A Raw Material Receiving Document Sample for Manufacturing outlines the details of materials delivered to a production facility, ensuring accuracy in quantity and quality. This document typically includes supplier information, item descriptions, batch numbers, and inspection results. Proper use of this sample helps streamline inventory management and maintain compliance with manufacturing standards.

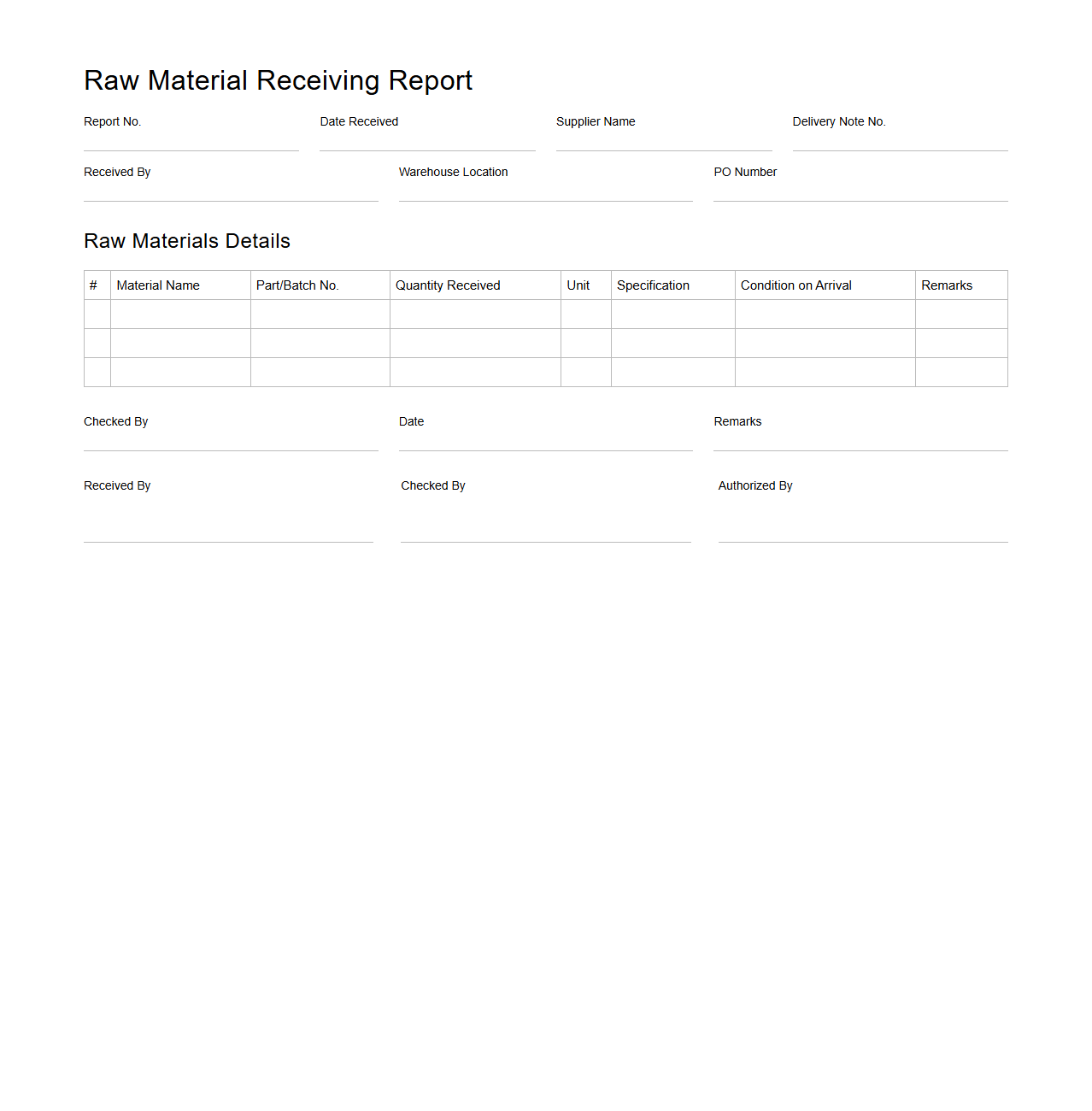

Raw Material Receiving Report Template for Manufacturing

A

Raw Material Receiving Report Template for manufacturing is a structured document used to record the details of raw materials received from suppliers, ensuring accurate tracking and quality verification. It typically includes information such as material type, quantity, supplier details, delivery date, and inspection results to maintain inventory accuracy and support production planning. This template helps streamline the receiving process, minimize errors, and enhance supply chain transparency.

