The Machine Downtime Report Document Sample for Production Line provides a detailed record of equipment stoppages, capturing the duration and reasons for each downtime event. This report helps identify recurring issues, enabling production managers to implement targeted maintenance and improve operational efficiency. Accurate downtime tracking is essential for minimizing productivity losses and optimizing the overall performance of the production line.

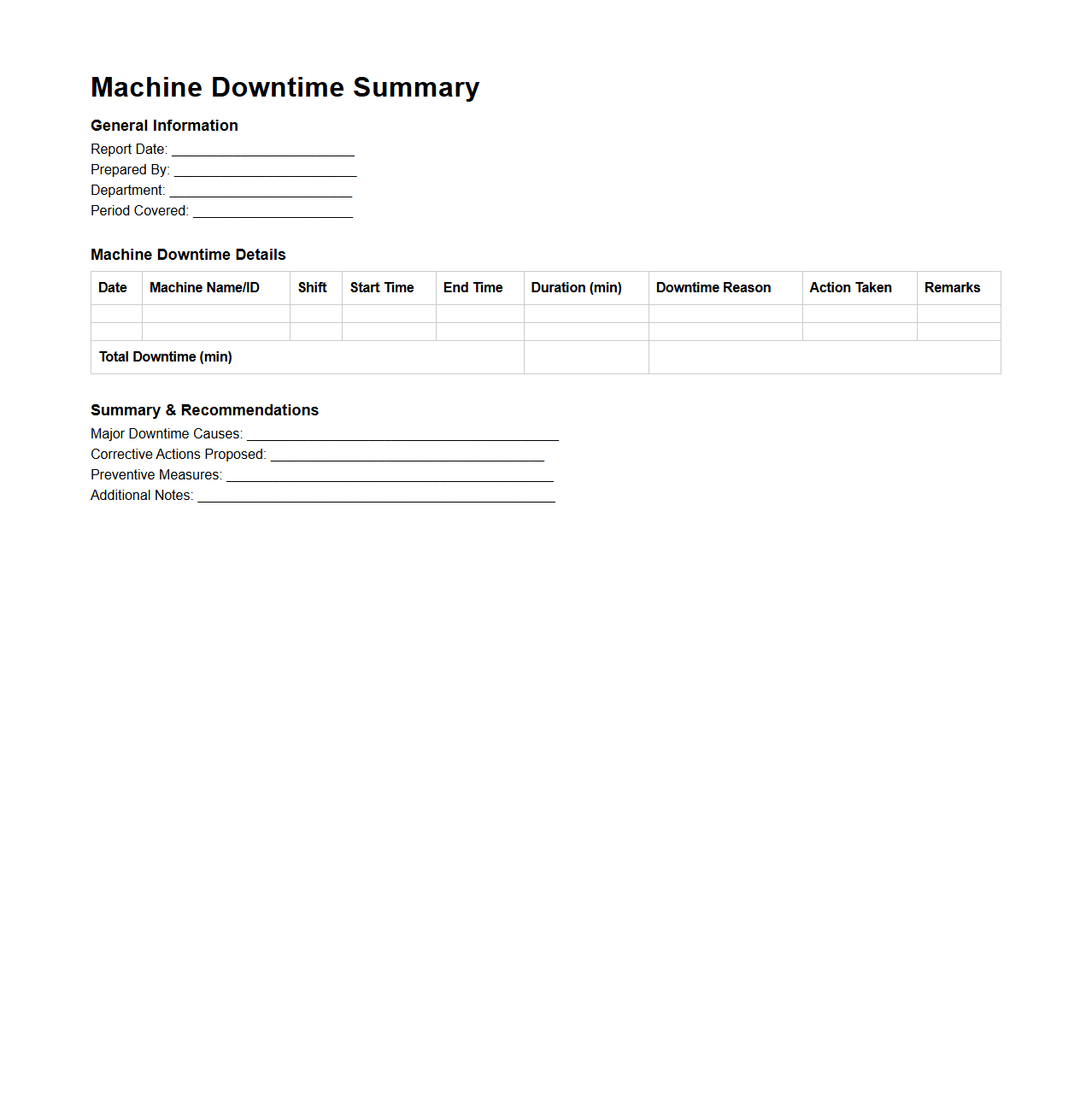

Machine Downtime Summary Template for Manufacturing

A

Machine Downtime Summary Template for manufacturing is a structured document used to record and analyze periods when production equipment is non-operational. It captures essential data such as downtime duration, reasons for stoppage, and impact on overall productivity, enabling efficient maintenance planning and reduction of operational losses. This template helps manufacturers improve equipment reliability and optimize production schedules by providing clear insights into downtime trends.

