A Tool Calibration Document Sample for Manufacturing outlines the procedures and standards used to verify the accuracy and precision of tools and equipment in production environments. This document ensures consistent quality control by recording calibration dates, results, and any necessary adjustments. Proper documentation helps maintain compliance with industry regulations and supports traceability in manufacturing processes.

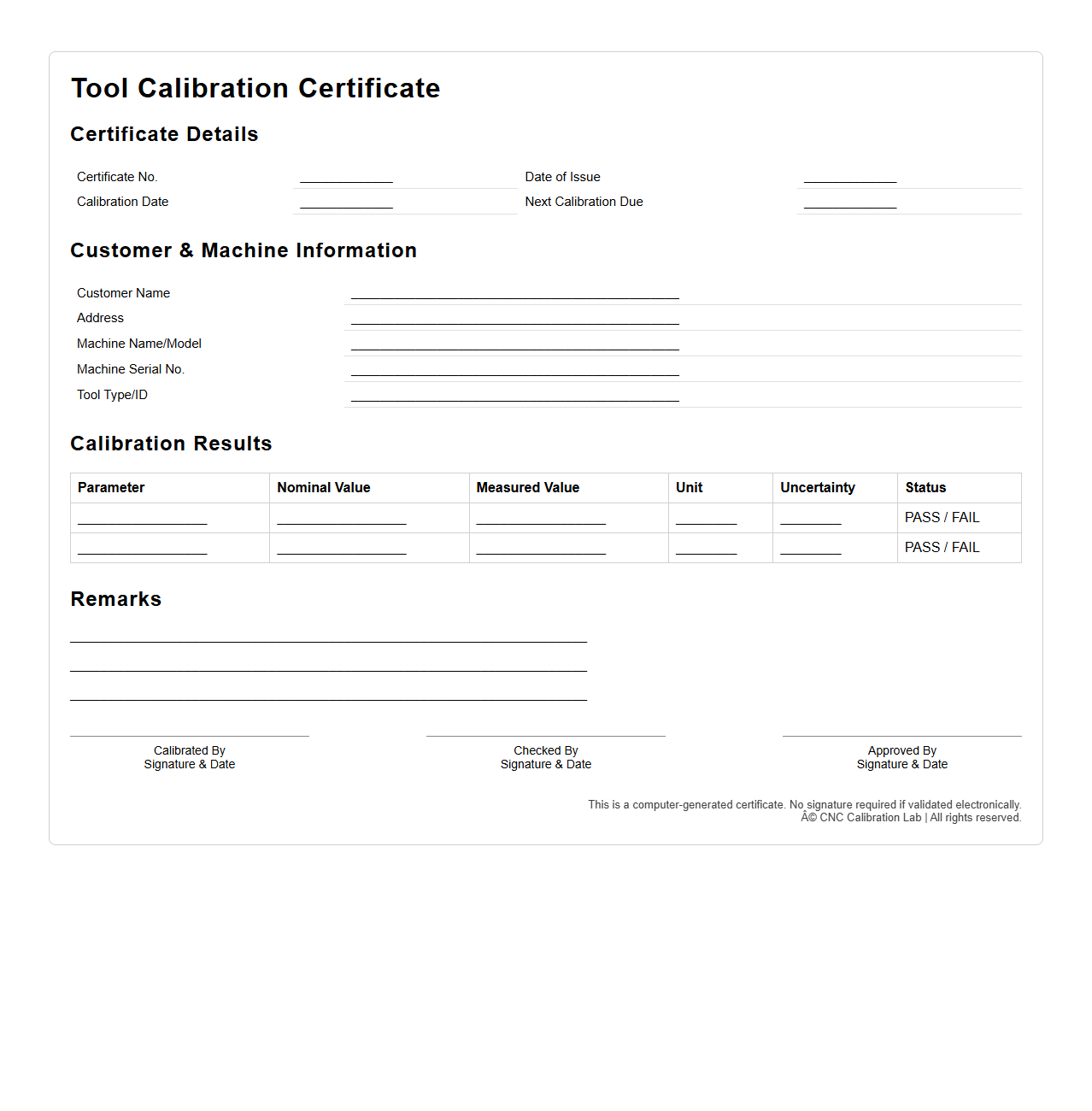

Tool Calibration Certificate Example for CNC Machines

A

Tool Calibration Certificate for CNC machines documents the verification process ensuring cutting tools meet precise measurement standards. This certificate includes details such as calibration date, instrument ID, measurement results, and compliance with industry standards like ISO 9001. It serves as proof that tools are accurately calibrated to maintain machining quality and operational efficiency.

