A Production Schedule Document Sample for Manufacturing outlines the timeline, tasks, and resources required to complete manufacturing processes efficiently. It coordinates labor, machinery, and materials to ensure timely product delivery. This document helps optimize workflow and minimize downtime in production operations.

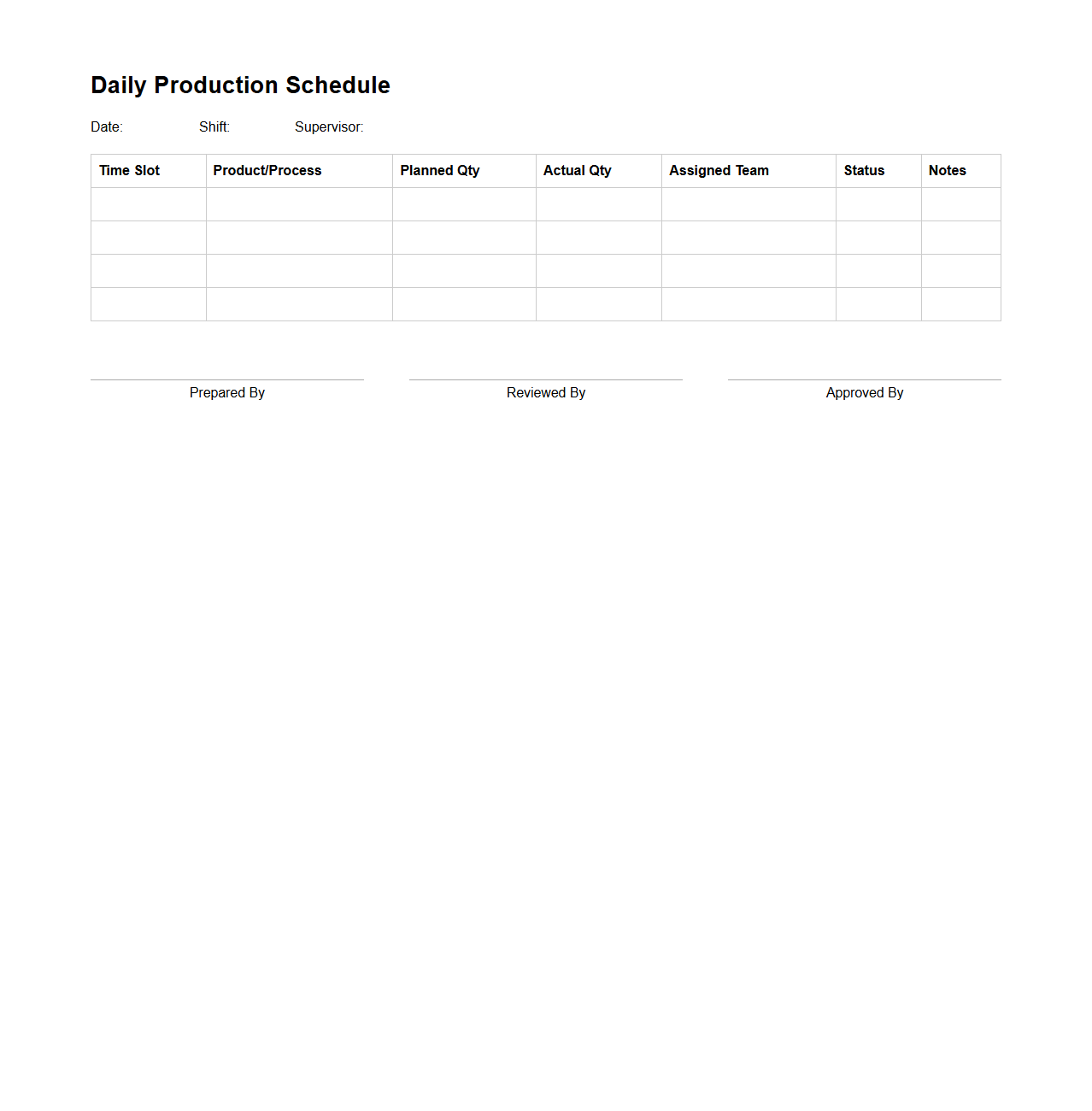

Daily Production Schedule Template for Manufacturing Operations

A

Daily Production Schedule Template for manufacturing operations is a structured document designed to organize and track daily tasks, resources, and timelines essential for efficient production workflows. It outlines production orders, machine assignments, labor allocation, and inventory usage to maximize productivity and minimize downtime. This template serves as a vital communication tool to ensure alignment between production teams and management, enhancing operational efficiency.