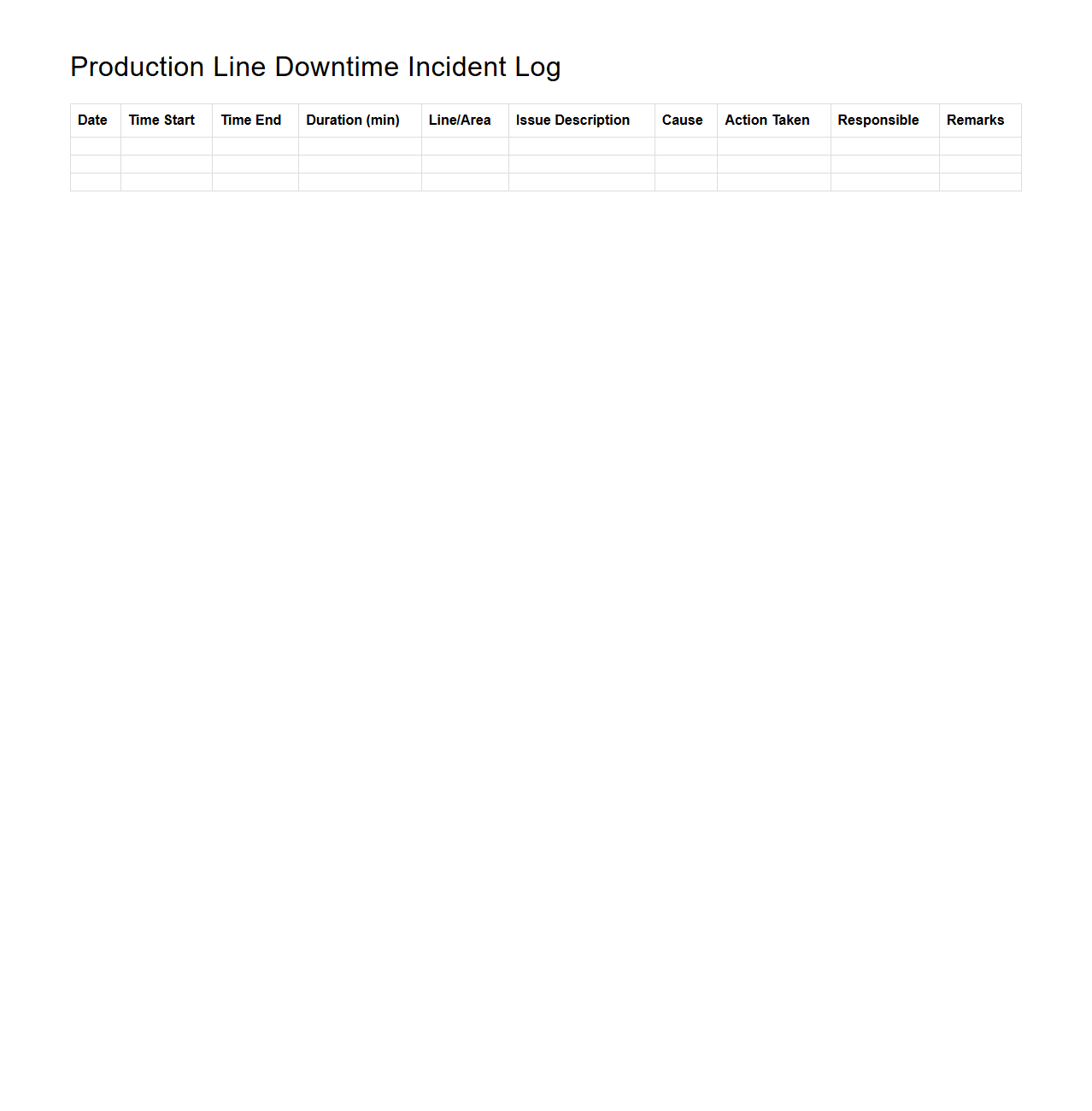

Production Line Downtime Incident Log

A

Production Line Downtime Incident Log document records detailed information about interruptions in manufacturing processes, including the duration, cause, and impact of each downtime event. This log facilitates root cause analysis, supports maintenance planning, and drives improvements in operational efficiency by providing data essential for minimizing future disruptions. Tracking these incidents systematically enables organizations to enhance productivity and ensure consistent output quality.

