A Standard Operating Procedure Document Sample for Machine Operation provides a clear, step-by-step guide to ensure consistent and safe use of machinery. It outlines key safety measures, operational steps, and maintenance requirements to minimize errors and enhance productivity. Following this document helps standardize processes and improves compliance with industry regulations.

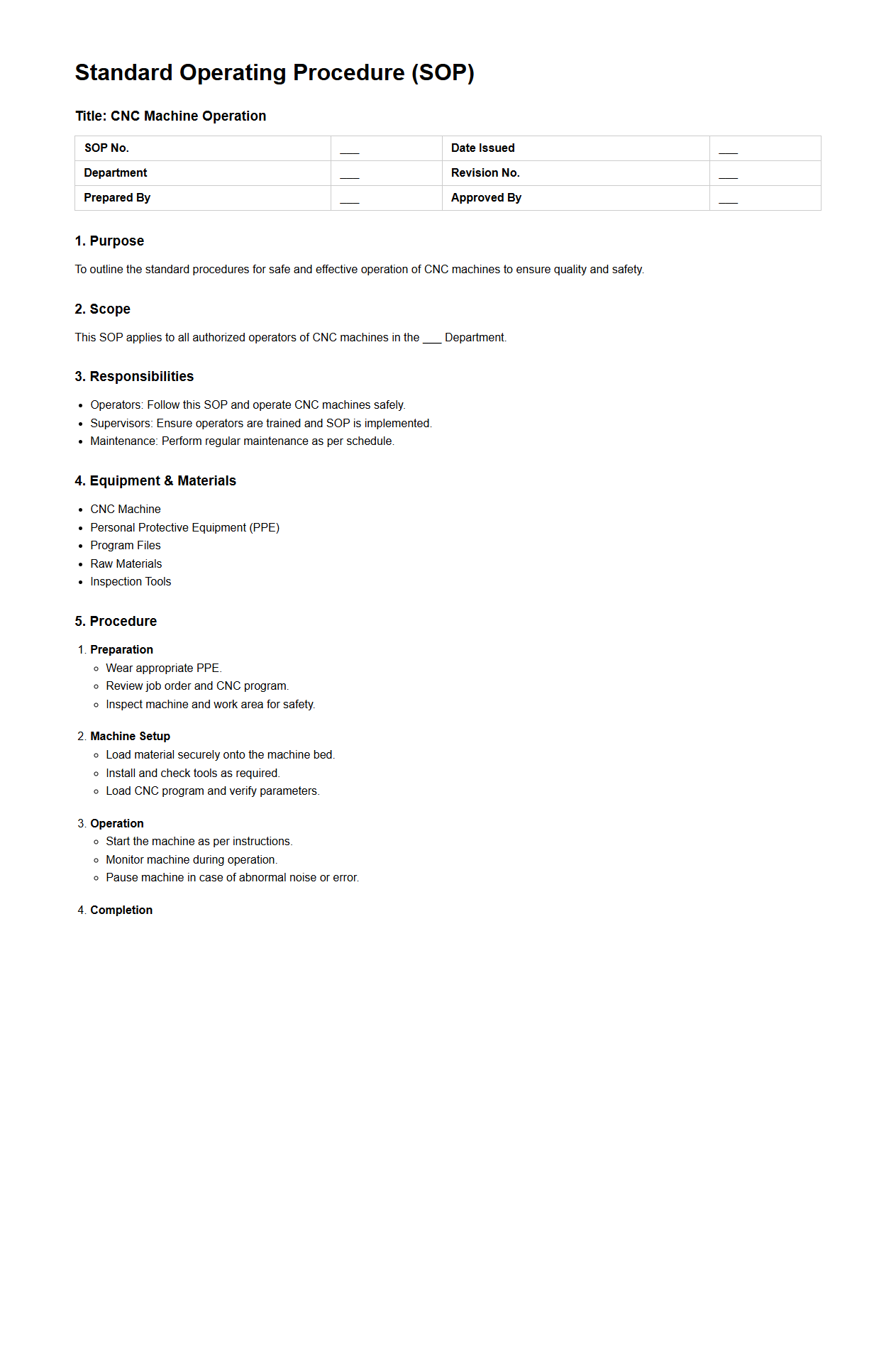

Standard Operating Procedure for CNC Machine Operation

A

Standard Operating Procedure (SOP) for CNC Machine Operation document outlines detailed, step-by-step instructions to ensure the consistent and safe use of CNC machines. It includes guidelines on machine setup, programming, tool changes, maintenance, and safety protocols to optimize performance and minimize errors. This document serves as a critical reference for operators to maintain quality control and operational efficiency in manufacturing environments.