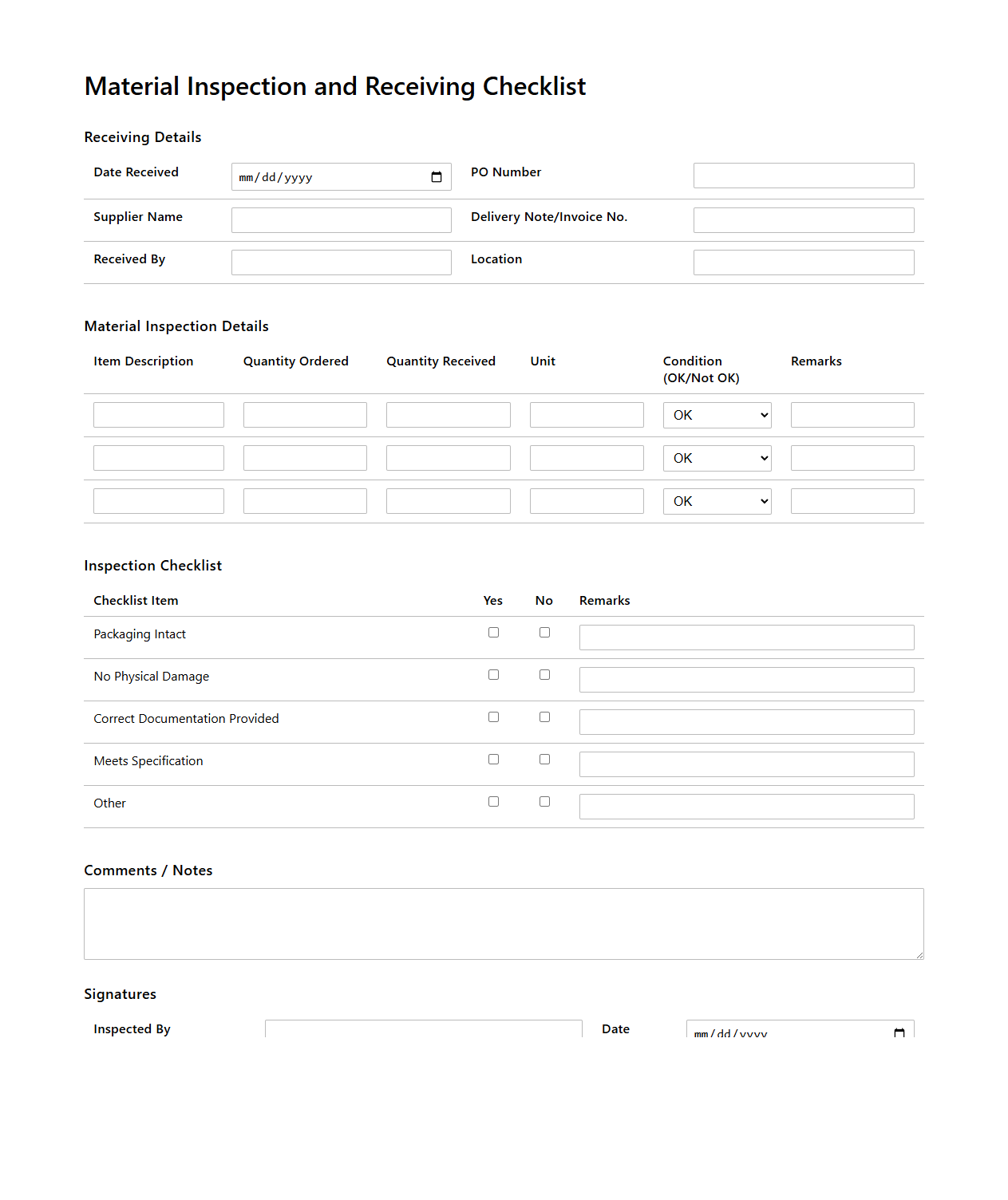

Material Inspection and Receiving Checklist Example

A

Material Inspection and Receiving Checklist is a document used to verify the quality and quantity of materials received against purchase orders and specifications. It helps ensure that all items meet required standards before acceptance and facilitates quick identification of discrepancies or damages. This checklist typically includes sections for item description, quantity, condition, supplier details, and inspection results.