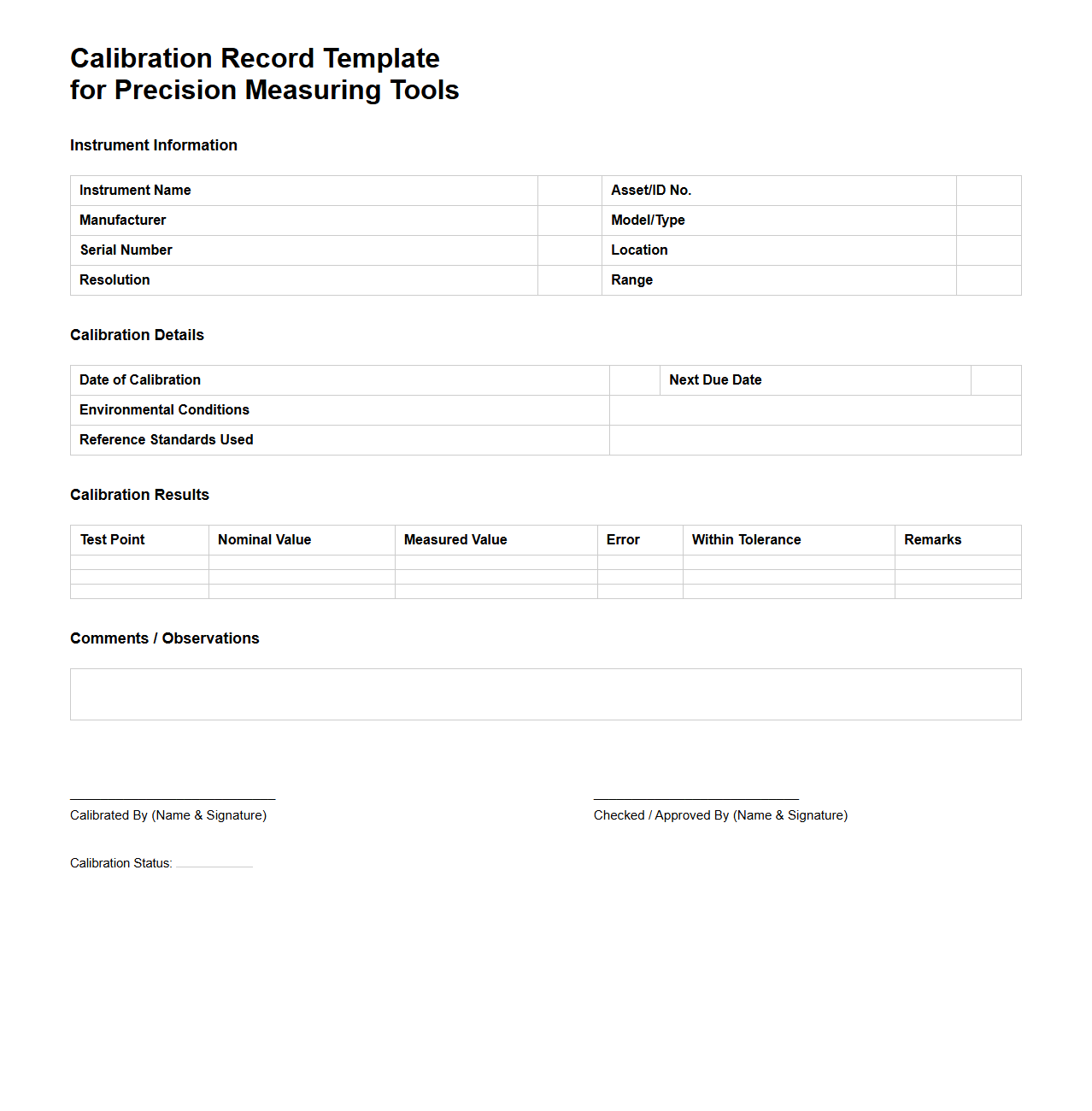

Calibration Record Template for Precision Measuring Tools

A

Calibration Record Template for Precision Measuring Tools document serves as a standardized format to document the calibration details of measuring instruments, ensuring accuracy and traceability. It typically includes fields for equipment identification, calibration dates, measurement results, technician's information, and compliance standards. Maintaining this template helps organizations uphold quality control, reduce measurement errors, and meet industry regulatory requirements.