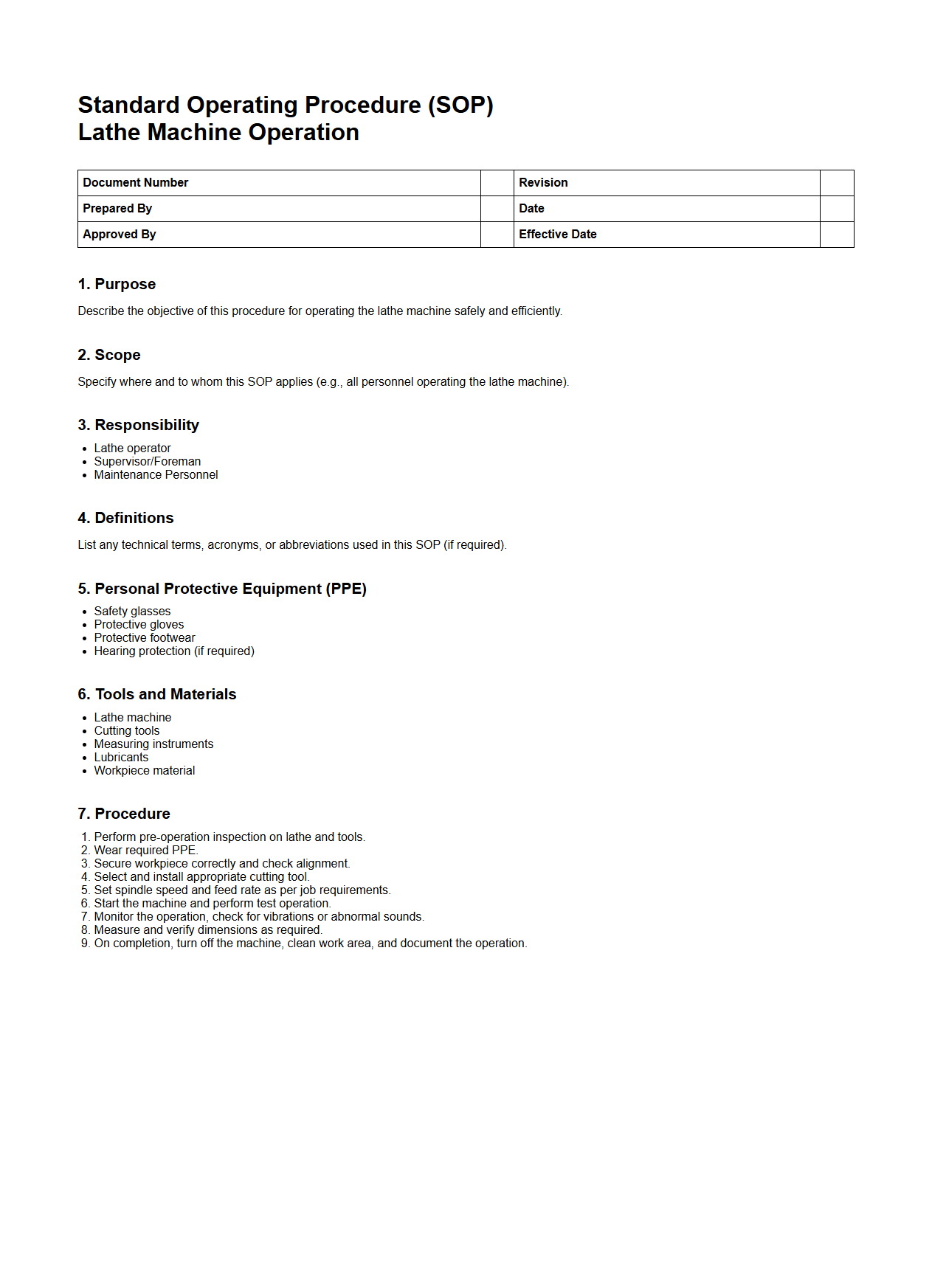

SOP Template for Lathe Machine Operation

An

SOP Template for Lathe Machine Operation document provides a standardized framework outlining step-by-step instructions for safely and efficiently operating a lathe machine. It ensures consistency in workflow, adherence to safety protocols, and optimal machine performance by detailing setup procedures, operational guidelines, and maintenance tasks. This template serves as a critical reference for operators and trainers to minimize errors and improve productivity in manufacturing environments.