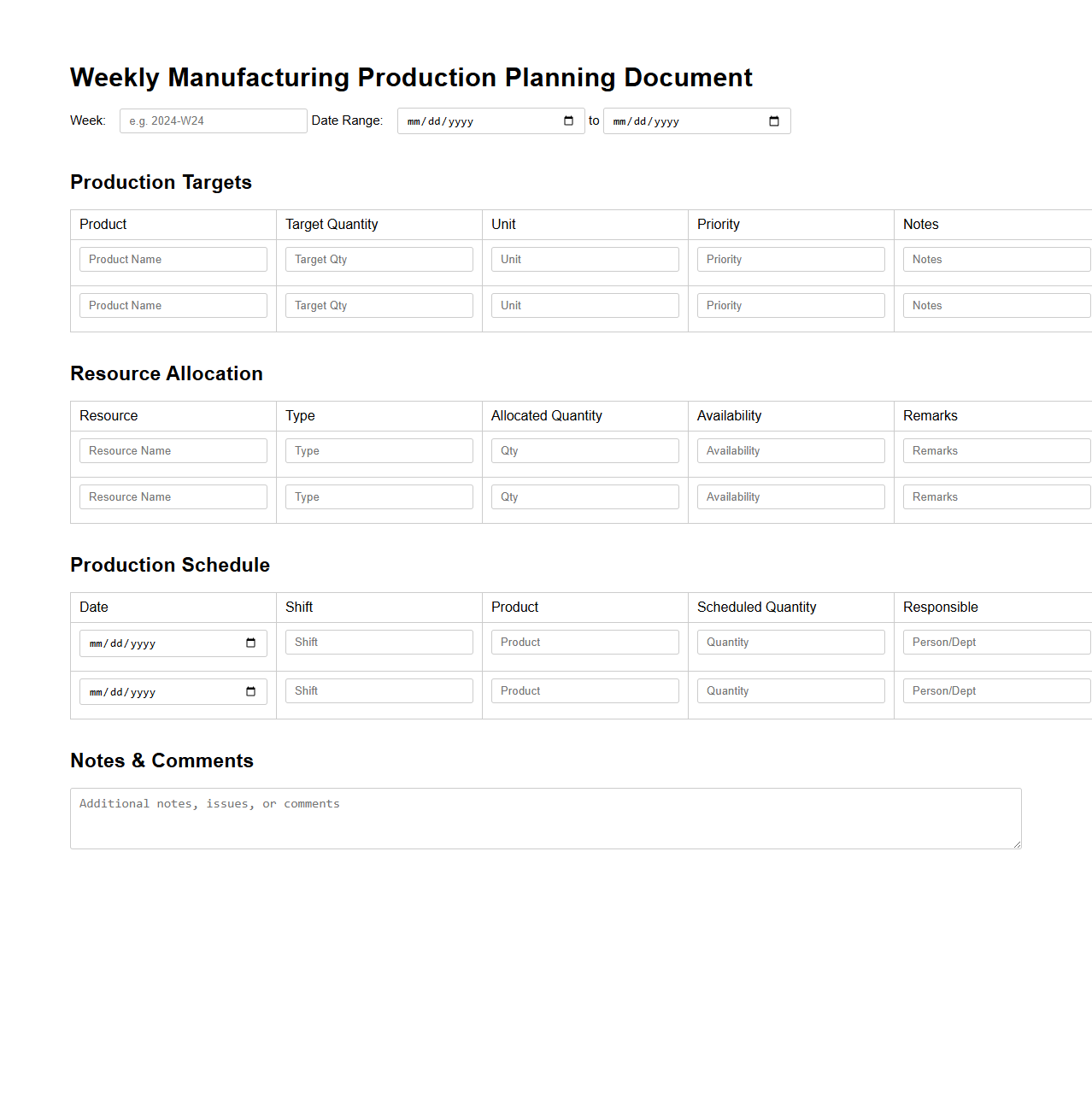

Weekly Manufacturing Production Planning Document

The

Weekly Manufacturing Production Planning Document outlines the scheduled production activities, resource allocation, and workflow timelines for a manufacturing facility within a specific week. It serves as a critical tool to coordinate operations, track progress, and ensure alignment with demand forecasts and inventory levels. This document facilitates efficient manufacturing processes by optimizing capacity utilization and minimizing downtime.

