A Production Planning Sheet Document Sample for Manufacturing serves as a crucial tool to organize and schedule production activities efficiently. It outlines essential details such as material requirements, workflow timelines, and resource allocation, ensuring smooth operations and minimizing downtime. This document helps manufacturers optimize production processes, enhance productivity, and maintain quality control.

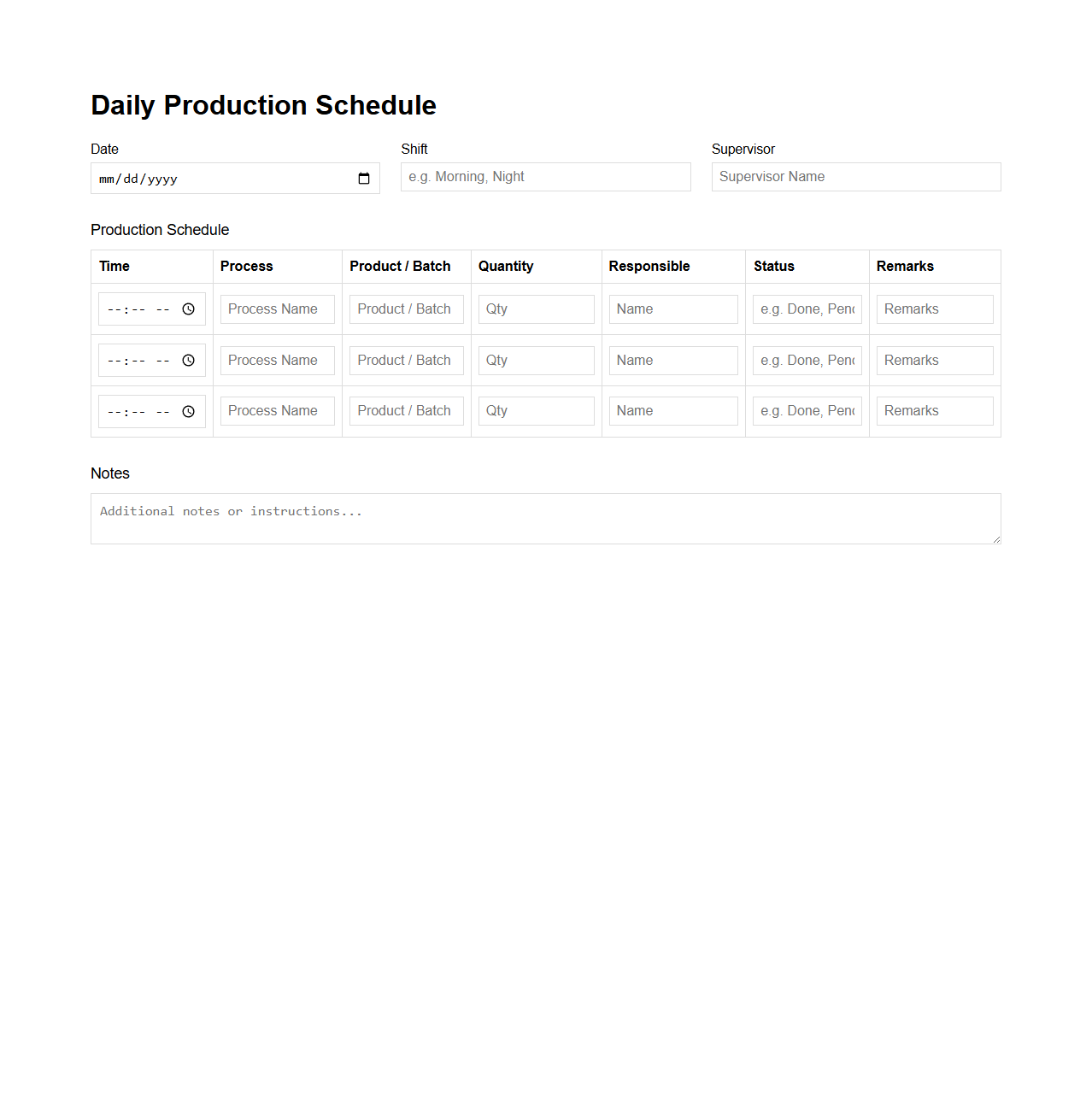

Daily Production Schedule Template

A

Daily Production Schedule Template is a structured document used to plan and track manufacturing or production activities on a daily basis. It outlines tasks, timelines, resources, and personnel assignments to ensure efficient workflow and timely completion of production goals. This template helps improve productivity, minimize downtime, and maintain clear communication across teams.