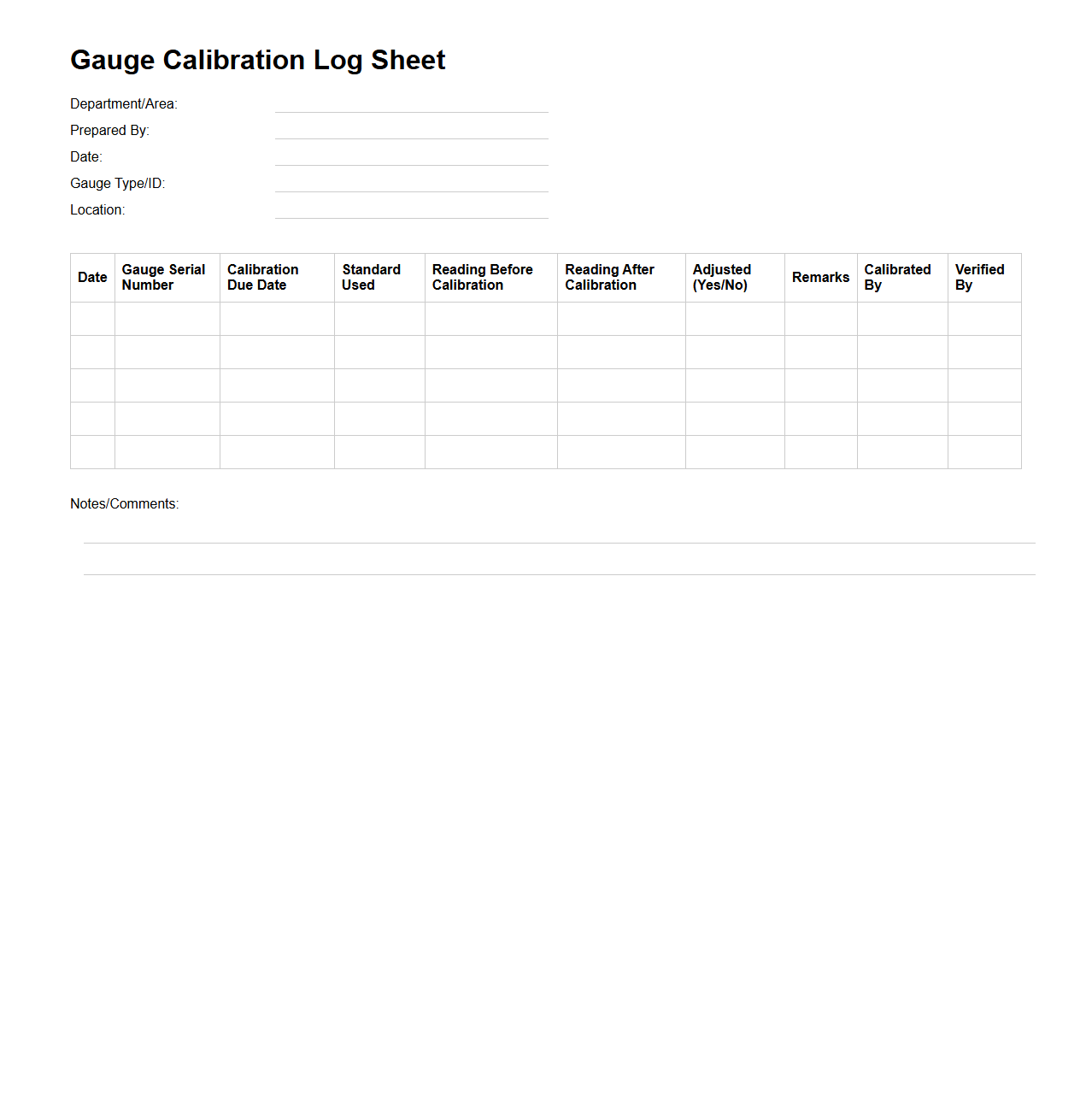

Gauge Calibration Log Sheet for Production Environments

A

Gauge Calibration Log Sheet for Production Environments document records the calibration status and history of measurement instruments used in manufacturing processes. It ensures accuracy and consistency by tracking calibration dates, results, and any adjustments made to the gauges. Maintaining this log supports quality control compliance and minimizes production errors caused by faulty equipment.