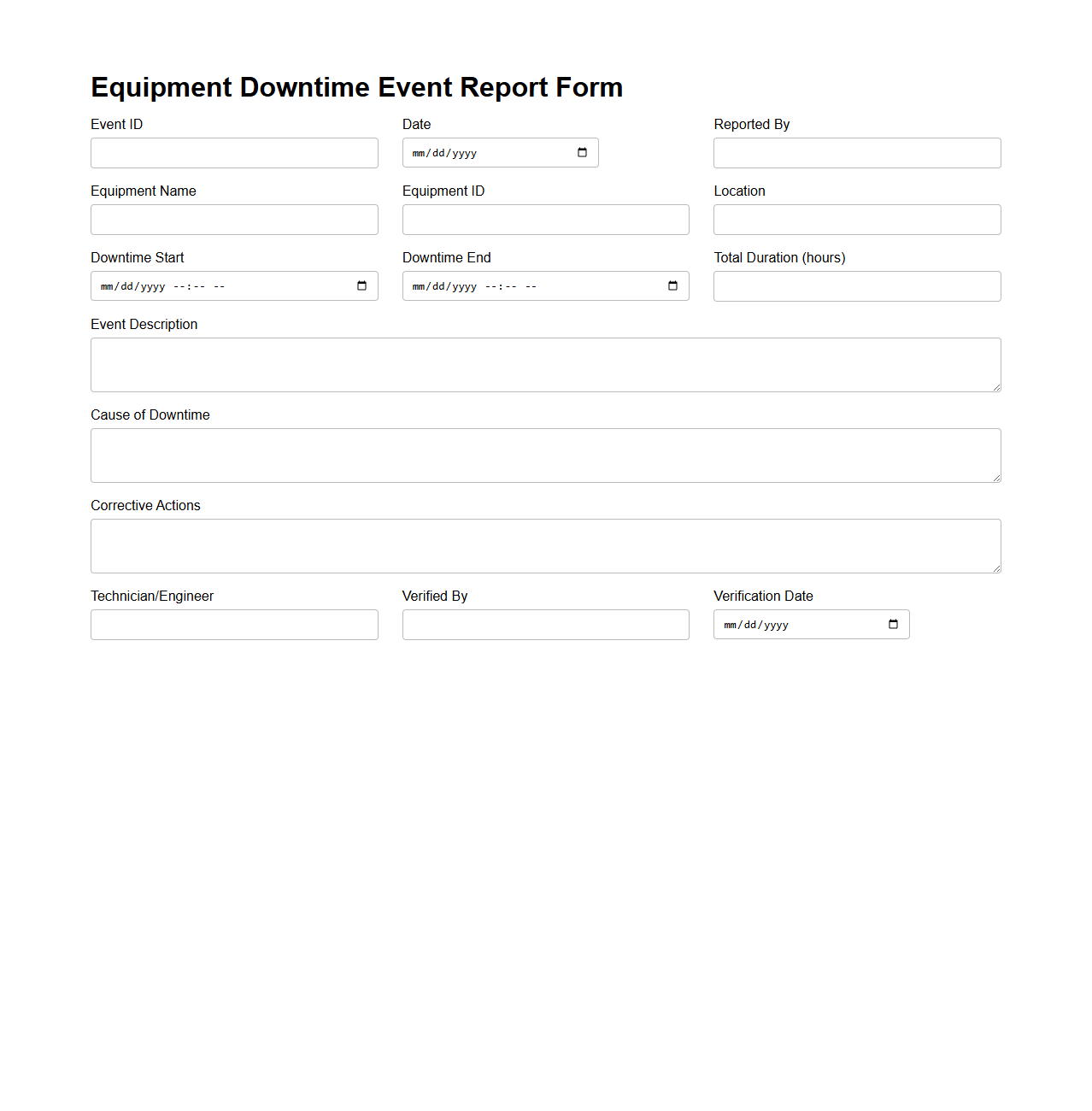

Equipment Downtime Event Report Form

The

Equipment Downtime Event Report Form document is a structured record used to log instances when machinery or equipment ceases to operate. It captures essential data such as the equipment identification, time and duration of the downtime, the cause of the failure, and corrective actions taken. This report helps organizations analyze maintenance needs, improve operational efficiency, and reduce the frequency and impact of equipment failures.

Automated Line Downtime Tracking Sheet

The

Automated Line Downtime Tracking Sheet document is a digital tool designed to monitor and record production line stoppages efficiently. It captures real-time data on downtime causes, duration, and frequency, enabling manufacturers to identify bottlenecks and improve operational efficiency. By automating this process, it reduces manual errors and enhances the accuracy of downtime analysis for better decision-making.