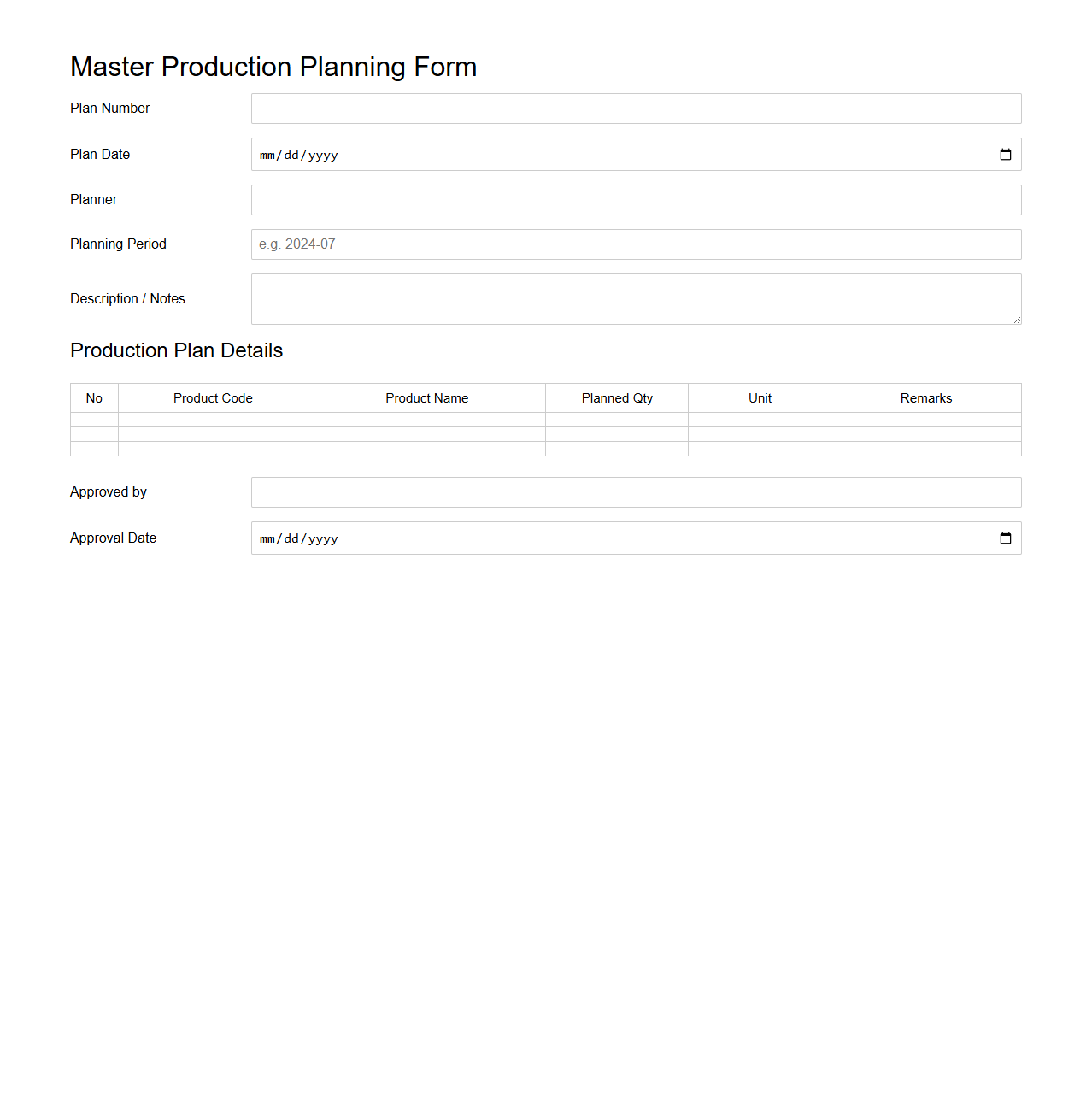

Master Production Planning Form

The

Master Production Planning Form document serves as a strategic tool used by manufacturing companies to outline production schedules, resource allocation, and inventory levels. It details the quantities and timelines for finished goods to meet customer demand while optimizing operational efficiency. This form enables precise coordination between procurement, production, and sales departments to minimize delays and cost overruns.

