A Assembly Line Checklist Document Sample for Manufacturing provides a structured guide to ensure all critical steps are followed during the production process. It helps maintain quality control, streamline workflow, and minimize errors by listing detailed tasks and safety protocols. This document is essential for optimizing efficiency and consistency across manufacturing operations.

Daily Assembly Line Inspection Checklist Template

A

Daily Assembly Line Inspection Checklist Template document is a structured tool used to systematically verify the quality, safety, and efficiency of assembly line operations each day. It helps identify potential issues such as equipment malfunctions, process deviations, and safety hazards, ensuring consistent production standards. By using this checklist, manufacturing teams can maintain compliance, reduce downtime, and enhance overall operational performance.

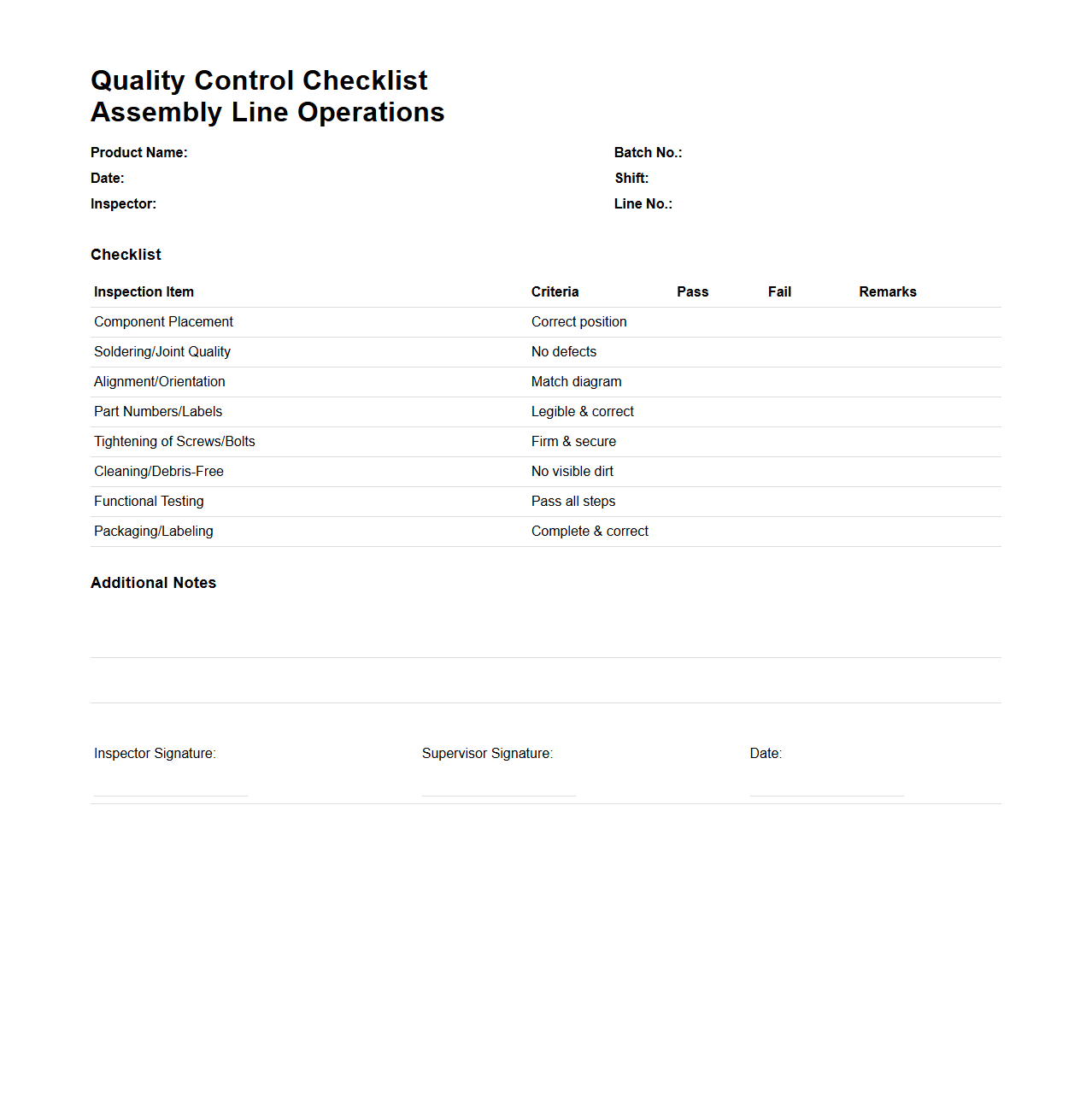

Quality Control Checklist for Assembly Line Operations

A

Quality Control Checklist for Assembly Line Operations document ensures that every stage of the production process meets predefined standards, helping to maintain product consistency and reduce defects. It systematically outlines inspection points, critical quality parameters, and corrective actions to guarantee compliance with manufacturing specifications. This checklist is essential for streamlining quality assurance, minimizing errors, and improving overall efficiency in assembly line workflows.

