A Root Cause Analysis Document Sample for Manufacturing provides a detailed template to identify, analyze, and address underlying issues affecting production processes. It includes sections for problem description, data collection, cause identification, and corrective action plans to ensure efficient resolution of manufacturing defects. This document helps improve quality control and prevent recurring problems in the manufacturing industry.

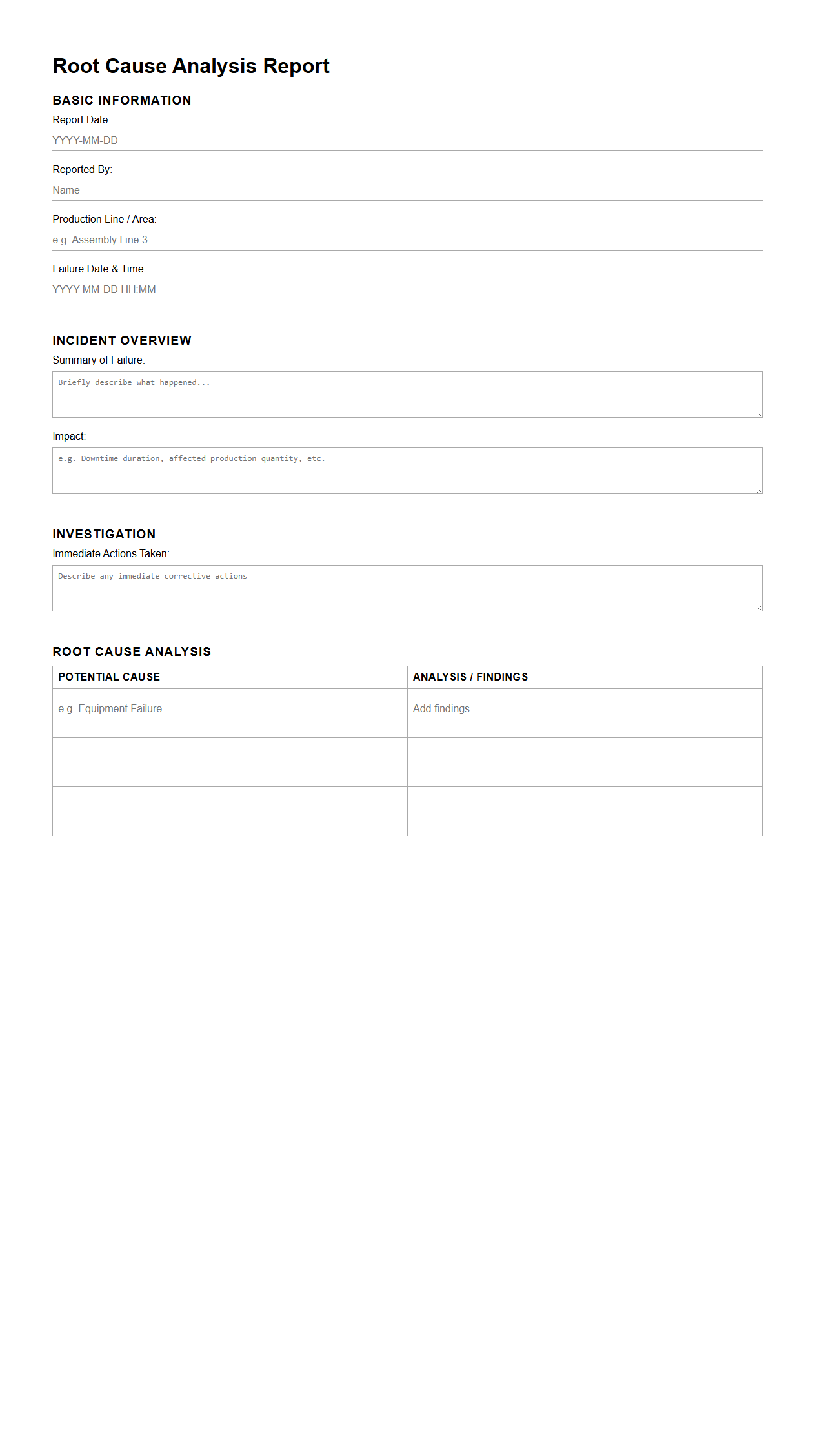

Root Cause Analysis Report Template for Production Line Failures

A

Root Cause Analysis Report Template for Production Line Failures document provides a structured framework for systematically identifying, analyzing, and documenting the underlying causes of production disruptions. It includes sections for failure description, data collection, cause investigation, corrective actions, and preventive measures to enhance manufacturing efficiency. This template is essential for manufacturing teams aiming to reduce downtime, improve quality control, and prevent recurring faults.

