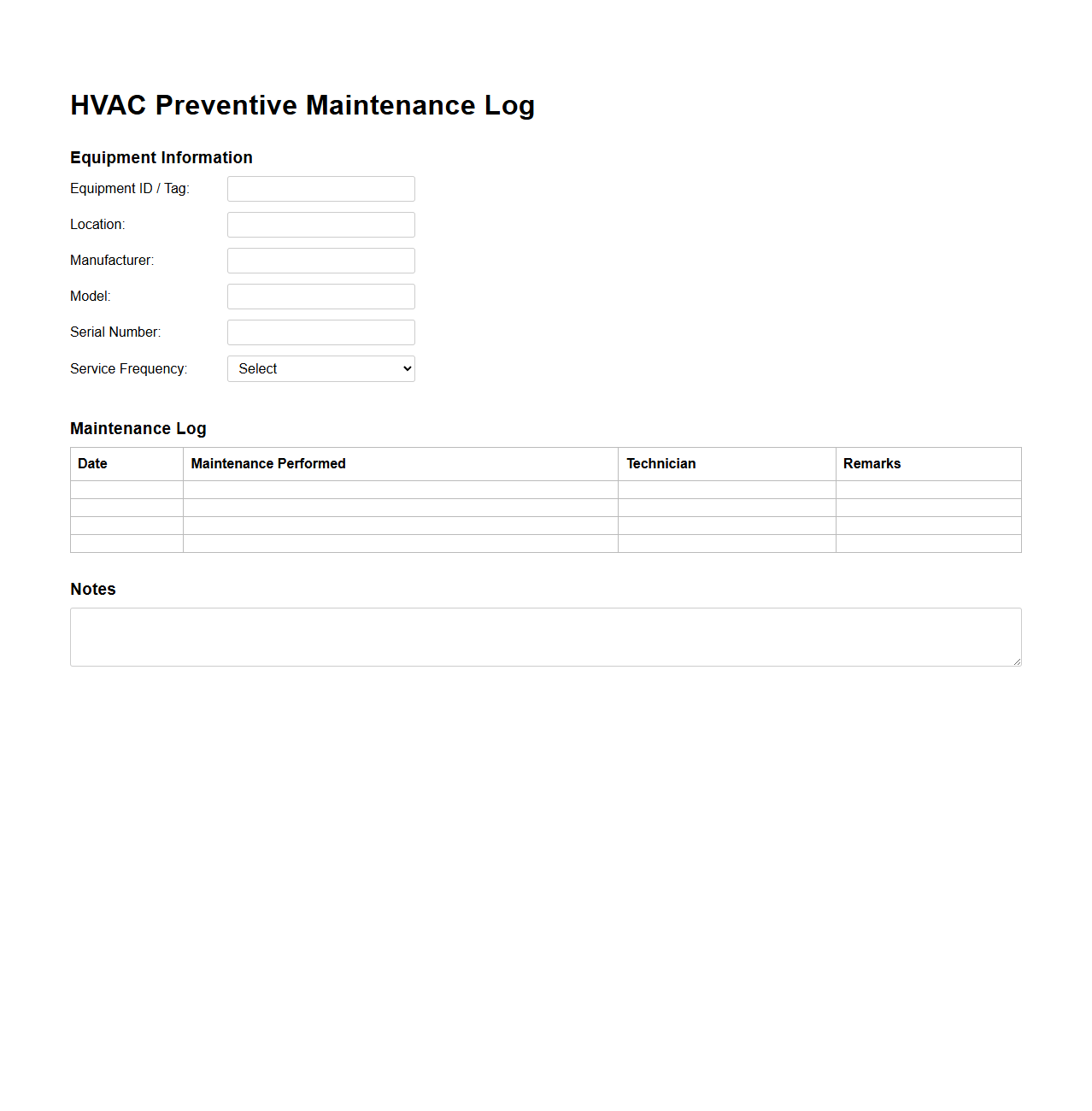

HVAC Preventive Maintenance Log Example

An

HVAC Preventive Maintenance Log Example document is a detailed record used to track routine inspections, cleaning, and servicing of heating, ventilation, and air conditioning systems. It includes information such as dates of maintenance, tasks performed, technician details, and any detected issues to ensure optimal system performance and longevity. Maintaining this log helps prevent unexpected breakdowns and supports compliance with maintenance schedules.