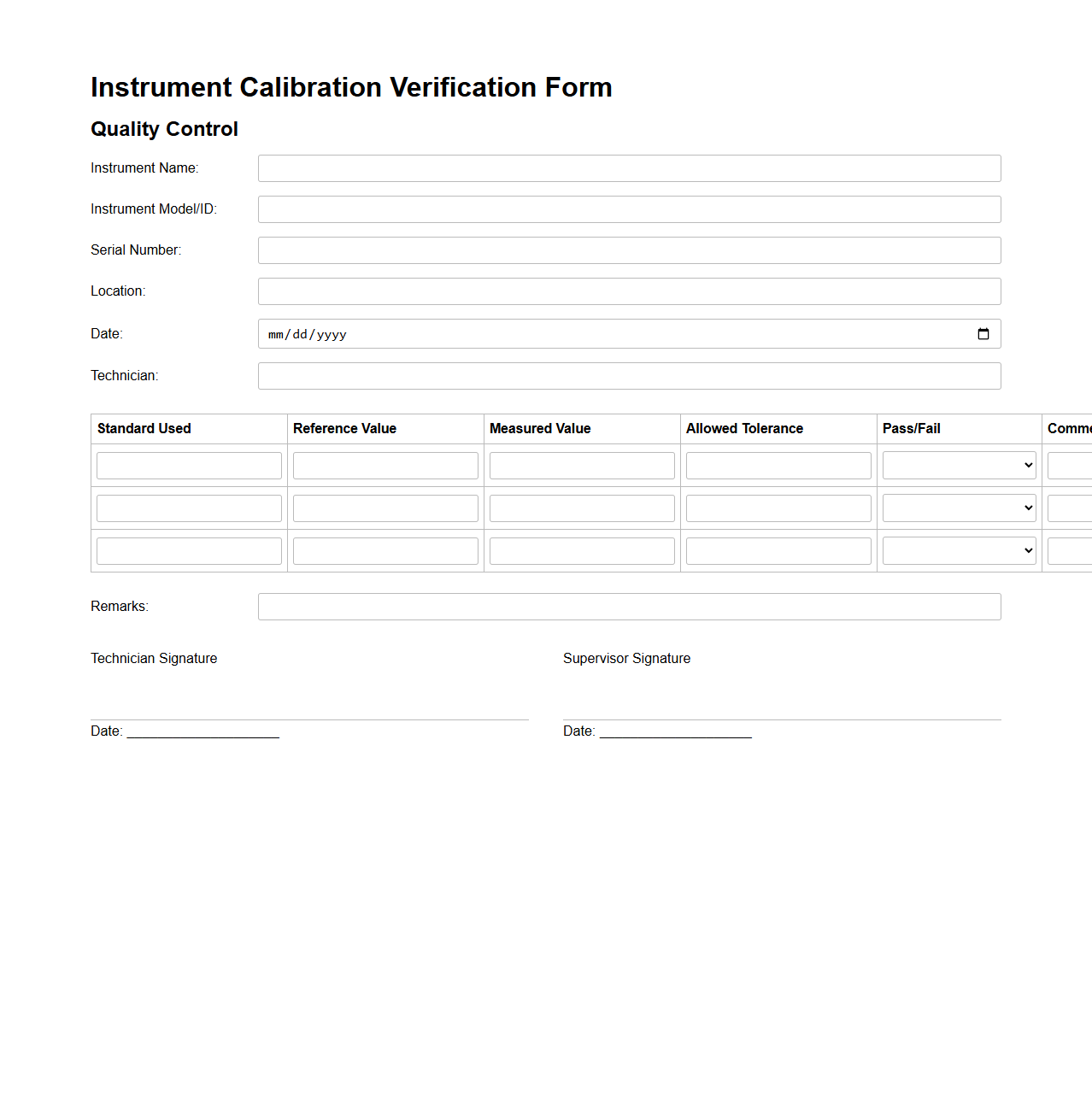

Instrument Calibration Verification Form for Quality Control

Instrument Calibration Verification Form is a

critical quality control document used to ensure measurement instruments meet specified accuracy standards. It records calibration data, verification results, and confirms that instruments function correctly within established tolerances. This form supports compliance with industry regulations and maintains consistent product quality by preventing measurement errors.