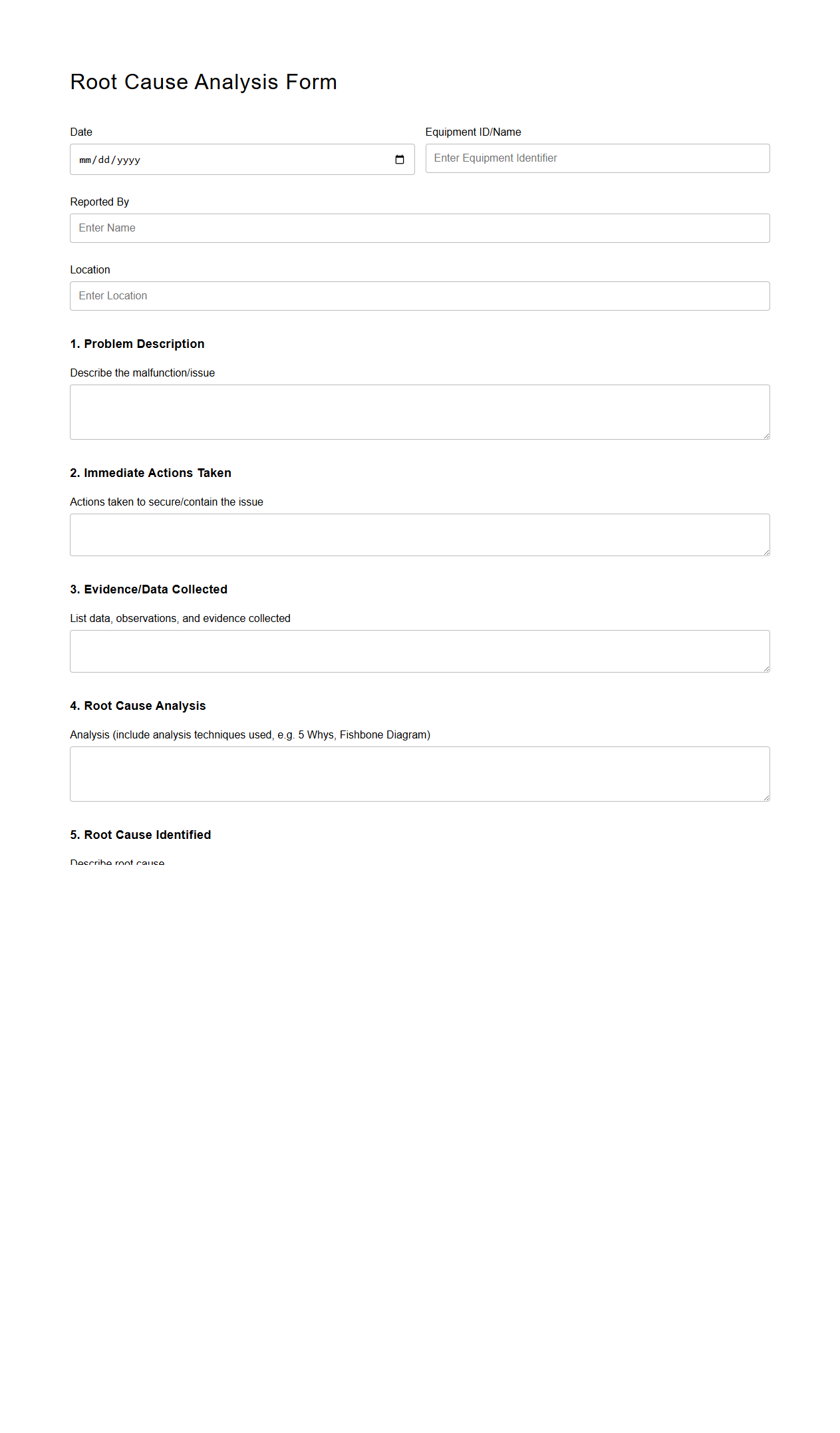

Root Cause Analysis Form for Equipment Malfunction in Manufacturing

A

Root Cause Analysis Form for Equipment Malfunction in manufacturing is a structured document used to systematically identify the underlying reasons for equipment failure. It collects essential data such as malfunction symptoms, machine history, operator observations, and environmental conditions to pinpoint issues and prevent recurrence. This form supports continuous improvement by guiding maintenance teams in implementing effective corrective actions and enhancing equipment reliability.

