A Incident Report Document Sample for Manufacturing provides a structured template to record and analyze workplace accidents or safety breaches. It captures critical details such as the date, time, location, individuals involved, and a description of the incident to facilitate timely investigation and corrective actions. Using this document helps improve safety protocols and ensures regulatory compliance within manufacturing environments.

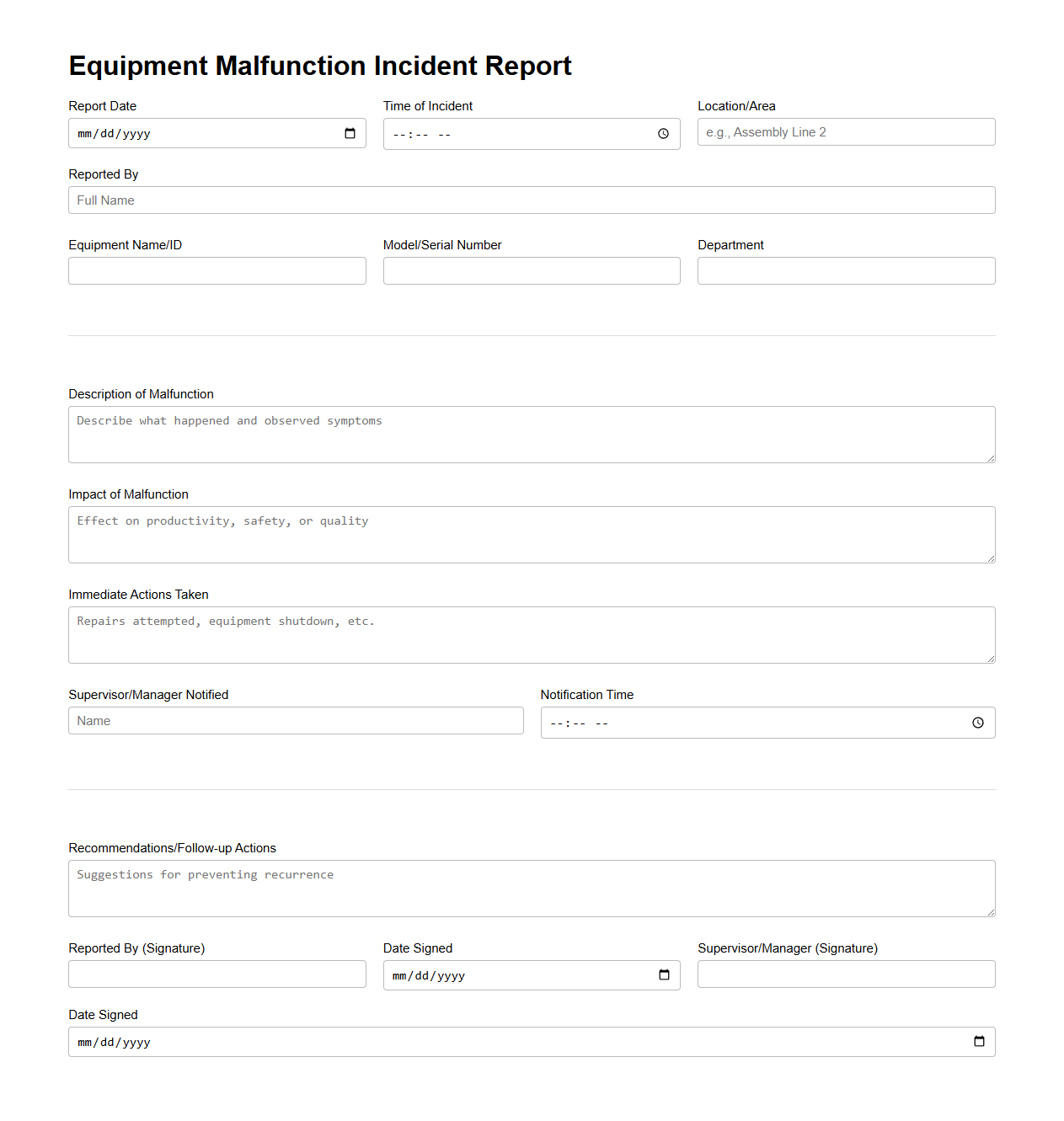

Equipment Malfunction Incident Report Sample for Manufacturing

An

Equipment Malfunction Incident Report Sample for Manufacturing document provides a structured template for recording details of machinery failures during production processes. It typically includes sections for identifying the equipment involved, the nature and time of the malfunction, immediate actions taken, and impact on production. This report supports root cause analysis, corrective measures, and helps maintain quality and safety standards in manufacturing operations.