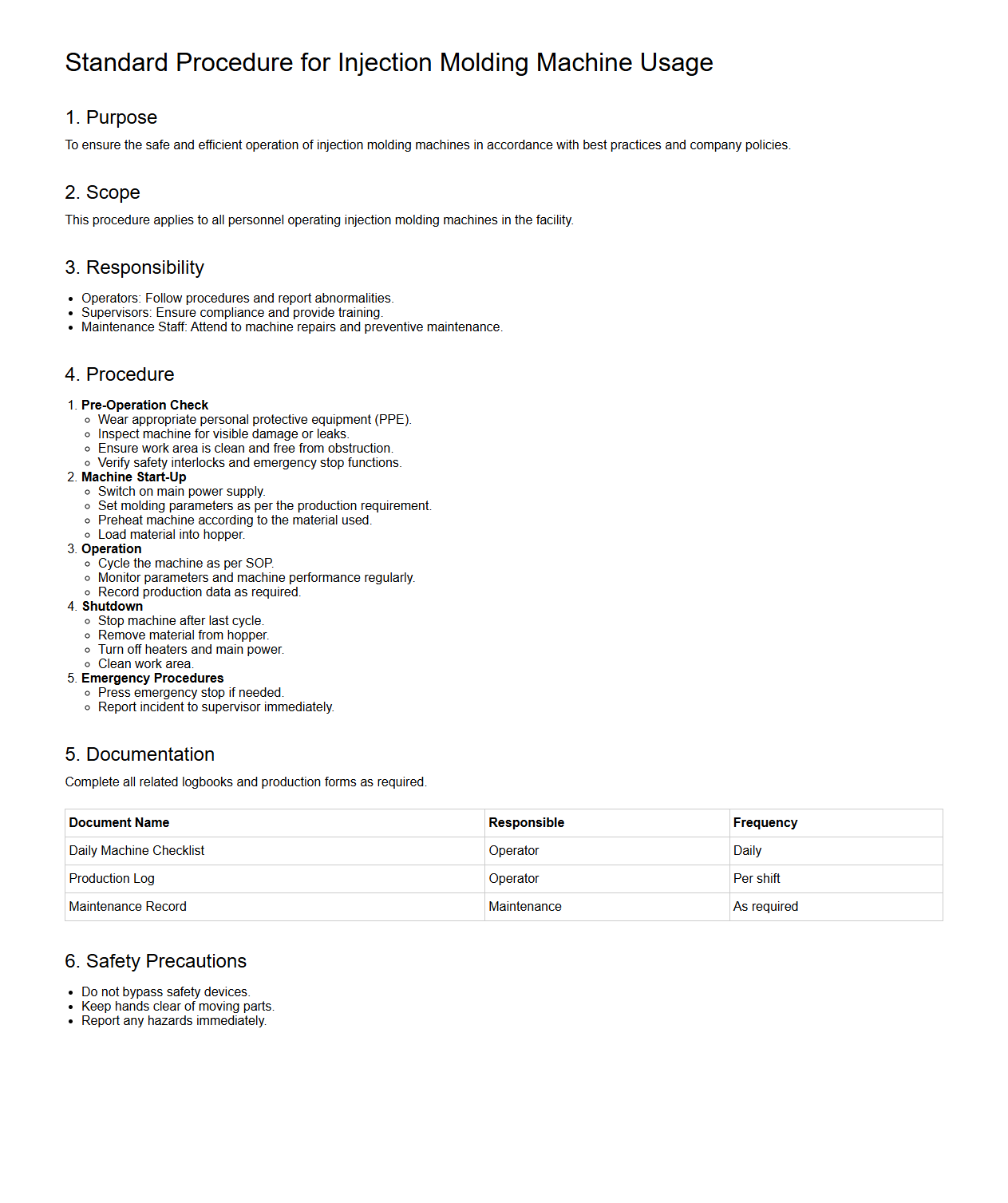

Standard Procedure for Injection Molding Machine Usage

The

Standard Procedure for Injection Molding Machine Usage document outlines the essential steps and safety protocols for operating injection molding machines efficiently and safely. It provides detailed instructions on machine setup, operation parameters, and troubleshooting to ensure consistent product quality and minimize downtime. This procedure helps maintain equipment longevity and ensures compliance with industry standards and safety regulations.