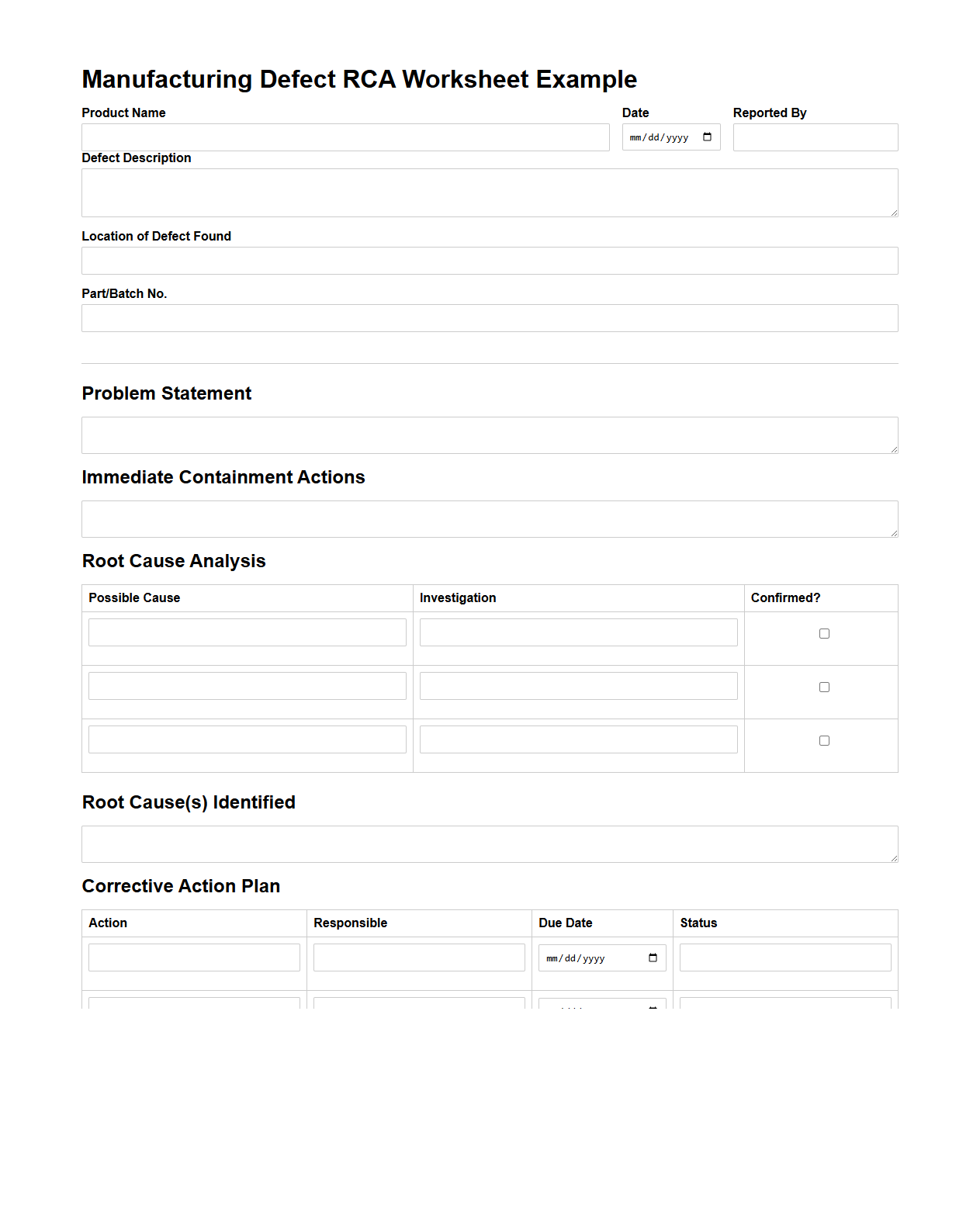

Manufacturing Defect RCA Worksheet Example

A

Manufacturing Defect RCA Worksheet Example document serves as a crucial tool for systematically identifying the root causes of defects in manufacturing processes. It guides quality engineers and production teams through structured analysis steps, documenting detailed findings such as defect types, contributing factors, and corrective actions. This worksheet enhances problem-solving efficiency by promoting consistent data collection and facilitating continuous improvement in product quality.

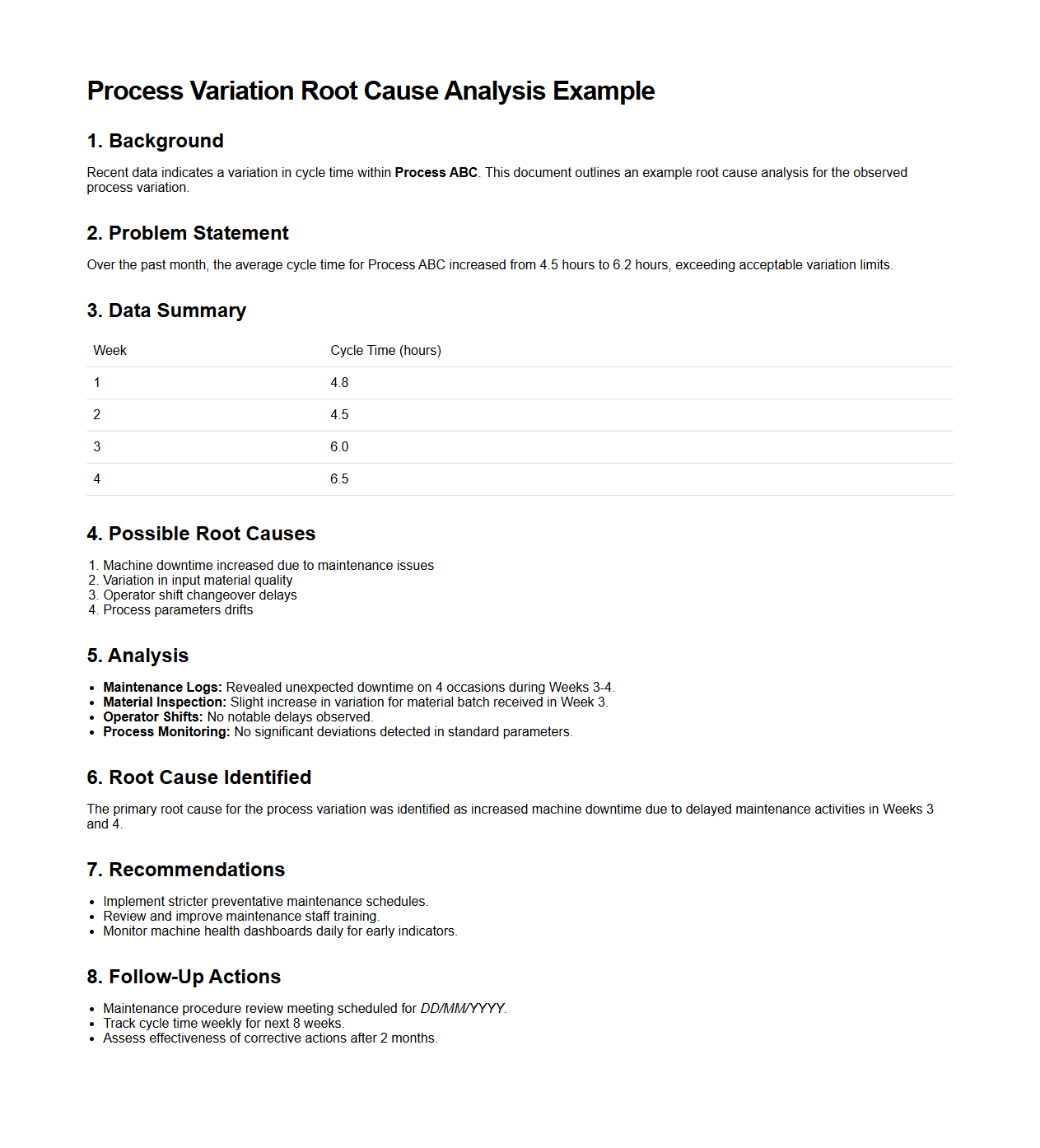

Process Variation Root Cause Analysis Example

A

Process Variation Root Cause Analysis Example document demonstrates systematic steps to identify and address sources of variability in manufacturing or business processes. It includes data collection, analysis of contributing factors, and recommended corrective actions to improve consistency and quality. This document serves as a practical guide to minimizing defects and enhancing process performance through targeted problem-solving techniques.