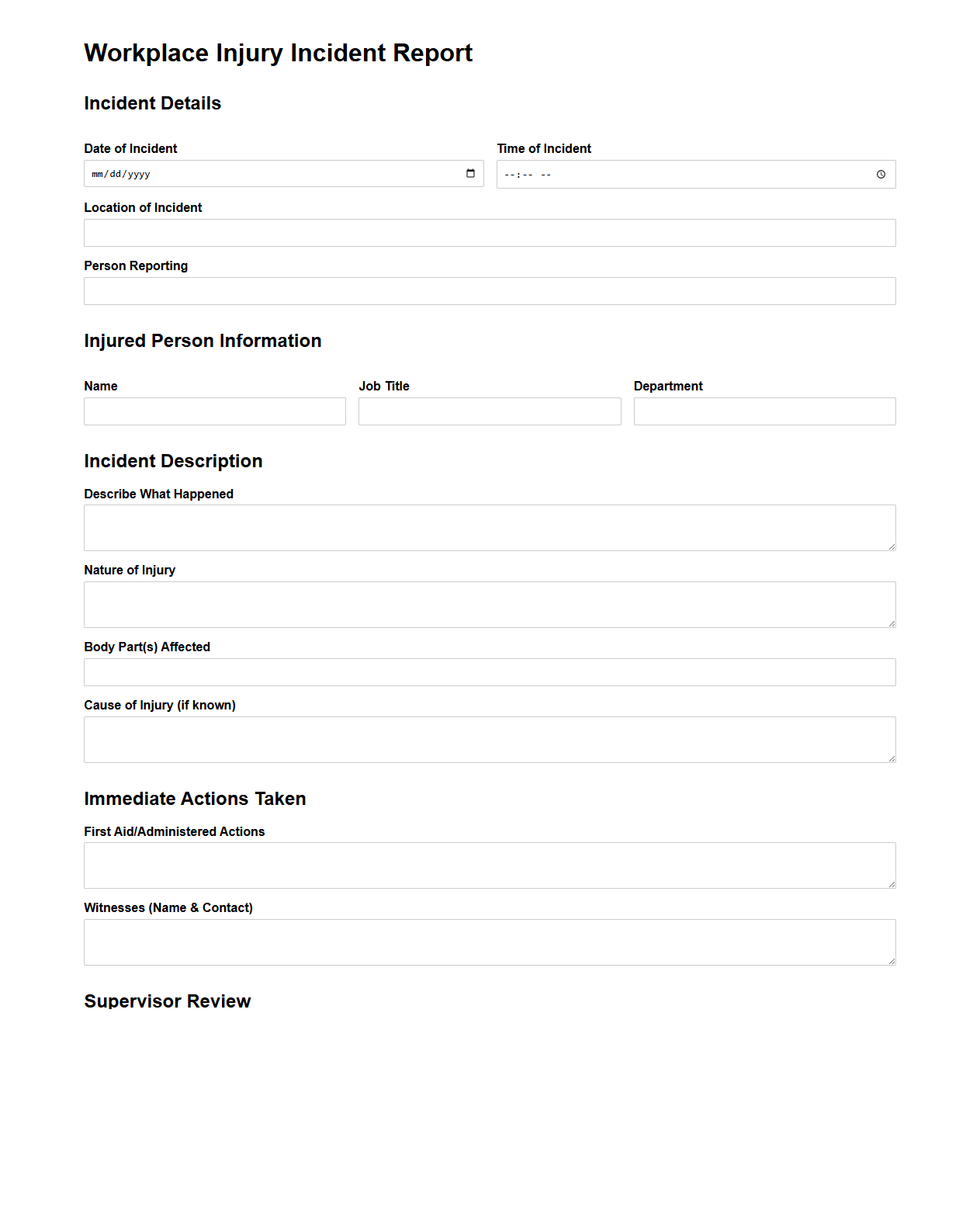

Workplace Injury Incident Report Sample for Manufacturing

A

Workplace Injury Incident Report Sample for Manufacturing is a standardized document used to record detailed information about accidents or injuries occurring on the manufacturing floor. It captures critical data such as the nature of the injury, affected body parts, equipment involved, and environmental conditions at the time of the incident. This report helps organizations analyze risks, comply with OSHA regulations, and implement safety improvements to prevent future incidents.