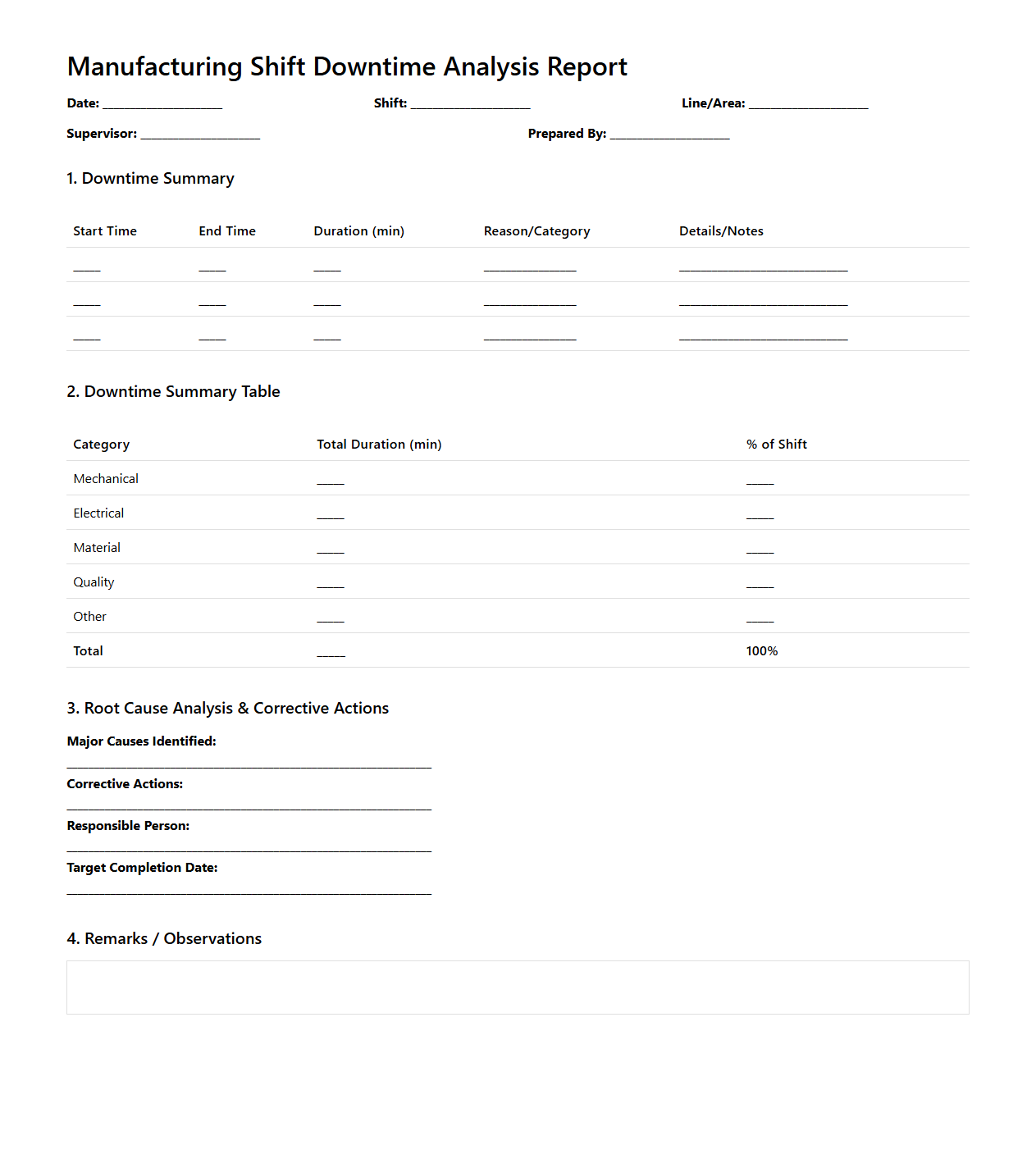

Manufacturing Shift Downtime Analysis Report

A

Manufacturing Shift Downtime Analysis Report document details the periods when production equipment or processes are non-operational during specific shifts. It includes data on downtime causes, duration, and frequency to identify bottlenecks or recurring issues affecting productivity. This report supports continuous improvement by enabling targeted maintenance and operational adjustments.