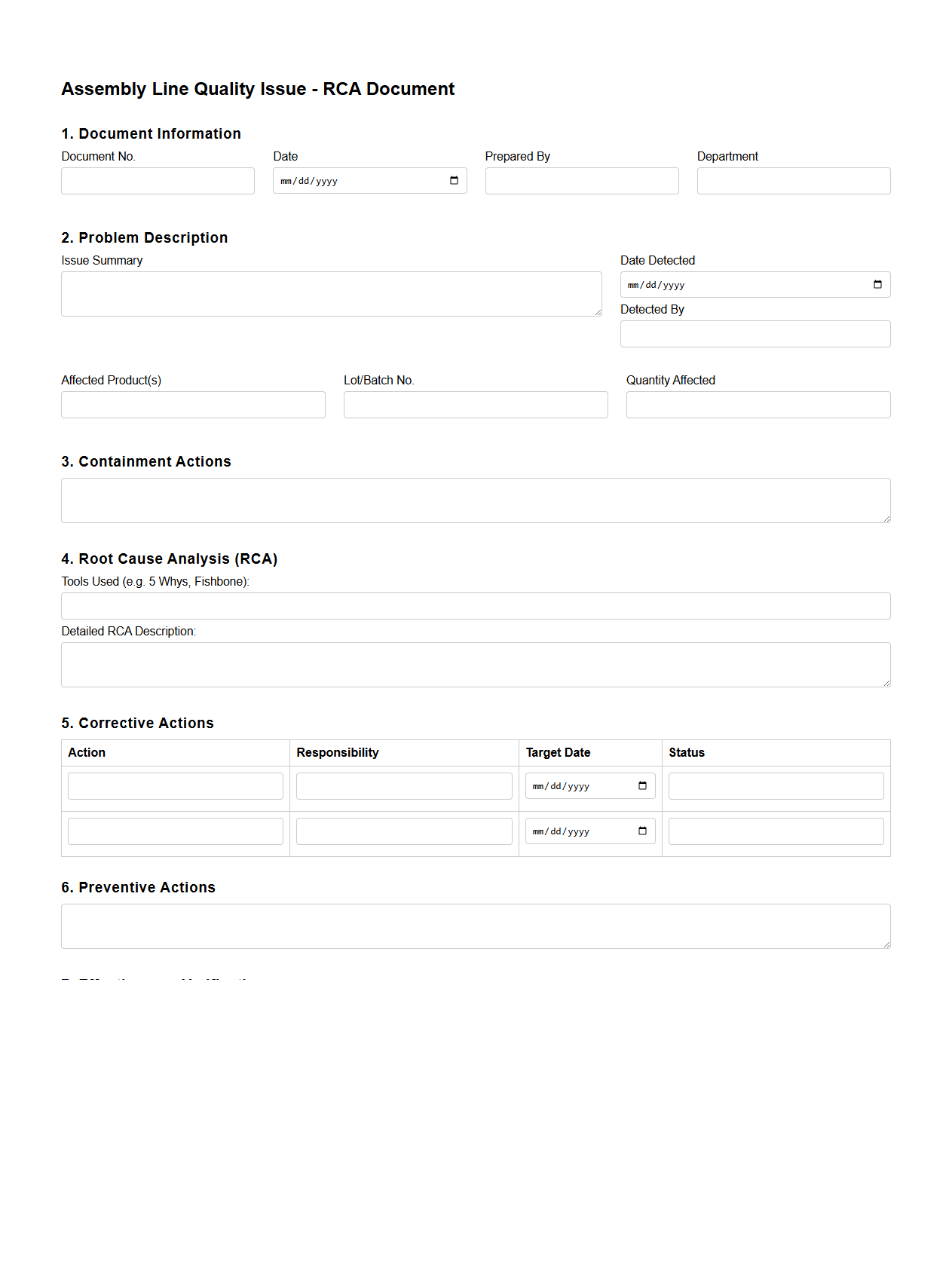

Assembly Line Quality Issue RCA Document

The

Assembly Line Quality Issue RCA Document is a critical report used to identify and analyze the root causes of defects or inconsistencies in the manufacturing process. It systematically captures data from quality checks, process deviations, and material inconsistencies to facilitate targeted corrective actions. This document helps manufacturers improve product reliability, reduce downtime, and enhance overall production efficiency.