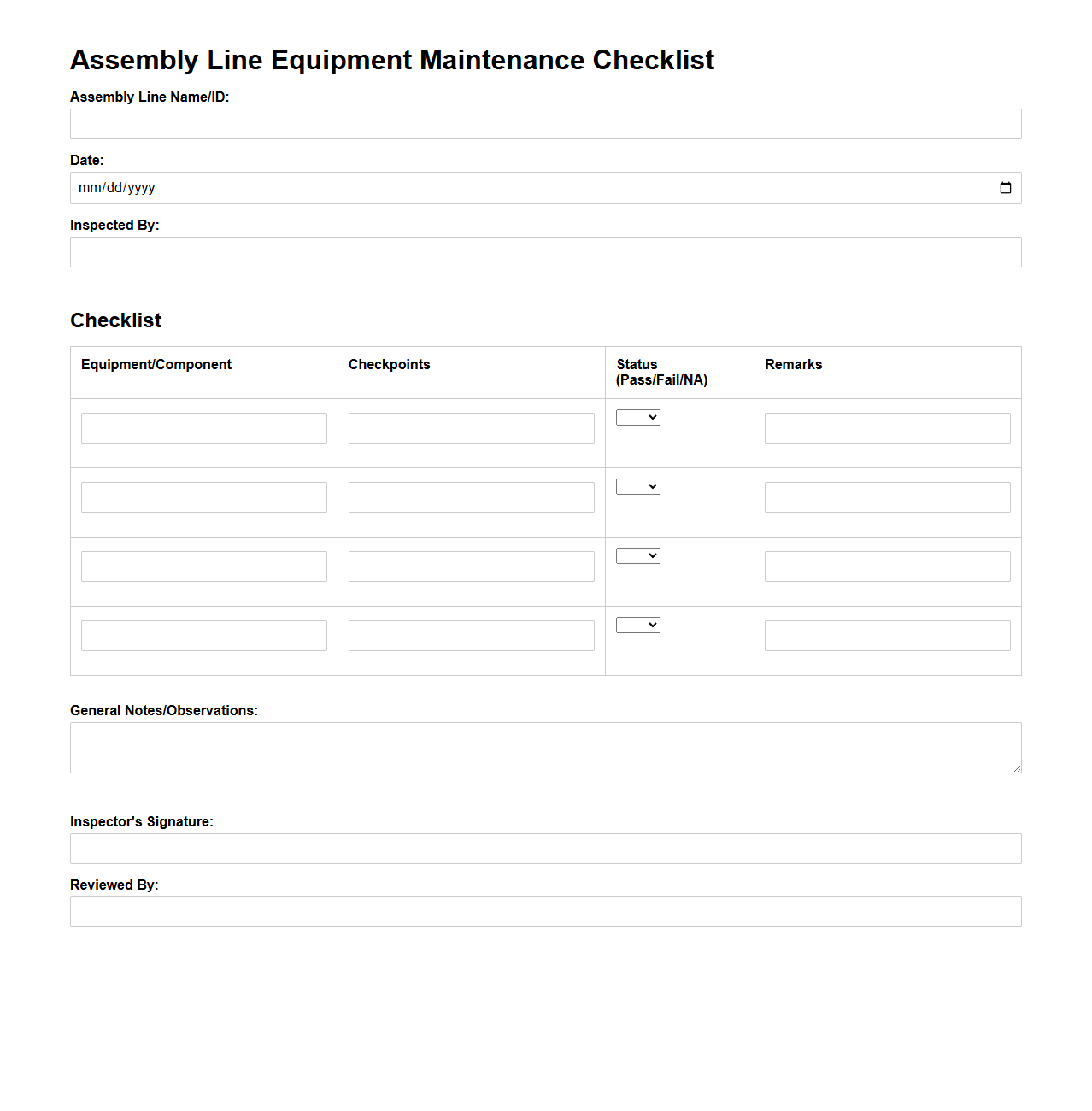

Assembly Line Equipment Maintenance Checklist Format

The Assembly Line Equipment Maintenance Checklist Format is a structured document designed to systematically track and ensure the upkeep of machinery used in production lines. It includes detailed sections for inspecting critical components, recording routine service dates, and noting required repairs or adjustments to prevent operational disruptions. Utilizing this checklist enhances the reliability and efficiency of manufacturing processes by promoting regular maintenance and early detection of potential equipment failures.

