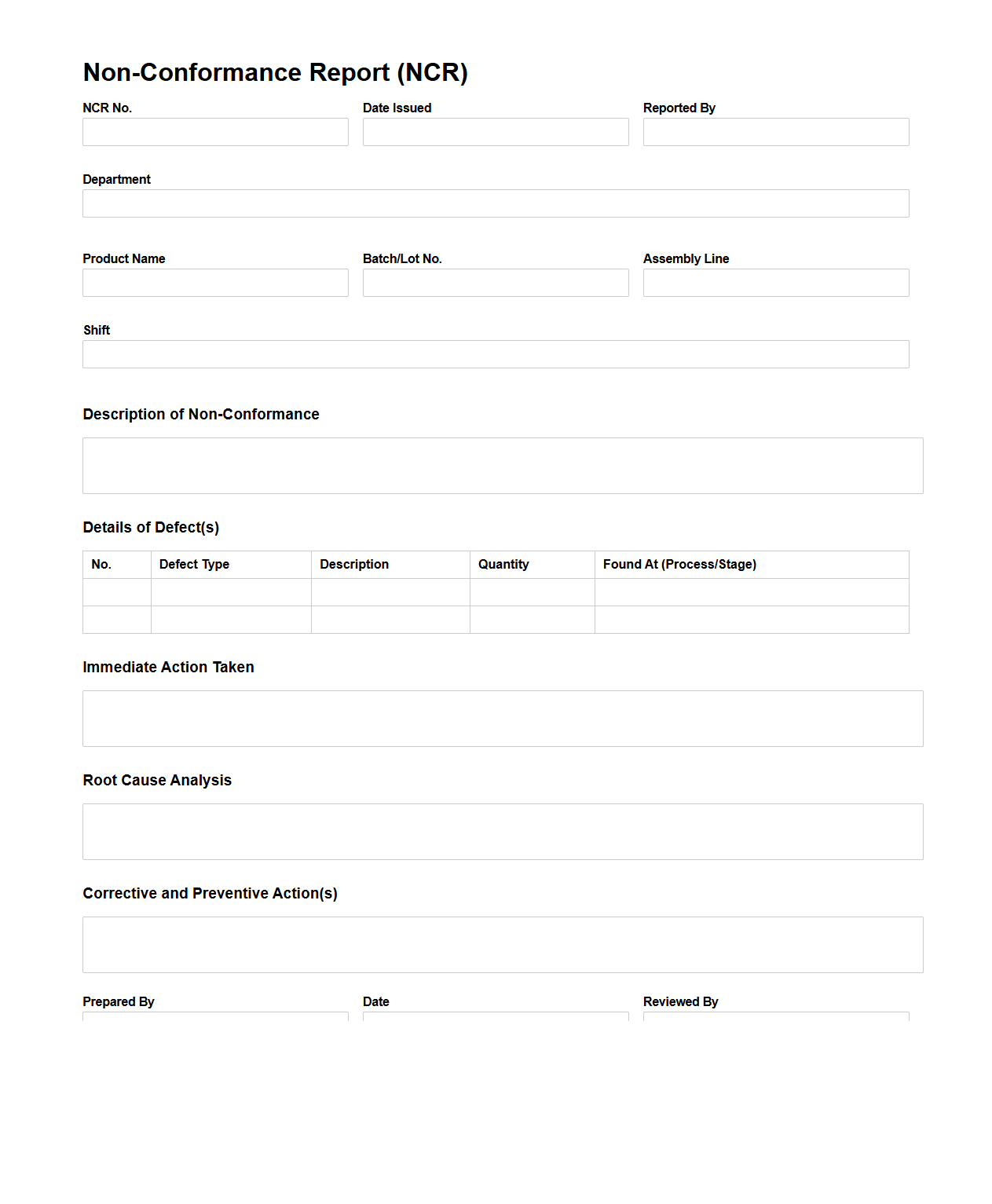

Non-Conformance Report Example for Assembly Line Defects

The

Non-Conformance Report (NCR) Example for Assembly Line Defects document provides a structured template to identify, record, and analyze defects occurring during the production process on an assembly line. It includes essential sections such as defect description, root cause analysis, corrective actions, and responsible personnel, ensuring consistent tracking and resolution of quality issues. This document serves as a critical tool to maintain product quality standards and improve manufacturing efficiency by preventing recurrence of assembly line defects.