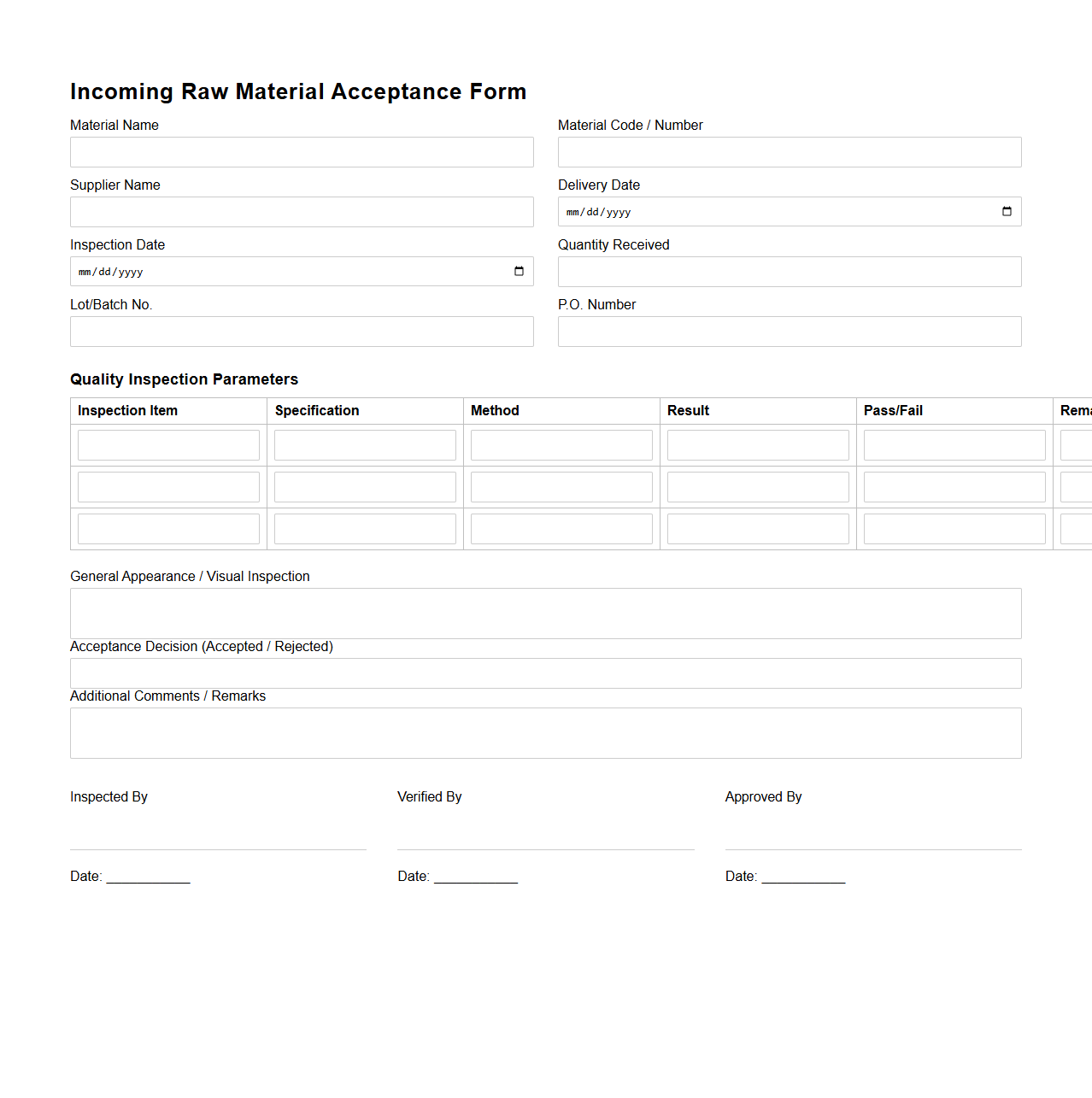

Incoming Raw Material Acceptance Form for Factories

The

Incoming Raw Material Acceptance Form for factories is a critical document used to verify and record the quality, quantity, and specifications of raw materials received before production begins. It ensures compliance with established standards and prevents defective or substandard materials from entering the manufacturing process. Accurate completion of this form supports quality control, traceability, and inventory management within the factory.

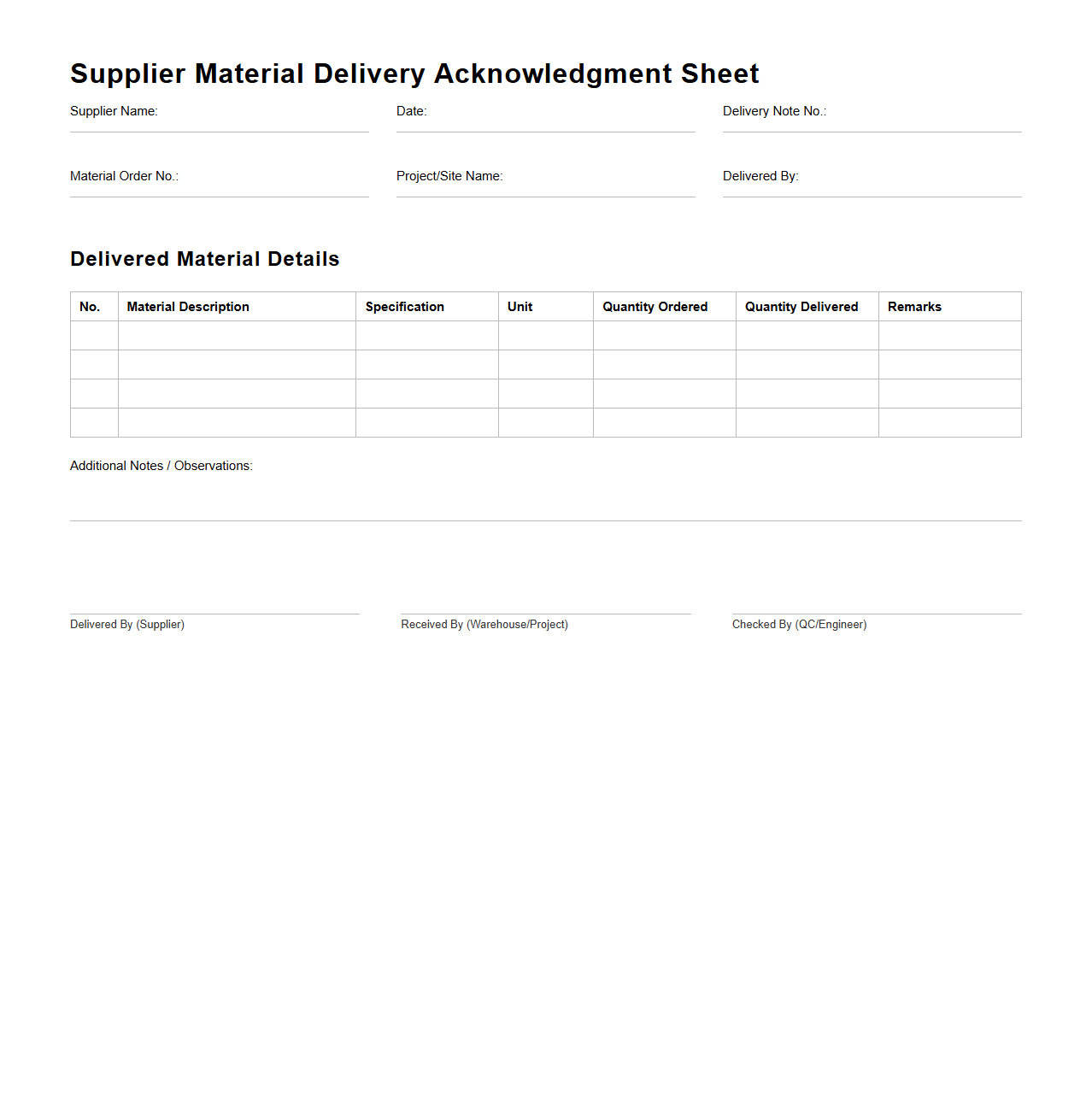

Supplier Material Delivery Acknowledgment Sheet

The

Supplier Material Delivery Acknowledgment Sheet is a critical document used to confirm receipt of materials supplied by vendors, ensuring the accuracy and quality of delivered goods. It records essential details such as delivery date, item descriptions, quantities received, and any discrepancies or damages noted upon arrival. This document facilitates smooth inventory management, supplier accountability, and supports efficient procurement and quality control processes.