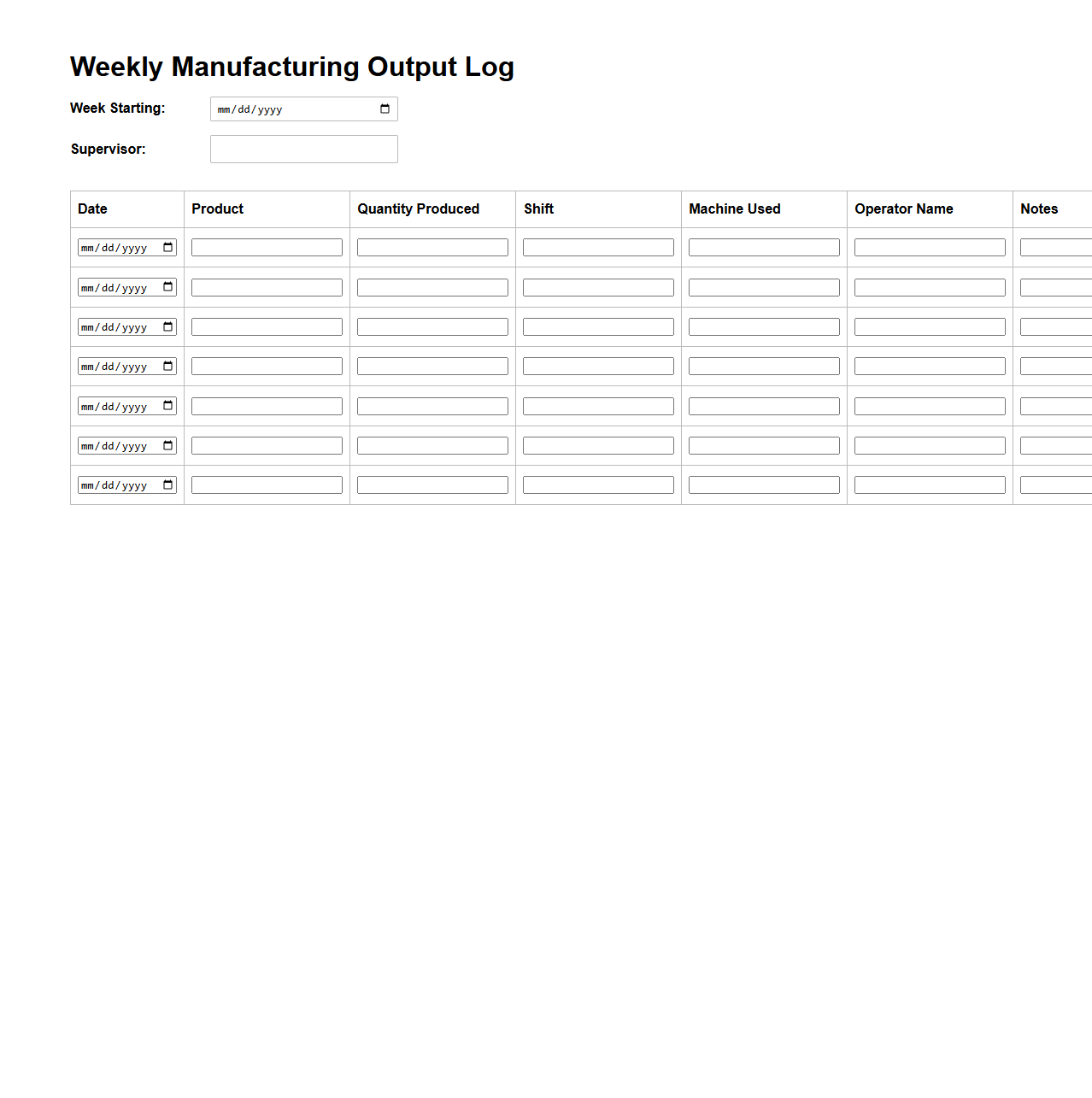

Weekly Manufacturing Output Log

The

Weekly Manufacturing Output Log document records detailed production data, including quantity of goods produced, machine performance, and labor efficiency for each manufacturing shift throughout the week. It helps track operational productivity, identify bottlenecks, and monitor compliance with production targets. This log is essential for analyzing trends, improving manufacturing processes, and ensuring accurate reporting to management.