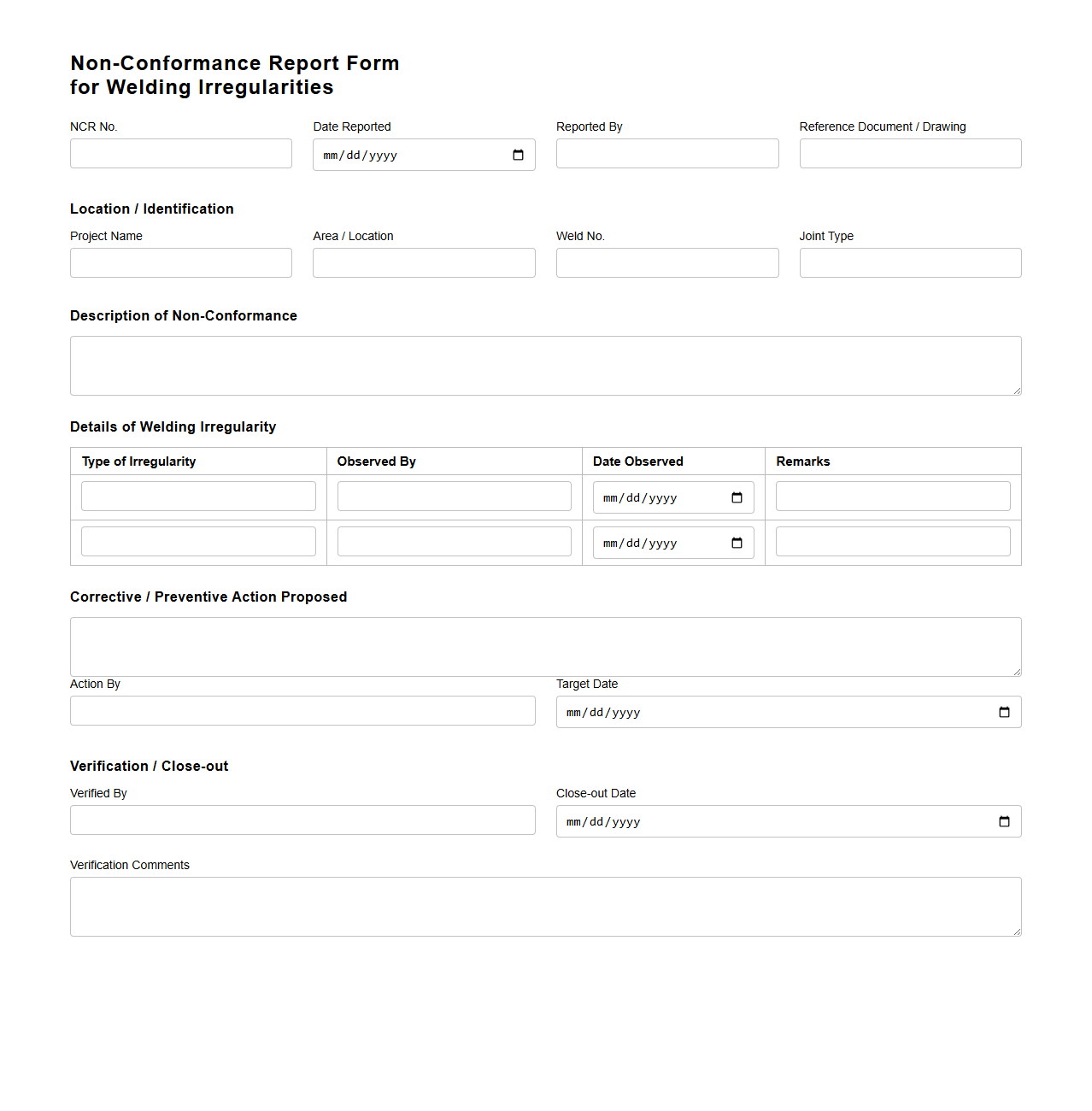

Non-Conformance Report Form for Welding Irregularities

A

Non-Conformance Report Form for Welding Irregularities is a critical document used to identify, record, and track deviations from welding standards and specifications. It details the nature of the welding defect, such as cracks, porosity, or incomplete fusion, along with the location, severity, and corrective actions required. This form ensures quality control by facilitating root cause analysis and supporting compliance with industry welding codes and regulations.