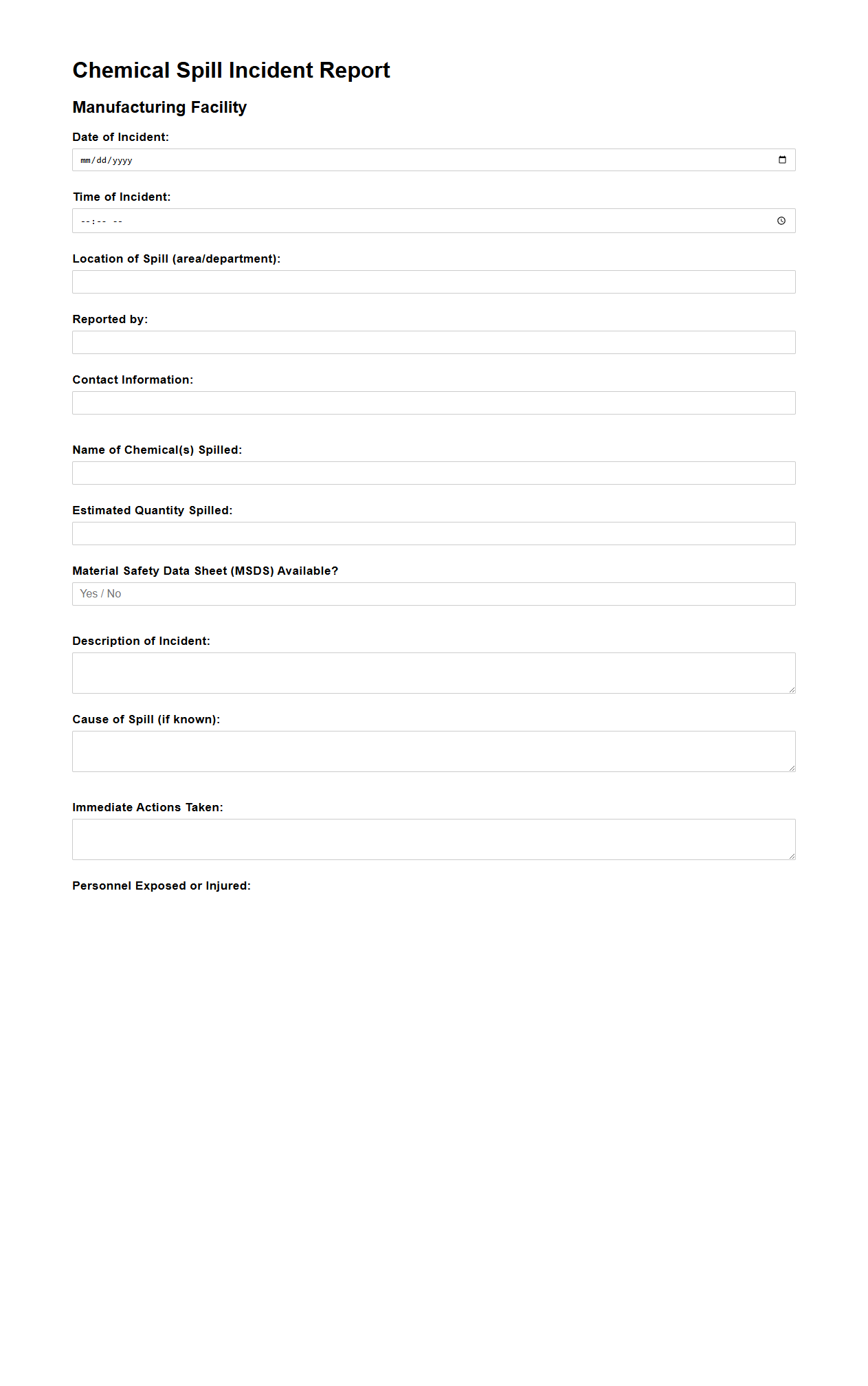

Chemical Spill Incident Report Document Sample for Manufacturing

A

Chemical Spill Incident Report Document Sample for Manufacturing is a standardized template designed to capture detailed information about chemical spill events within a manufacturing facility. It includes sections for identifying the spilled substance, time and location of the spill, extent of contamination, personnel involved, and immediate containment measures taken. This document ensures compliance with safety regulations, facilitates incident analysis, and supports effective risk management and preventive strategies.