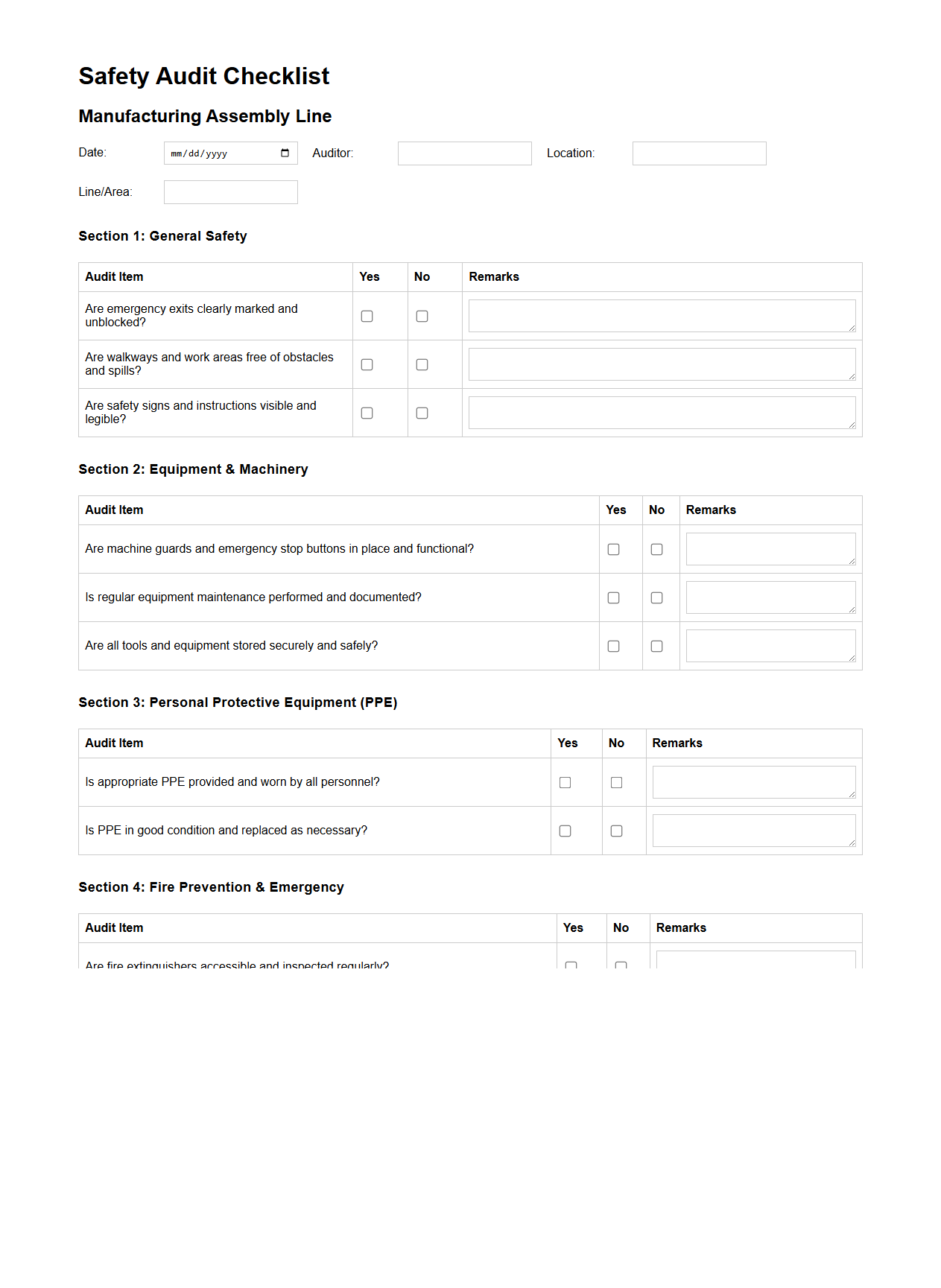

Safety Audit Checklist for Manufacturing Assembly Line

A

Safety Audit Checklist for Manufacturing Assembly Line is a comprehensive document designed to systematically evaluate workplace safety standards and compliance in an assembly line environment. It includes critical inspection points such as machine guarding, personal protective equipment usage, emergency exits, and hazard communication to identify potential risks and ensure adherence to OSHA regulations. This checklist helps manufacturers maintain a safe work environment, reduce accidents, and improve operational efficiency by addressing safety gaps proactively.