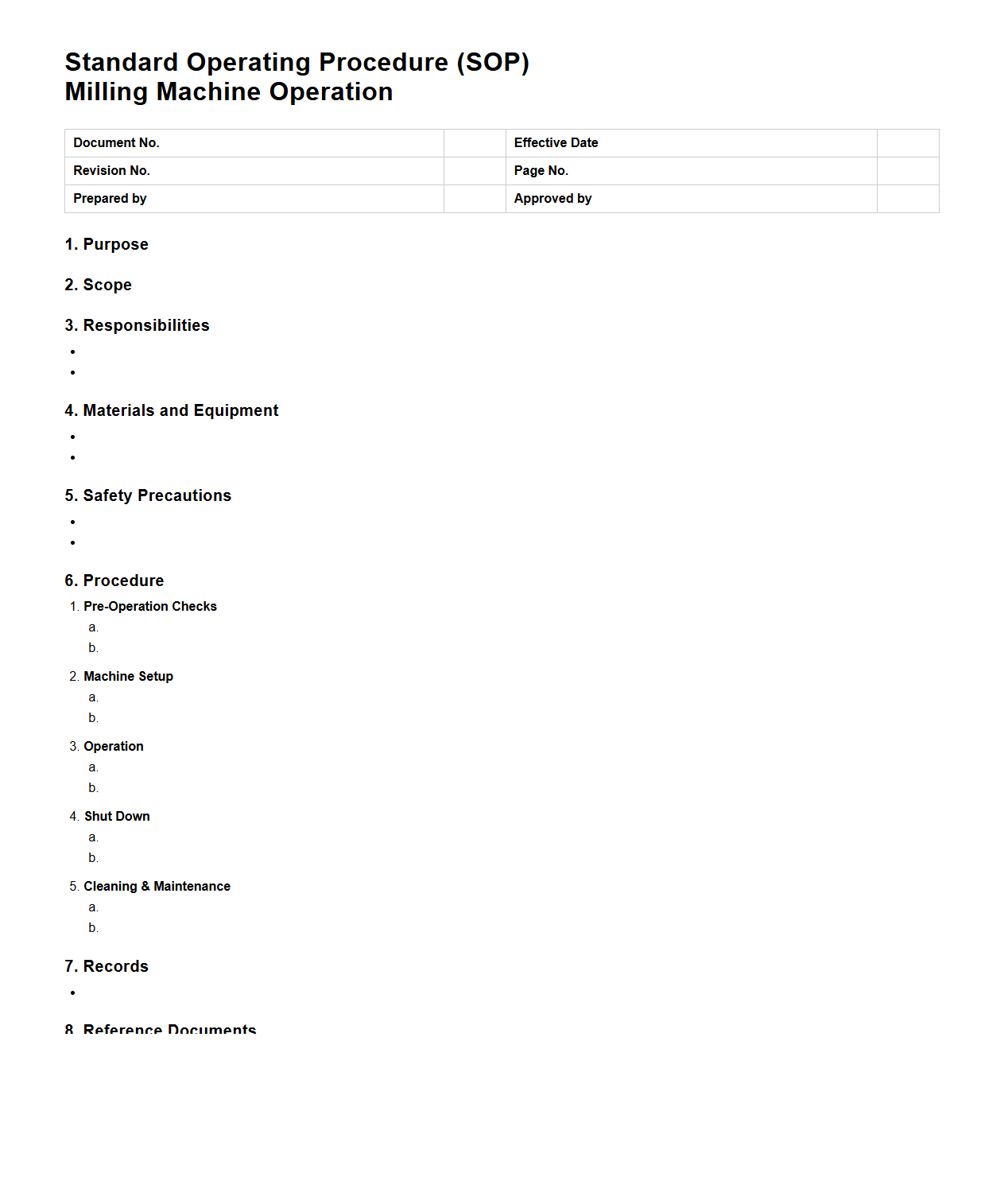

SOP Format for Milling Machine Operation

The SOP Format for Milling Machine Operation is a structured document that outlines step-by-step procedures to ensure safe and efficient use of a milling machine. It includes detailed instructions on machine setup, tool selection, operation parameters, maintenance checks, and safety protocols. Following the

SOP format helps maintain consistency, improve productivity, and reduce the risk of errors or accidents during milling operations.