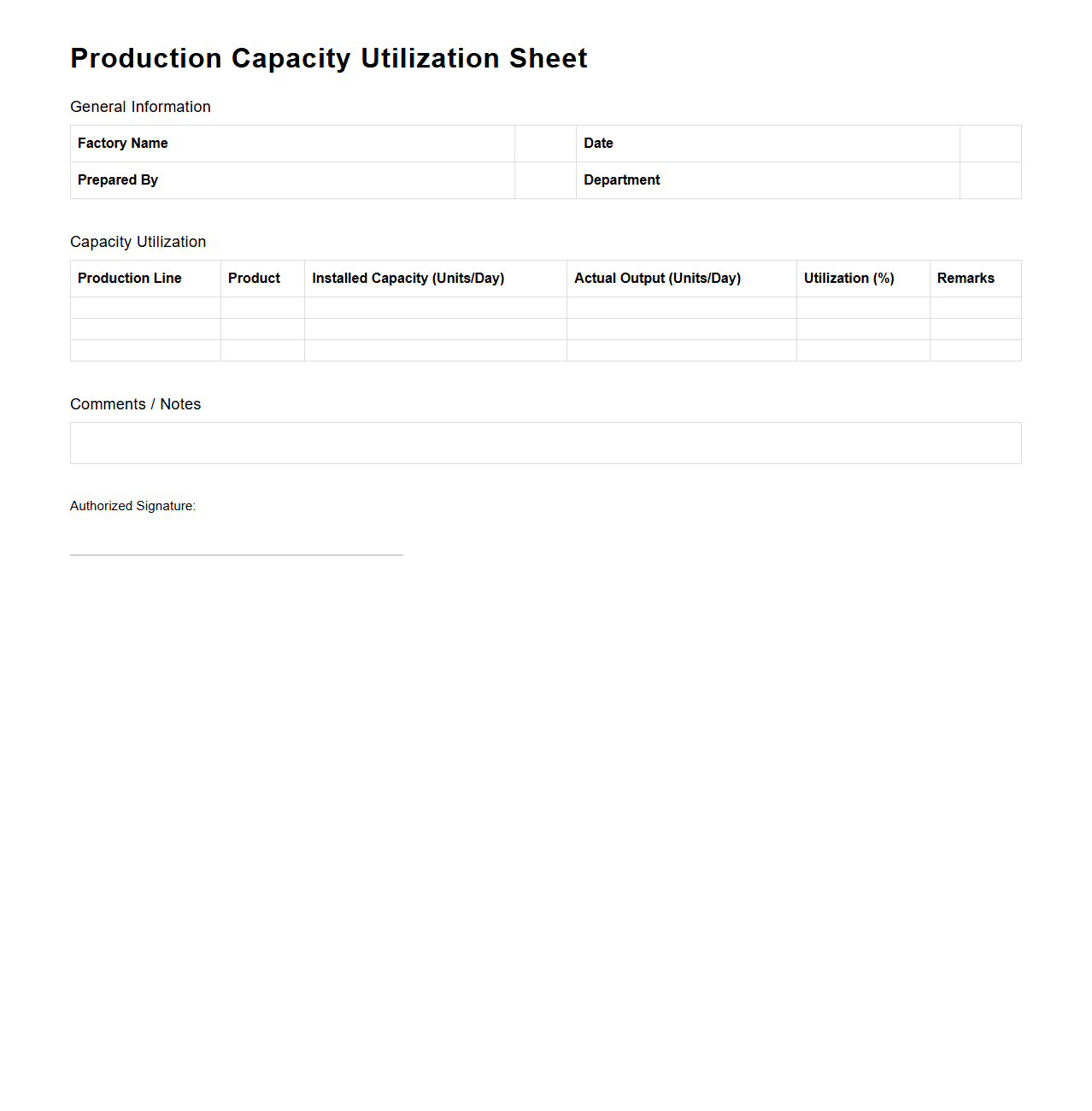

Production Capacity Utilization Sheet

A

Production Capacity Utilization Sheet is a document used to measure and analyze the extent to which a manufacturing facility's production capacity is being used over a specific period. It tracks the ratio of actual output to the maximum possible output, helping managers identify inefficiencies, plan resource allocation, and optimize production processes. This sheet is essential for improving operational efficiency and ensuring that production goals align with available resources and market demand.