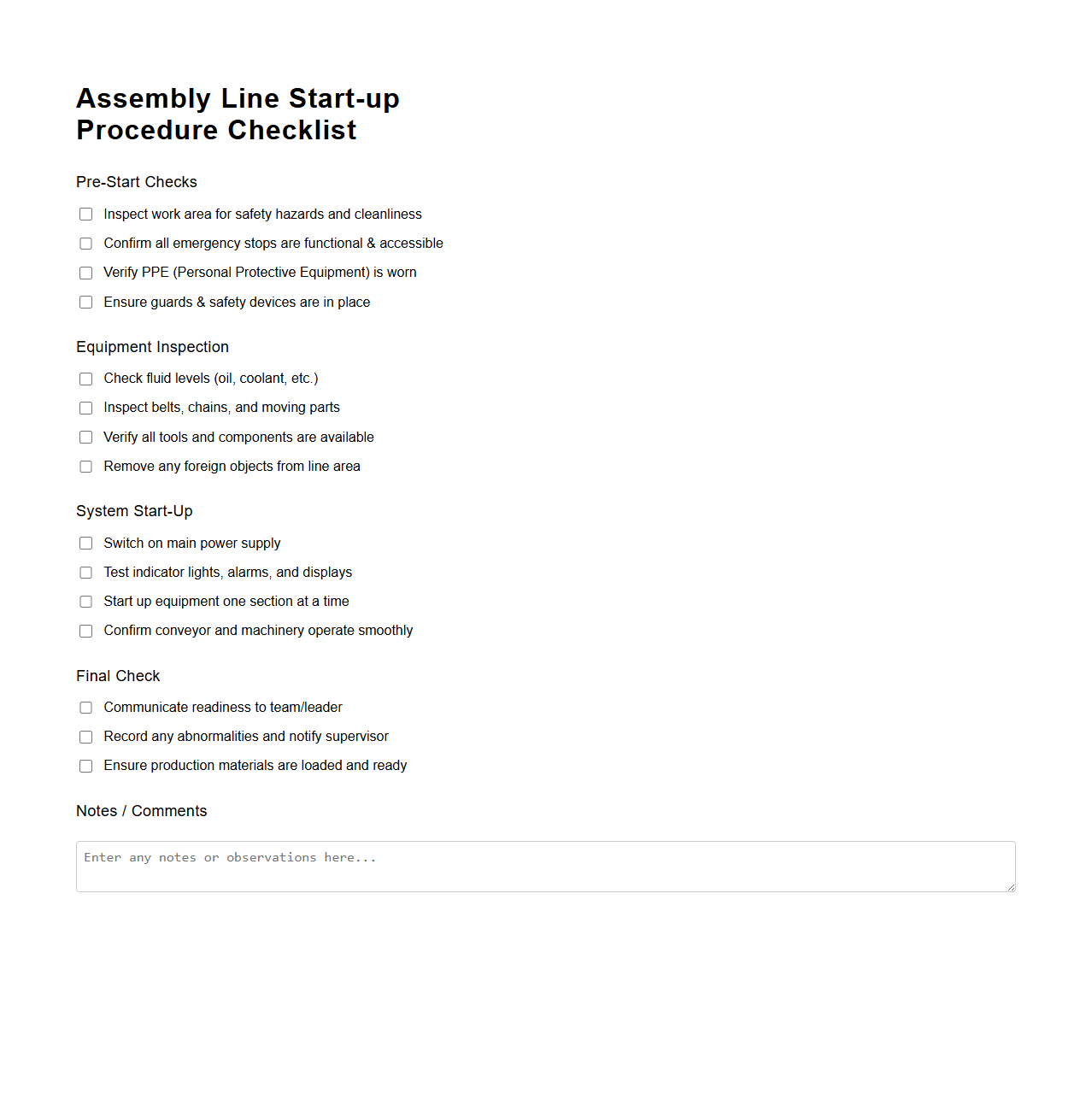

Assembly Line Start-up Procedure Checklist

The

Assembly Line Start-up Procedure Checklist document outlines the essential steps and safety protocols required to initiate production on an assembly line, ensuring operational efficiency and compliance with quality standards. It includes equipment inspections, verification of material availability, and confirmation of worker readiness to minimize downtime and prevent errors. This checklist serves as a critical tool for supervisors and operators to maintain consistent production flow and reduce the risk of costly disruptions.