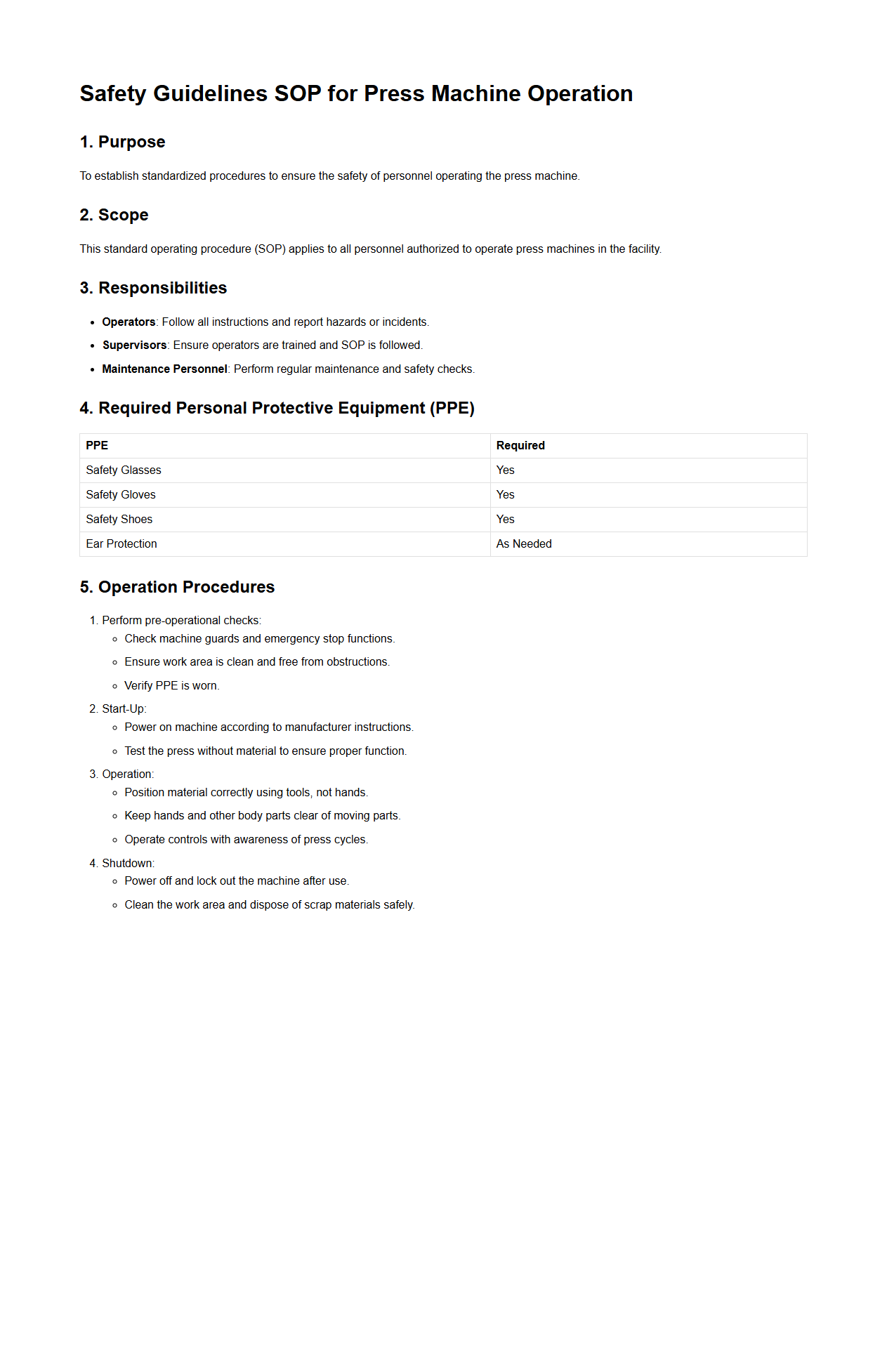

Safety Guidelines SOP for Press Machine Operation

The

Safety Guidelines SOP for Press Machine Operation is a detailed document outlining standardized procedures to ensure the safe use of press machines in industrial settings. It includes essential safety measures, operational protocols, and emergency response steps to minimize the risk of accidents and injuries. Compliance with these guidelines is crucial for protecting workers and maintaining a safe manufacturing environment.