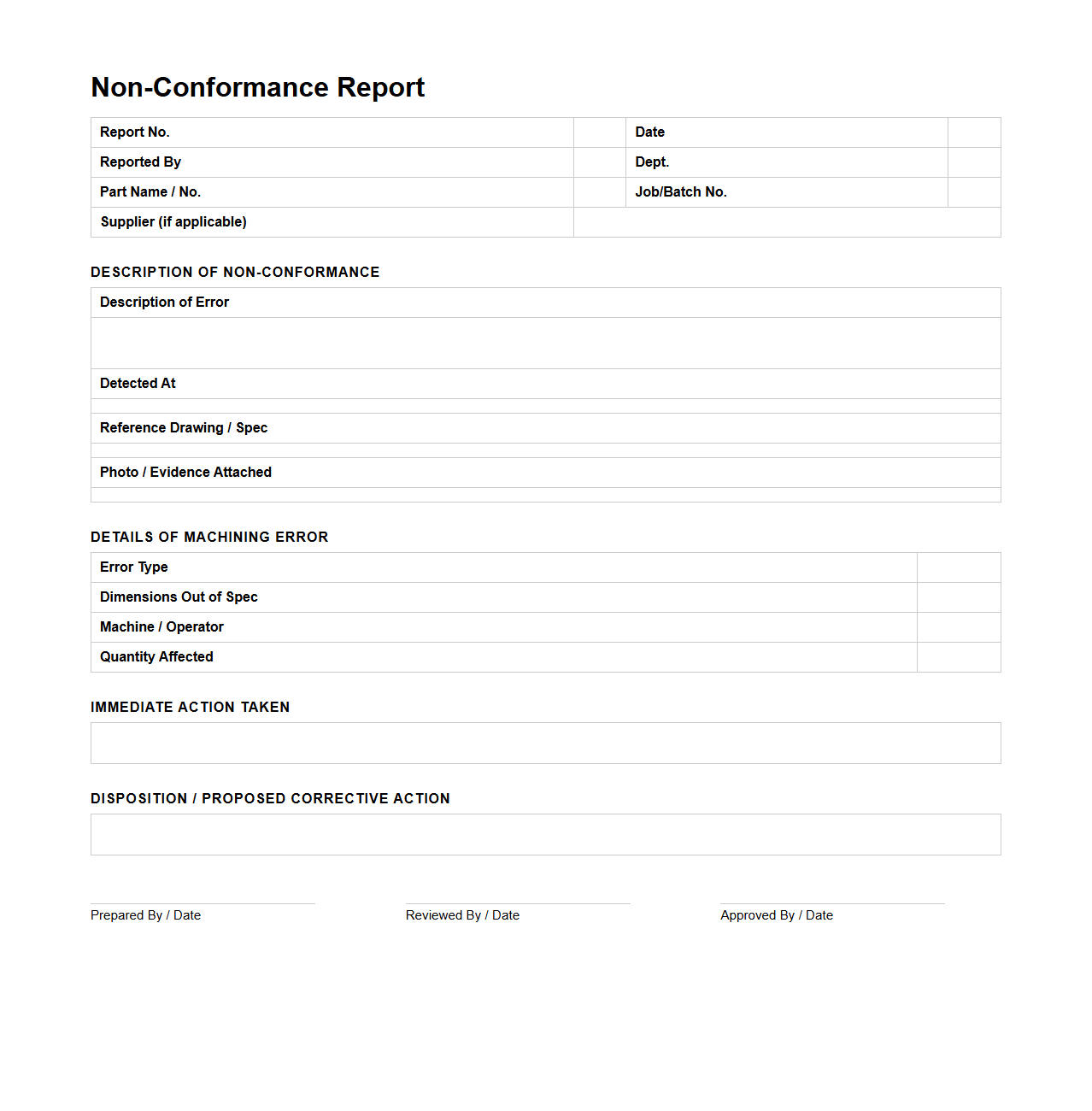

Non-Conformance Report Sample for Machining Errors

A

Non-Conformance Report Sample for Machining Errors document serves as a standardized template to identify, document, and address deviations from specified machining processes or product standards. It details the nature of the machining error, root cause analysis, corrective actions, and verification steps to ensure quality control and continuous improvement in manufacturing operations. This report is essential for maintaining compliance with industry standards and minimizing defects in machining production.