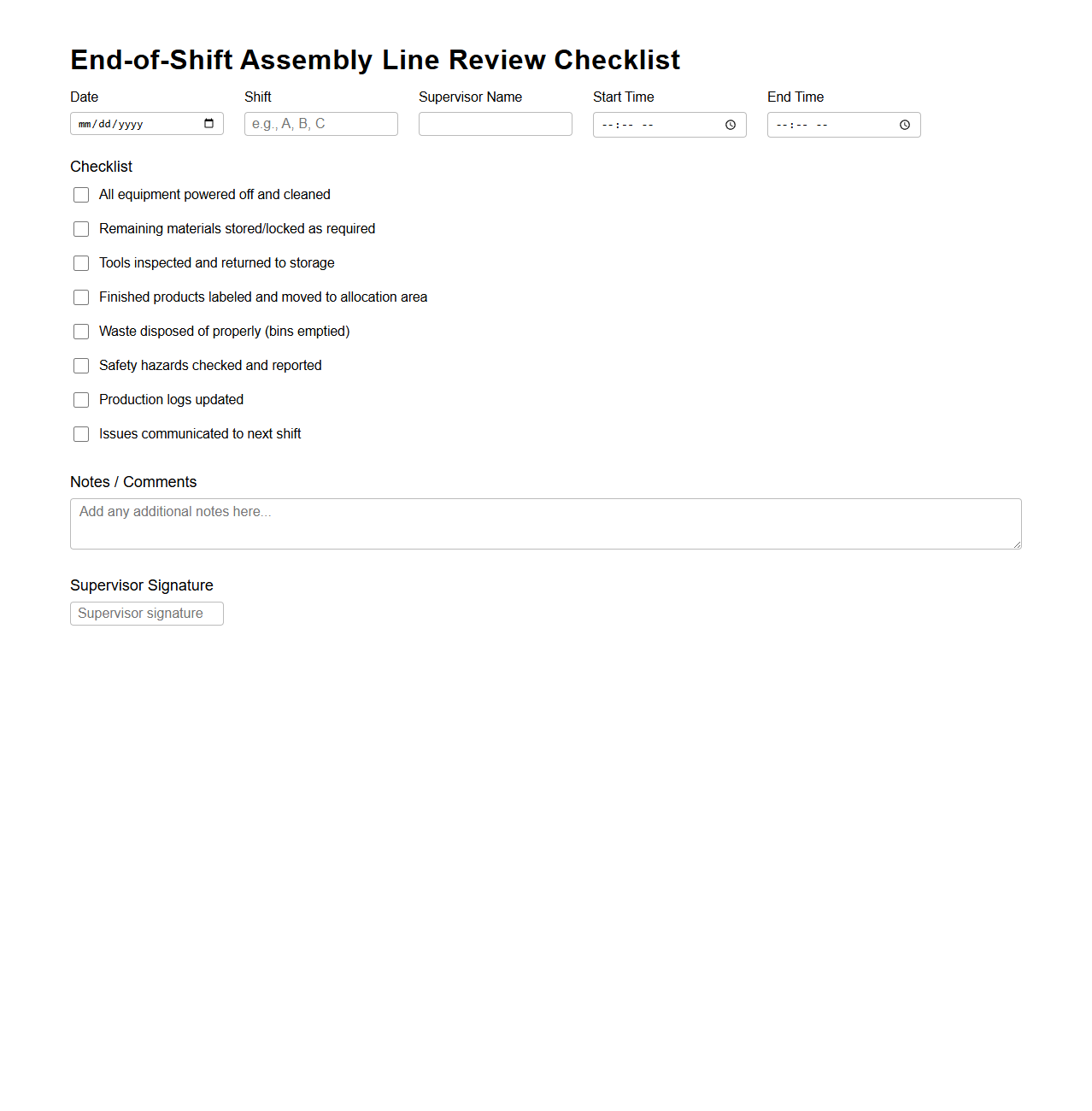

End-of-Shift Assembly Line Review Checklist

The

End-of-Shift Assembly Line Review Checklist is a critical document used to ensure all assembly tasks are completed accurately and safely before a shift ends. It systematically verifies equipment status, quality control measures, and any pending issues that require follow-up, enhancing operational efficiency and reducing errors. This checklist supports seamless shift transitions by providing clear communication and accountability among team members.