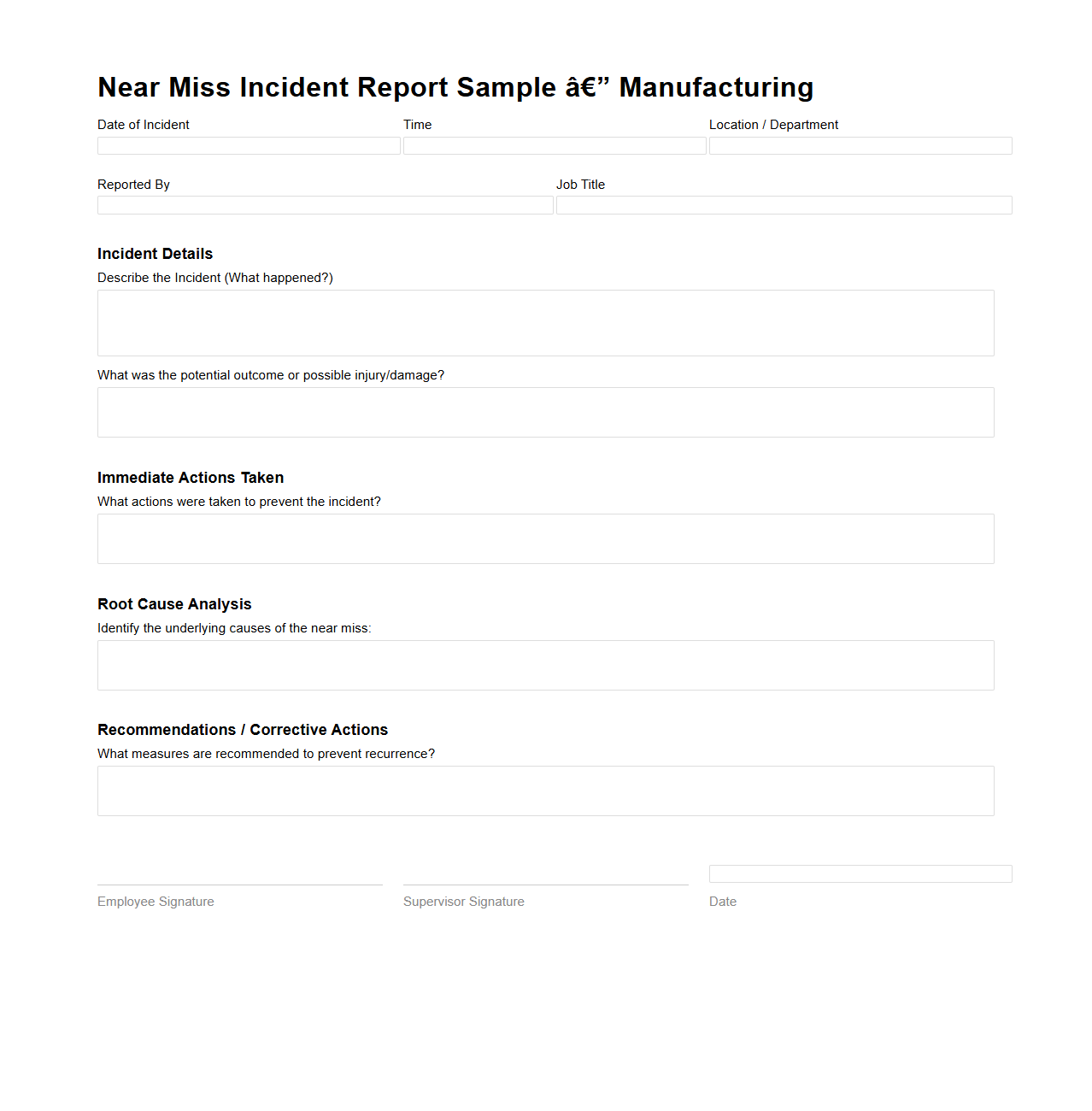

Near Miss Incident Report Sample for Manufacturing

A

Near Miss Incident Report Sample for manufacturing is a structured document designed to capture detailed information about incidents that could have caused harm or damage but were narrowly avoided. This report helps organizations identify potential hazards, analyze root causes, and implement corrective actions to prevent future accidents. By systematically documenting near misses, manufacturers can enhance workplace safety, reduce downtime, and promote a proactive safety culture.

Fire Incident Report Sample for Manufacturing Facility

A

Fire Incident Report Sample for Manufacturing Facility document serves as a standardized template to detail the occurrence, causes, and consequences of fire incidents within a manufacturing setting. It systematically records critical information such as the date, time, location, personnel involved, damage assessment, and emergency response actions taken. This report is essential for improving safety protocols, ensuring regulatory compliance, and facilitating thorough investigation and prevention measures.