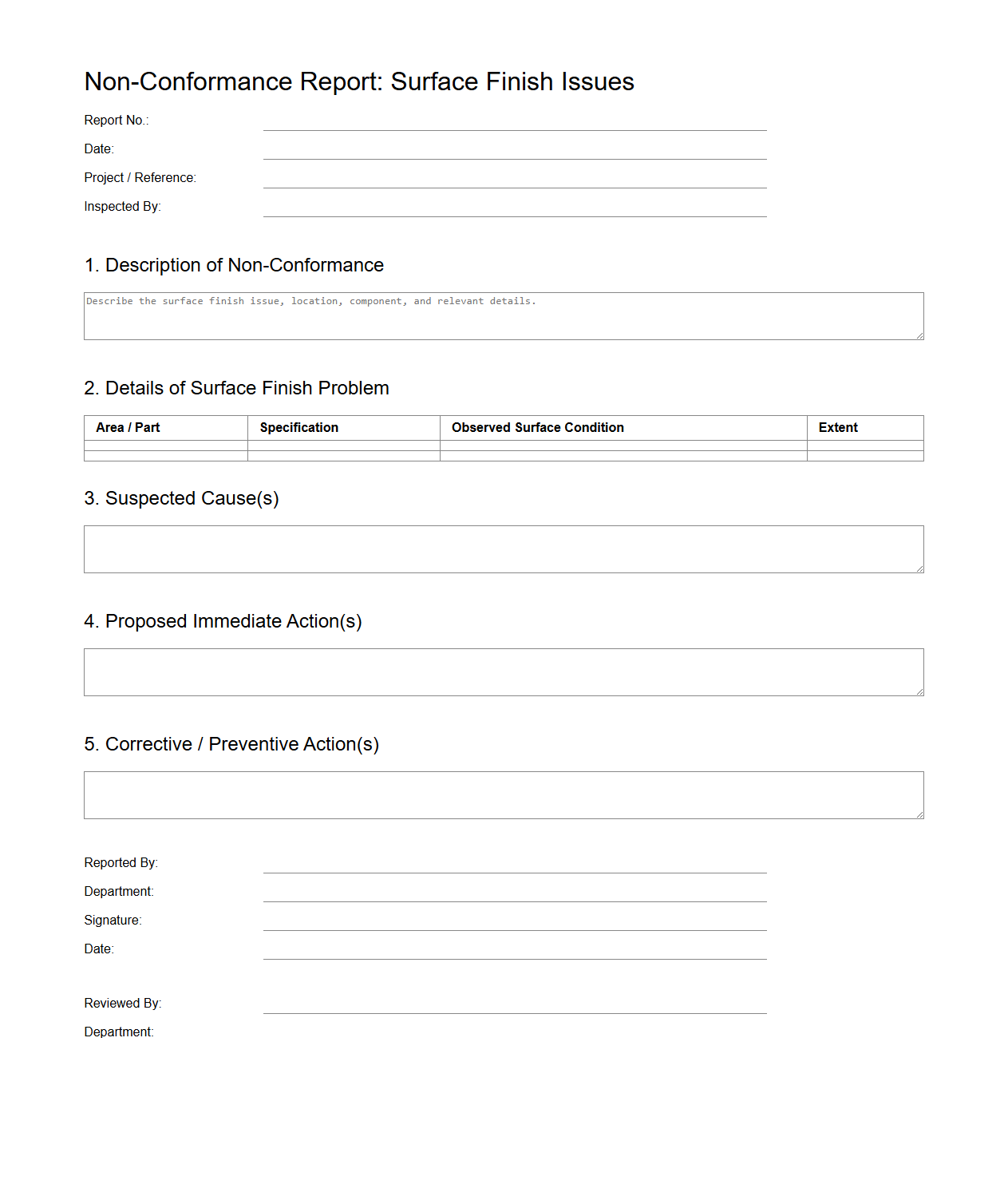

Non-Conformance Report Format for Surface Finish Issues

A

Non-Conformance Report (NCR) Format for Surface Finish Issues document is a structured template used to identify, document, and analyze deviations from specified surface finish standards in manufacturing or quality control processes. It captures critical information such as the nature of the surface defect, measurement data, affected batch or component details, root cause analysis, and corrective actions. This format ensures consistent reporting and facilitates effective communication between quality assurance teams and production staff to address and prevent recurrent surface finish non-conformities.