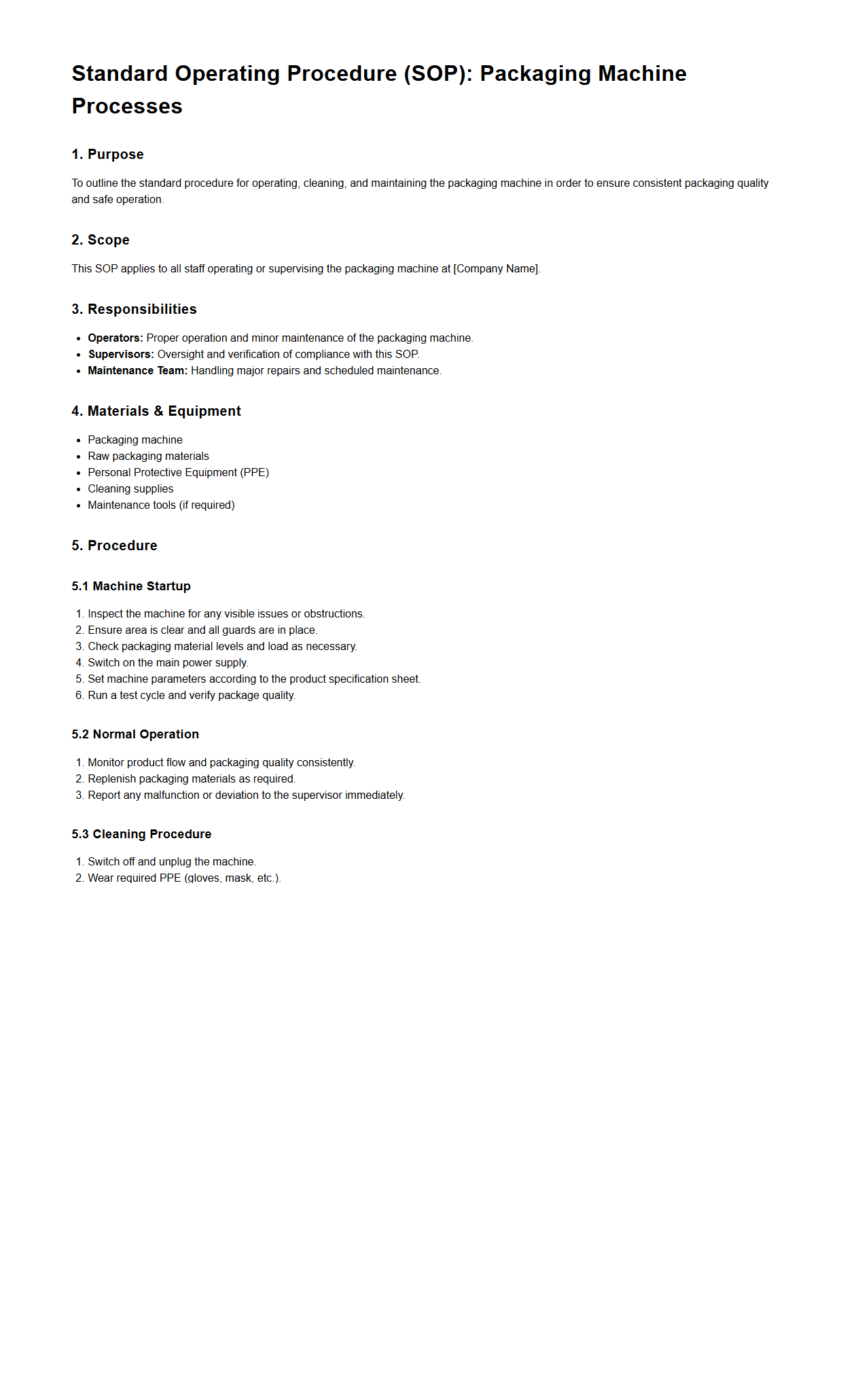

SOP Example for Packaging Machine Processes

An

SOP Example for Packaging Machine Processes document provides a detailed, step-by-step guide to ensure consistent operation and maintenance of packaging machinery. It outlines standardized procedures for machine setup, operation, troubleshooting, and safety protocols to maximize efficiency and minimize errors. This document is essential for training operators, maintaining product quality, and adhering to regulatory compliance.