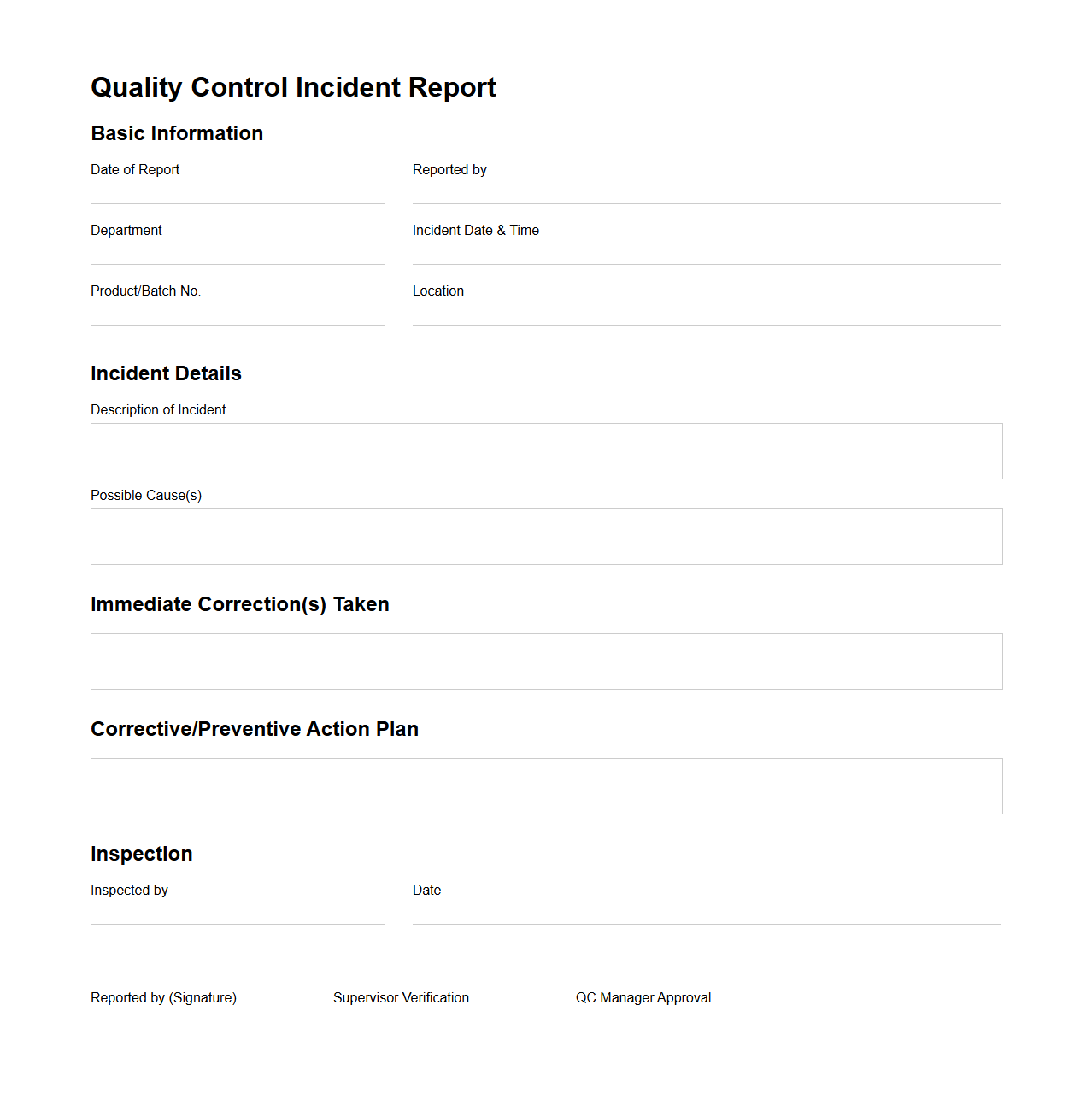

Quality Control Incident Report Document Sample for Manufacturing

A

Quality Control Incident Report Document Sample for manufacturing serves as a standardized template to record and analyze deviations from quality standards during the production process. It captures crucial details such as the nature of the defect, time of occurrence, responsible personnel, and corrective actions taken to prevent recurrence. This document ensures consistent monitoring, facilitates root cause analysis, and supports compliance with industry quality management systems.