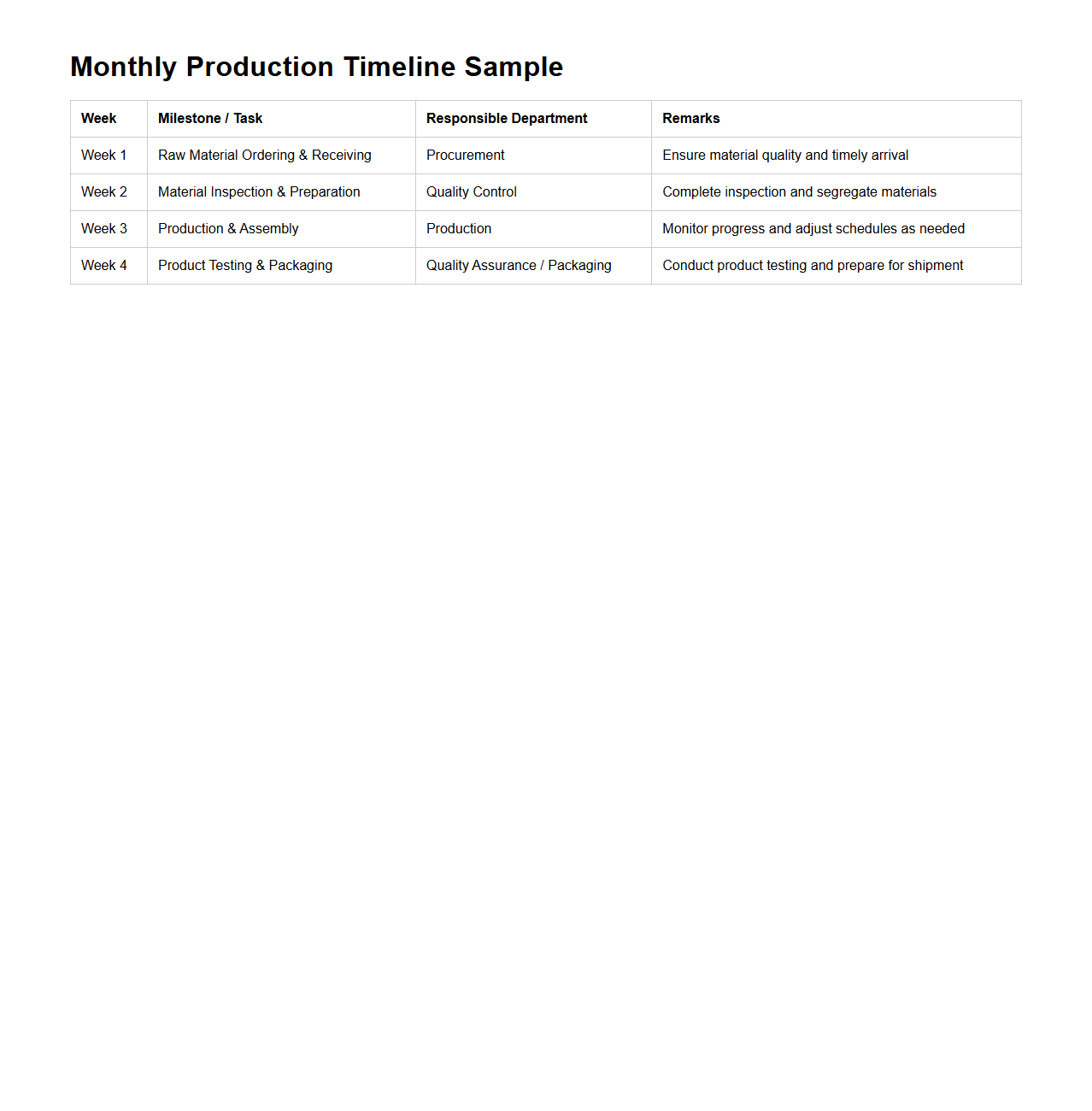

Monthly Production Timeline Sample for Factories

A

Monthly Production Timeline Sample for factories is a detailed schedule that outlines the planned manufacturing activities and deadlines across a given month. It helps factories track production stages, allocate resources efficiently, and ensure timely completion of orders. This document typically includes key milestones such as raw material procurement, assembly phases, quality checks, and shipping dates.