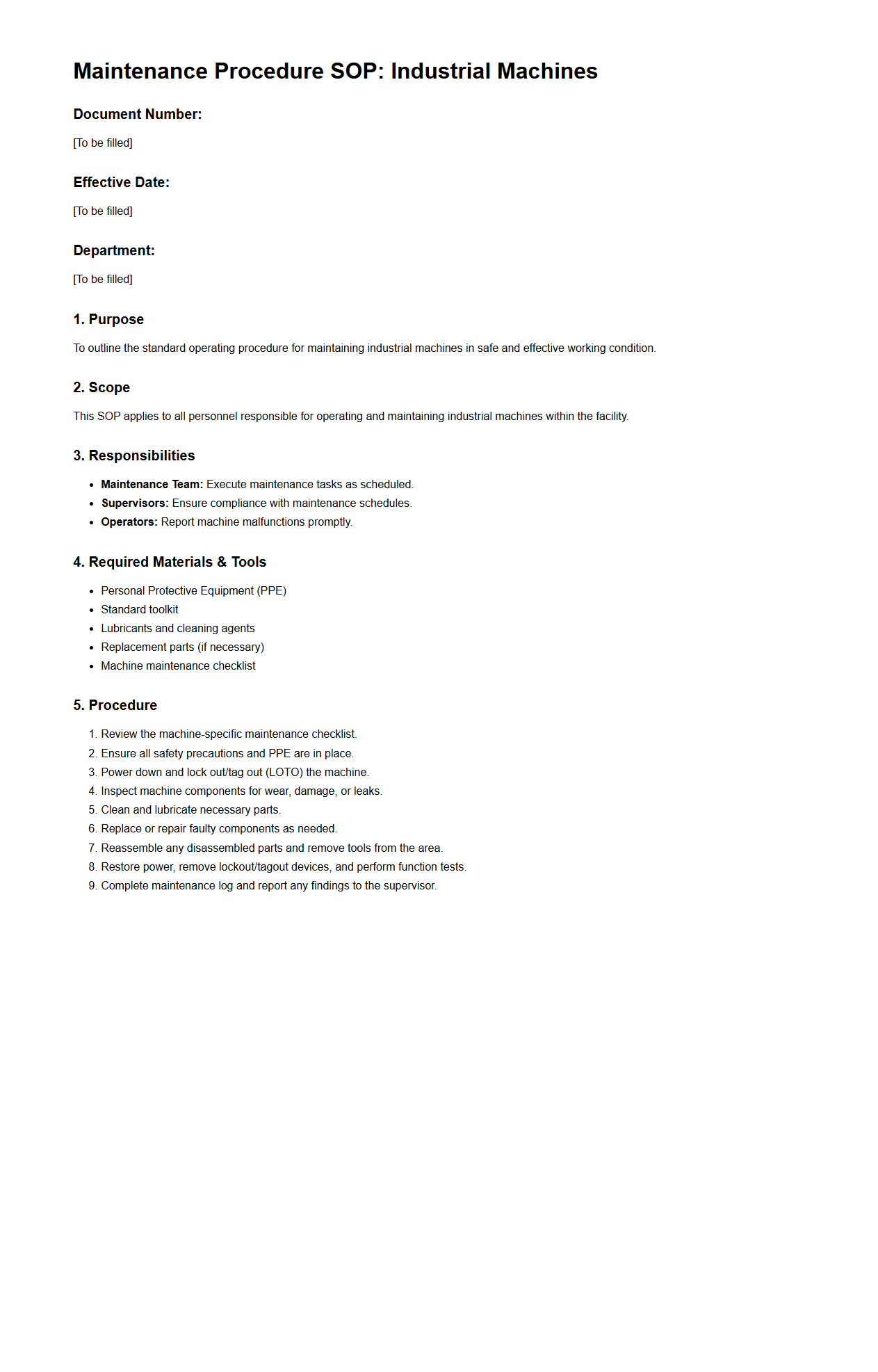

Maintenance Procedure SOP for Industrial Machines

A

Maintenance Procedure SOP for Industrial Machines document outlines standardized steps and guidelines to ensure consistent and effective upkeep of machinery, minimizing downtime and prolonging equipment life. It specifies routine inspection, lubrication, cleaning, and repair processes while detailing safety protocols and required tools. This SOP helps technicians adhere to best practices, enhances operational efficiency, and reduces the risk of unexpected failures.