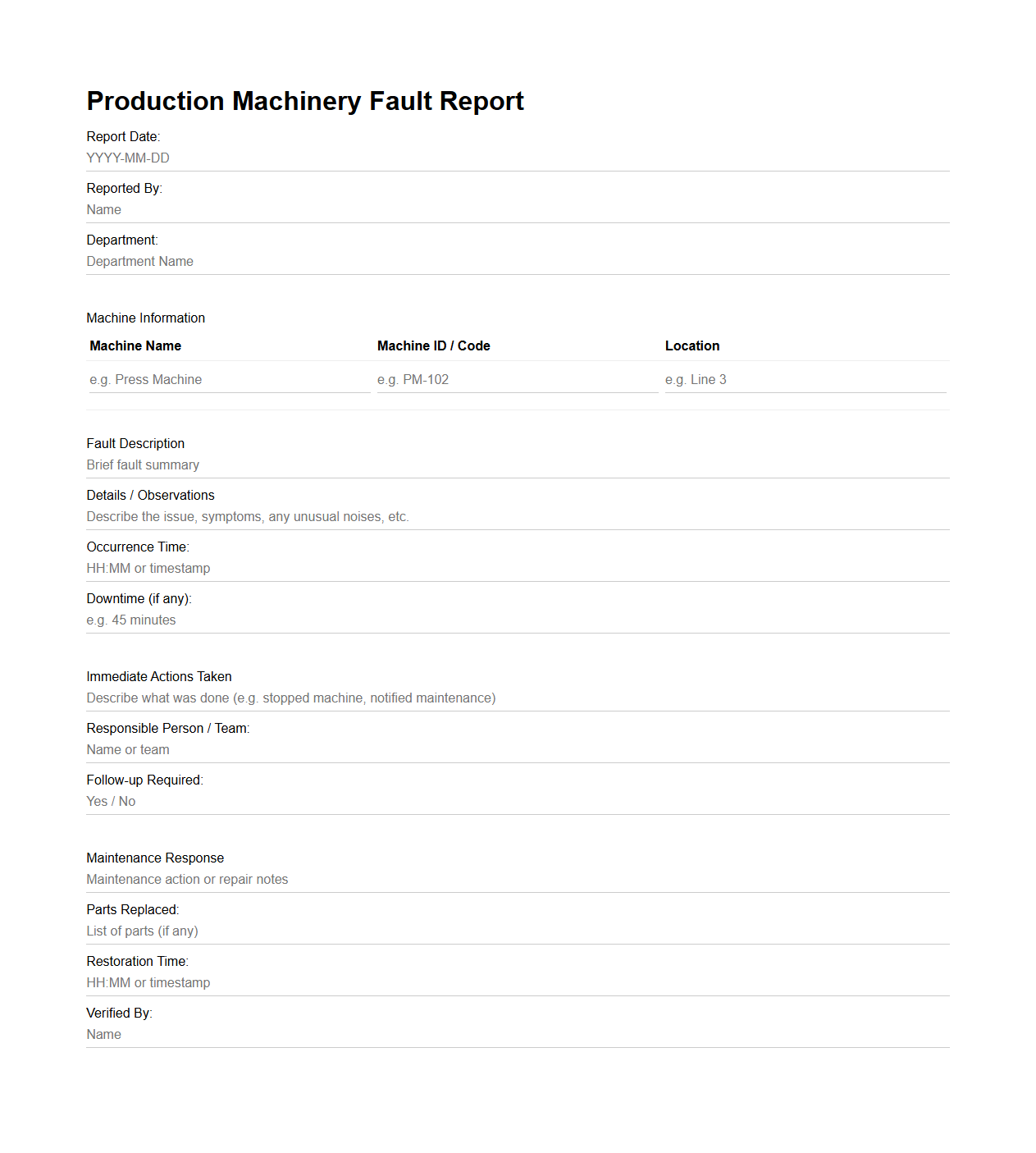

Production Machinery Fault Report Example

A

Production Machinery Fault Report Example document is a detailed record used to identify, document, and analyze malfunctions in industrial equipment. It typically includes sections for machine identification, fault description, date and time of occurrence, root cause analysis, and corrective action taken. This document is essential for maintaining operational efficiency and minimizing downtime in manufacturing environments.