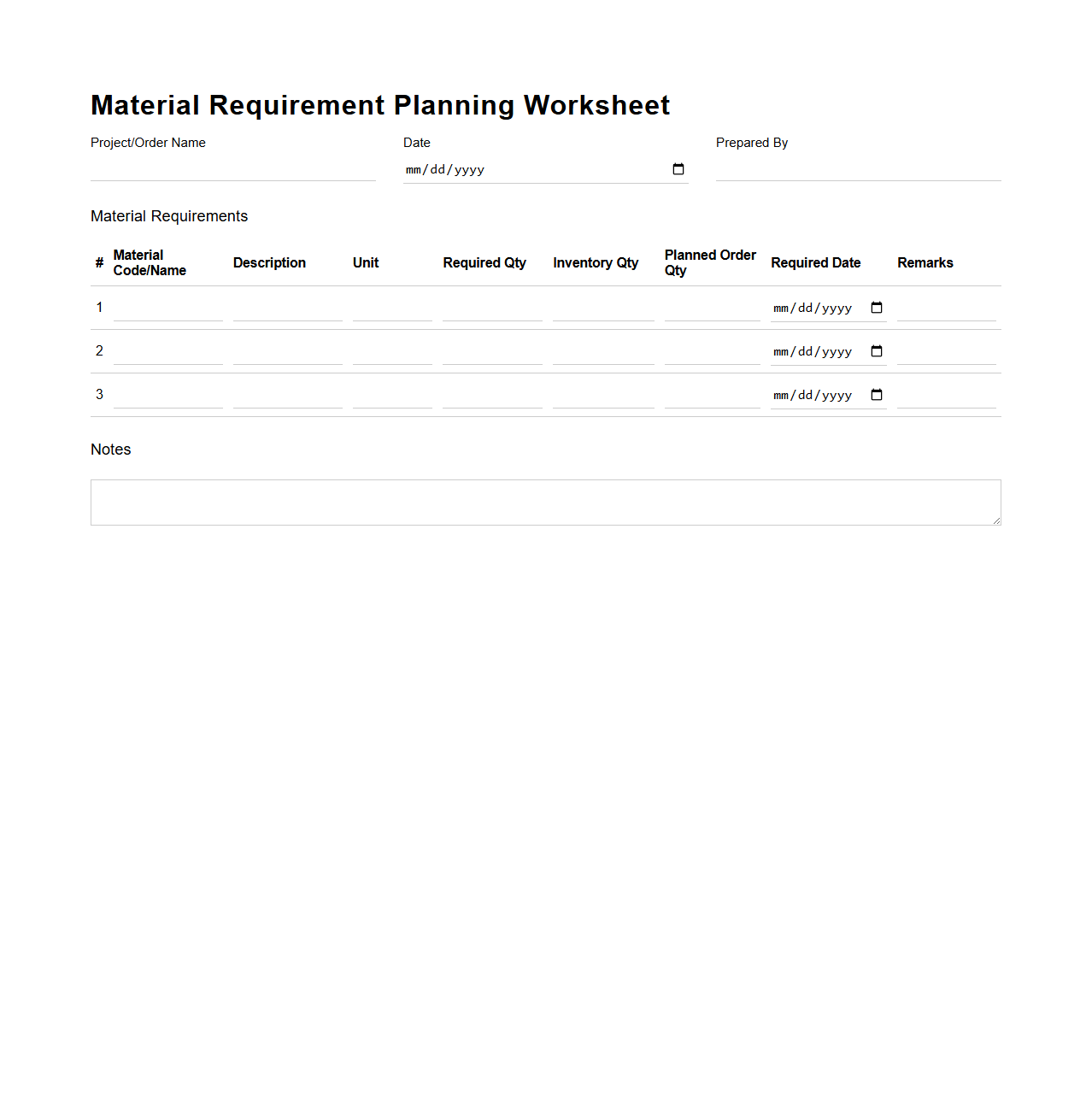

Material Requirement Planning Worksheet

The

Material Requirement Planning (MRP) Worksheet document is a crucial tool in manufacturing and production management that helps determine the quantity and timing of raw materials needed for production schedules. It details the inventory status, gross requirements, scheduled receipts, and planned order releases to ensure efficient procurement and minimize inventory costs. This worksheet enables precise coordination of materials, reducing delays and optimizing production workflow.

Production Order Tracking Sheet

A

Production Order Tracking Sheet is a document used to monitor and manage the progress of manufacturing orders from initiation to completion. It records critical data such as order numbers, production stages, timelines, resource allocation, and status updates to ensure efficient workflow and timely delivery. This tool helps in identifying bottlenecks, improving production planning, and maintaining quality control throughout the manufacturing process.