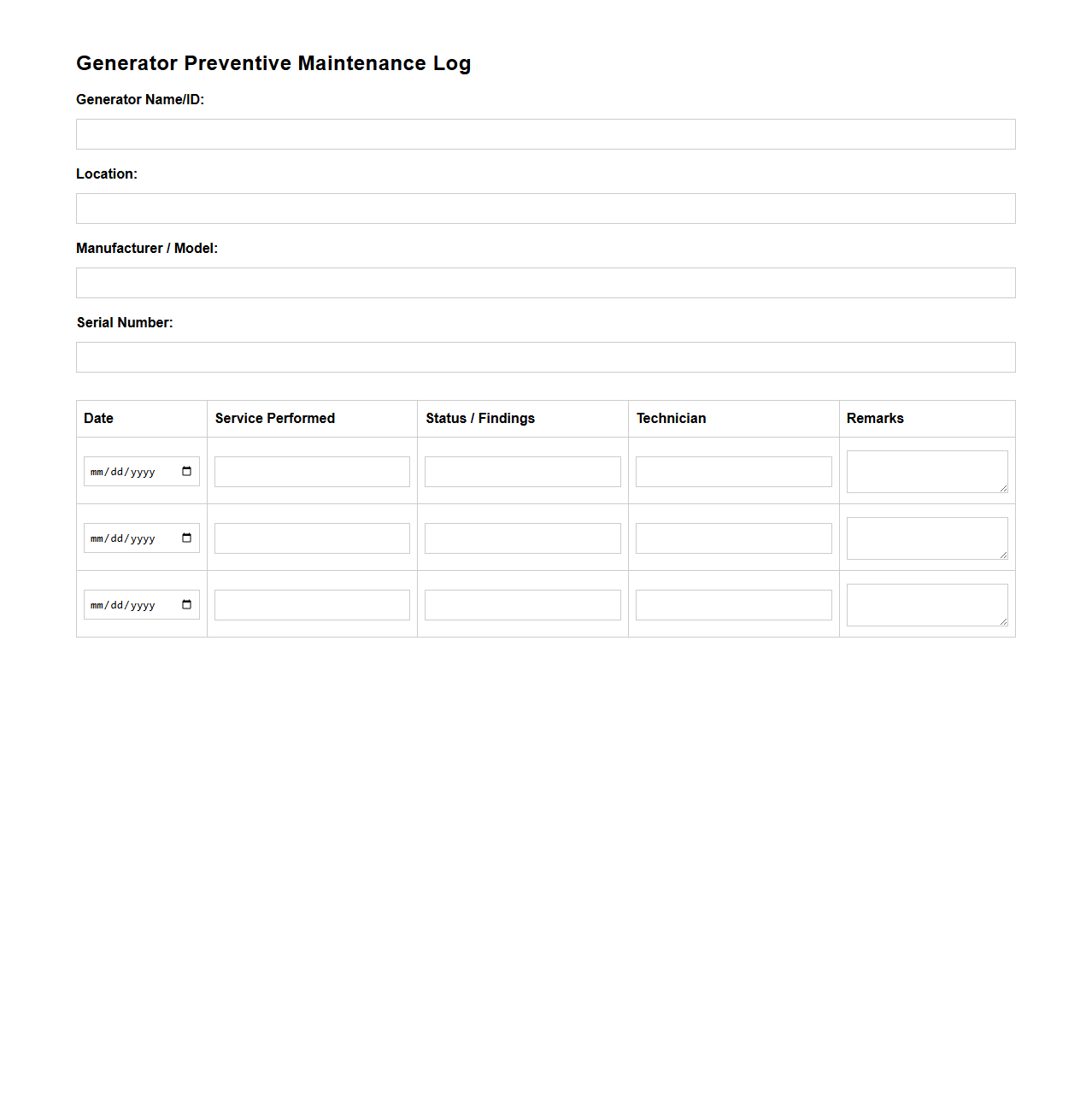

Generator Preventive Maintenance Log Template

A

Generator Preventive Maintenance Log Template document is designed to systematically record all maintenance activities performed on generators, ensuring operational reliability and longevity. It tracks essential details such as inspection dates, types of service conducted, parts replaced, and any identified issues for proactive troubleshooting. This template supports compliance with maintenance schedules, reduces downtime, and aids in optimizing generator performance.