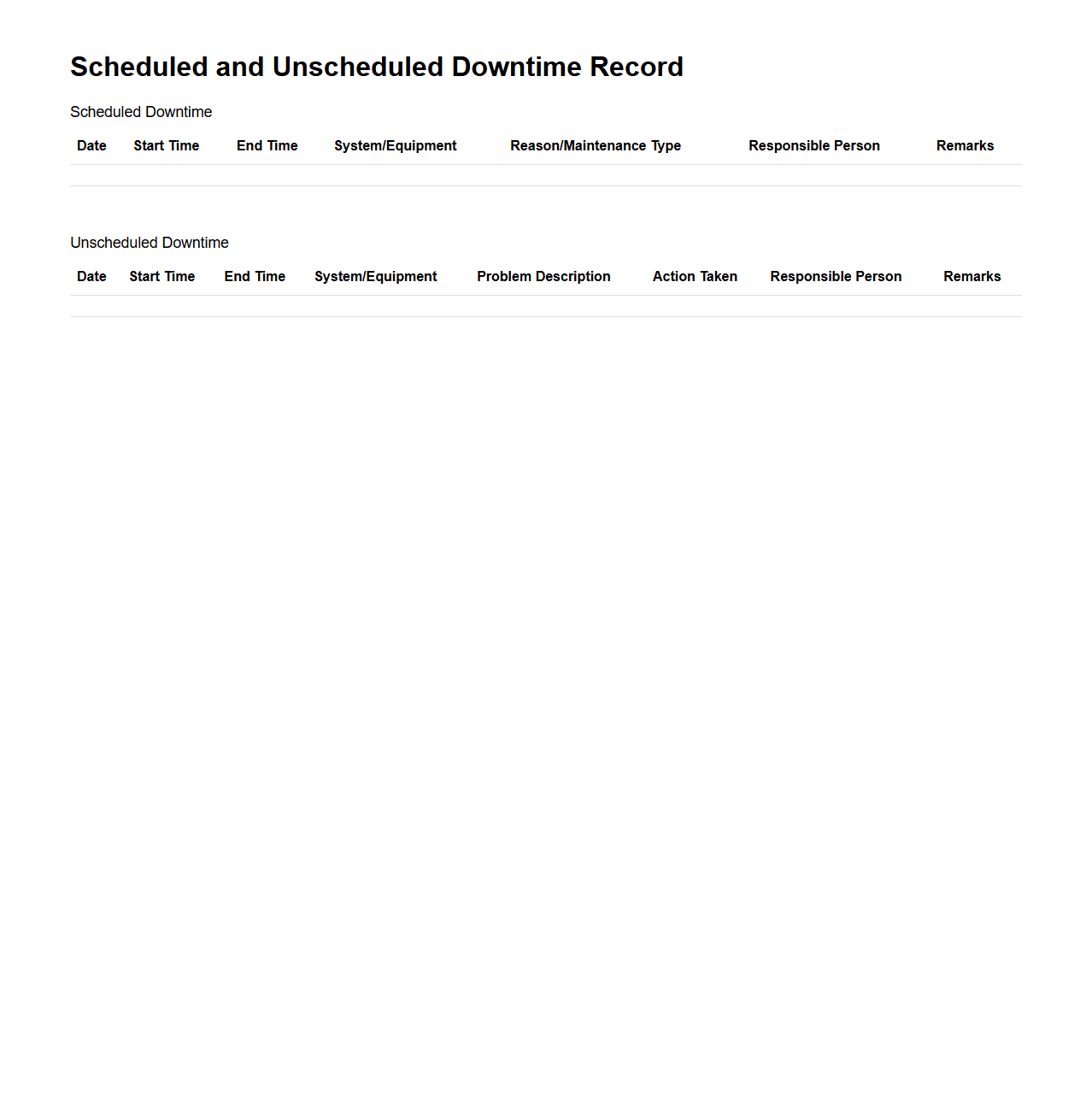

Scheduled and Unscheduled Downtime Record

A

Scheduled and Unscheduled Downtime Record document meticulously tracks both planned maintenance activities and unexpected interruptions in equipment or system operations. This record helps organizations analyze downtime patterns, optimize maintenance schedules, and improve overall operational efficiency. Accurate documentation supports data-driven decision-making to minimize disruptions and enhance productivity.

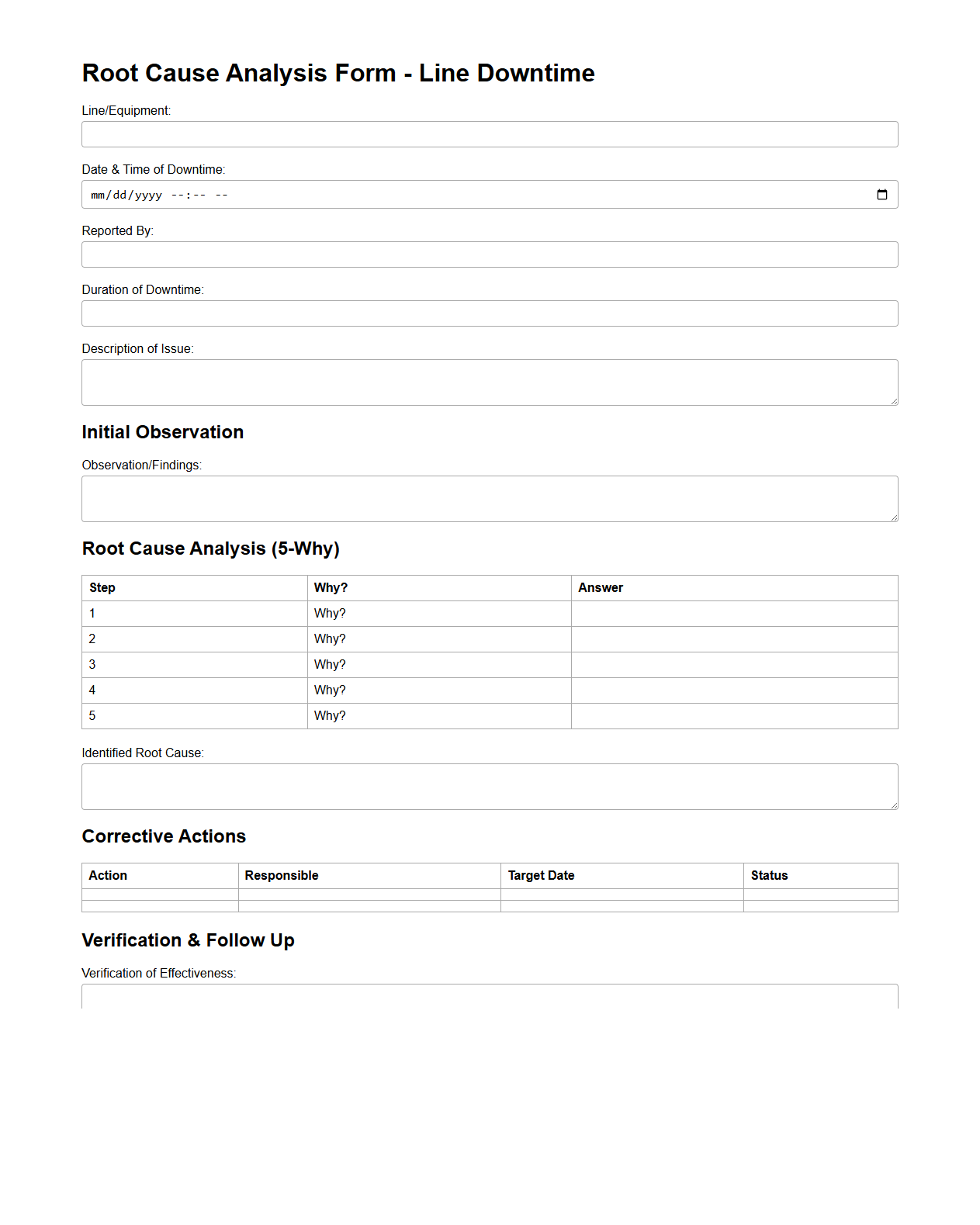

Root Cause Analysis Form for Line Downtime

The

Root Cause Analysis Form for Line Downtime document is a structured tool used to systematically identify and record the underlying reasons for production line stoppages. It captures critical data such as the type of downtime, specific causes, and corrective actions implemented to prevent recurrence. This form supports continuous improvement by enabling teams to analyze trends, reduce downtime, and enhance overall manufacturing efficiency.