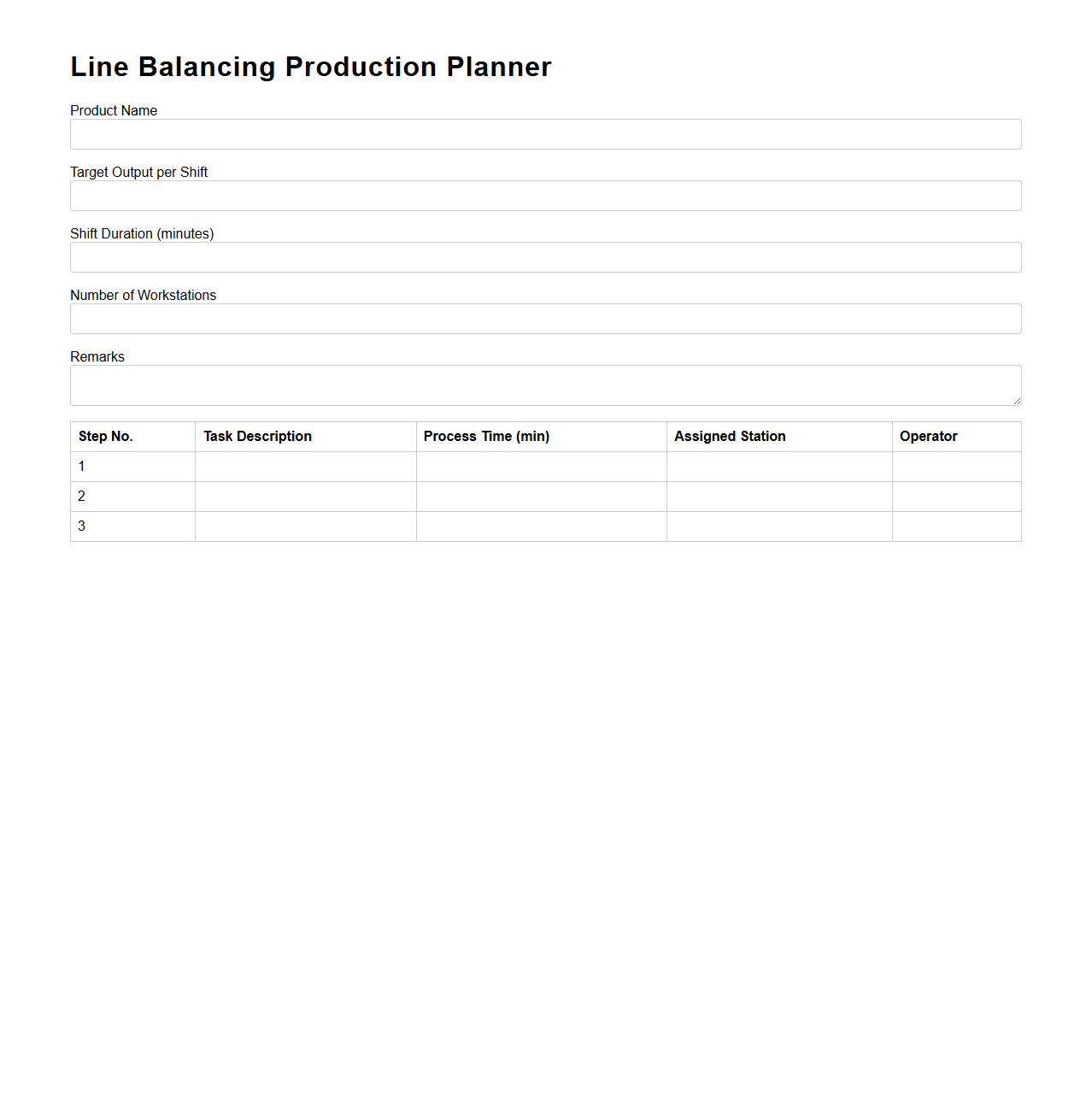

Line Balancing Production Planner

The

Line Balancing Production Planner document is a strategic tool used in manufacturing to distribute tasks evenly across workstations, ensuring optimal workflow and minimizing idle time. It helps in allocating resources effectively, improving productivity, and reducing bottlenecks on the production line. This document provides detailed task sequences, cycle times, and labor requirements essential for efficient production scheduling and capacity planning.

Shift-wise Production Tracking Sheet

The

Shift-wise Production Tracking Sheet is a critical document used to monitor and record production data across different shifts within a manufacturing or production facility. It captures detailed information such as output quantities, machine performance, downtime, and quality metrics for each shift, enabling real-time analysis and decision-making. This sheet helps optimize productivity, identify bottlenecks, and maintain consistent production standards throughout various operational periods.