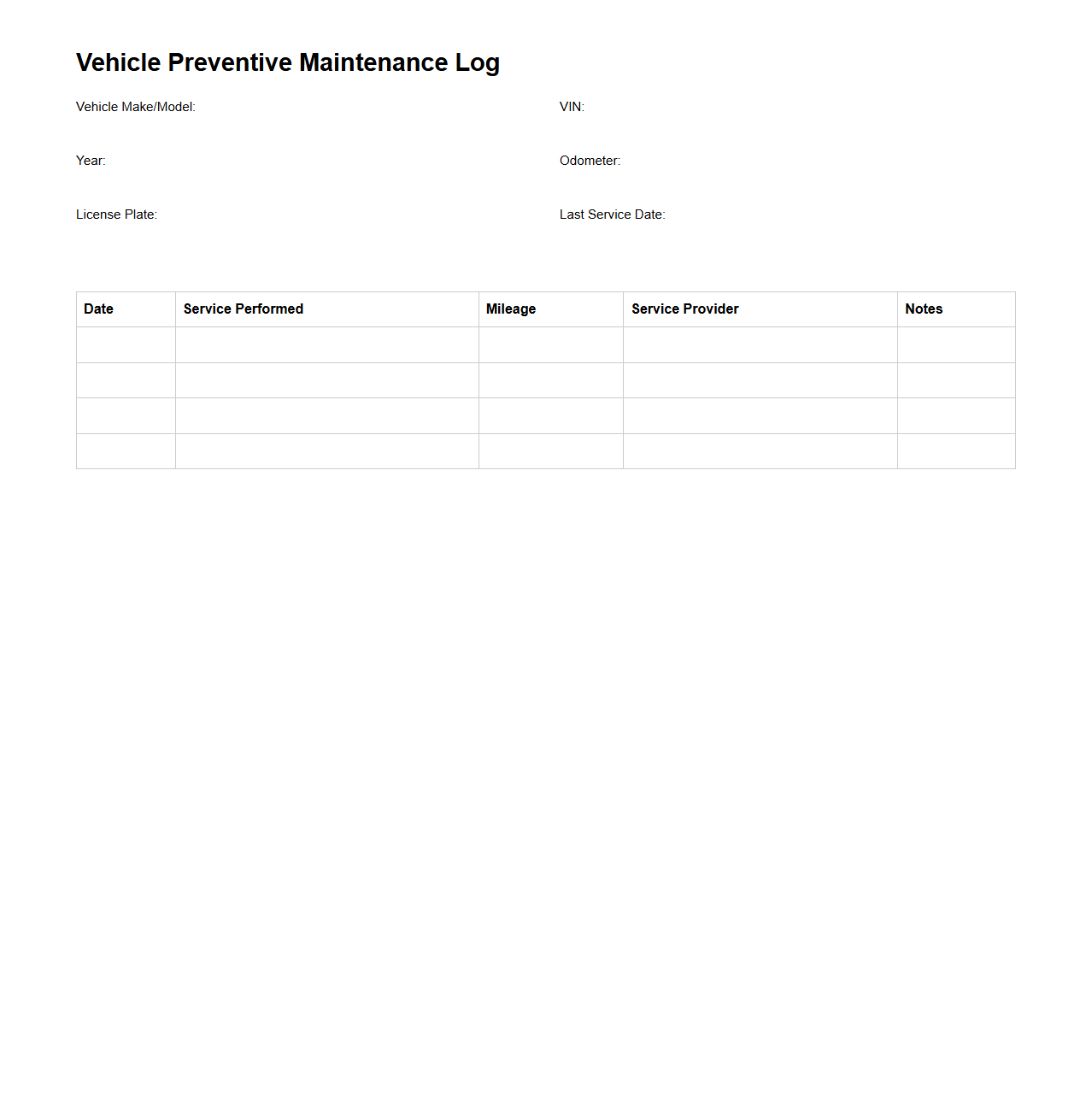

Vehicle Preventive Maintenance Log Sample

A

Vehicle Preventive Maintenance Log Sample document is a structured record used to track routine maintenance activities for vehicles, including oil changes, tire rotations, brake inspections, and fluid checks. It helps fleet managers and vehicle owners ensure timely service, improve vehicle reliability, and reduce the risk of costly repairs. By systematically documenting maintenance dates, performed tasks, and mileage, this log supports compliance with manufacturer recommendations and regulatory requirements.

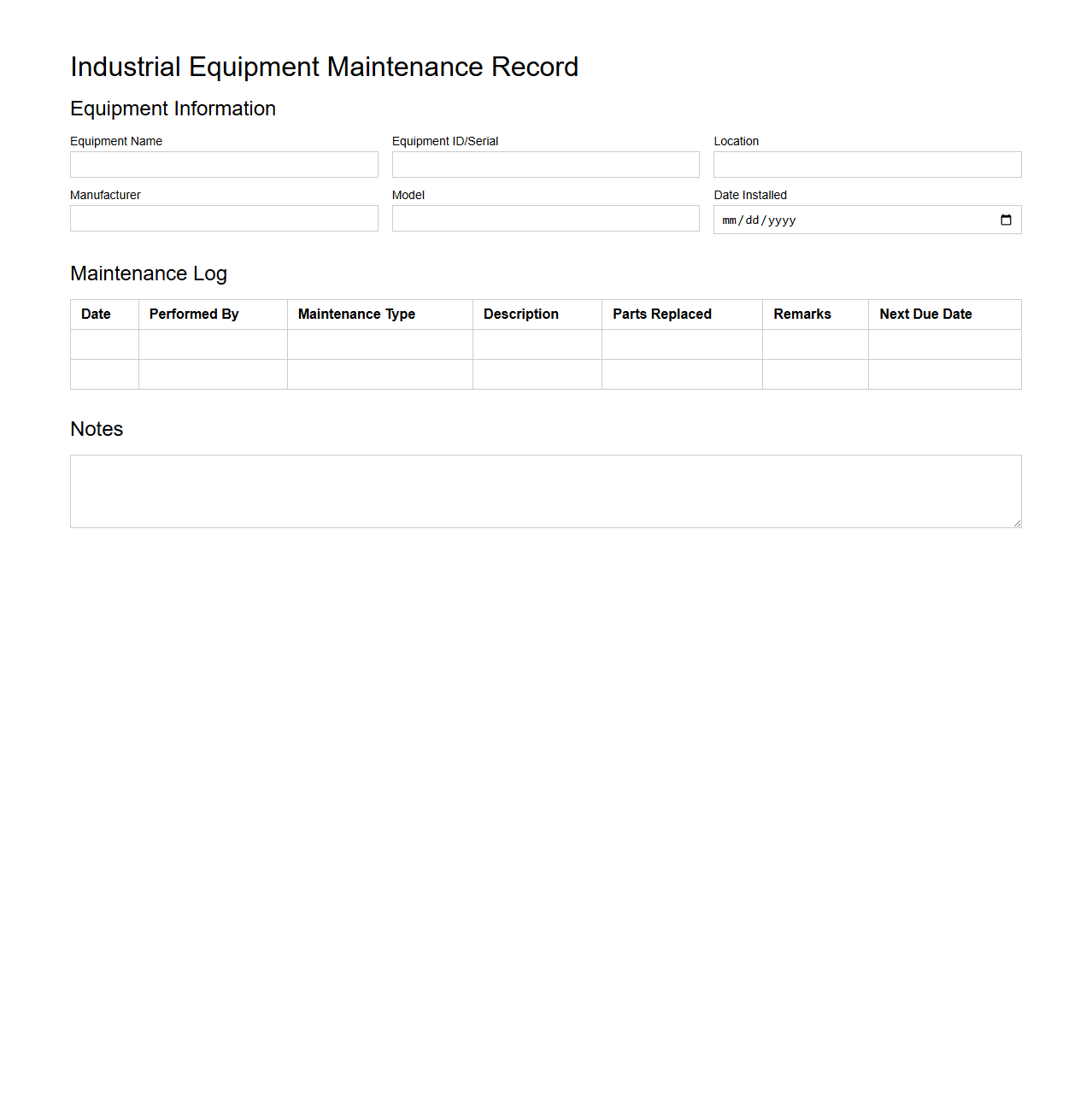

Industrial Equipment Maintenance Record Format

The

Industrial Equipment Maintenance Record Format document is a standardized template used to systematically log all maintenance activities performed on machinery and industrial equipment. It typically includes fields for equipment identification, maintenance dates, types of service conducted, parts replaced, and technician details, ensuring accurate tracking and compliance with safety regulations. This format enhances operational efficiency by facilitating preventive maintenance schedules and minimizing equipment downtime.