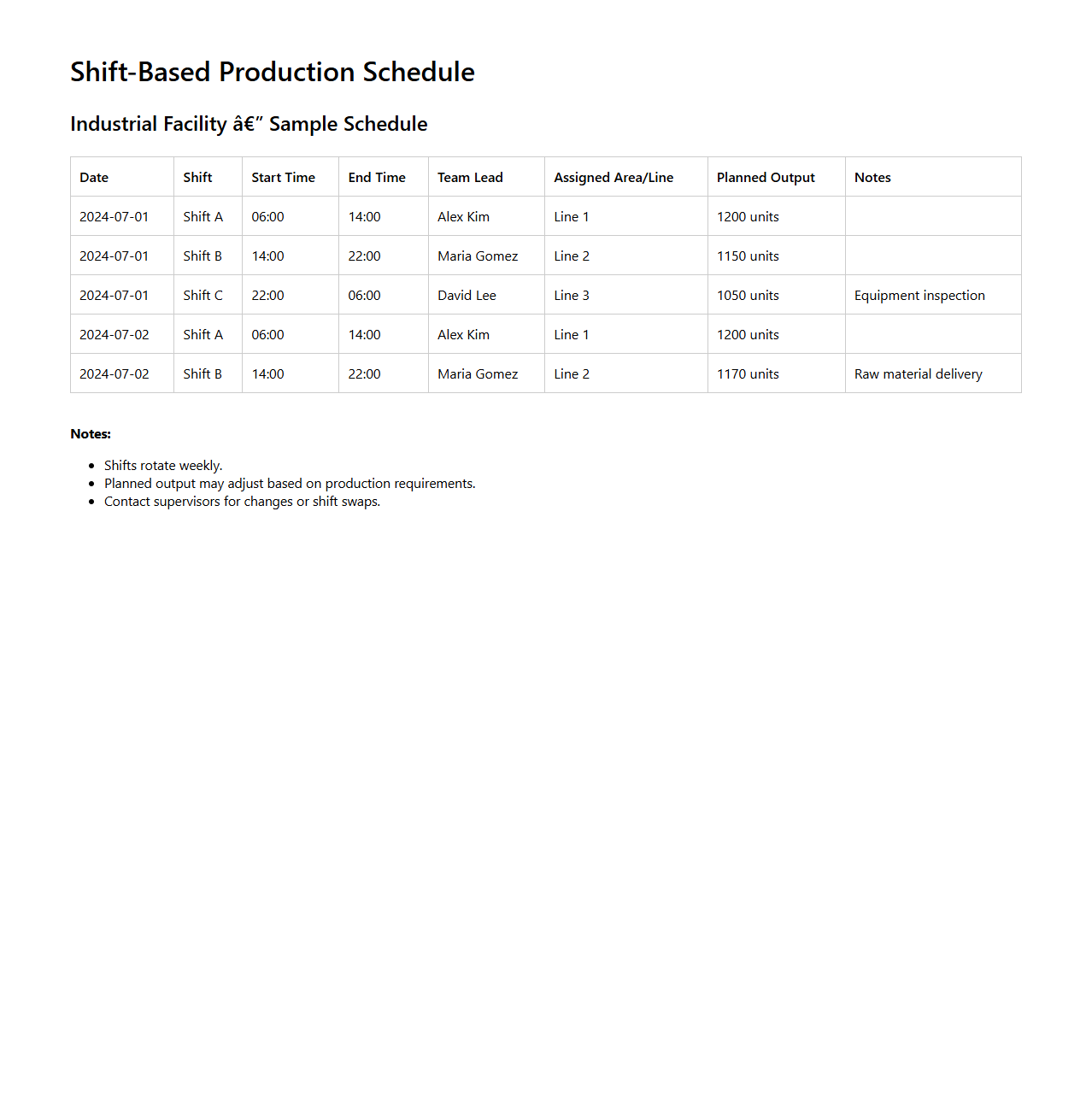

Shift-Based Production Schedule for Industrial Facilities

The

Shift-Based Production Schedule for Industrial Facilities document outlines the detailed allocation of work shifts to optimize manufacturing processes and resource utilization. It includes specific timelines, workforce assignments, and machinery operation periods to ensure continuous production flow and minimize downtime. This schedule supports efficient labor management and aligns production targets with operational capacity.