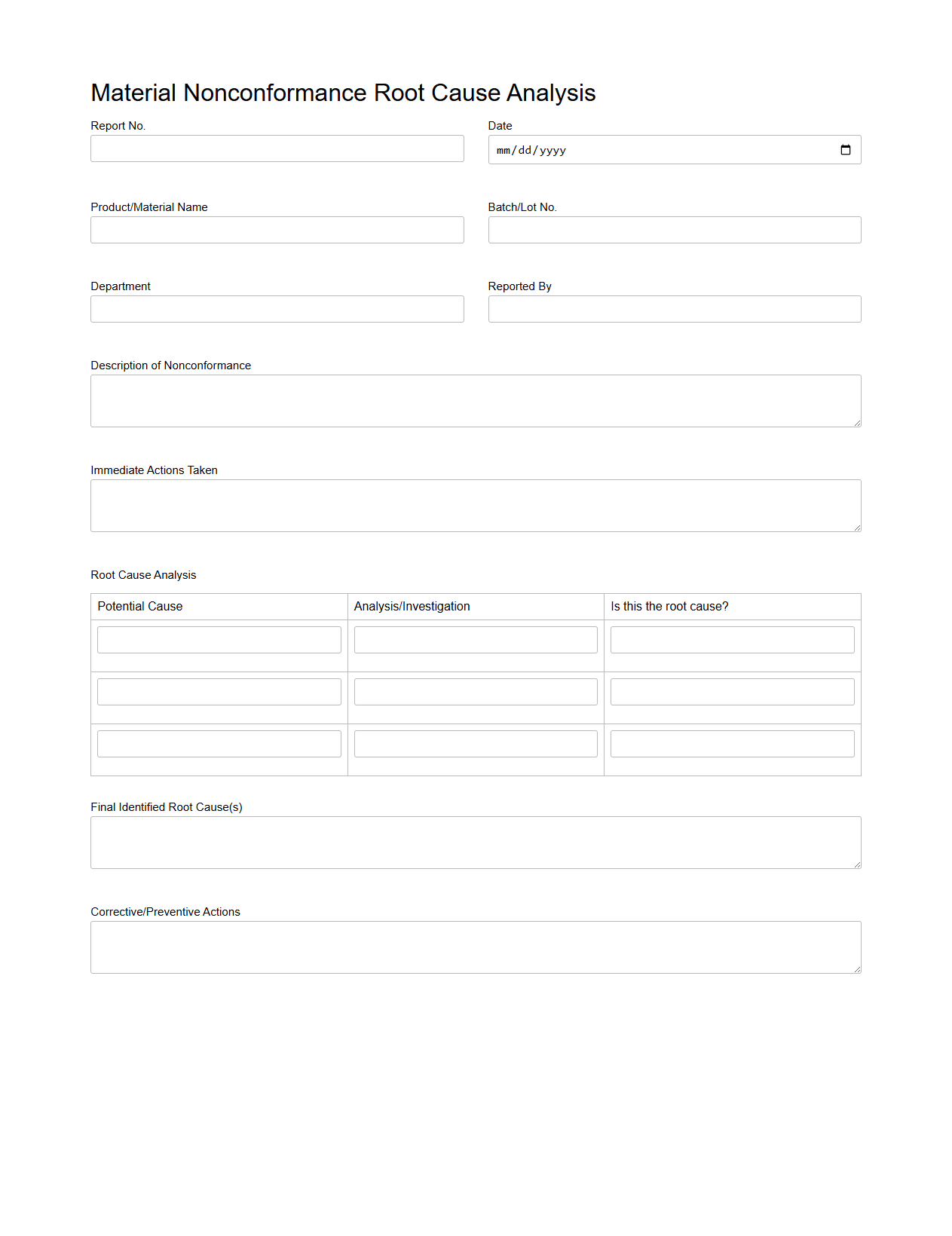

Material Nonconformance Root Cause Analysis Sample

A

Material Nonconformance Root Cause Analysis Sample document serves as a structured template designed to identify, analyze, and address the underlying reasons for material defects or deviations in manufacturing or quality processes. It includes sections for documenting the nonconformance details, root cause identification methods, corrective actions, and verification steps to prevent recurrence. This sample document aids organizations in maintaining quality standards and improving process reliability by systematically resolving material issues.