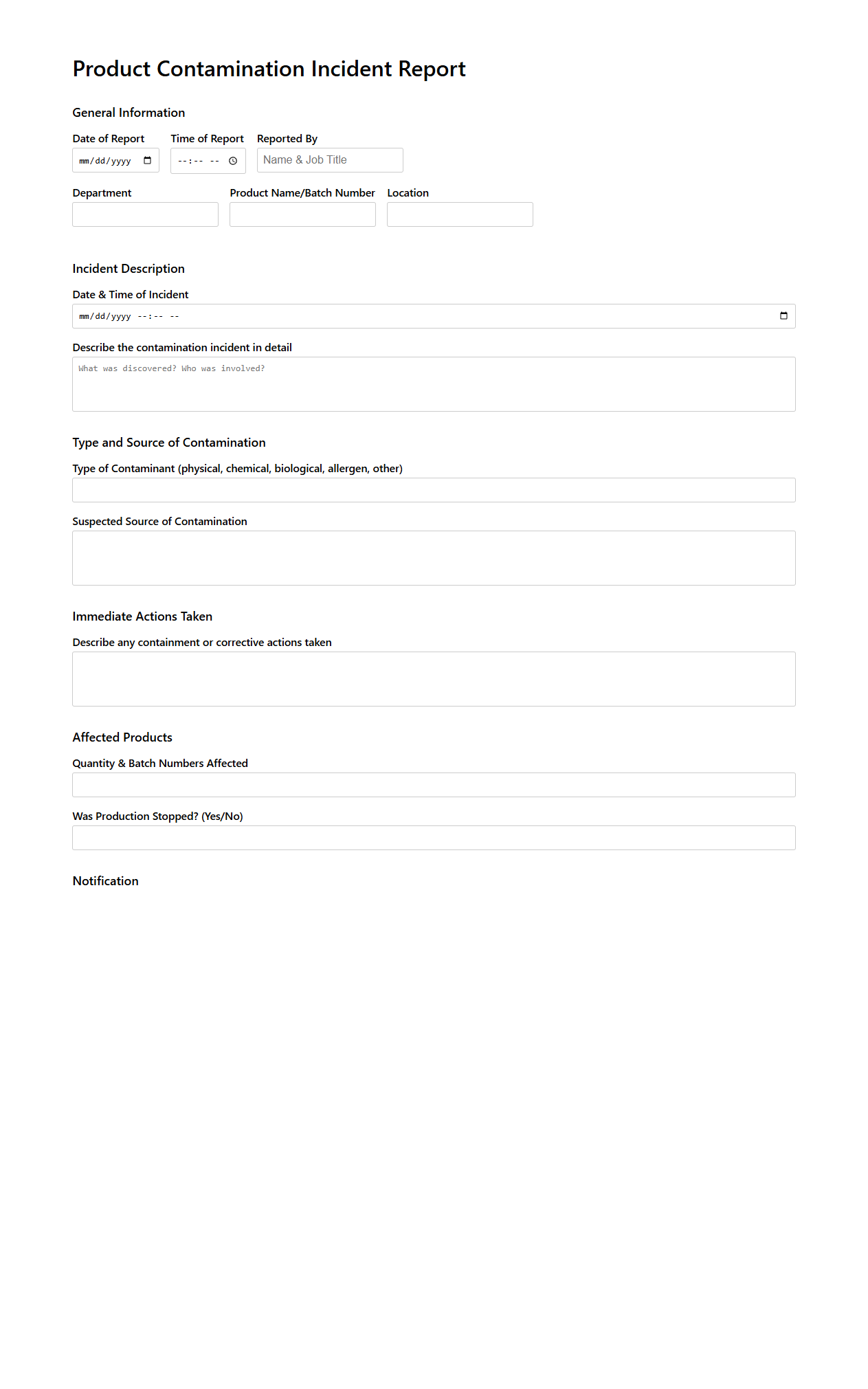

Product Contamination Incident Report Sample for Manufacturing

A

Product Contamination Incident Report Sample for manufacturing is a detailed document used to record and analyze instances where a product becomes contaminated during the production process. It includes essential information such as the type of contamination, affected batch numbers, root cause analysis, corrective actions taken, and preventive measures to avoid recurrence. This report is critical for maintaining quality control, ensuring compliance with regulatory standards, and safeguarding consumer safety.

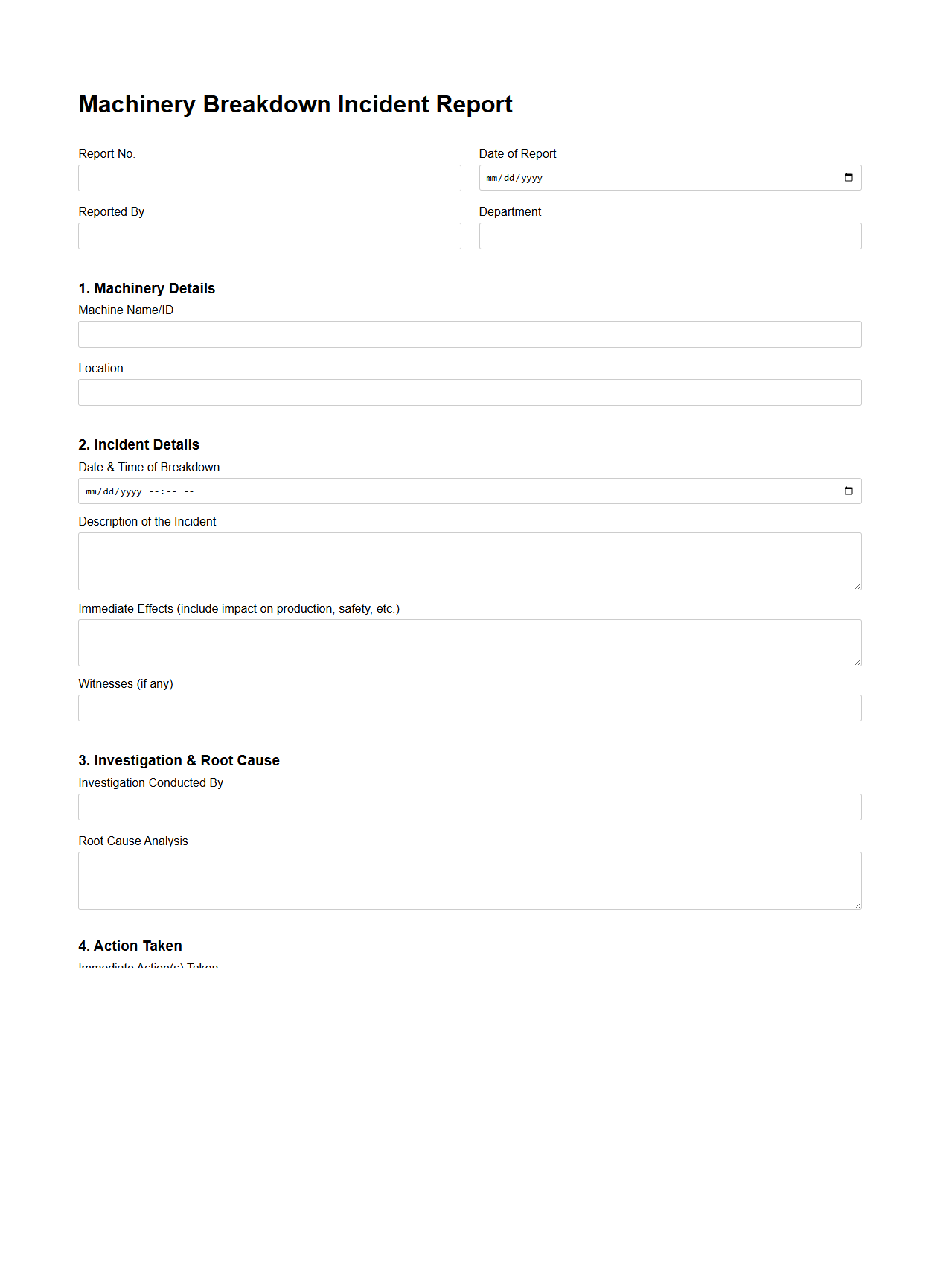

Machinery Breakdown Incident Report Sample for Manufacturing

A

Machinery Breakdown Incident Report Sample for manufacturing is a standardized document used to record detailed information about equipment failures during production processes. It captures essential data such as the machinery involved, the time and cause of the breakdown, and immediate corrective actions taken to minimize downtime. This report aids in identifying recurring issues, improving maintenance strategies, and ensuring compliance with safety and operational protocols.