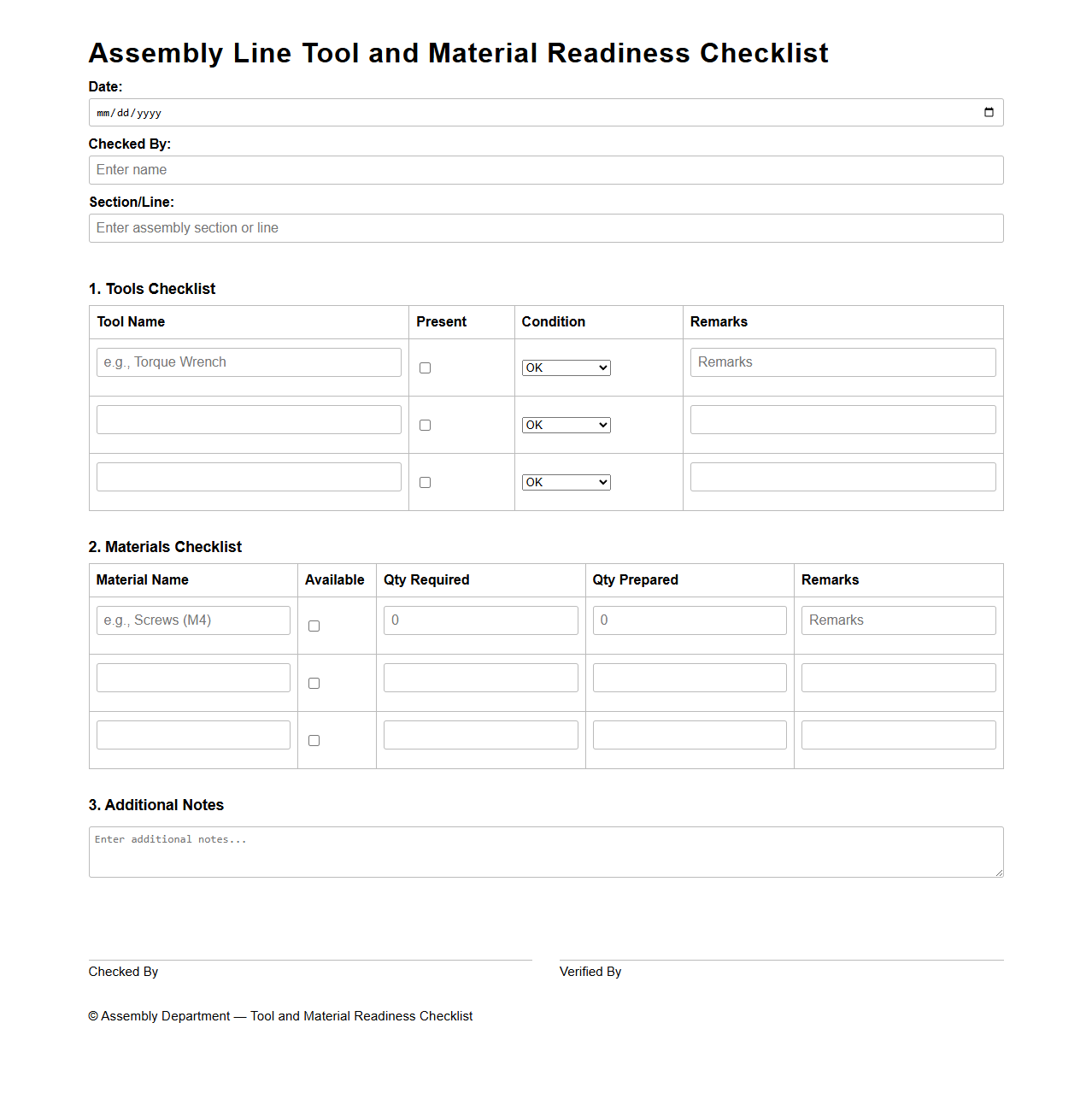

Assembly Line Tool and Material Readiness Checklist

The

Assembly Line Tool and Material Readiness Checklist document ensures that all necessary tools and materials are prepared and verified before production begins, minimizing downtime and enhancing workflow efficiency. It includes detailed inventory lists, status verification points, and safety compliance checks specific to the assembly line environment. This checklist serves as a critical quality control measure to maintain consistent production standards and prevent errors during the manufacturing process.

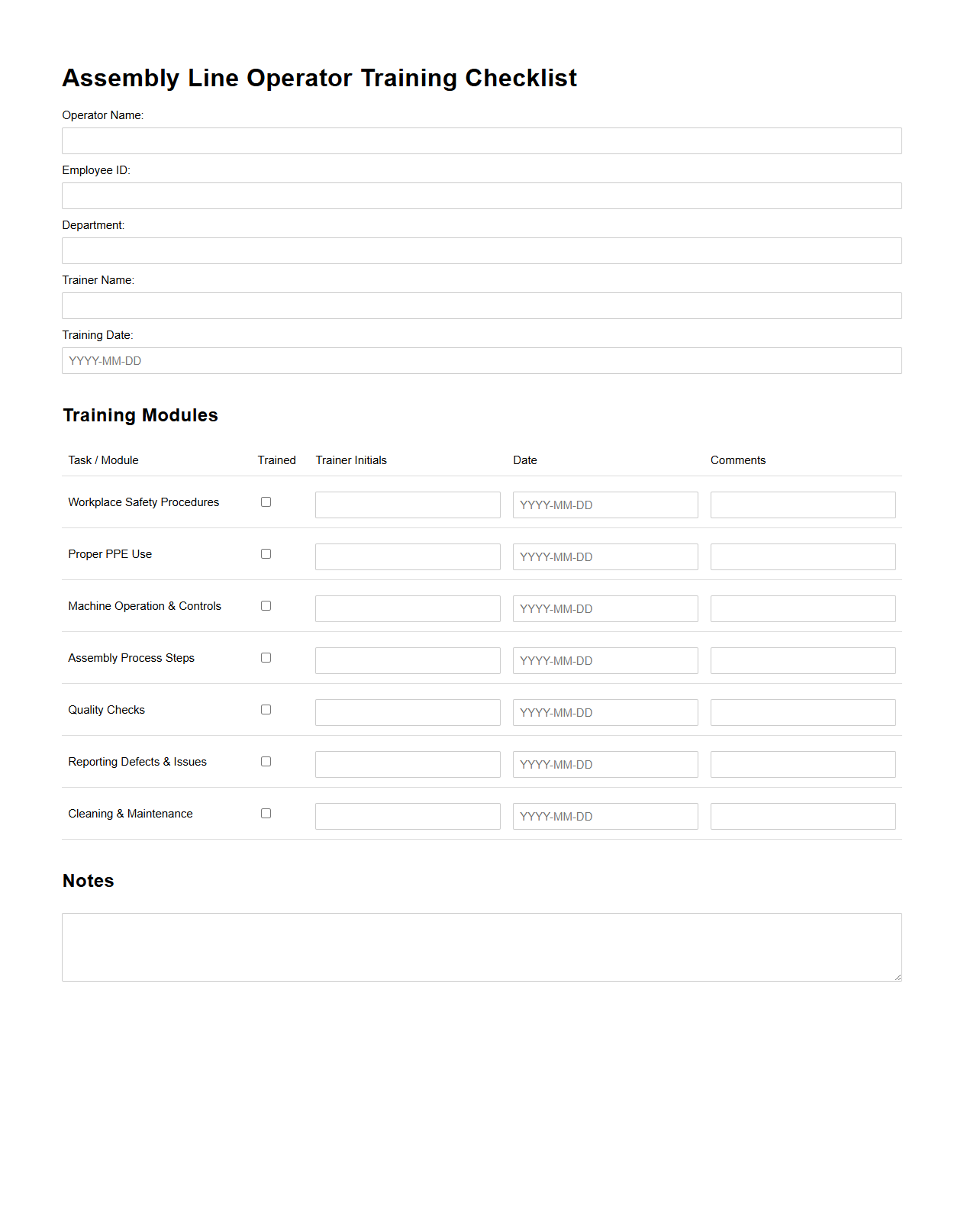

Assembly Line Operator Training Checklist Sample

An

Assembly Line Operator Training Checklist Sample document outlines the essential skills, safety protocols, and operational procedures that new operators must master to ensure efficient and safe assembly line production. This checklist serves as a structured guide for trainers to systematically evaluate trainee competencies, covering machine operation, quality control checks, and workplace safety standards. Using this checklist improves training consistency, reduces errors, and enhances overall manufacturing productivity.