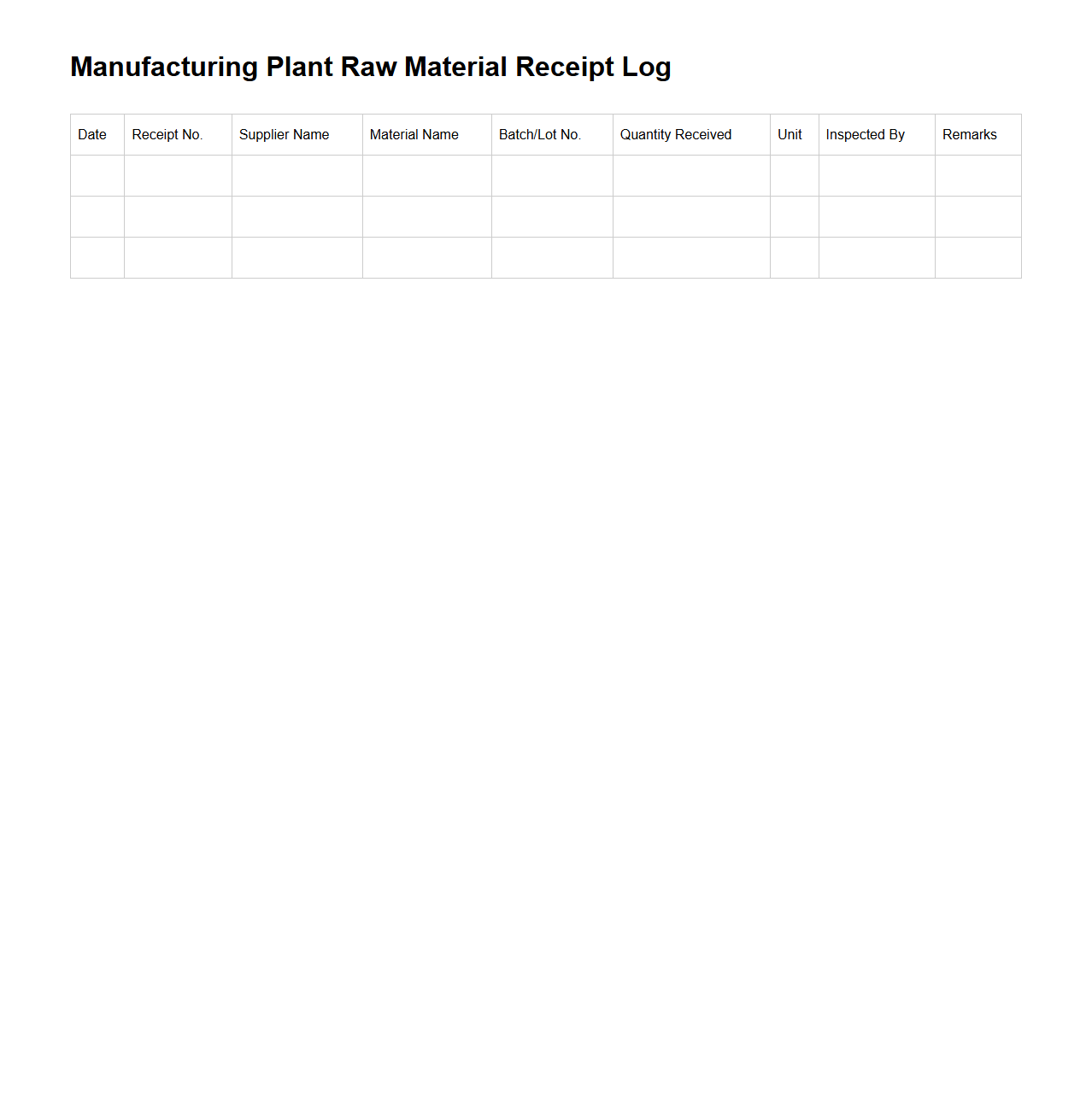

Manufacturing Plant Raw Material Receipt Log

The

Manufacturing Plant Raw Material Receipt Log is a critical document used to record detailed information about raw materials received at the manufacturing facility, including supplier details, batch numbers, quantities, and delivery dates. This log ensures traceability and quality control by tracking incoming materials and verifying compliance with purchase orders and quality standards. Maintaining this document helps prevent discrepancies, supports inventory management, and facilitates audits and regulatory compliance processes.