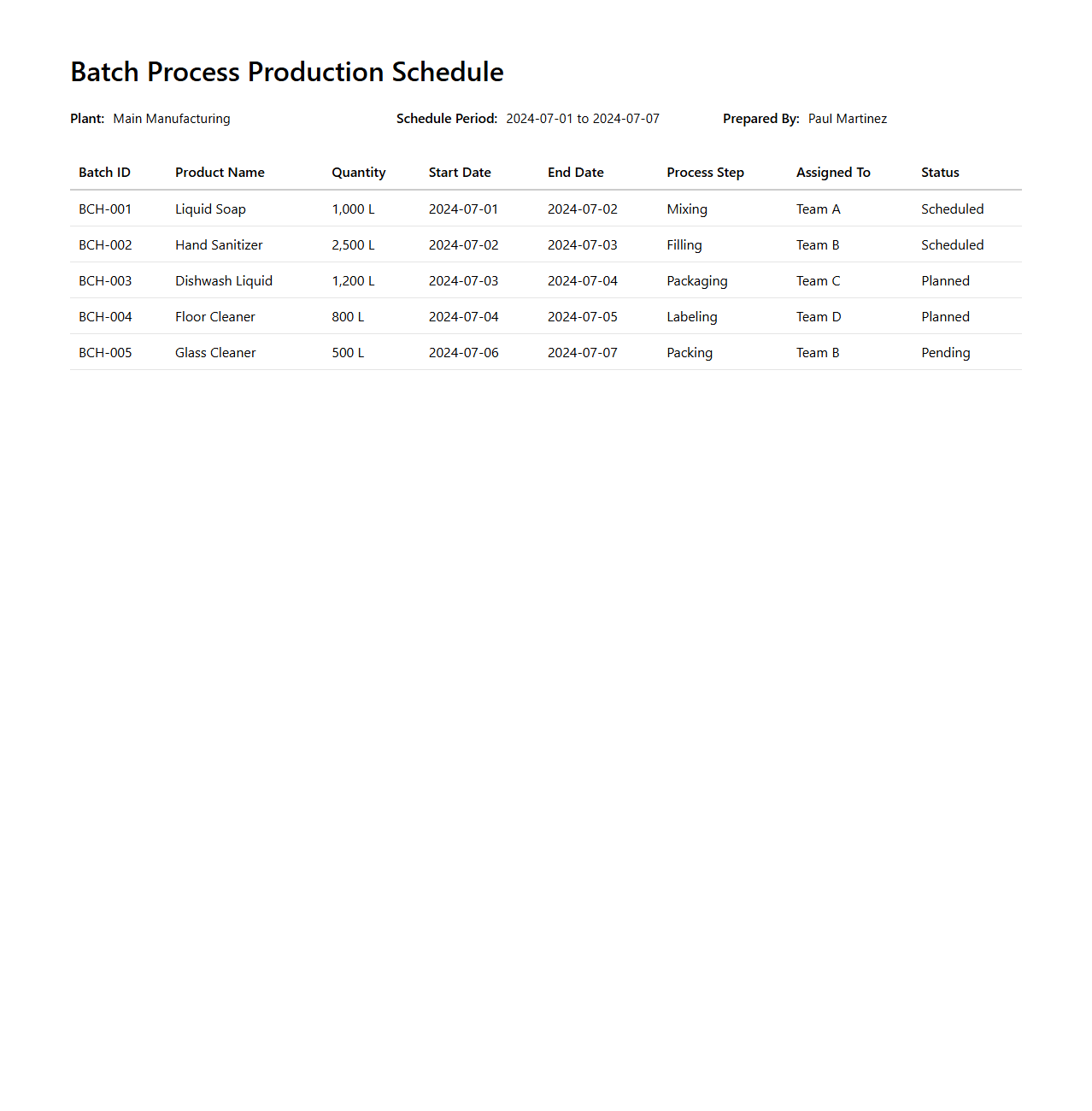

Batch Process Production Schedule Example

A

Batch Process Production Schedule Example document outlines the planned timing and sequencing of production batches within a manufacturing process. It details start and end times for each batch, resource allocation, and equipment usage to ensure efficient workflow and meet demand targets. This schedule is essential for optimizing production efficiency, minimizing downtime, and maintaining quality control in batch manufacturing environments.

Assembly Line Production Schedule Document

An

Assembly Line Production Schedule Document is a detailed plan that outlines the timing, sequence, and allocation of tasks for each stage of the assembly line process. It ensures efficient resource utilization, minimizes downtime, and coordinates workforce activities to meet production targets and deadlines. This document is essential for maintaining a continuous flow in manufacturing operations and optimizing overall productivity.