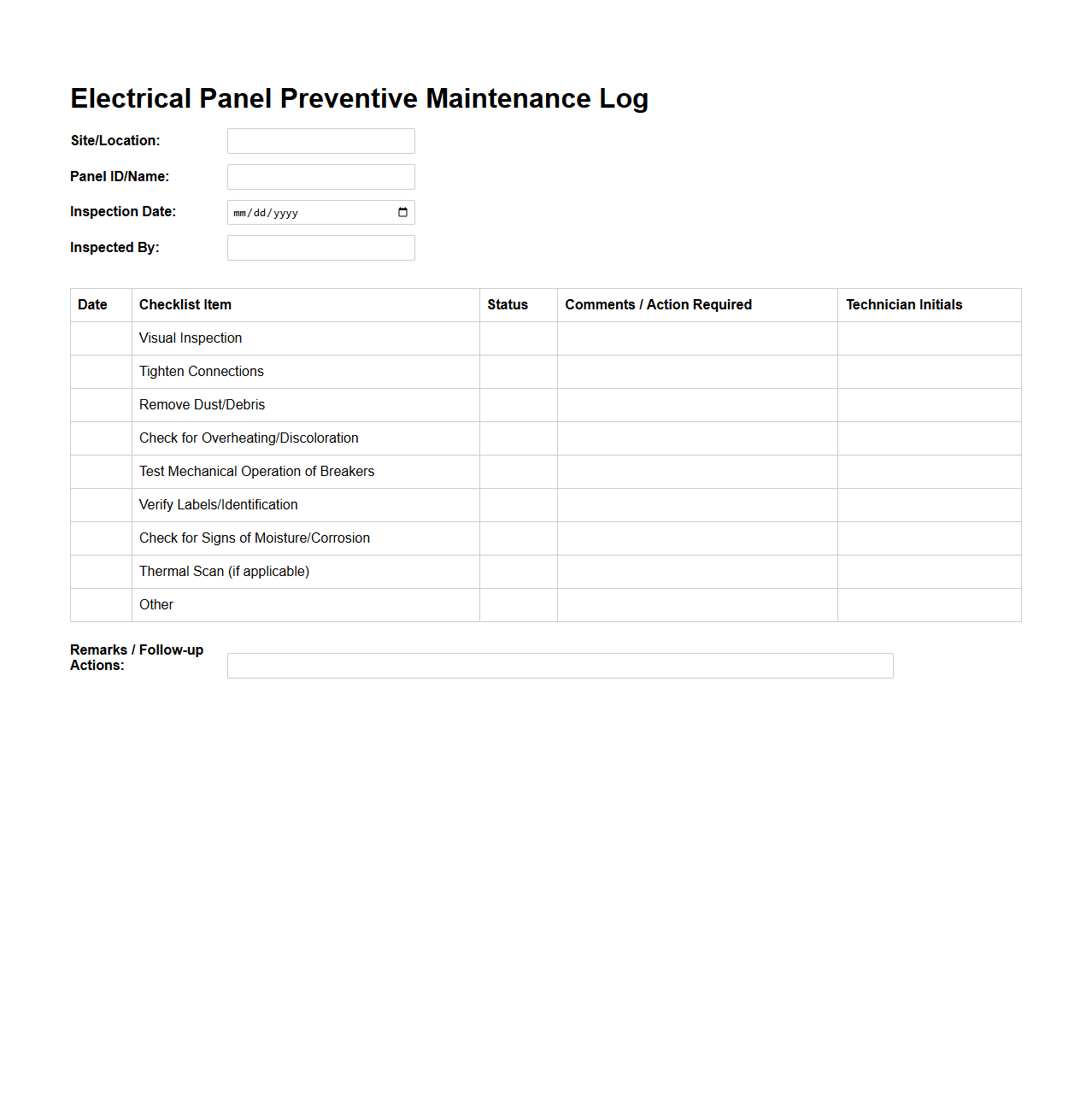

Electrical Panel Preventive Maintenance Log

An

Electrical Panel Preventive Maintenance Log document records routine inspection and servicing activities of electrical panels to ensure optimal performance and safety. It tracks dates, performed tasks, component conditions, and any identified issues to prevent unexpected failures and reduce downtime. Maintaining this log enhances compliance with safety regulations and extends the lifespan of electrical systems.