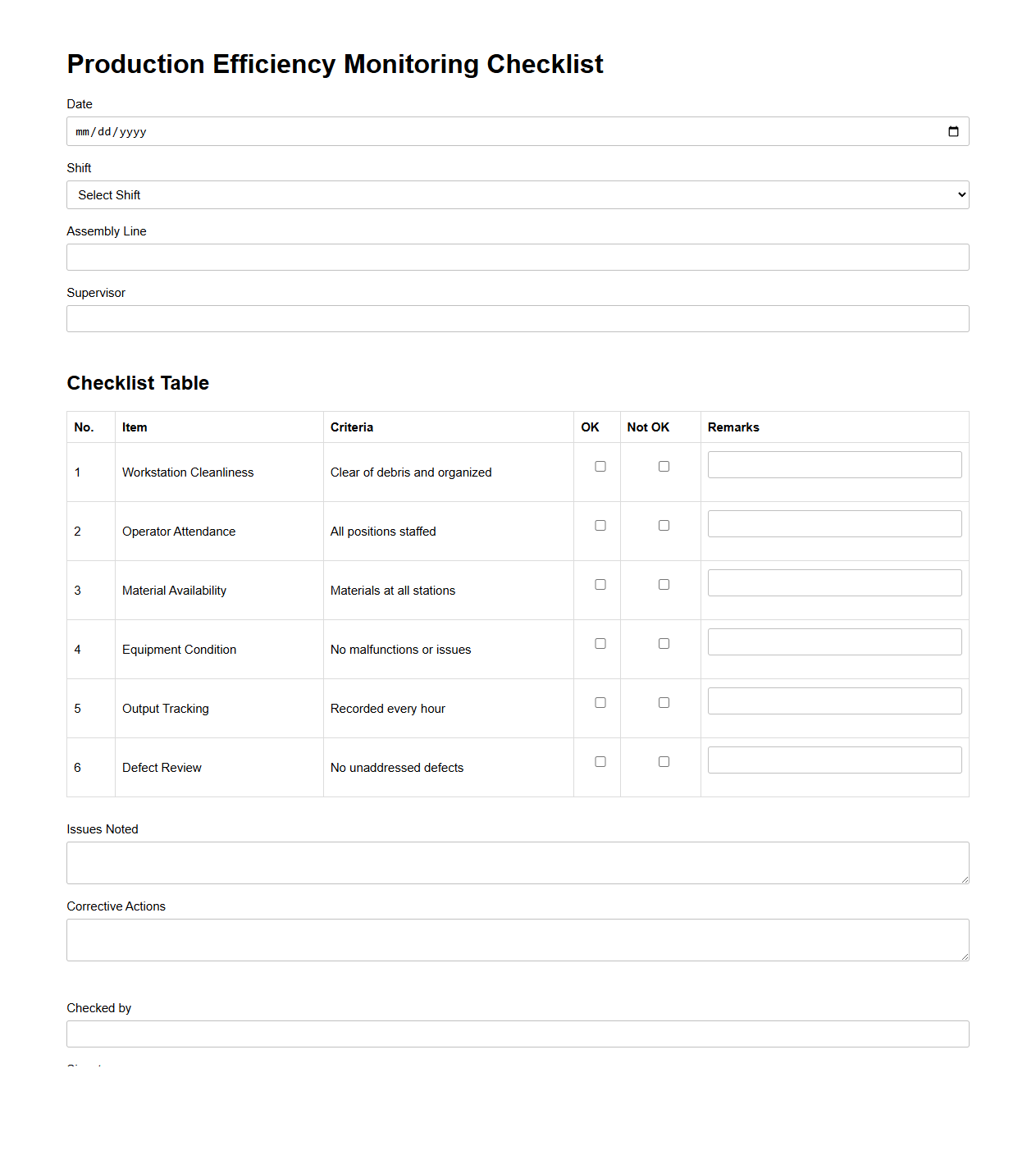

Production Efficiency Monitoring Checklist for Assembly Line

The

Production Efficiency Monitoring Checklist for an assembly line is a structured tool designed to track and evaluate key performance indicators such as cycle time, machine downtime, and defect rates. It enables supervisors and engineers to identify bottlenecks, ensure adherence to standard operating procedures, and implement continuous improvement measures. Regular use of this checklist supports optimizing resource utilization and increasing overall production output.