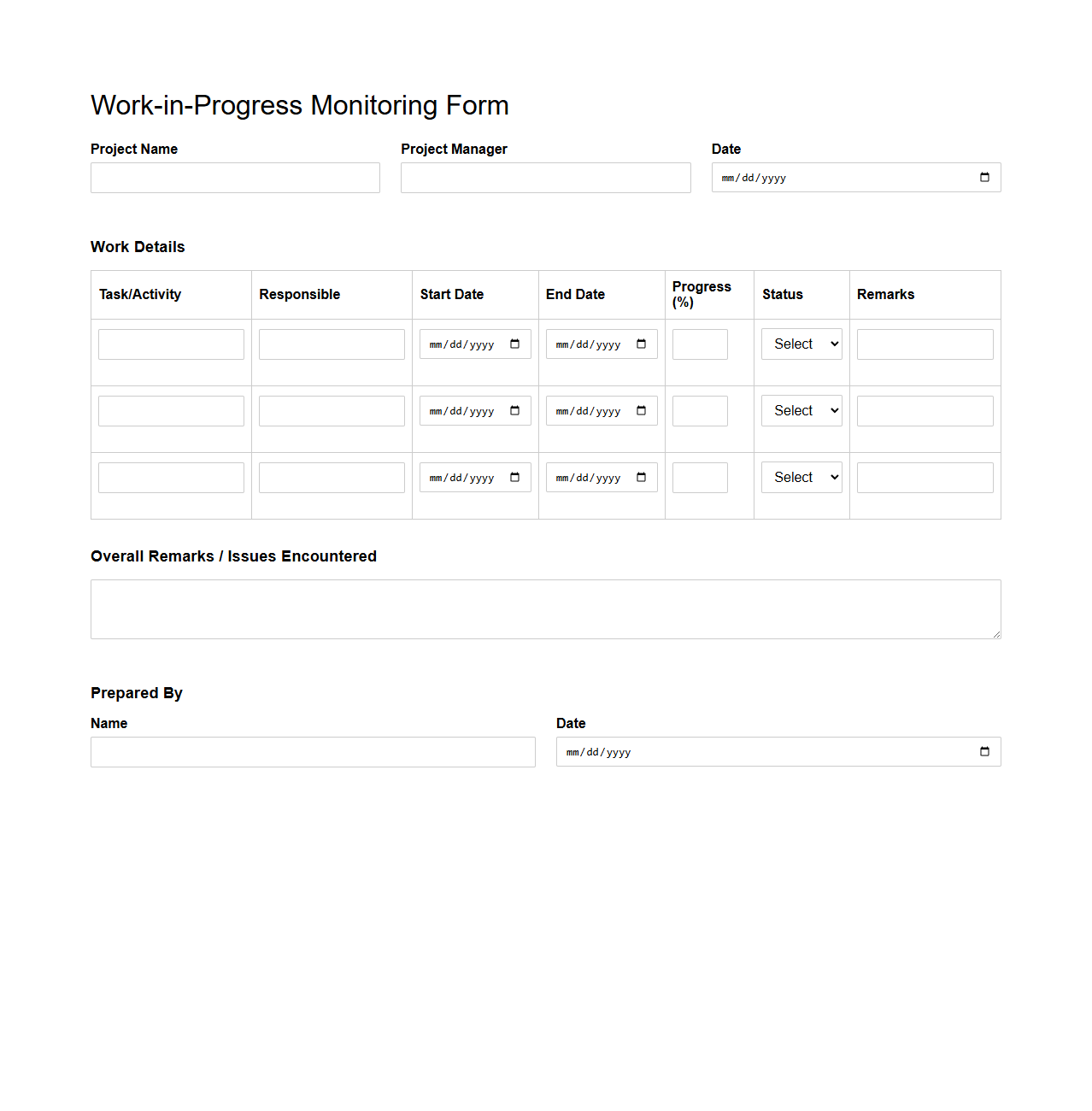

Work-in-Progress Monitoring Form

A

Work-in-Progress Monitoring Form is a vital document used to track the ongoing status and progress of tasks, projects, or production stages within an organization. It captures key data such as task descriptions, completion percentages, deadlines, responsible personnel, and any obstacles encountered, facilitating effective project management and timely decision-making. Regular updates on this form help maintain transparency, optimize resource allocation, and ensure projects stay on schedule.