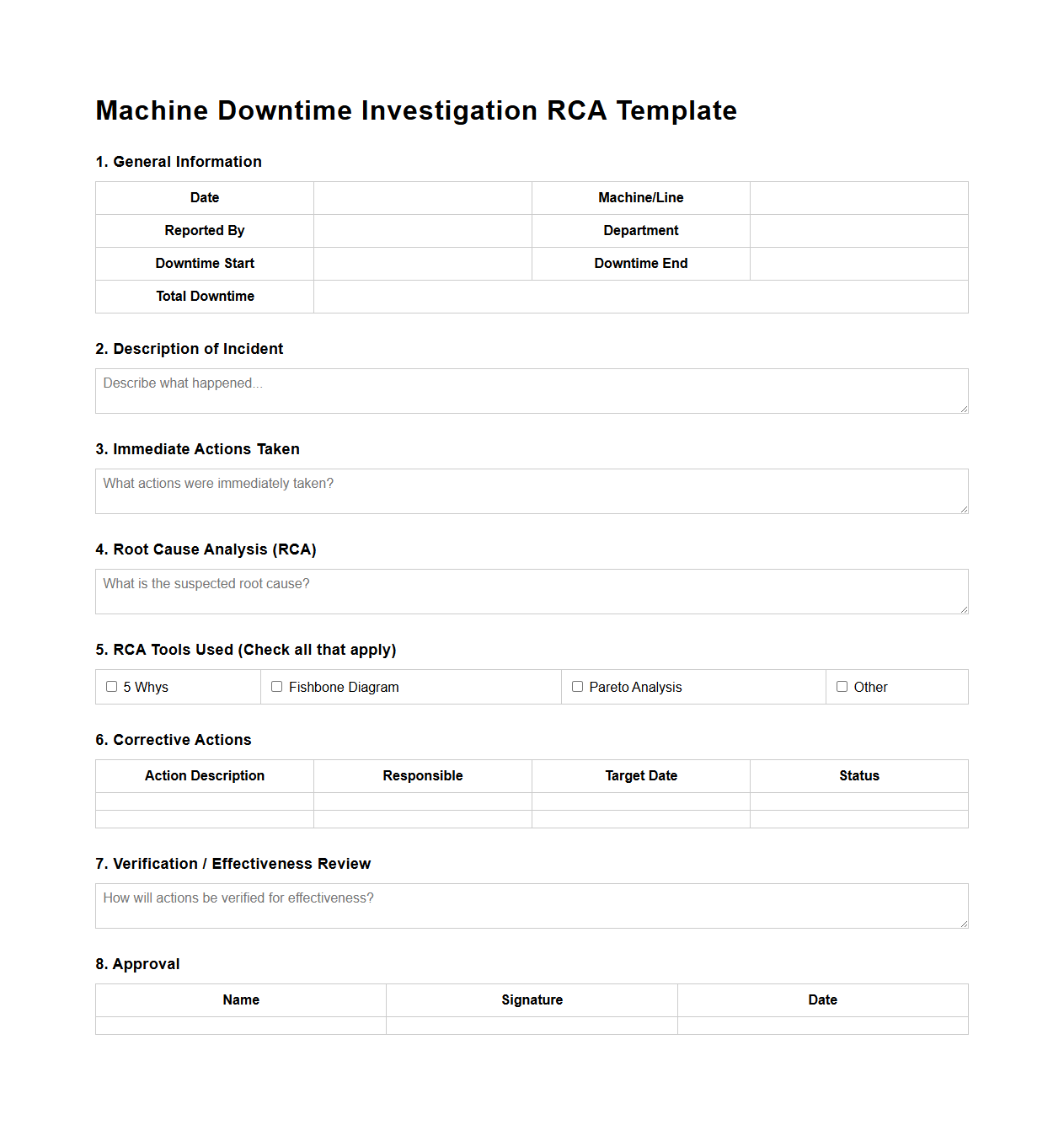

Machine Downtime Investigation RCA Template

The

Machine Downtime Investigation RCA Template document serves as a structured tool to systematically identify the root causes of equipment failures and production interruptions. It guides users through data collection, analysis, and documentation processes to pinpoint issues affecting operational efficiency. This template facilitates targeted corrective actions, reducing downtime and improving overall manufacturing productivity.