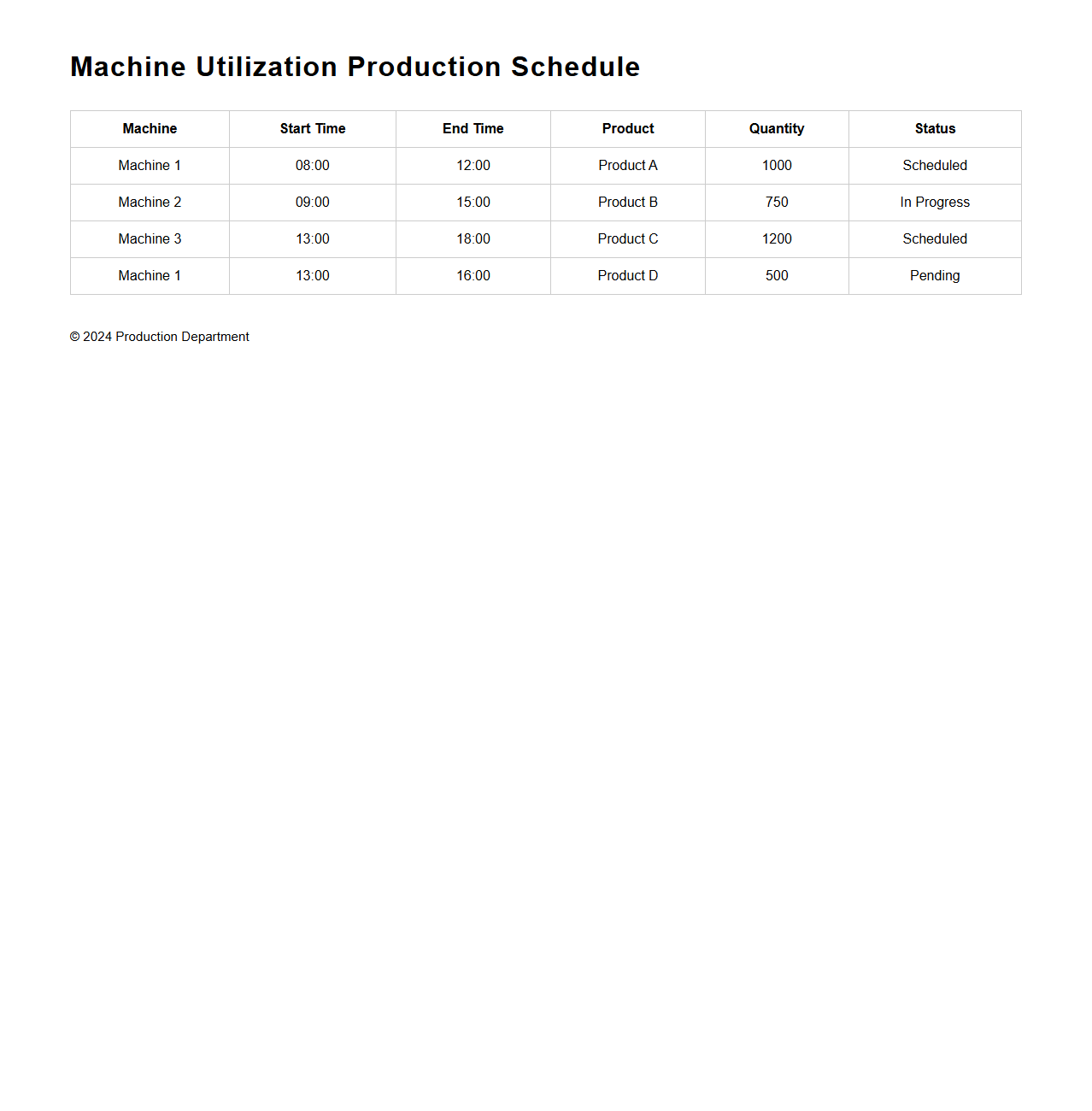

Machine Utilization Production Schedule Layout

The

Machine Utilization Production Schedule Layout document outlines the allocation and timing of machinery use within a manufacturing process to maximize efficiency and minimize downtime. It details machine operating hours, maintenance periods, and production tasks, helping managers optimize workflow and resource allocation. This document is crucial for balancing production capacity with demand, ensuring smooth operations and reducing bottlenecks.

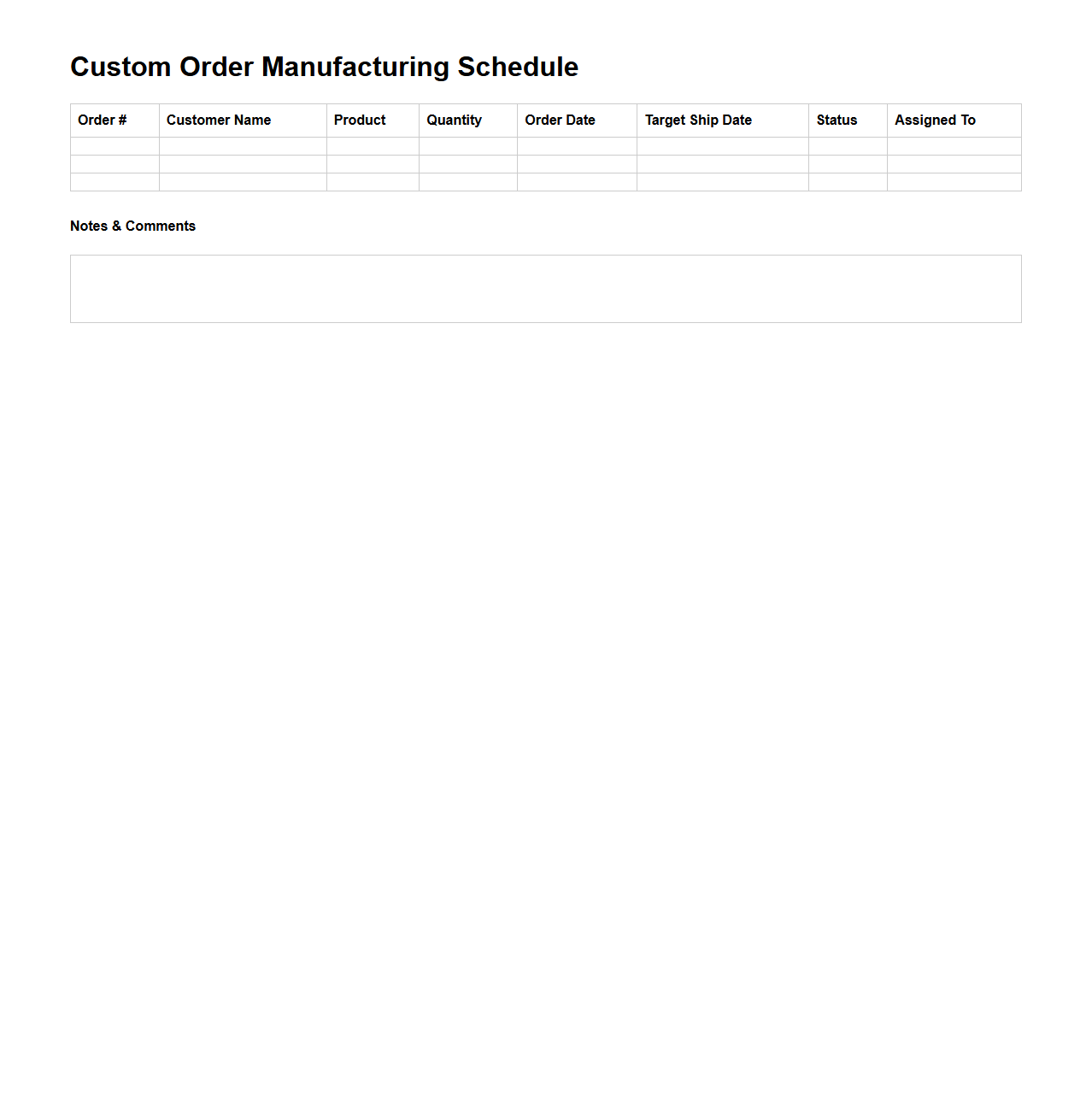

Custom Order Manufacturing Schedule Template

A

Custom Order Manufacturing Schedule Template document is a structured tool used to plan and track production timelines for bespoke manufacturing projects. It organizes order-specific details such as client requirements, material procurement, production phases, and delivery deadlines to ensure efficient workflow management. This template enhances coordination between departments, reduces lead times, and improves overall production accuracy for custom orders.