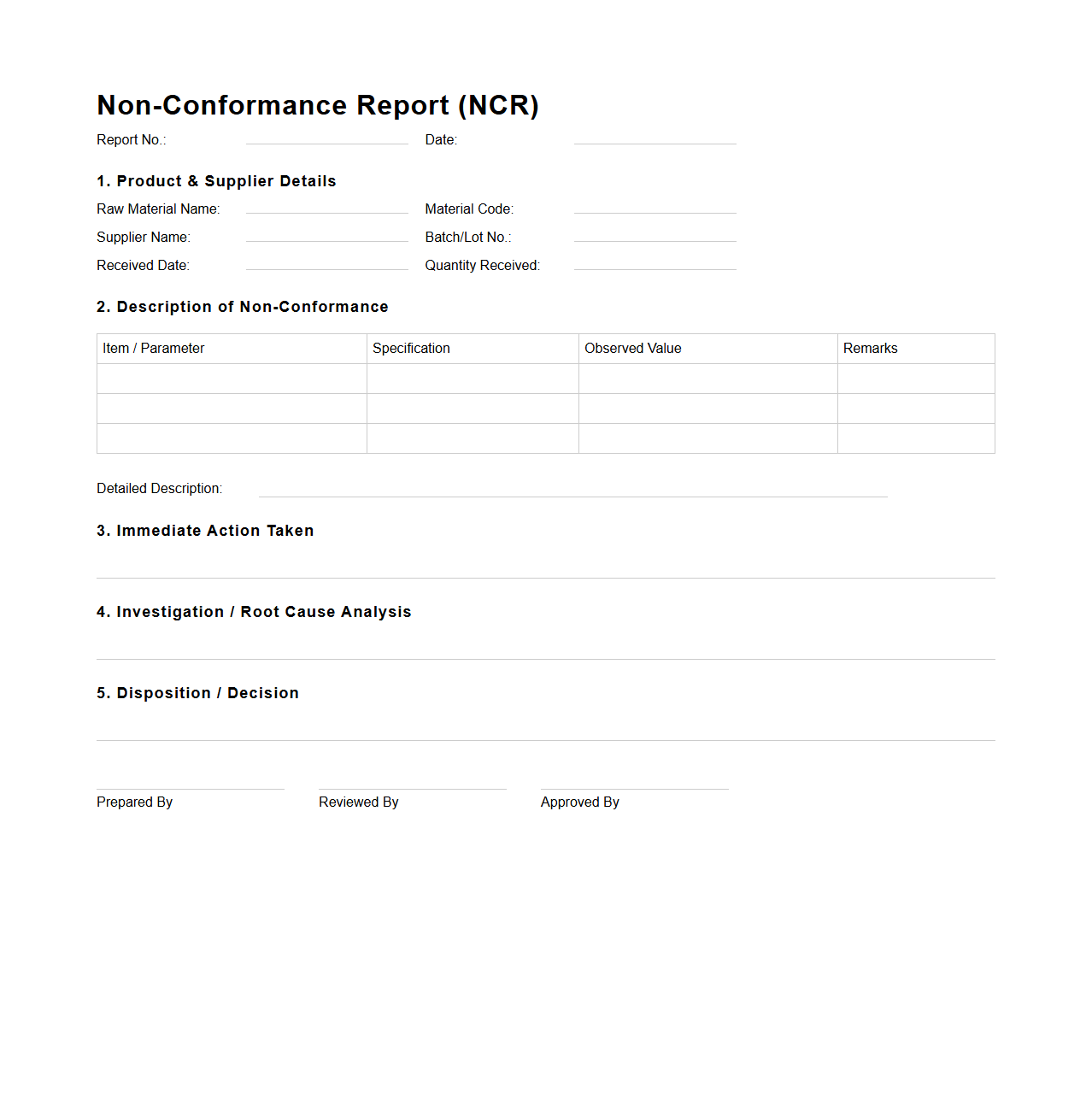

Non-Conformance Report Document for Raw Material Non-Compliance

A

Non-Conformance Report (NCR) document for Raw Material Non-Compliance details deviations from specified raw material standards and quality requirements. It serves as an official record identifying the nature, extent, and root causes of the non-conformity, enabling corrective and preventive actions to maintain supply chain integrity. This document ensures traceability and supports compliance with regulatory and industry standards, minimizing production risks and quality issues.

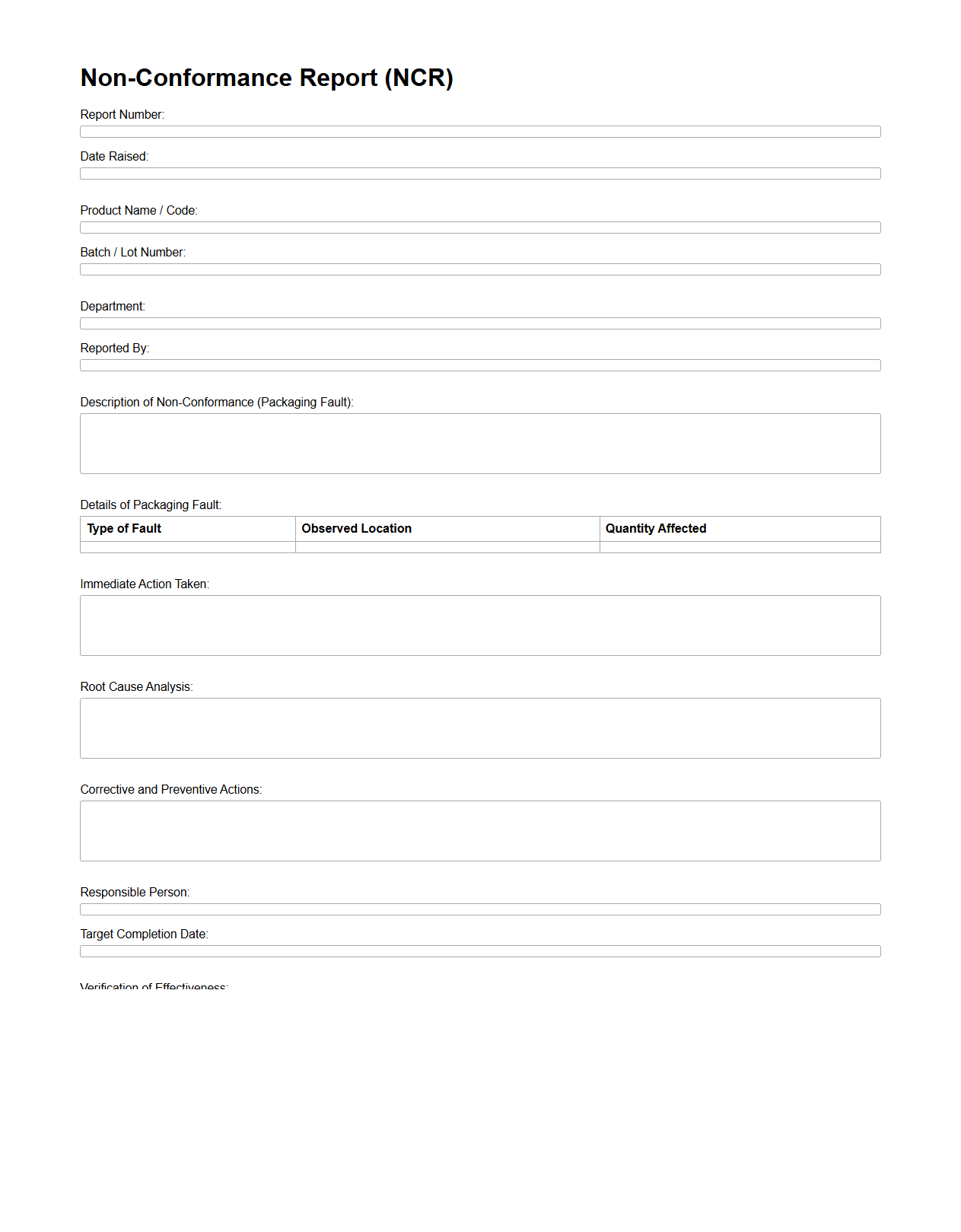

Non-Conformance Report Example for Packaging Faults

A

Non-Conformance Report (NCR) Example for Packaging Faults document details specific instances where packaging fails to meet quality standards or specifications. It includes descriptions of defects, root causes, impact assessments, and corrective actions to prevent recurrence. This document serves as a critical tool for quality control teams to systematically address and resolve packaging issues.