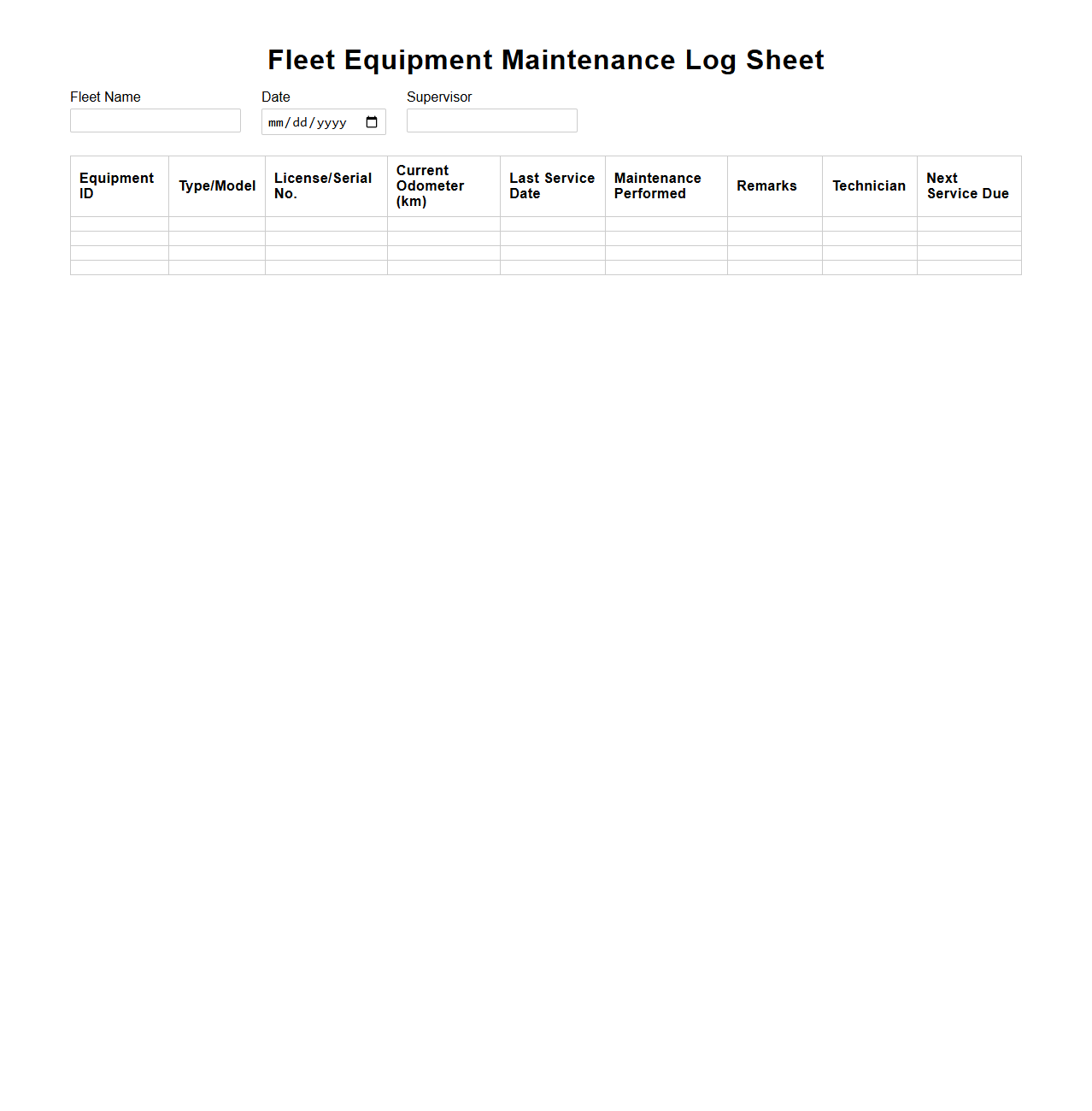

Fleet Equipment Maintenance Log Sheet

A

Fleet Equipment Maintenance Log Sheet document systematically records all maintenance activities, repairs, inspections, and servicing details for vehicles or machinery within a fleet. It ensures accurate tracking of equipment condition, helps schedule preventive maintenance, and supports compliance with safety regulations. This log sheet enhances operational efficiency by minimizing downtime and extending the lifespan of fleet assets.