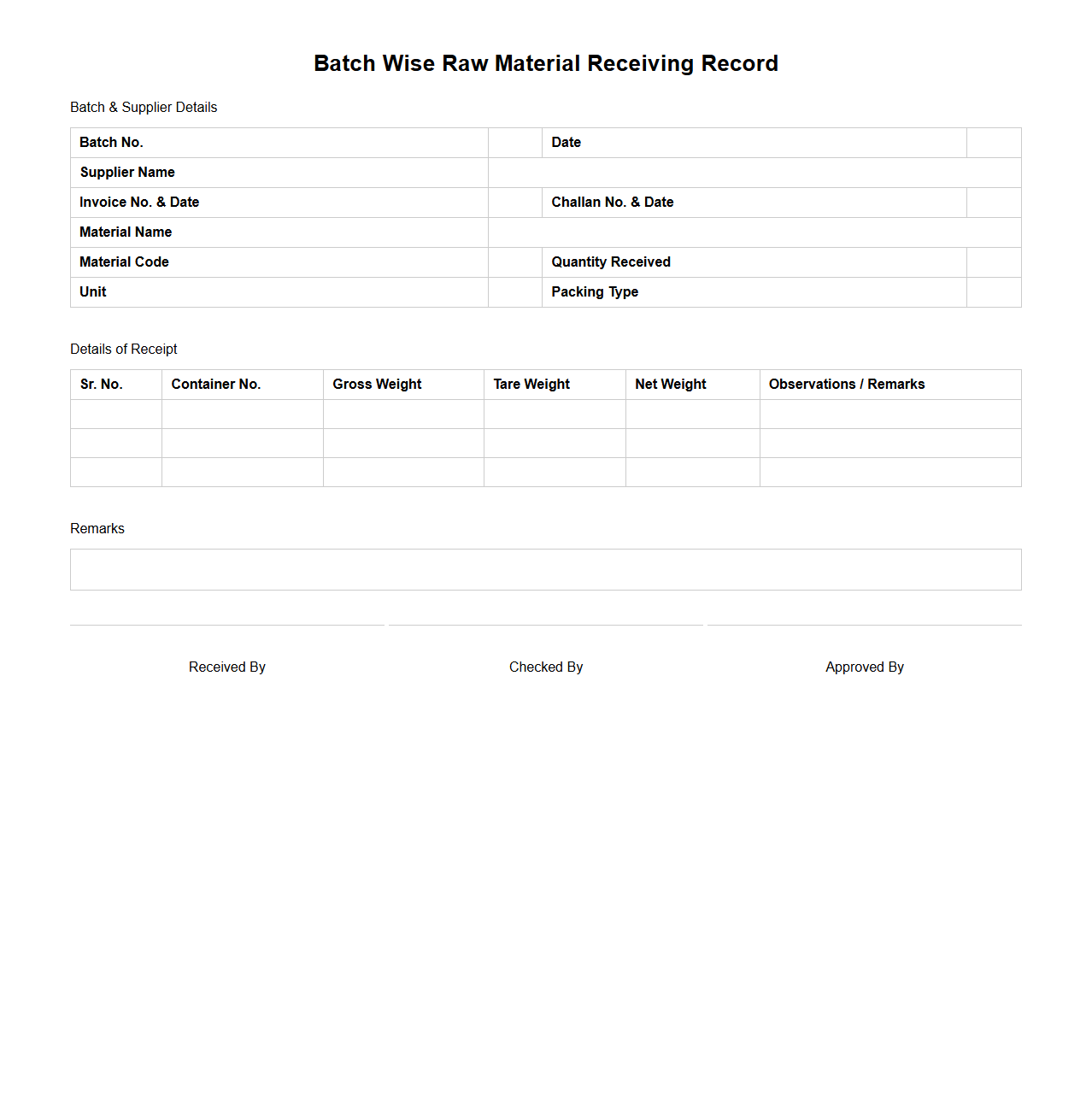

Batch Wise Raw Material Receiving Record Format

The

Batch Wise Raw Material Receiving Record Format document is a structured template used to systematically log details of raw materials received in specific batches. It ensures accurate tracking of supplier information, batch numbers, quantities, and quality checks, facilitating inventory management and traceability. Maintaining this format aids in compliance with regulatory standards and enhances production efficiency by providing clear documentation for audits and quality control processes.