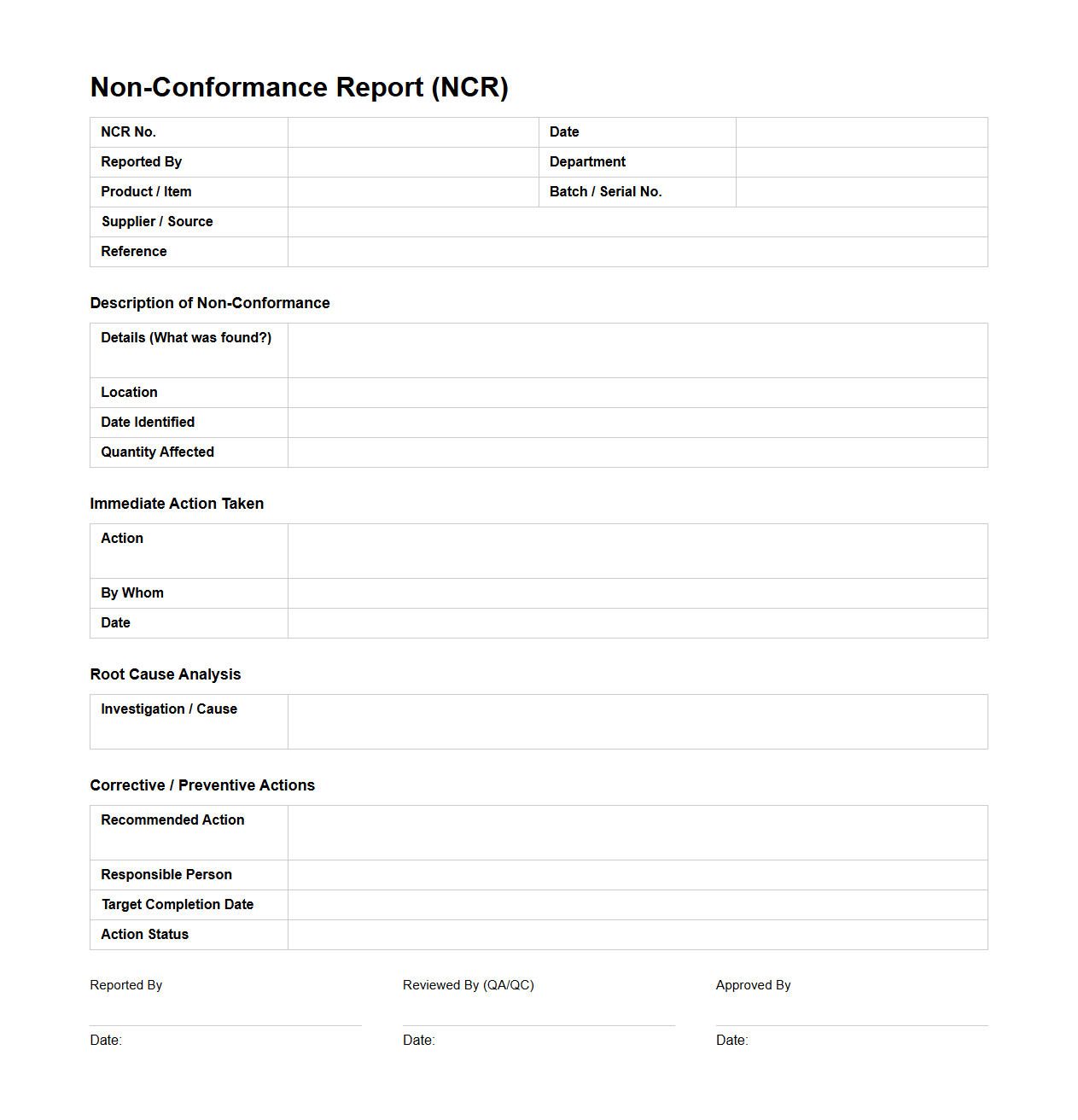

Non-Conformance Report Template for Quality Inspection Failures

A

Non-Conformance Report Template for Quality Inspection Failures is a standardized document used to systematically record and analyze deviations from specified quality standards during product or process inspections. It captures crucial details such as the nature of the defect, root cause analysis, corrective actions, and responsible parties to ensure effective resolution and prevention of recurrence. This template enhances traceability and accountability, contributing to continuous quality improvement and compliance with industry regulations.