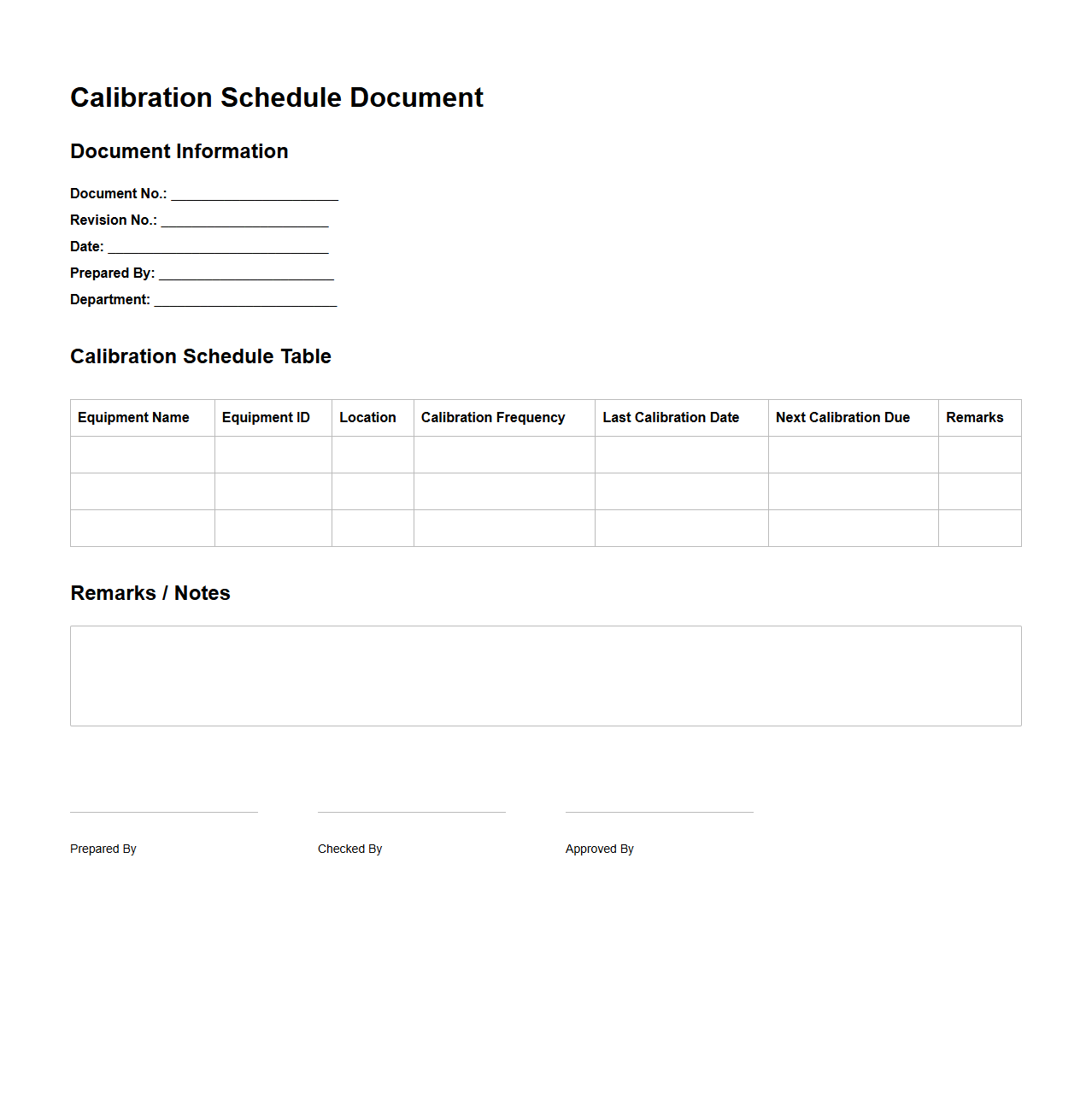

Calibration Schedule Document for Manufacturing Equipment

A

Calibration Schedule Document for manufacturing equipment is a detailed plan that outlines the specific dates and intervals for calibrating machinery to ensure accurate performance and compliance with industry standards. This document helps to track calibration history, maintain equipment reliability, and prevent production errors by scheduling regular checks and adjustments. Proper adherence to the calibration schedule supports quality control and regulatory requirements in manufacturing processes.

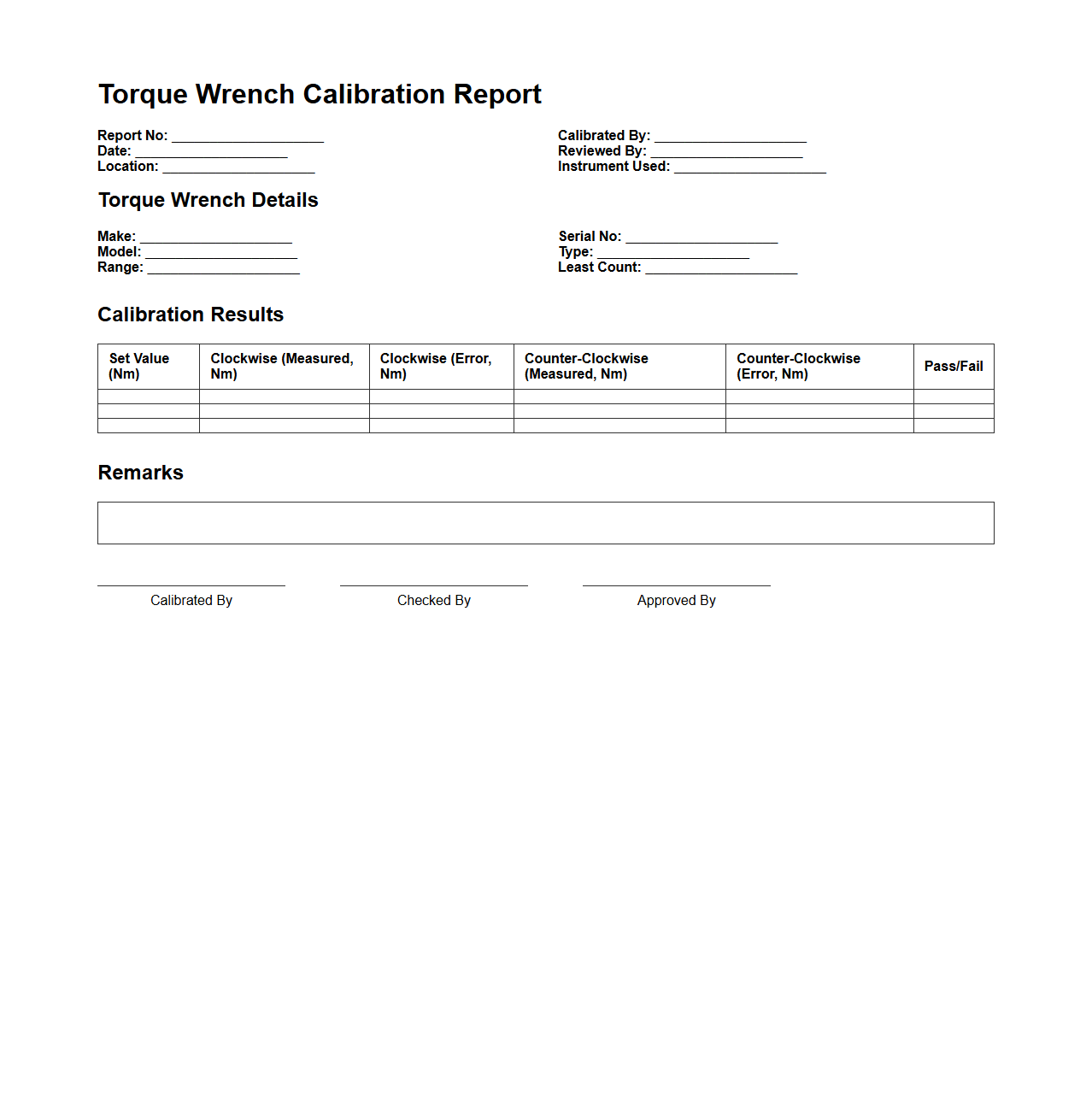

Torque Wrench Calibration Report Format

A

Torque Wrench Calibration Report Format document outlines the standardized structure for recording the calibration results of torque wrenches, ensuring accuracy and traceability. It typically includes essential data such as equipment identification, calibration date, applied torque values, measured readings, and allowable tolerances. This format is crucial for maintaining quality control, compliance with industry standards like ISO 6789, and validating the reliability of torque measurement tools.