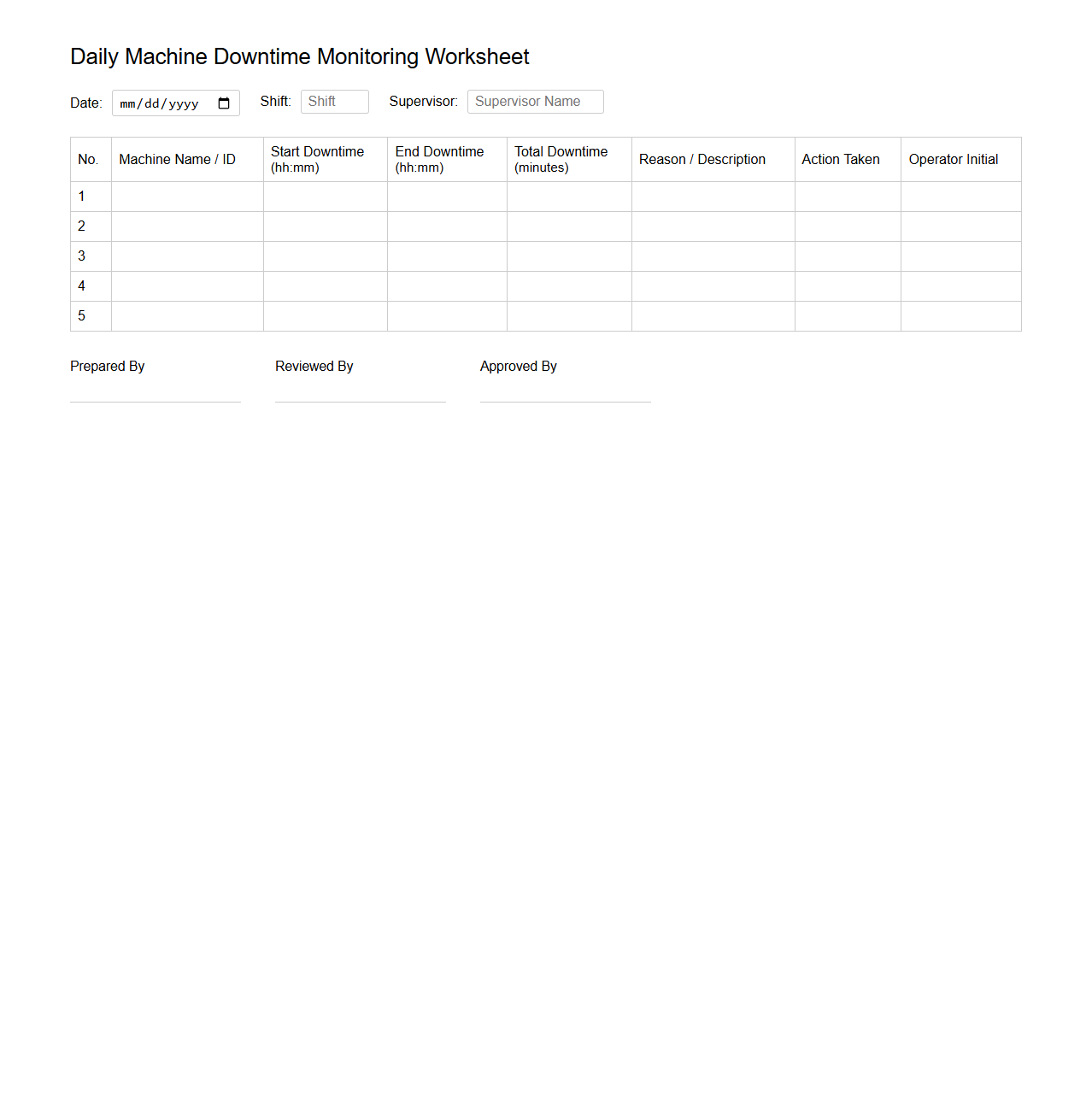

Daily Machine Downtime Monitoring Worksheet

The

Daily Machine Downtime Monitoring Worksheet is a document used to systematically record and analyze periods when production equipment is not operational. It captures essential data such as machine ID, downtime duration, reasons for stoppage, and maintenance actions taken to identify patterns and improve maintenance strategies. This worksheet supports manufacturing efficiency by minimizing unplanned downtime and enhancing overall equipment effectiveness (OEE).