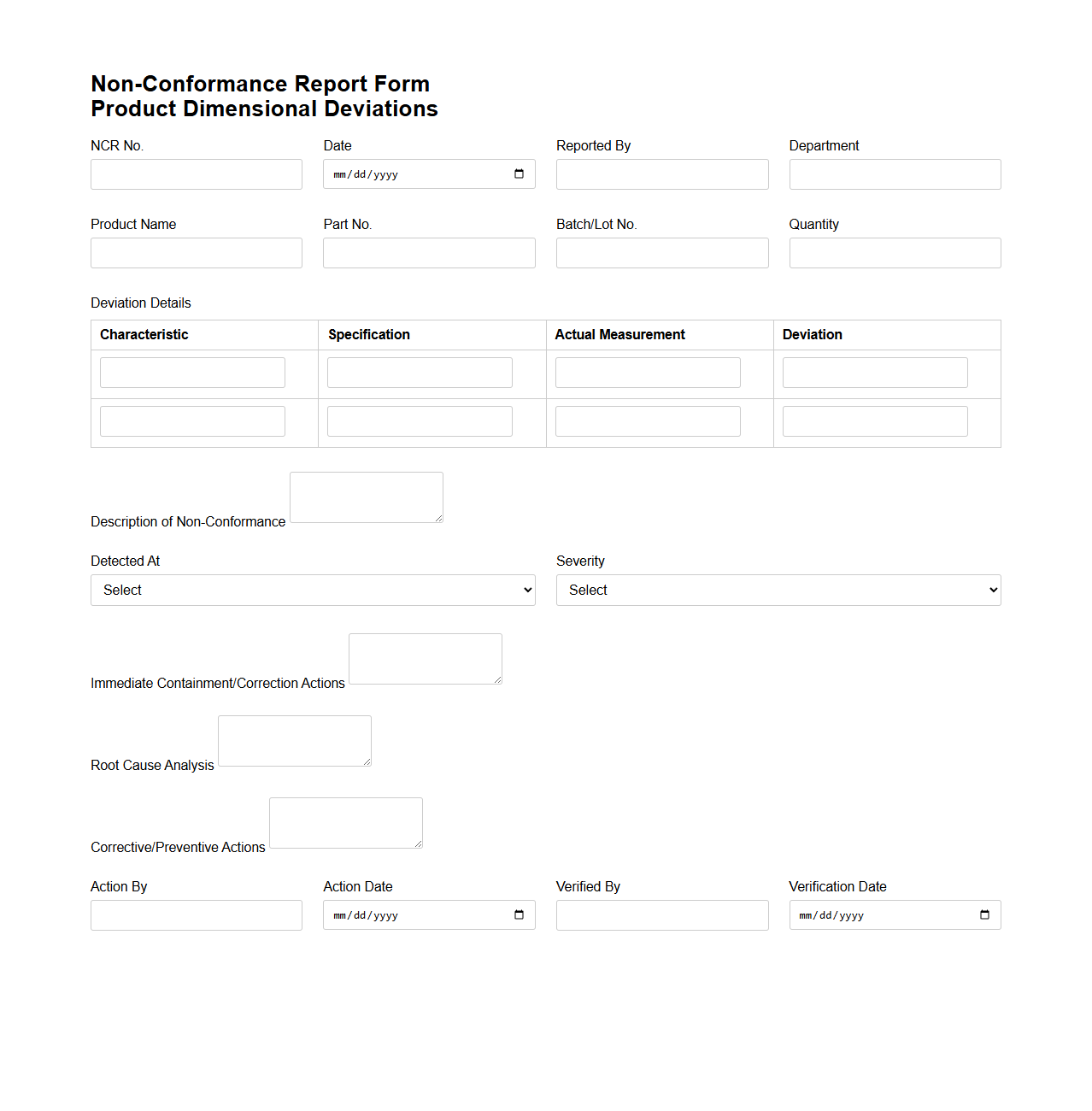

Non-Conformance Report Form for Product Dimensional Deviations

A

Non-Conformance Report (NCR) Form for Product Dimensional Deviations is a critical quality management document used to identify, record, and address discrepancies between the actual product dimensions and specified design requirements. It ensures traceability of deviations, facilitating corrective actions and preventing recurrence in manufacturing processes. This form supports compliance with industry standards and maintains product integrity by systematically documenting and managing dimensional non-conformities.