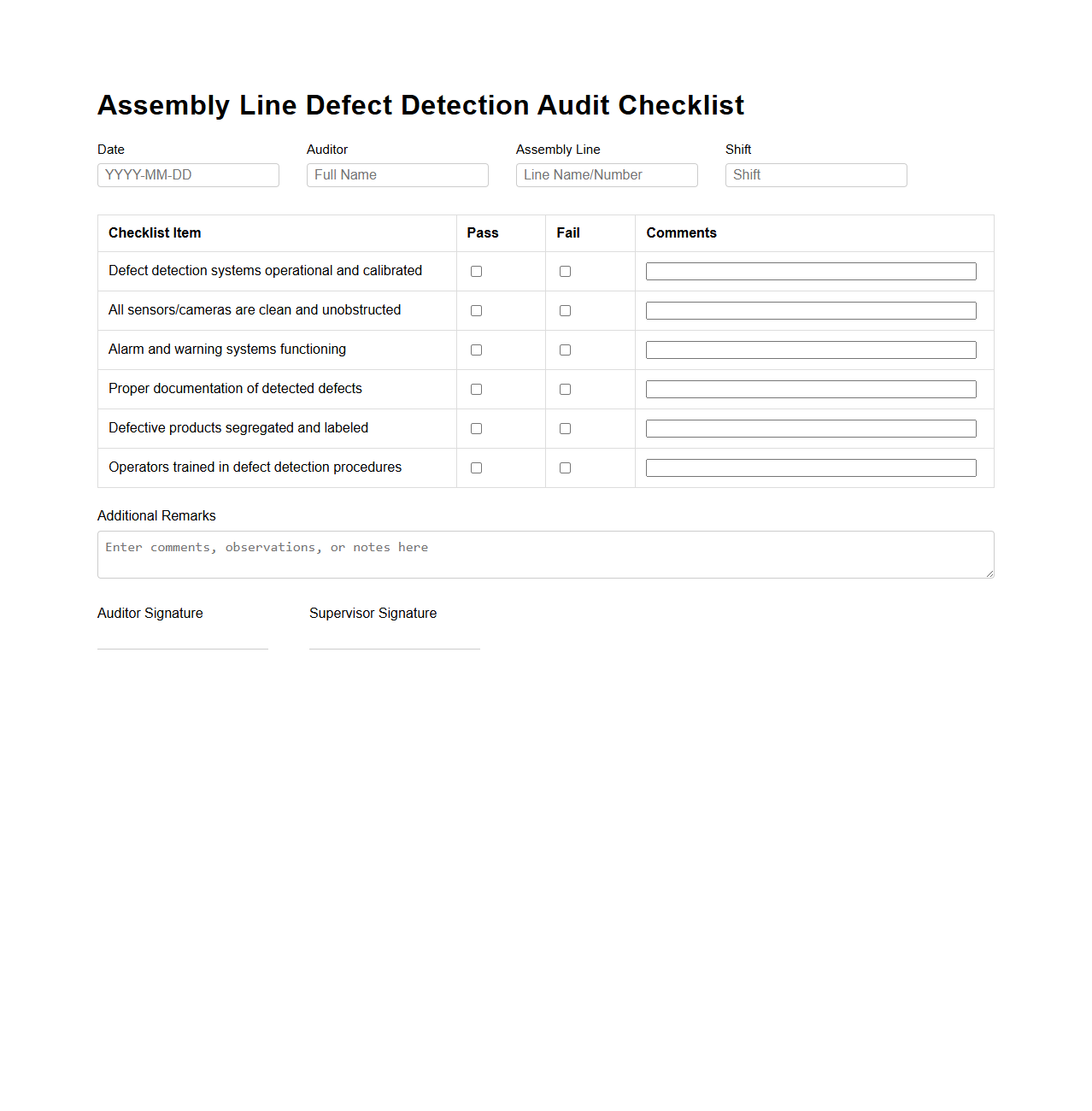

Assembly Line Defect Detection Audit Checklist

The

Assembly Line Defect Detection Audit Checklist document serves as a systematic tool to identify and record imperfections during the manufacturing process on an assembly line. It outlines specific criteria and inspection points to ensure product quality and compliance with industry standards. This checklist enhances operational efficiency by enabling early detection of defects, reducing waste and rework costs.

Key Components of an Effective Assembly Line Checklist

An effective assembly line checklist must include step-by-step instructions to ensure consistency in manufacturing processes. It should have clear quality control checkpoints to detect defects early and maintain product standards. Additionally, equipment and tool verification must be part of the checklist to guarantee operational readiness.

Verification of Compliance with Safety Regulations and Quality Standards

The checklist verifies compliance by including mandatory safety inspection steps aligned with regulatory requirements. It incorporates quality assurance tests to confirm adherence to product specifications and industry standards. Regular documentation of completed safety and quality checks ensures traceability and accountability.

Essential Sections for Tracking Progress and Identifying Bottlenecks

The document sample should contain sections for task completion status, enabling real-time monitoring of assembly stages. Including a time tracking segment helps identify delays and potential bottlenecks in the workflow. A comments area allows operators to report issues, facilitating continuous process improvement.

Documenting Accountability of Personnel in the Checklist

The checklist should assign specific responsibility fields where personnel sign off after completing tasks. Recording timestamps alongside signatures increases accountability and traceability. This documentation ensures that each team member is aware of their duties within the assembly line process.

Criteria for Updating or Customizing the Checklist

Checklist updates should be based on product variations and changes in manufacturing procedures. Incorporating feedback from frontline workers can identify necessary adjustments for efficiency and accuracy. Additionally, ensuring compliance with the latest regulatory changes is critical when customizing the checklist for different product lines.

More Manufacturing Templates