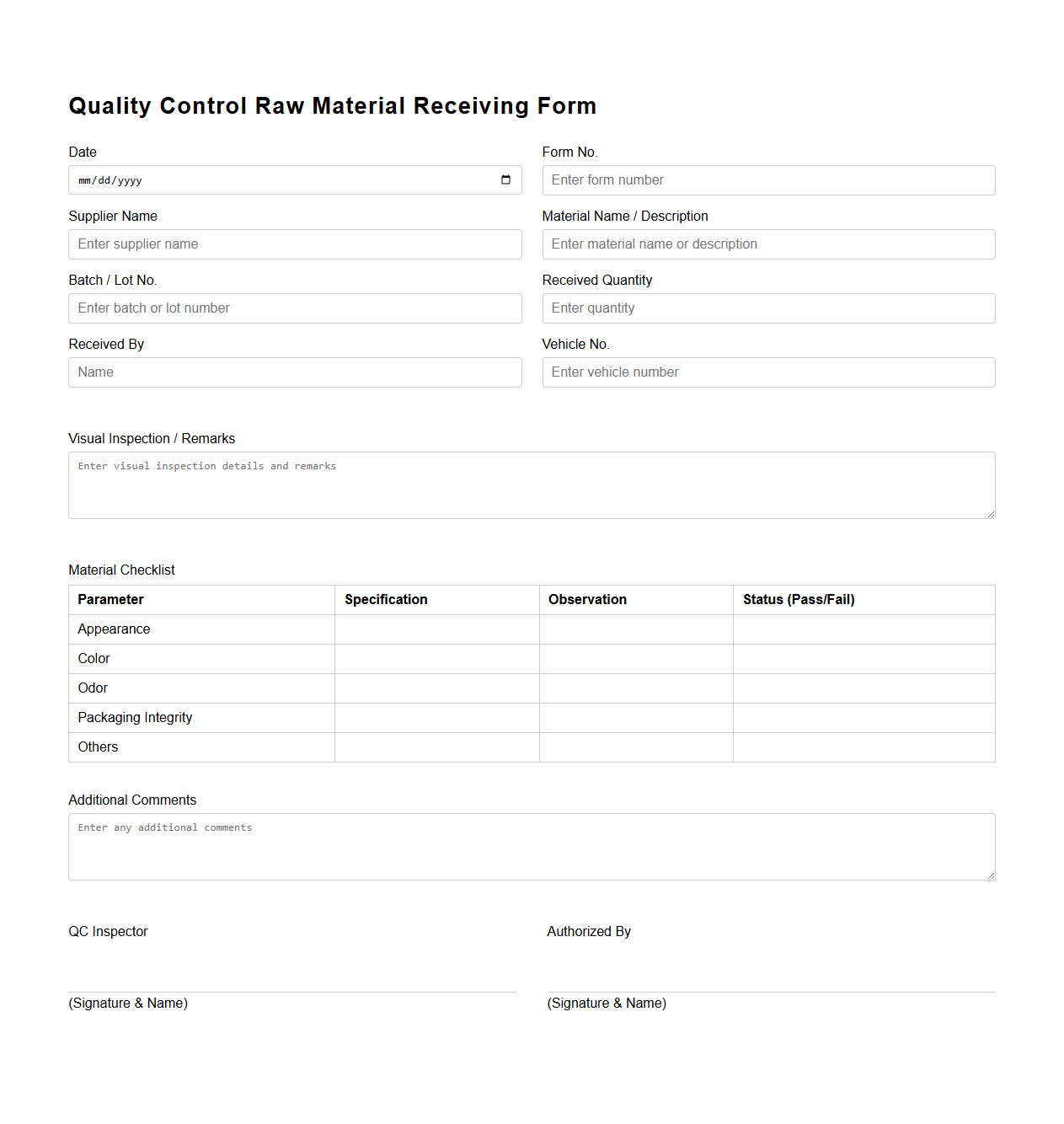

Quality Control Raw Material Receiving Form Sample

A

Quality Control Raw Material Receiving Form Sample document is used to accurately record and verify the specifications and condition of raw materials upon arrival at a manufacturing facility. It ensures compliance with quality standards by capturing critical data such as supplier details, batch numbers, inspection results, and any deviations from the expected criteria. This form plays a crucial role in preventing defective materials from entering the production process and maintaining overall product quality.