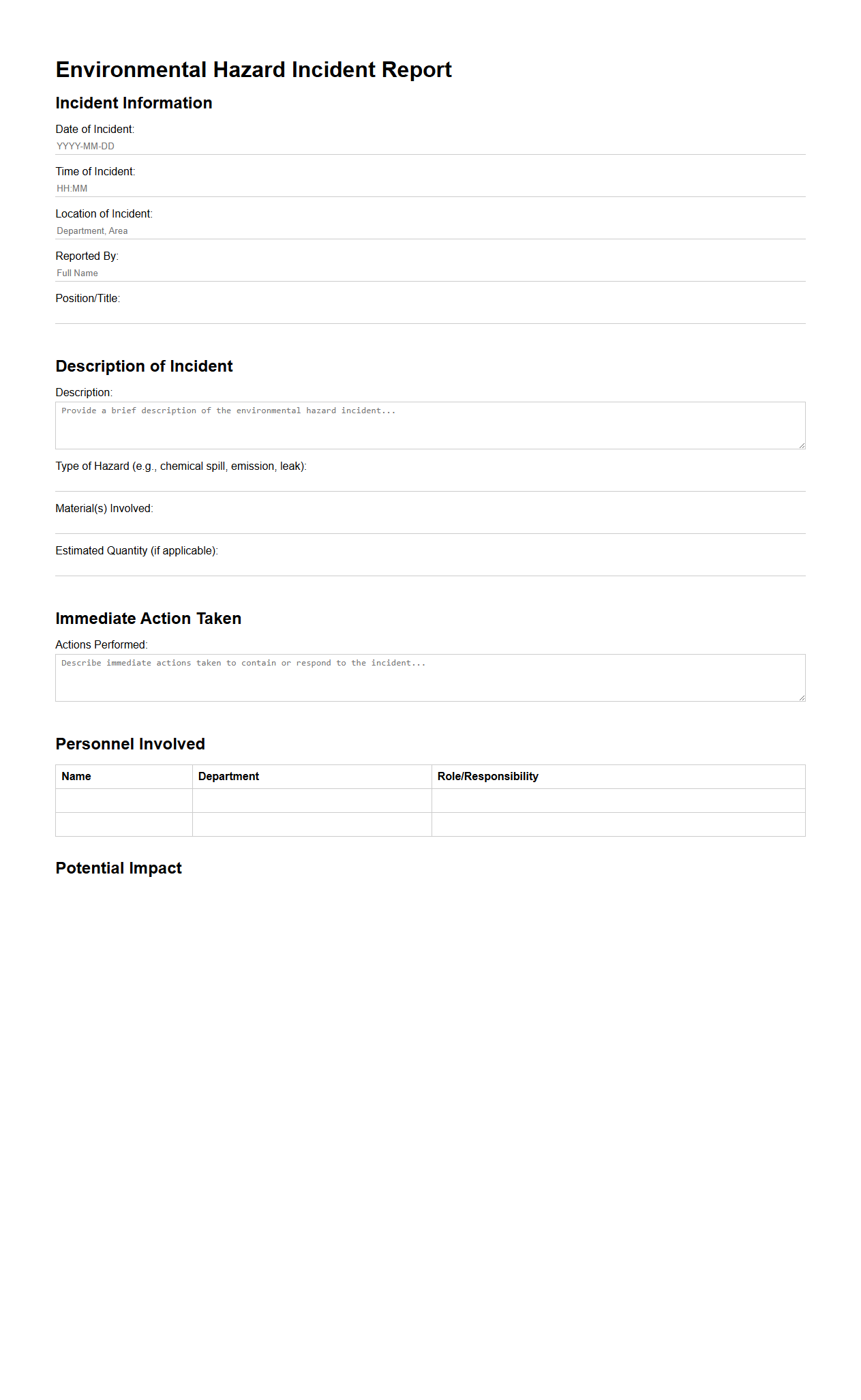

Environmental Hazard Incident Report Document Sample for Manufacturing

An

Environmental Hazard Incident Report document sample for manufacturing serves as a structured template to record and analyze incidents involving environmental risks such as chemical spills, emissions, or waste management failures. It captures critical data including incident description, affected areas, response actions, and impact assessment to ensure compliance with environmental regulations and improve workplace safety. This document is essential for manufacturing facilities to systematically address and mitigate environmental hazards while supporting regulatory audits and continuous improvement efforts.