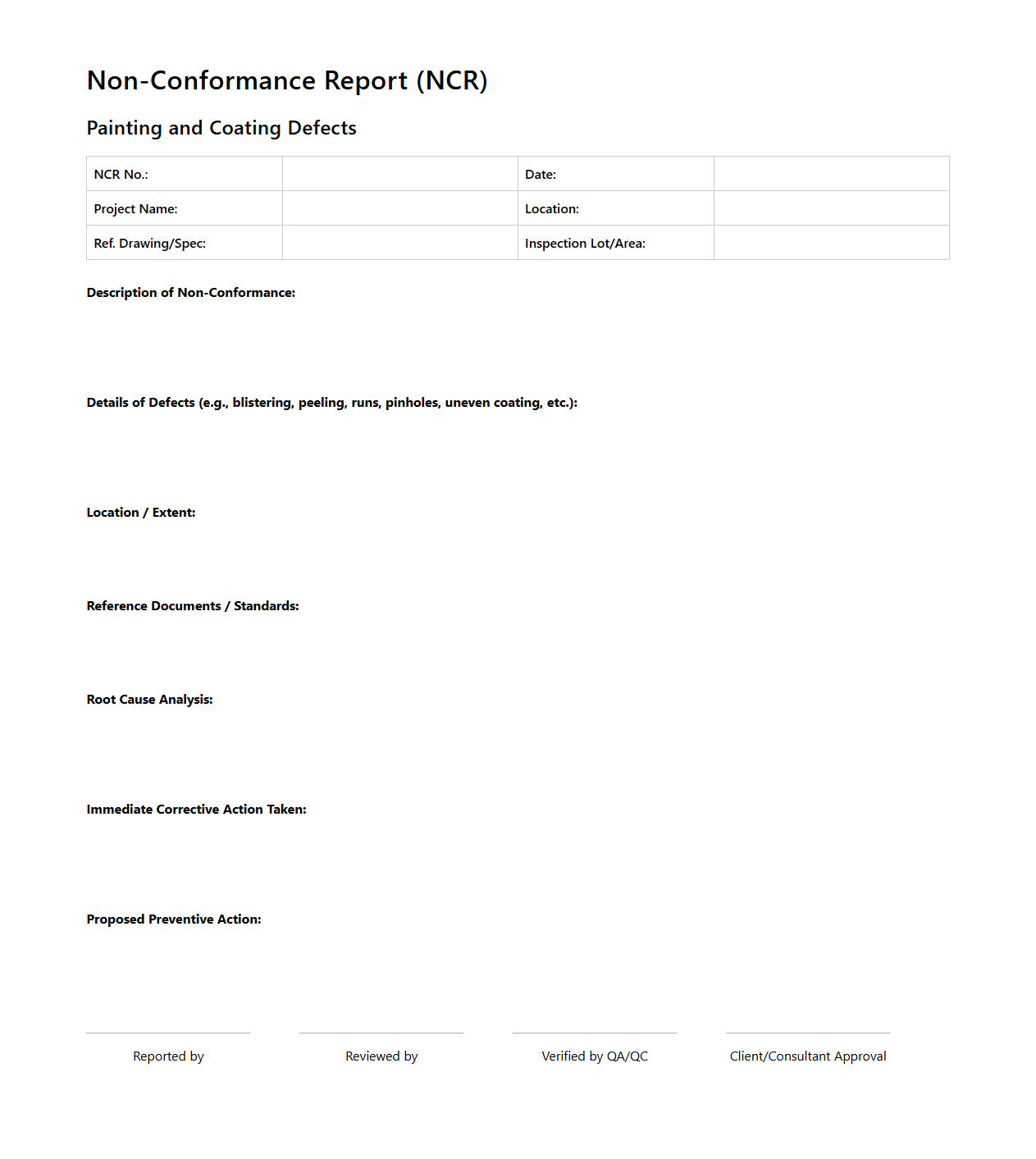

Non-Conformance Report Sample for Painting and Coating Defects

A

Non-Conformance Report (NCR) Sample for Painting and Coating Defects document is a formal record used to identify, document, and address issues related to imperfections or failures in paint and coating applications. It includes detailed descriptions of the defect types, such as blistering, peeling, or insufficient thickness, along with photographic evidence and corrective action recommendations. This report ensures quality control, helps maintain project standards, and facilitates communication between contractors, inspectors, and clients.

What critical information must be included in a Non-Conformance Report for manufacturing processes?

A Non-Conformance Report (NCR) must include the description of the non-conformance, date, and affected product or process details for clear identification. It should document the severity and impact on quality and production. Additionally, relevant personnel and departments involved must be recorded for communication and resolution.

How is the root cause of non-conformance documented and analyzed in the report?

The root cause is identified using structured methodologies such as 5 Whys or Fishbone diagrams to ensure thorough analysis. The report captures detailed evidence and observations leading to the non-conformance. This analysis helps highlight underlying issues rather than just symptoms, facilitating effective problem resolution.

Which corrective and preventive actions are outlined in the sample document for addressing the non-conformance?

The sample NCR outlines specific corrective actions to resolve the current issue and restore compliance. Preventive actions focus on process improvements to avoid recurrence and enhance overall quality control. Both actions are time-bound and assigned to responsible personnel for accountability.

What are the roles and responsibilities assigned in the sample NCR for managing non-conformance incidents?

The report assigns roles such as Quality Assurance, Production Supervisor, and Root Cause Analyst for effective incident management. Each role has defined tasks including investigation, documentation, and follow-up actions. This structured delegation ensures timely response and resolution of non-conformance.

How does the sample report ensure traceability and accountability for each non-conformance detected?

The sample NCR uses unique identification numbers and timestamps to track each reported incident. It includes signatures and approval fields for verification and responsibility confirmation. This traceability system enhances transparency and supports audit requirements in manufacturing processes.