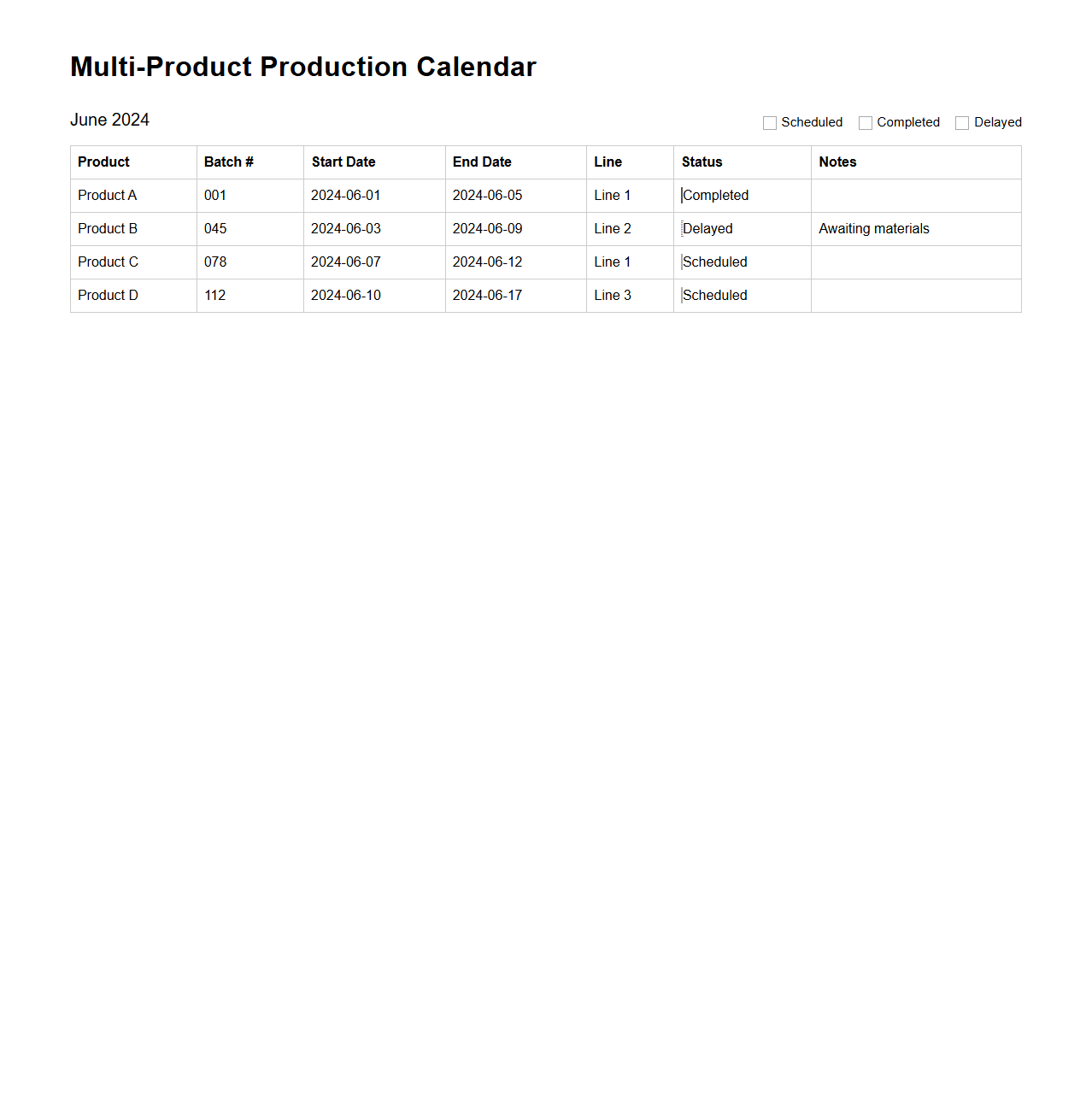

Multi-Product Production Calendar for Manufacturers

The

Multi-Product Production Calendar for manufacturers is a detailed scheduling document that coordinates the production timelines of multiple products within a manufacturing facility. It outlines key dates for raw material procurement, production phases, quality checks, and shipment schedules, ensuring efficient resource allocation and minimizing downtime. This calendar is essential for optimizing manufacturing workflows and meeting delivery commitments across different product lines.