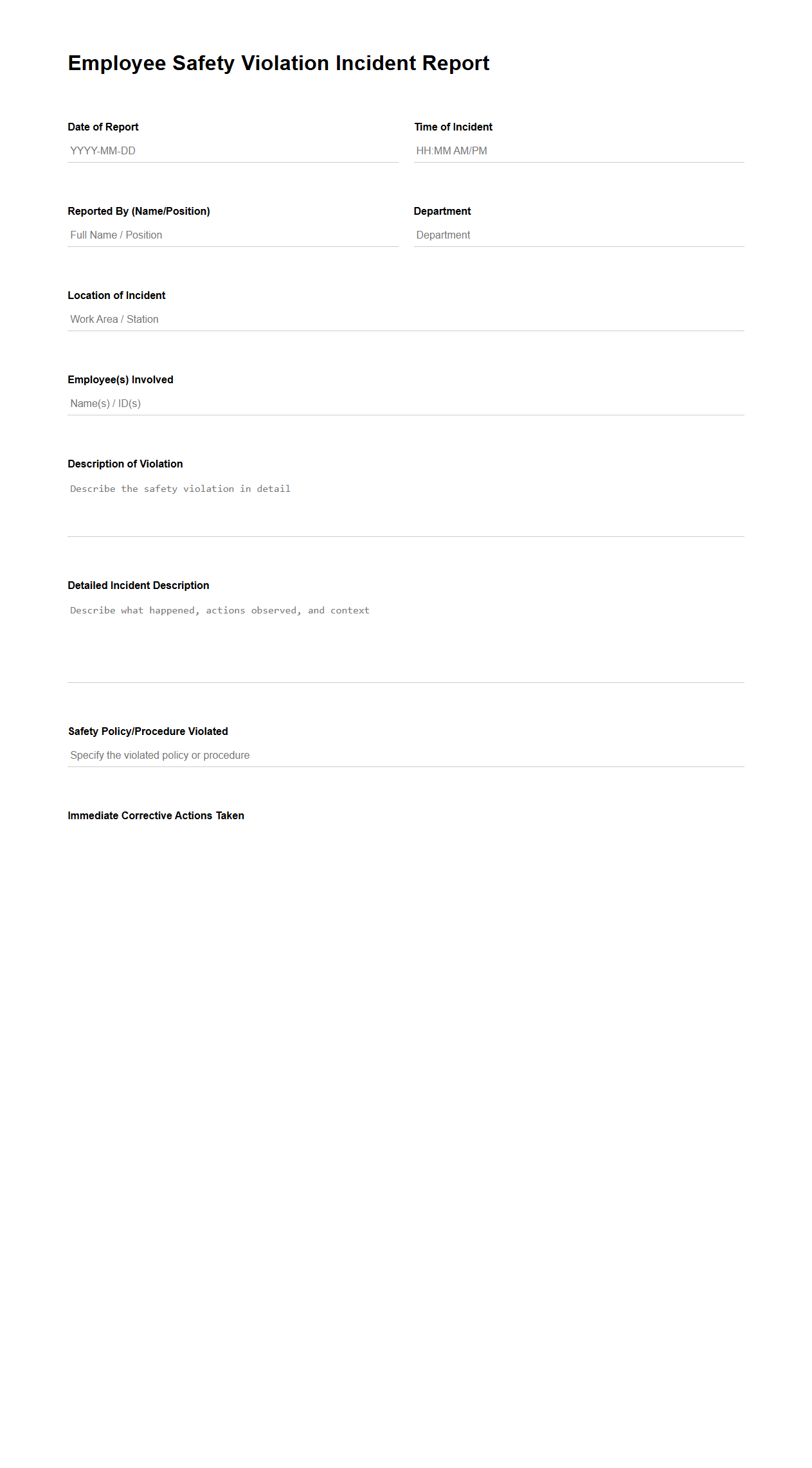

Employee Safety Violation Incident Report Sample for Manufacturing

An

Employee Safety Violation Incident Report Sample for manufacturing is a standardized document used to record and detail instances where employees breach established safety protocols in a manufacturing environment. This report captures critical information such as the nature of the violation, date, time, location, involved personnel, and corrective actions taken to prevent recurrence. It serves as a vital tool for compliance monitoring, risk management, and fostering a safer workplace culture.

What specific incident details must be documented in a manufacturing incident report sample?

The incident report must document the exact date, time, and location of the event. It should include detailed descriptions of the incident, including the sequence of events leading up to the occurrence. Additionally, information about personnel involved and any equipment affected is critical for a comprehensive record.

Which sections are essential for ensuring regulatory compliance in the incident report document?

Essential sections include a detailed incident description, immediate corrective actions taken, and notifications made to regulatory authorities. The report must also capture any witness statements and photographic evidence to provide a complete overview. Proper documentation of these elements ensures adherence to industry regulations and legal standards.

How does the report structure facilitate root cause analysis in manufacturing incidents?

The structured layout includes sections for incident facts, contributing factors, and preliminary analysis, enabling thorough examination. By organizing data systematically, it supports identifying underlying causes rather than just symptoms. This approach is key to preventing recurrence through effective corrective measures.

What roles and responsibilities are defined within the incident report sample template?

The template clearly delineates responsibilities such as who reports the incident, who investigates, and who approves the corrective actions. Assigning roles ensures accountability and streamlines communication during the incident resolution process. This clarity helps maintain operational efficiency and safety standards.

How does the document ensure clarity and accountability in incident follow-up actions?

The incident report includes follow-up action plans with assigned responsible persons and specific deadlines. Clear documentation of these follow-ups promotes transparency and tracks the progress of corrective measures. This framework fosters accountability and continuous improvement within the manufacturing process.

More Manufacturing Templates