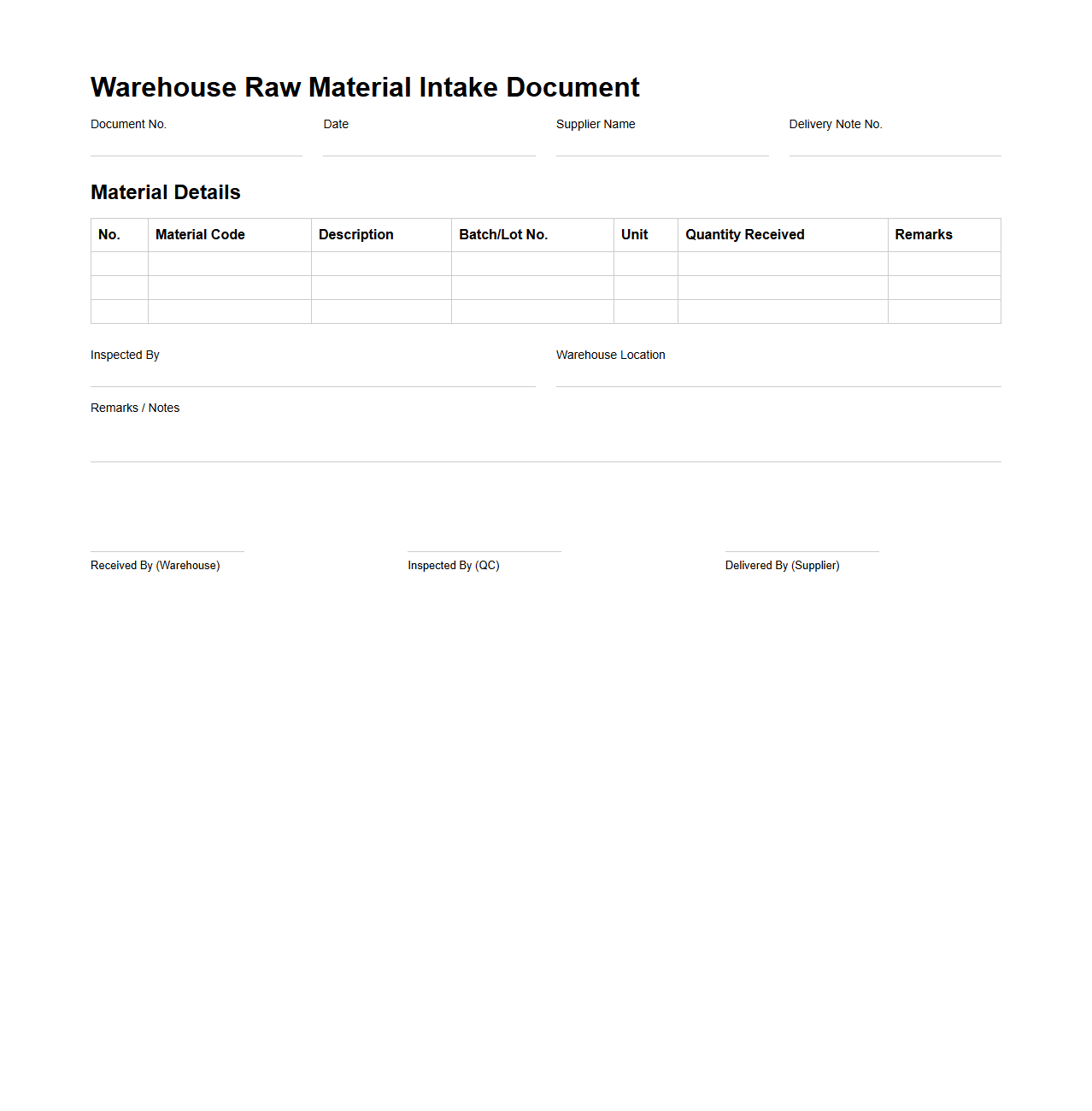

Warehouse Raw Material Intake Document Sample

A

Warehouse Raw Material Intake Document Sample is a standardized form used to record the receipt and inspection of raw materials entering a warehouse. This document ensures accurate tracking of inventory, quality verification, and compliance with supplier specifications. It typically includes details such as purchase order numbers, material descriptions, quantities received, and inspection results.

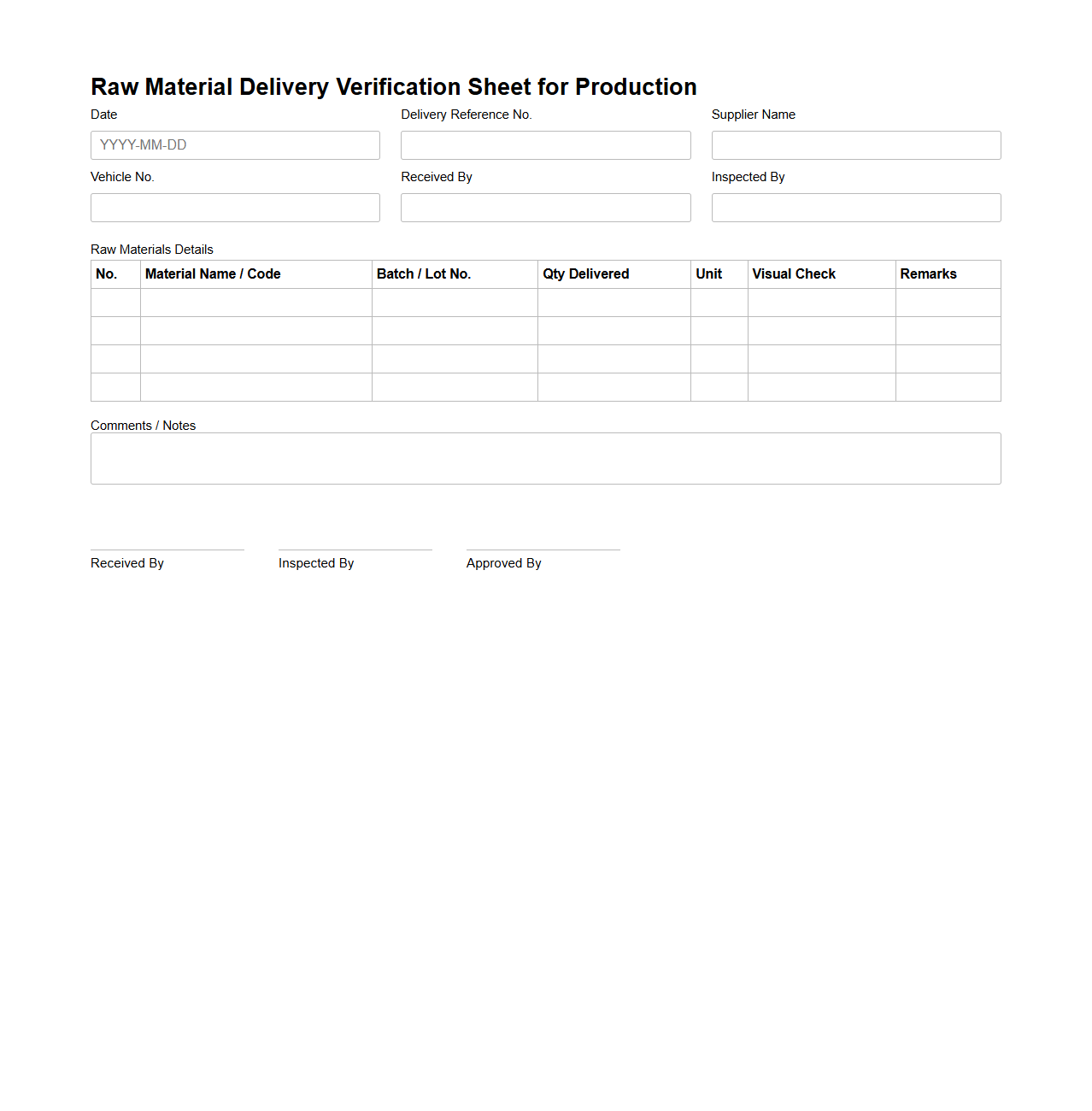

Raw Material Delivery Verification Sheet for Production

A

Raw Material Delivery Verification Sheet for production is a crucial document used to confirm the receipt and quality of raw materials delivered to the manufacturing facility. It records detailed information such as batch numbers, quantities, supplier details, and inspection results to ensure materials meet specified standards before entering the production process. This sheet helps maintain inventory accuracy, traceability, and compliance with quality control protocols.