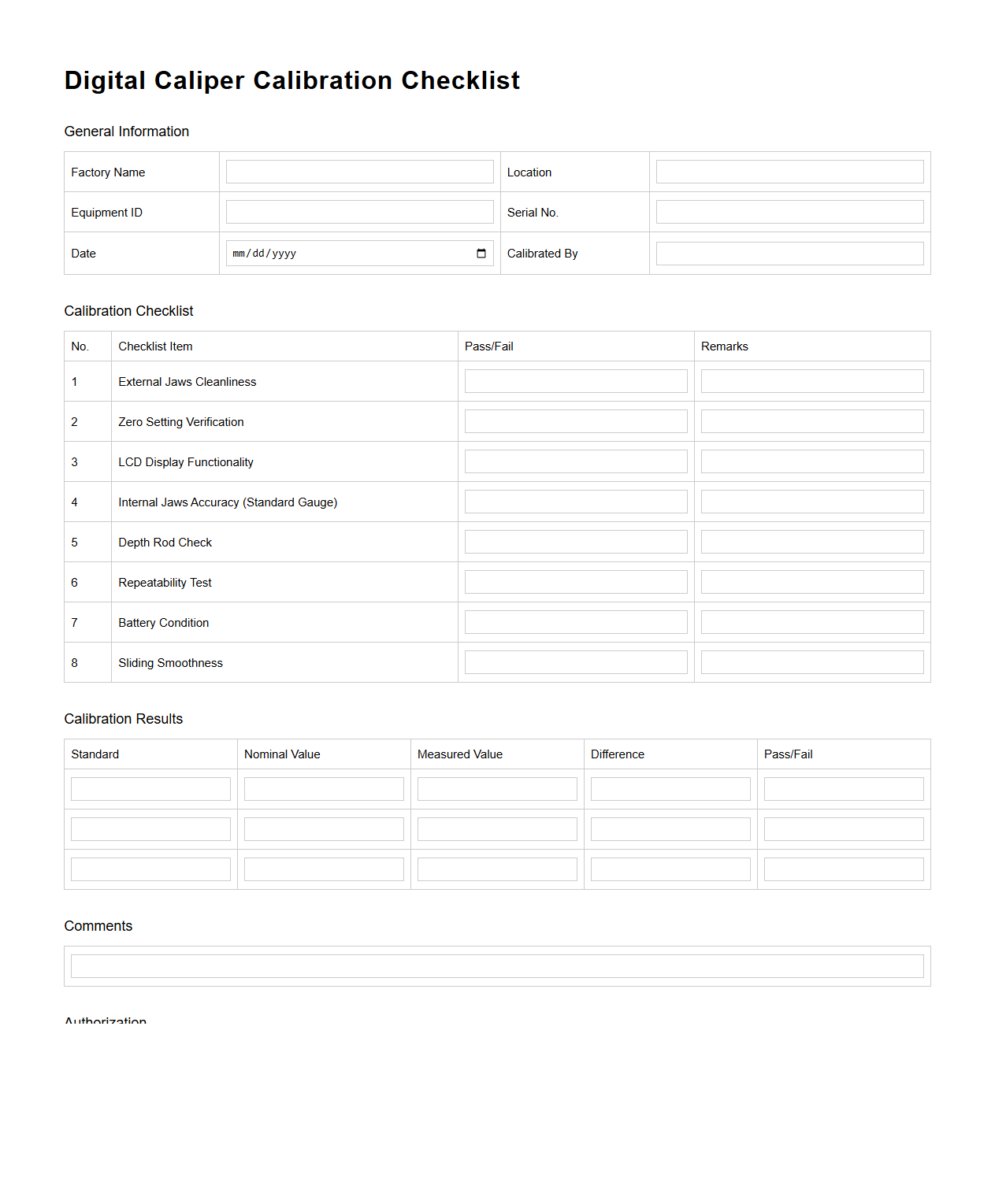

Digital Caliper Calibration Checklist for Factories

A

Digital Caliper Calibration Checklist for factories is a detailed guide ensuring the accuracy and reliability of digital calipers used in precision measurements. This document outlines essential calibration steps, verification methods, and maintenance procedures to maintain compliance with industry standards and quality control protocols. Regular adherence to this checklist helps prevent measurement errors, enhances product quality, and supports consistent manufacturing processes.