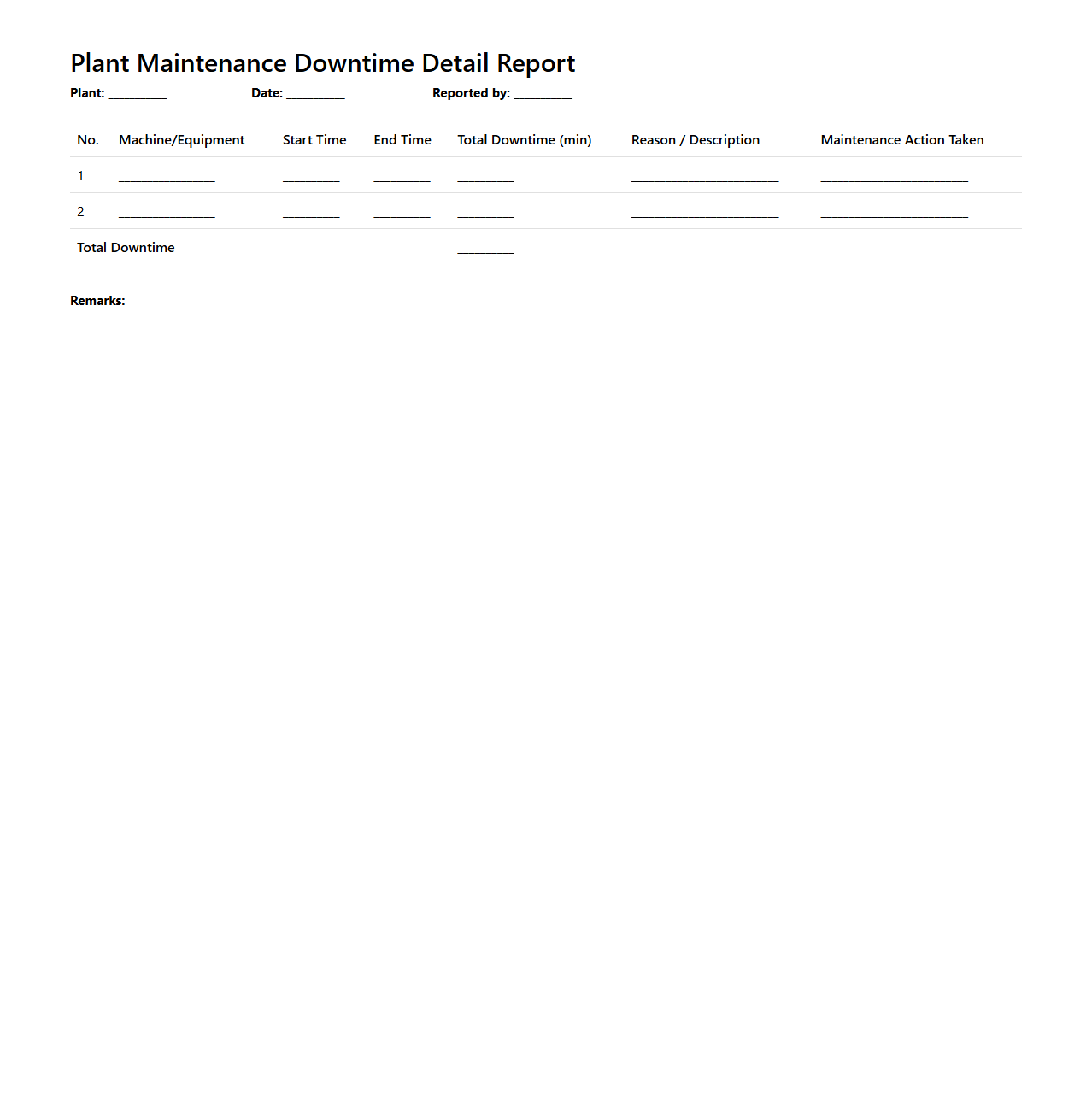

Plant Maintenance Downtime Detail Report

The

Plant Maintenance Downtime Detail Report document provides a comprehensive record of equipment or system downtimes within a plant, capturing the duration, cause, and impact of each maintenance event. It enables maintenance teams to analyze patterns, identify recurrent issues, and optimize scheduling to minimize operational disruptions. This report is essential for improving asset reliability, reducing unplanned outages, and enhancing overall plant efficiency.

Key Information in a Machine Downtime Report

A machine downtime report must include details such as the machine identification, the date and time of the downtime, and the duration of the outage. It should also capture the specific line or section affected to provide precise context. Additionally, the report should note the impact on production output during the downtime period for complete analysis.

Categorization of Machine Downtime Events

The document categorizes downtime events into types such as planned maintenance, unplanned stoppages, and operational delays. Each category helps in isolating patterns and prioritizing corrective measures. This classification aids in accurate reporting and effective downtime management strategies.

Tracking Start and End Times of Downtimes

The sample report includes fields labeled Start Time and End Time for precise recording of downtime duration. These timestamps allow for calculating the total downtime and analyzing its effect on production schedules. Accurate time tracking facilitates better resource allocation and process improvements.

Documenting the Root Cause of Downtime Incidents

Each downtime incident's root cause is documented through a dedicated section that captures detailed descriptions or standardized codes. This ensures a clear understanding of underlying issues leading to disruptions. Proper root cause analysis enables targeted solutions to prevent recurrence.

Sections for Recommendations or Corrective Actions

The report includes a recommendations section where corrective actions and improvement measures are proposed post-analysis. This segment is critical for continuous improvement and future downtime reduction strategies. It provides actionable steps to enhance machine reliability and operational efficiency.

More Manufacturing Templates