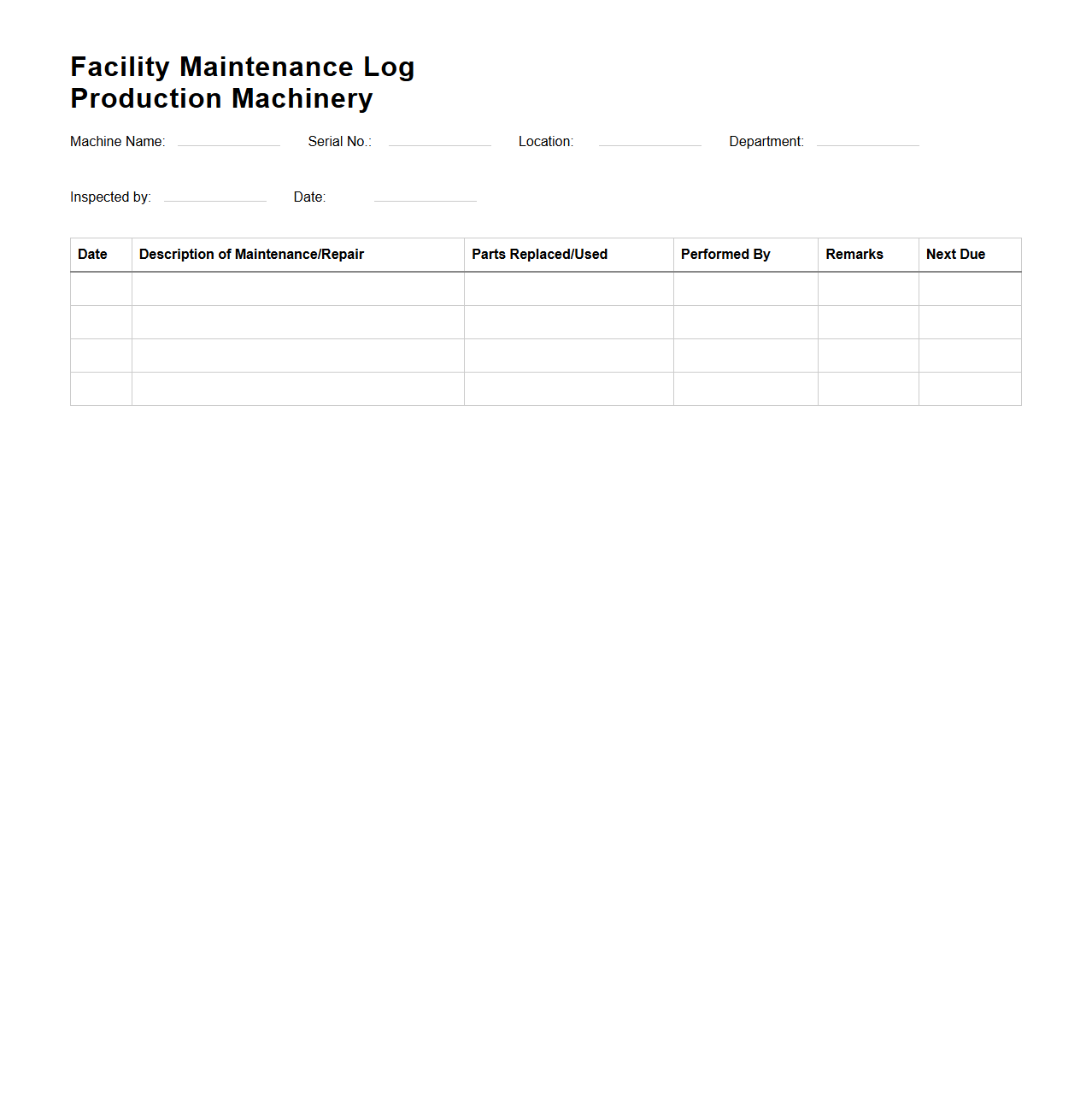

Facility Maintenance Log for Production Machinery

A

Facility Maintenance Log for Production Machinery document records detailed information about the upkeep and servicing of equipment used in manufacturing processes. It tracks maintenance activities, dates, technician details, and any repairs or inspections performed to ensure machinery operates efficiently and reduces downtime. This log supports compliance with safety standards and helps optimize production reliability by providing a clear maintenance history.