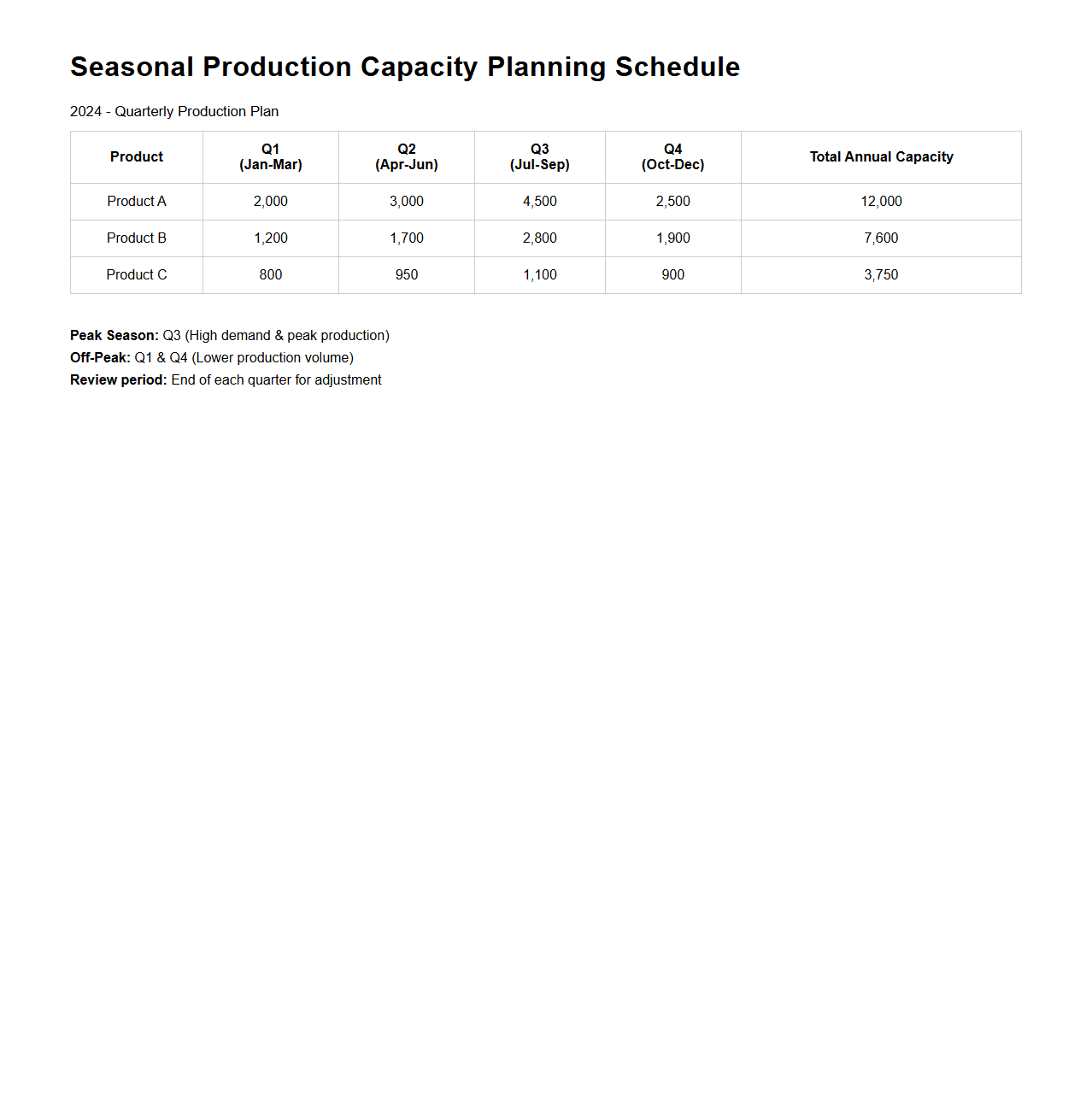

Seasonal Production Capacity Planning Schedule

A

Seasonal Production Capacity Planning Schedule document outlines the forecasted manufacturing capabilities aligned with fluctuating seasonal demand. It helps organizations optimize resource allocation, including labor, machinery, and raw materials, to meet peak production periods efficiently. This schedule supports minimizing downtime and inventory costs by synchronizing production output with market seasonality.

What key components should be included in a production schedule document for manufacturing?

A production schedule document must include detailed timelines for each manufacturing phase, clearly defining start and end dates. It should list all required resources, including machinery, workforce, and materials, to ensure smooth operations. Additionally, it must specify the priorities and quantities of products to be produced to align with demand forecasts.

How does the production schedule document align with inventory and supply chain management?

The production schedule serves as a critical link between manufacturing and inventory management by dictating material requirements and restocking timelines. It helps synchronize supply chain activities, ensuring raw materials and components arrive just in time to avoid delays. By aligning production with inventory levels, it minimizes excess stock and improves overall efficiency.

Which stakeholders are responsible for updating and maintaining the production schedule document?

Production planners and manufacturing supervisors are the primary stakeholders tasked with updating the production schedule document. Supply chain managers also play a vital role in ensuring the schedule reflects current material availability. Senior management reviews the schedule to align production goals with business objectives and customer demand.

What data sources are required for accurate production scheduling and tracking?

Accurate production scheduling relies on data from inventory management systems, real-time equipment status, and workforce availability. Sales forecasts and customer orders provide essential input to prioritize production runs. Additionally, supplier lead times and logistics data help optimize scheduling and reduce production lead times.

How does the document address potential delays or deviations in the manufacturing process?

The production schedule document includes built-in contingency plans and buffer times to accommodate unforeseen delays or process deviations. It outlines clear protocols for escalation and reallocation of resources to mitigate disruptions quickly. Continuous tracking and periodic updates ensure the schedule remains realistic and adaptive to changes.

More Manufacturing Templates