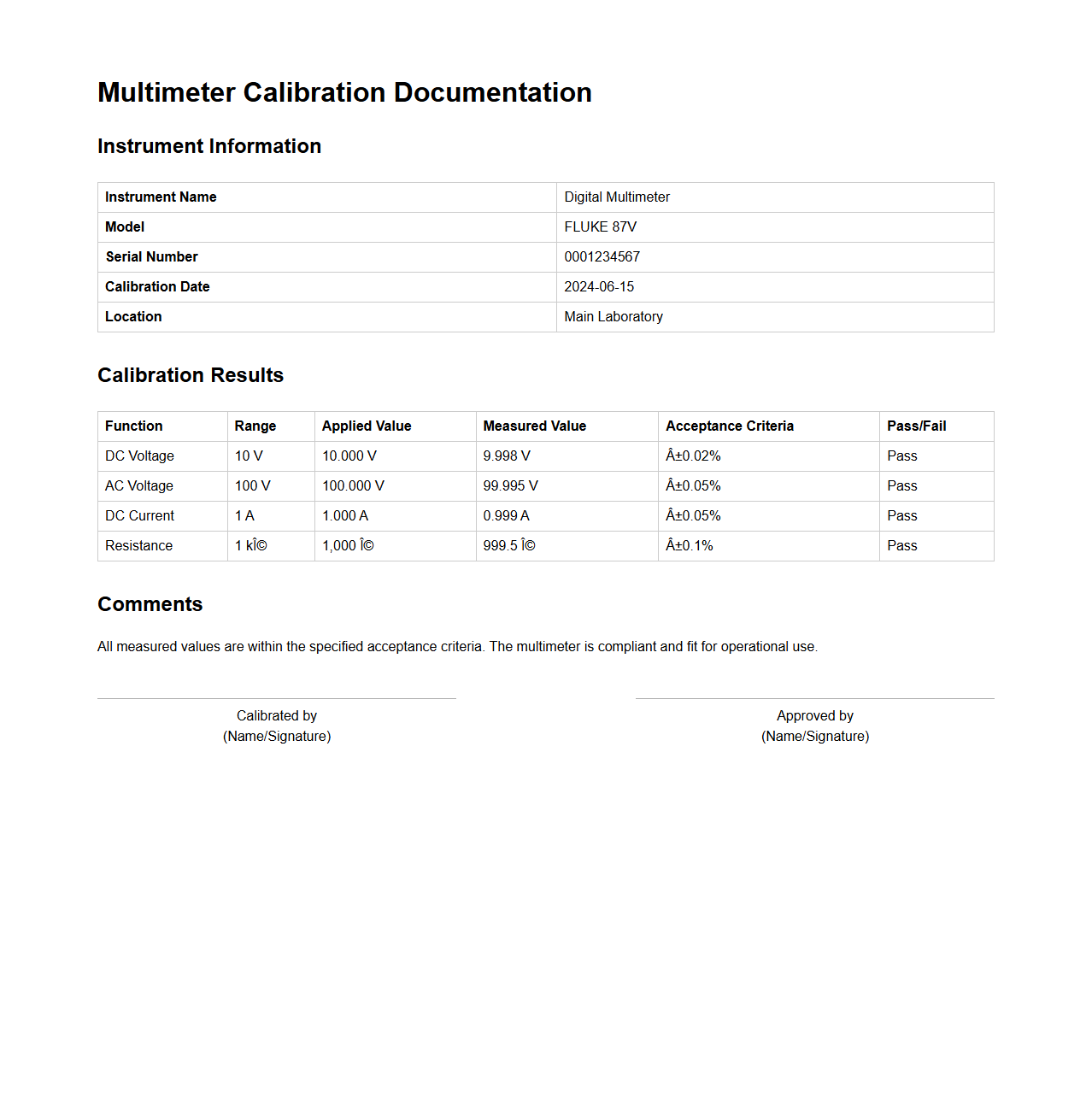

Multimeter Calibration Documentation Sample

A

Multimeter Calibration Documentation Sample provides a standardized record that details the calibration process of a multimeter, including measurement accuracy, calibration date, and technician information. This document ensures the multimeter meets industry standards and maintains reliable performance for precise electrical measurements. Proper documentation supports compliance with quality management systems and facilitates traceability in electrical testing and maintenance.