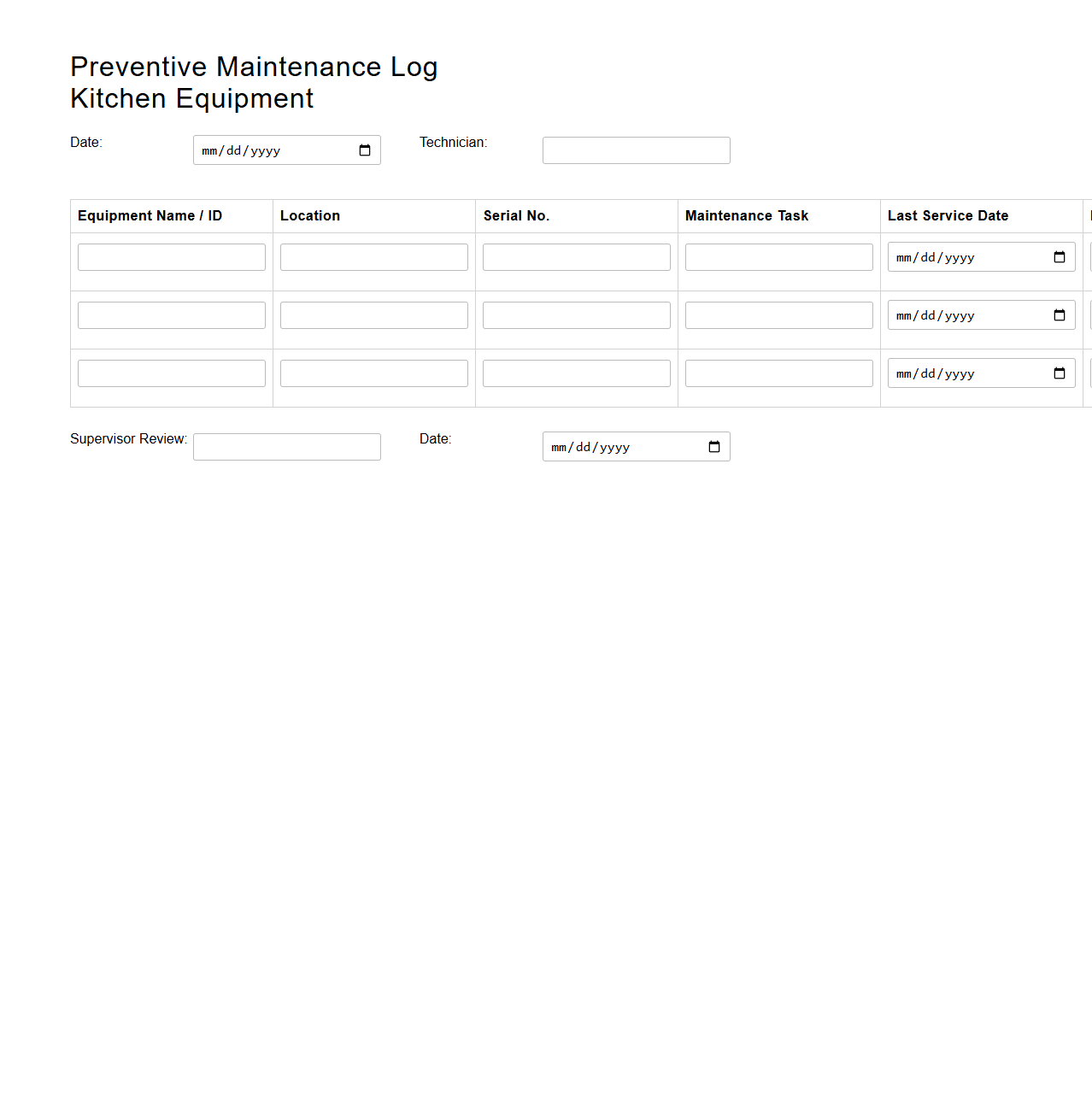

Preventive Maintenance Log for Kitchen Equipment

A

Preventive Maintenance Log for Kitchen Equipment document systematically records scheduled inspections, cleaning, and servicing of kitchen appliances to ensure optimal performance and prevent unexpected breakdowns. It includes details such as equipment identification, maintenance dates, tasks performed, and any detected issues requiring attention. Regular use of this log extends the lifespan of equipment, improves safety, and reduces costly emergency repairs in commercial or residential kitchens.

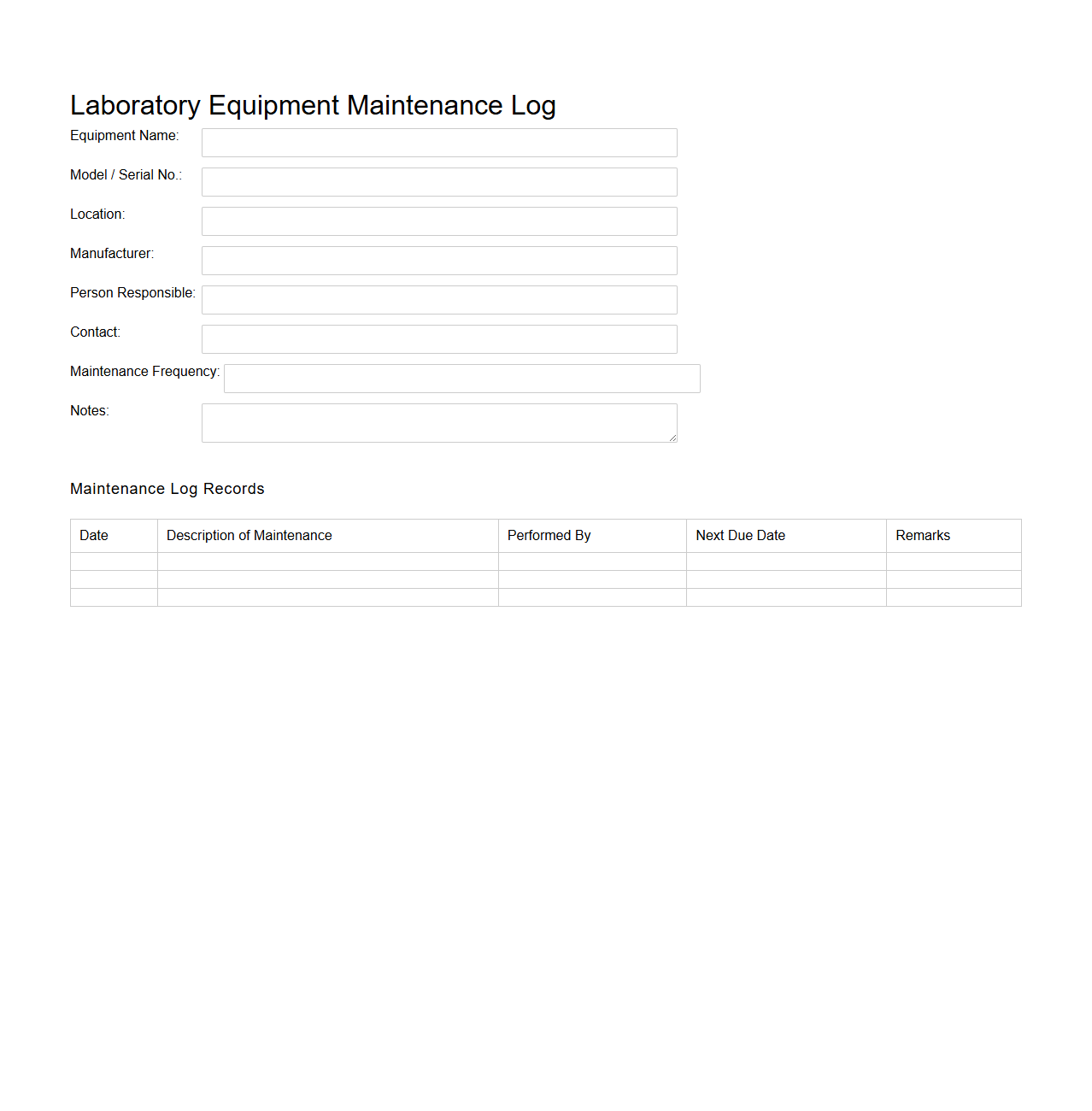

Laboratory Equipment Maintenance Log Example

A

Laboratory Equipment Maintenance Log Example document serves as a structured record for tracking the upkeep, calibration, and repairs of laboratory instruments. It ensures accurate documentation of maintenance activities, helping to maintain equipment reliability and compliance with safety standards. Regular updates in this log facilitate timely servicing, reduce downtime, and extend the lifespan of critical lab apparatus.