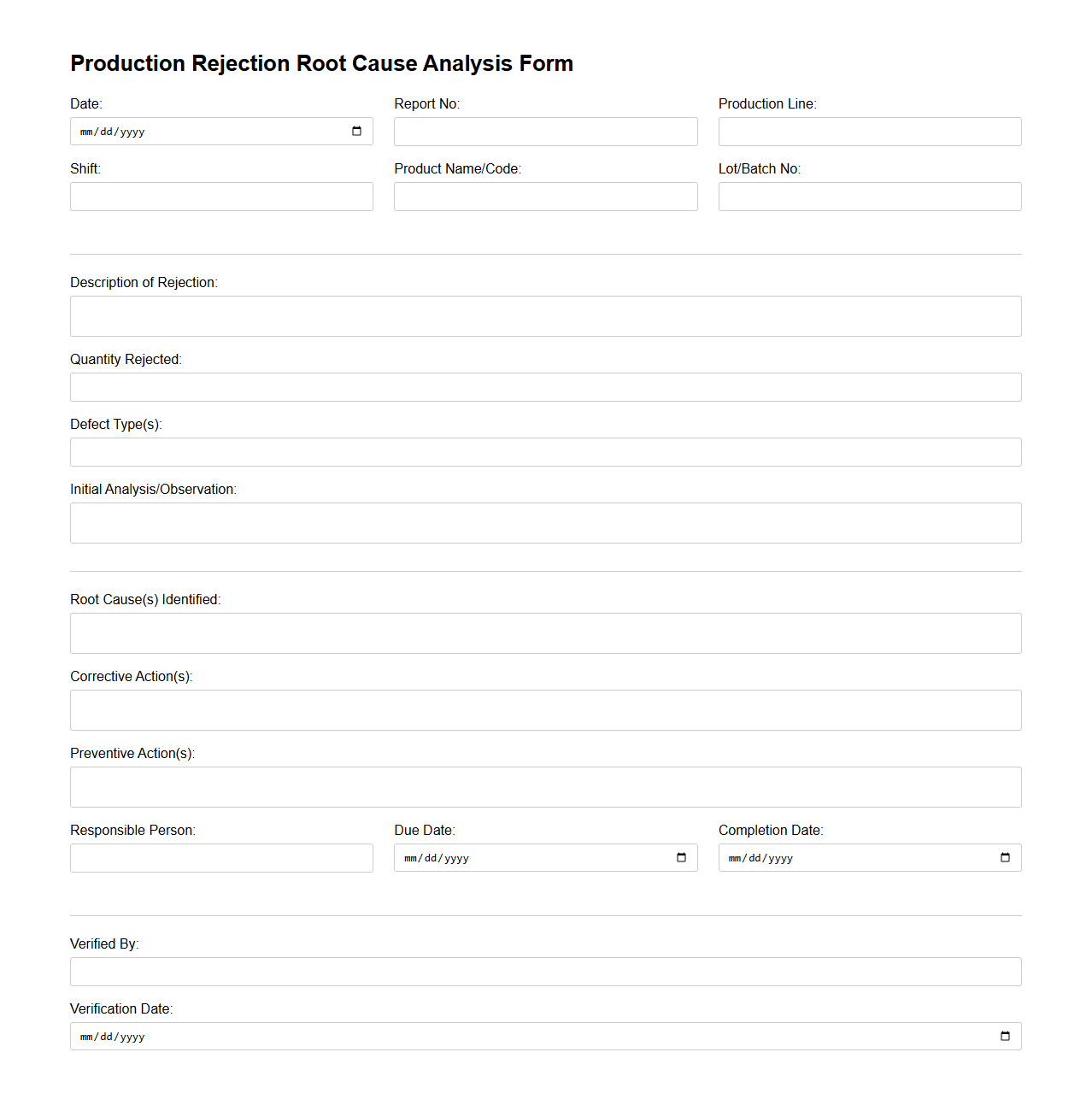

Production Rejection Root Cause Analysis Form

The

Production Rejection Root Cause Analysis Form document is a structured tool used to identify, document, and analyze the underlying causes of product rejections in manufacturing processes. It helps quality assurance teams systematically capture data related to defects, enabling targeted corrective actions to improve product quality and reduce waste. This form supports continuous improvement by facilitating comprehensive investigations into production issues and tracking resolution effectiveness.

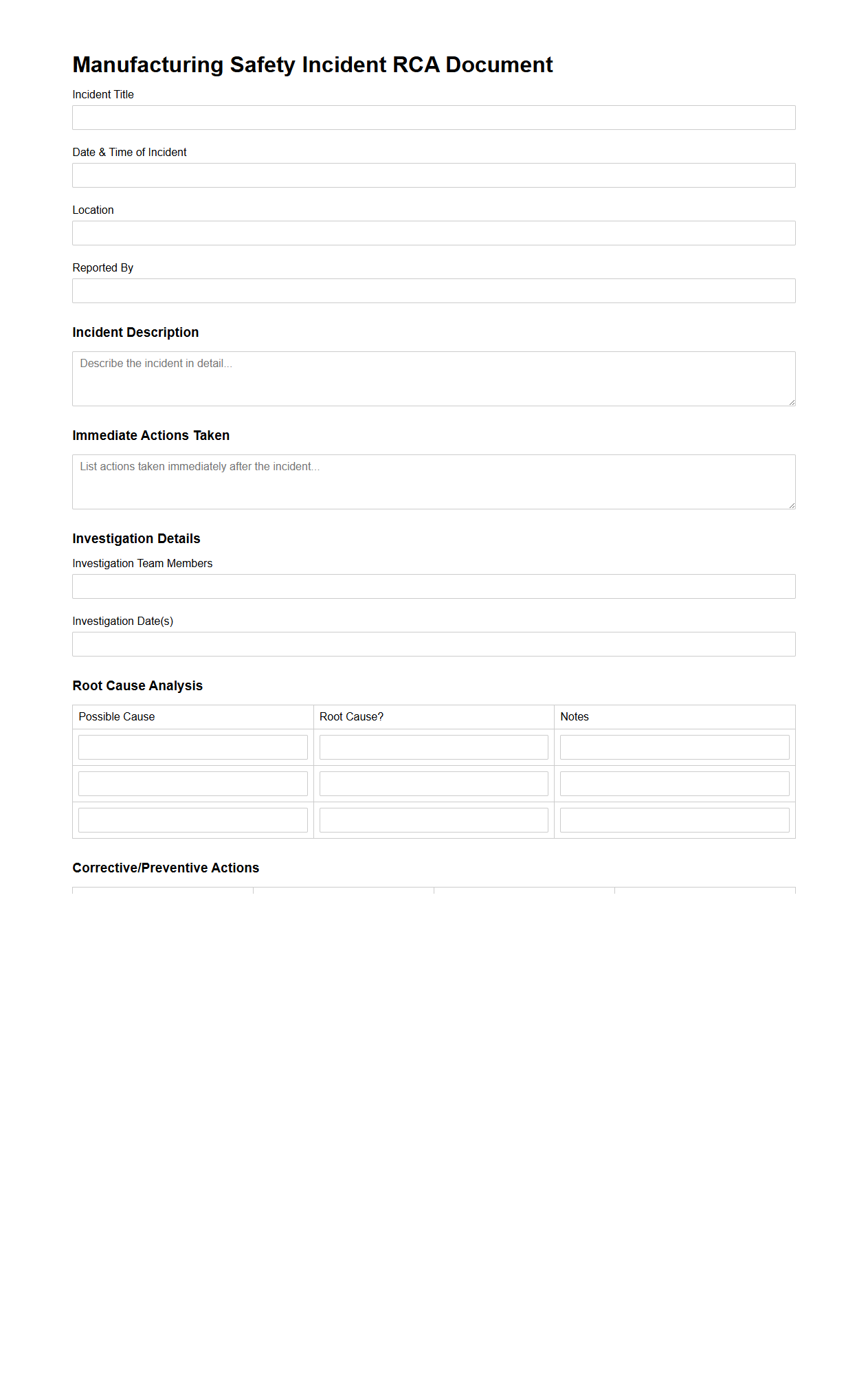

Manufacturing Safety Incident RCA Document

The

Manufacturing Safety Incident RCA Document is a detailed report used to identify and analyze the root causes of safety incidents in manufacturing environments. This document systematically examines contributing factors such as equipment failure, human error, or procedural gaps to prevent recurrence. It serves as a critical tool for continuous improvement and compliance with safety regulations in industrial operations.