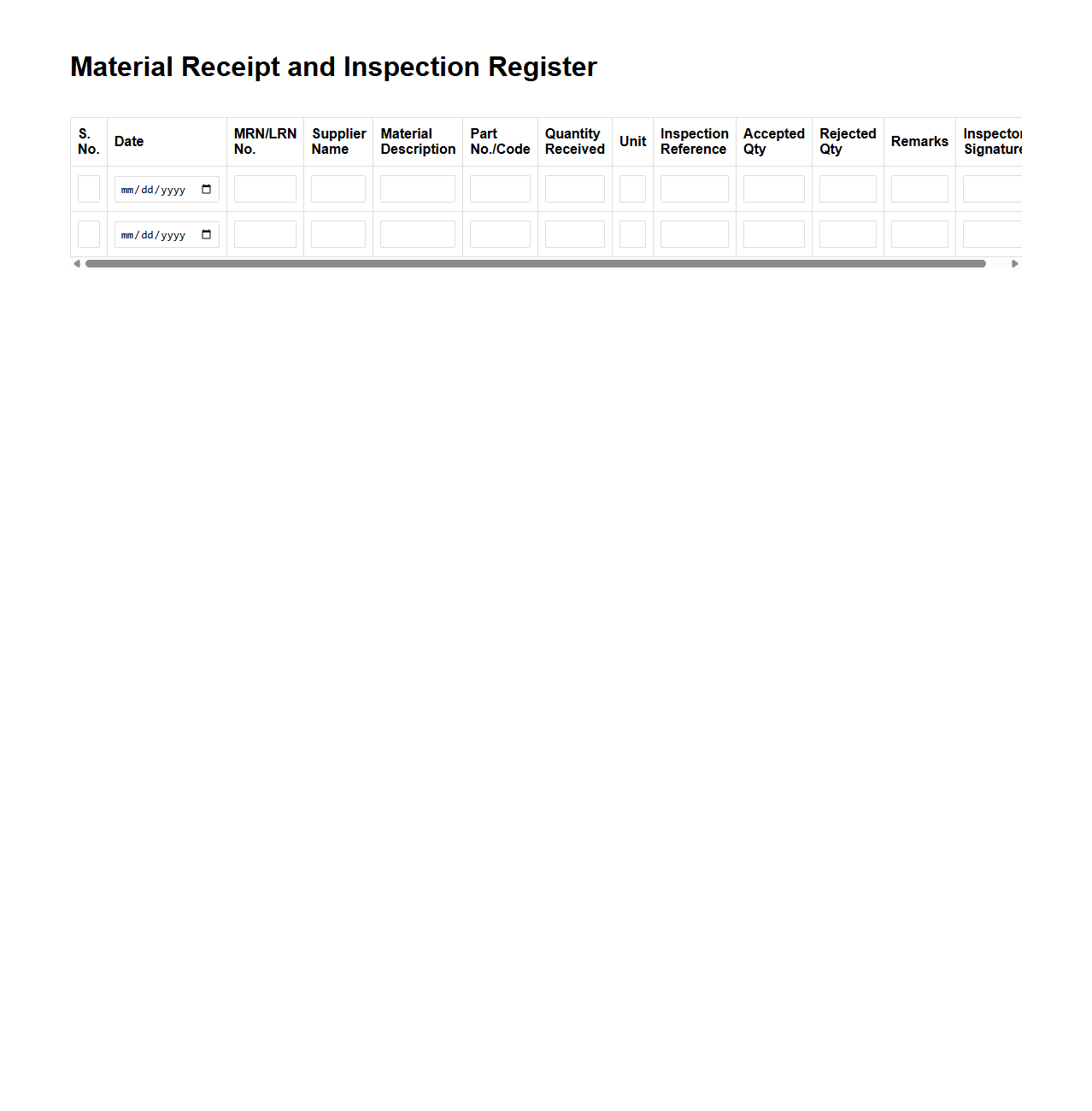

Material Receipt and Inspection Register for Manufacturing

Material Receipt and Inspection Register is a critical

manufacturing document that records the details of raw materials received from suppliers, including quantity, quality, and date of receipt. It serves as a verified log for inspection outcomes, ensuring that materials meet specified standards before entering the production process. Maintaining this register helps in quality control, inventory management, and traceability in the manufacturing workflow.

What critical information must be included in a Raw Material Receiving Document for traceability?

The Raw Material Receiving Document must include the lot number, supplier details, and the exact material description to ensure proper traceability. Additionally, the date of receipt and the quantity received are essential to track inventory accurately. This information allows for efficient identification and recall if necessary.

How does the document verify material specifications and supplier compliance?

The document verifies material specifications by recording the certified test reports or material safety data sheets (MSDS) provided by the supplier. It also includes a section confirming that the received materials meet the purchase order requirements and supplier compliance parameters. This ensures the materials align with the agreed standards before approval.

Which quality assurance checks are recorded on the document upon receipt?

Quality assurance checks such as visual inspection, dimensional verification, and contamination tests are documented on the receiving document. The results from these checks confirm the material's integrity and conformity to standards. Any deviations found during these checks are noted for further action.

How are discrepancies or damaged materials documented and addressed in the sample?

Discrepancies or damaged materials are recorded in a non-conformance report section on the document. The nature of the issue, quantity affected, and initial corrective actions are detailed clearly. This facilitates timely resolution and communication with the supplier for replacements or credits.

What authorization or approval signatures are required on the Raw Material Receiving Document?

The document requires signatures from the receiving warehouse personnel and the quality control inspector to validate the receipt and inspection process. Additionally, a supervisor or manager may need to approve the document to finalize acceptance. These approvals ensure accountability and compliance with company policies.

More Manufacturing Templates