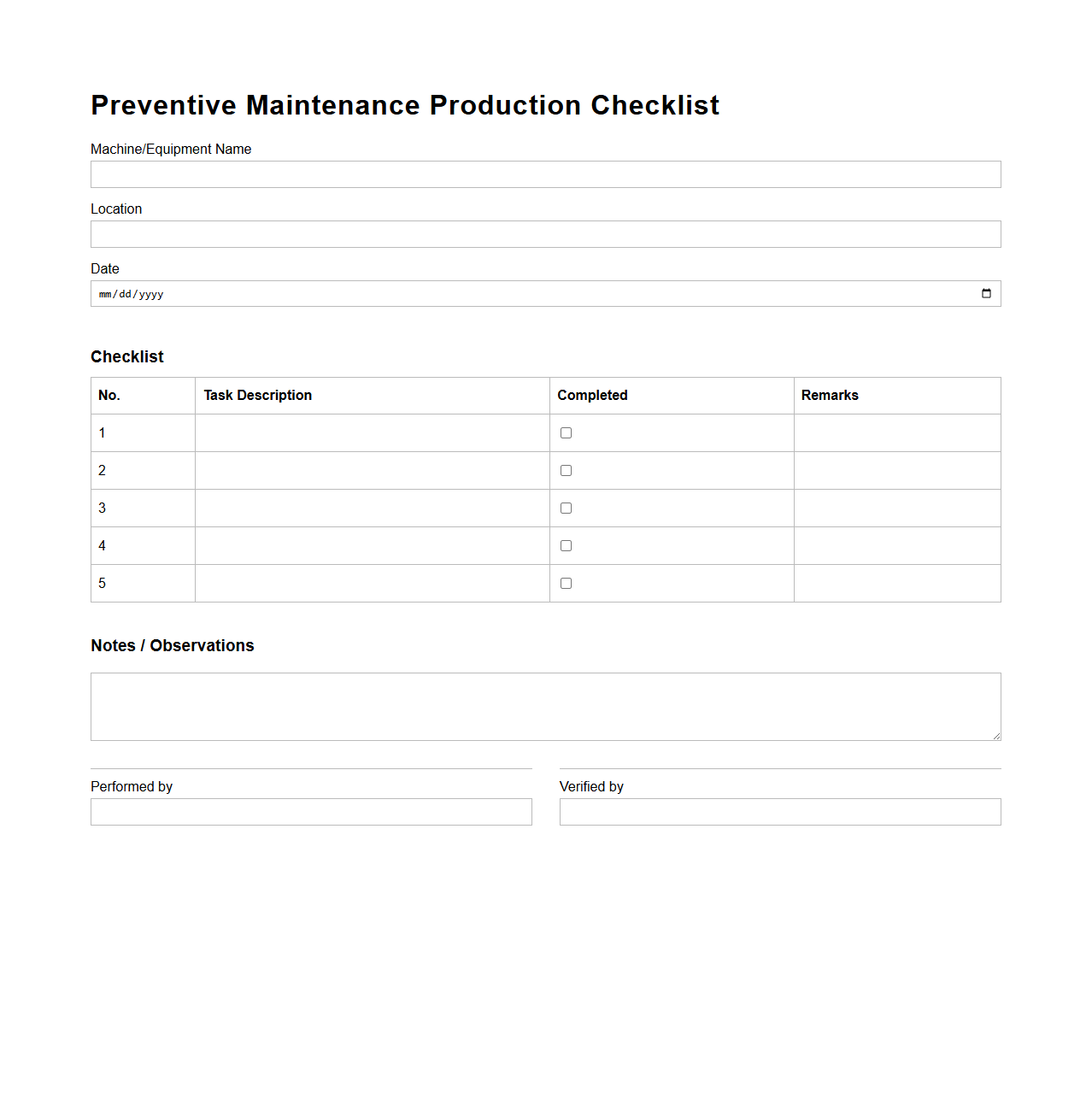

Preventive Maintenance Production Checklist

A

Preventive Maintenance Production Checklist document is a detailed guide used to schedule and track routine inspections and maintenance tasks for production equipment, ensuring optimal performance and minimizing downtime. It typically includes specific procedures, frequency of checks, responsible personnel, and documentation requirements to enhance reliability and extend equipment lifespan. This checklist is essential for maintaining production efficiency, reducing unexpected failures, and supporting compliance with safety and quality standards.

What key information is captured in the Production Planning Sheet Document for manufacturing processes?

The Production Planning Sheet captures essential data such as production schedules, work orders, and resource allocation. It details the quantities of products to be manufactured along with timelines and specific process steps. This comprehensive document ensures that all manufacturing activities are clearly defined and organized for efficient operations.

How does the document facilitate material requirements planning and inventory control?

The sheet provides a detailed breakdown of required raw materials and components, aligning with production schedules for accurate material requirements planning. It tracks inventory levels to prevent shortages or excess accumulation, thus optimizing stock control. This enables manufacturers to maintain a balanced inventory, reducing holding costs and avoiding production delays.

What role does the sheet play in scheduling and resource allocation decisions?

The Production Planning Sheet serves as a central tool for coordinating scheduling of production runs and assigning necessary resources like machinery and labor. It helps management allocate resources efficiently based on priority and availability. By setting clear timelines and resource needs, it maximizes productivity and minimizes downtime.

How are quality assurance measures documented and tracked in the planning sheet?

Quality assurance protocols, inspection points, and testing requirements are explicitly documented within the planning sheet. This ensures consistent monitoring and tracking of product quality throughout the manufacturing cycle. It enables timely identification of defects and corrective actions to maintain high standards.

In what ways does the Production Planning Sheet enhance communication among production team members?

The sheet acts as a unified reference that keeps all team members informed of production stages, tasks, and responsibilities. It fosters clear communication by providing real-time updates and facilitating coordination between departments. This collaboration reduces errors and improves overall process transparency.

More Manufacturing Templates