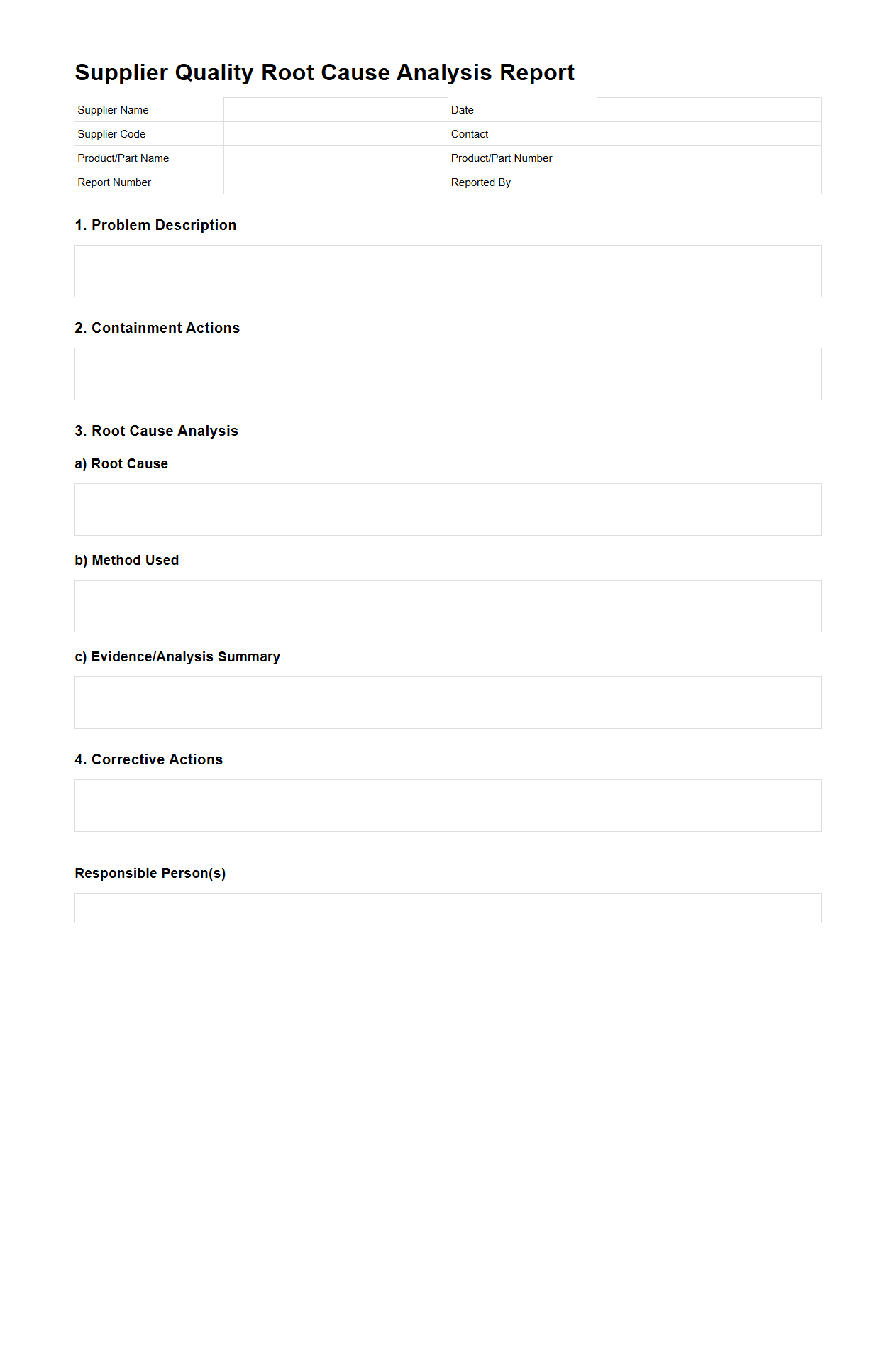

Supplier Quality Root Cause Analysis Report

A

Supplier Quality Root Cause Analysis Report document identifies the underlying reasons for defects or non-conformances in supplied materials or components. It systematically evaluates supplier processes, materials, and quality controls to pinpoint failure sources and recommend corrective actions. This report is essential for improving supplier performance, reducing rework costs, and ensuring product quality compliance.

Primary Problem or Defect Described in the Root Cause Analysis Document

The primary problem highlighted in the Root Cause Analysis Document is a consistent defect in the manufacturing process, leading to product failures. This defect notably impacts the overall quality and reliability of the final product. Identifying this issue promptly is crucial to maintaining production standards and customer satisfaction.

Data Sources or Evidence Referenced to Validate the Manufacturing Issue

The document references multiple data sources, including production logs, quality inspection reports, and customer complaint records, to validate the presence of the manufacturing defect. Statistical analysis of these datasets confirms the recurring nature of the problem. Additionally, physical inspection and testing results serve as concrete evidence supporting the issue's existence.

Root Cause Identification Methodology Documented

The Root Cause Analysis employs the 5 Whys methodology to systematically trace the defect back to its origin. This approach facilitates deep exploration of underlying causes by asking successive why-questions. The document details how this method enabled the team to isolate the fundamental root cause effectively.

Corrective and Preventive Actions (CAPA) Recommended or Implemented

The CAPA outlined includes process adjustments, enhanced employee training, and improved equipment maintenance schedules. These steps serve to correct the immediate defect and prevent its recurrence, focusing on both corrective and preventive measures. The document emphasizes a structured approach to implement these CAPAs efficiently.

Monitoring and Evaluation of the Action Plan Effectiveness

Effectiveness monitoring is conducted through continuous quality audits, feedback analysis, and key performance indicator (KPI) tracking. Regular review meetings are scheduled to evaluate progress and make necessary adjustments. This ongoing evaluation ensures the action plan's success and promotes sustained improvement in the manufacturing process.

More Manufacturing Templates