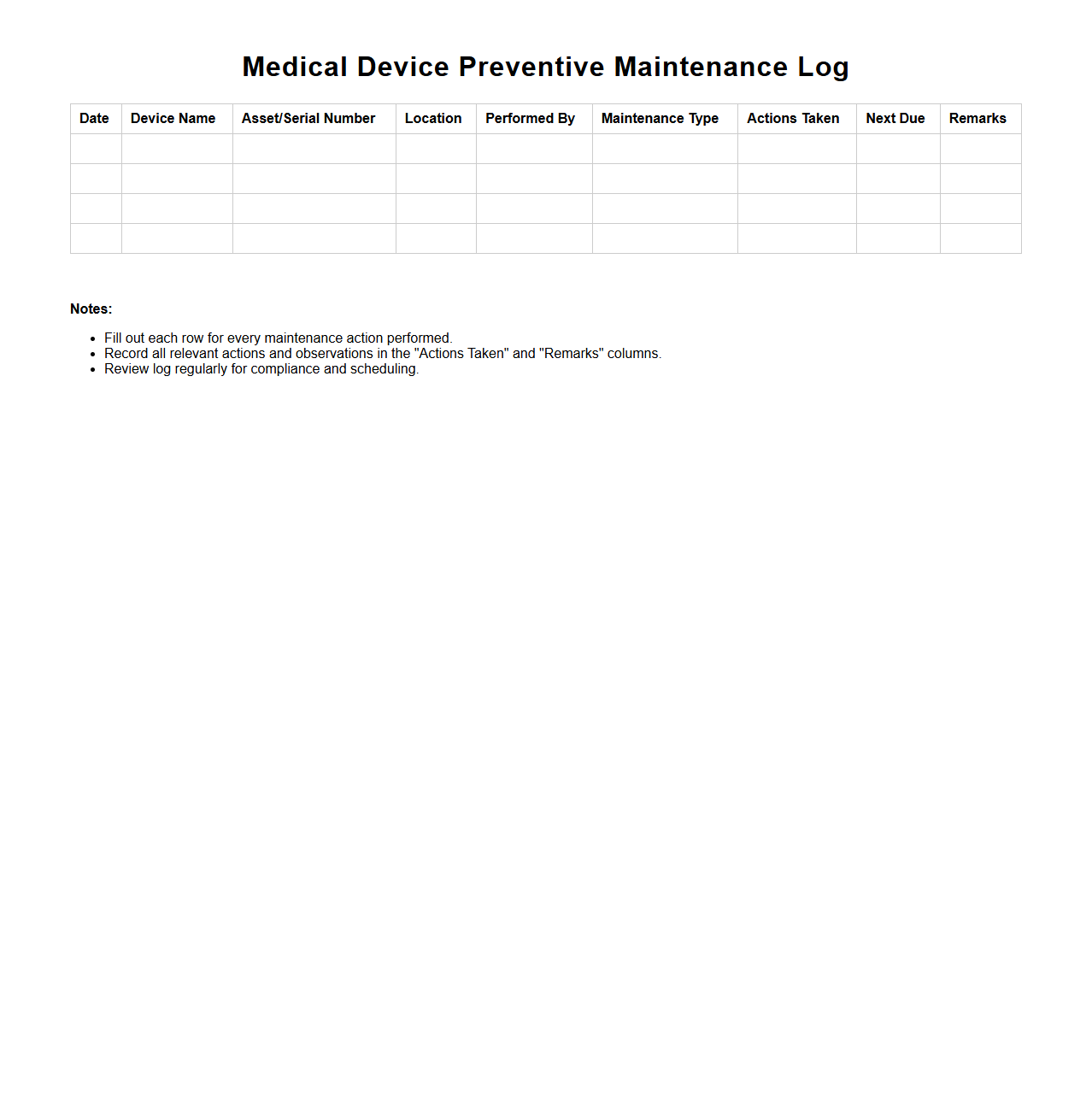

Medical Device Preventive Maintenance Log

A

Medical Device Preventive Maintenance Log document is a detailed record used to track scheduled maintenance activities performed on medical equipment to ensure optimal functionality and compliance with safety standards. It includes information such as inspection dates, calibration results, repairs, and technician signatures, helping healthcare facilities minimize breakdowns and extend device lifespan. This log is essential for regulatory audits and supports patient safety by ensuring reliable medical device performance.

What key information must be recorded in a preventive maintenance log for equipment?

A preventive maintenance log must record essential details such as the equipment identification, date of maintenance, and the specific tasks performed. It should also include the name of the technician responsible for the work and any observations or issues noted during the service. This comprehensive information ensures proper tracking of maintenance history and equipment condition.

How does the log document establish the frequency and schedule of maintenance tasks?

The preventive maintenance log outlines the maintenance schedule by specifying intervals based on time or usage metrics, such as hours operated or mileage. It includes next due dates and technician reminders to ensure timely completion of tasks. This organized scheduling helps prevent equipment failures and extends operational life.

Which personnel are responsible for documenting completed preventive maintenance activities?

Qualified maintenance technicians or engineers are typically responsible for documenting all completed preventive maintenance activities in the log. Supervisors may review entries to verify accuracy and compliance with maintenance protocols. Clear accountability ensures reliability in maintenance records and facilitates audits.

How does the log help track the performance and reliability of equipment over time?

The maintenance log provides a detailed record of all service activities, helping to monitor equipment performance trends and identify recurring issues early. By analyzing this data, maintenance teams can predict failures and optimize repair schedules. This proactive approach enhances reliability and reduces unplanned downtime.

What procedures are in place for updating and reviewing the preventive maintenance log document?

Regular updates to the preventive maintenance log are performed immediately after each maintenance activity to maintain current records. Periodic reviews are conducted by maintenance management to ensure compliance with standards and to assess the effectiveness of maintenance strategies. These procedures guarantee the log's accuracy and support continuous improvement.