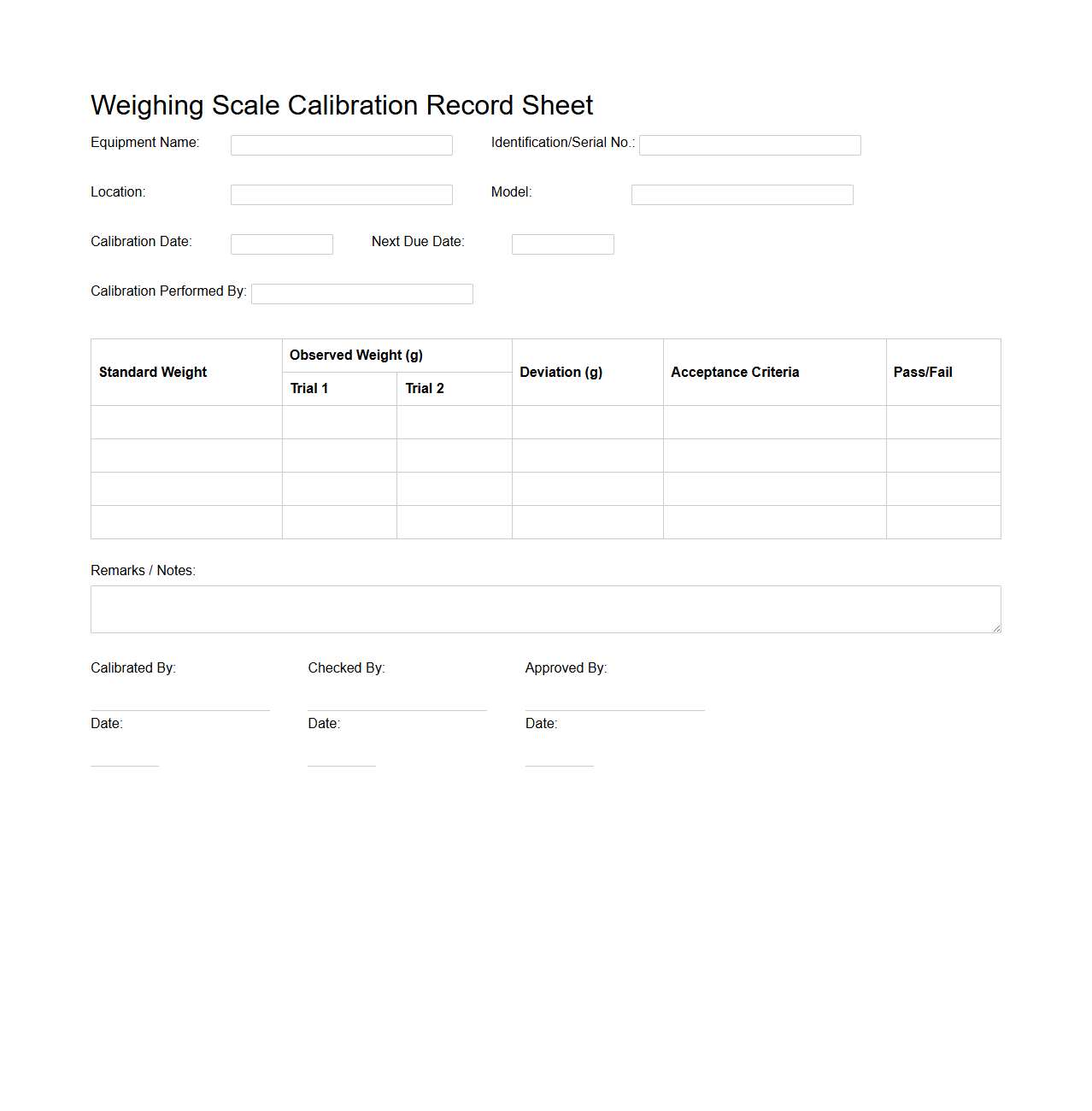

Weighing Scale Calibration Record Sheet

A

Weighing Scale Calibration Record Sheet document is used to systematically log the calibration details of weighing scales, ensuring their accuracy and compliance with industry standards. It records essential data such as date of calibration, calibration results, technician identity, and any adjustments made. Maintaining this document is crucial for quality control, regulatory audits, and maintaining measurement reliability in various industrial and laboratory settings.

Pressure Gauge Calibration Tracking Form

A

Pressure Gauge Calibration Tracking Form is a document used to systematically record and monitor the calibration status of pressure gauges. It ensures accuracy and compliance by tracking calibration dates, standards used, and the results of each calibration. This form helps maintain the reliability of pressure measurement instruments and supports quality control processes in industrial and laboratory settings.

What specific tools or equipment does the Tool Calibration Document pertain to in the manufacturing process?

The Tool Calibration Document specifically covers precision measuring devices and critical manufacturing equipment. It includes calipers, micrometers, torque wrenches, and coordinate measuring machines (CMM). These tools are essential for maintaining product quality and process accuracy.

Which calibration standards and reference materials are specified in the document?

The document mandates adherence to ISO/IEC 17025 standards for laboratory competence. It references national metrology institutes and certified gauge blocks as key reference materials. Compliance ensures traceability and uniformity in calibration results.

How frequently must each tool listed in the document undergo calibration?

Calibration intervals vary, but most tools require calibration every 3 to 6 months to maintain accuracy. High-usage or critical tools might need more frequent checks, sometimes monthly. The document outlines specific schedules based on tool type and operational impact.

What are the acceptable tolerance limits defined for tool accuracy?

The document defines strict tolerance limits aligned with manufacturing process requirements. For example, dimensional tools have tolerances within +-0.01 mm, while torque wrenches allow a deviation of +-2%. Exceeding these limits triggers recalibration or replacement protocols.

Which personnel are authorized to perform and verify the calibration procedures according to the document?

Only certified calibration technicians and quality assurance engineers are authorized to conduct and verify calibrations. Personnel must complete specific training programs and demonstrate competence regularly. This ensures consistent and reliable calibration practices throughout the facility.

More Manufacturing Templates