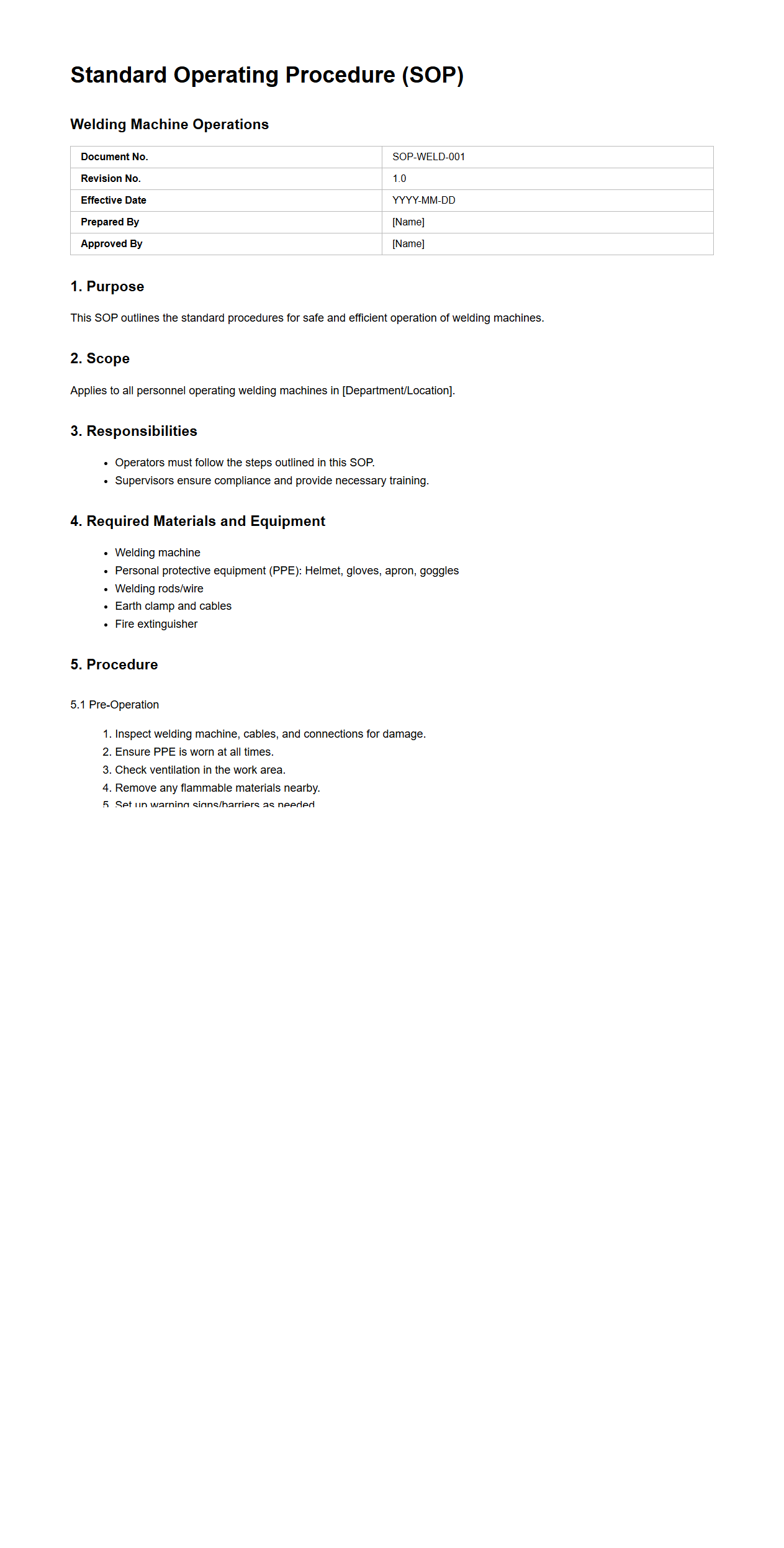

SOP Document for Welding Machine Operations

A

SOP Document for Welding Machine Operations is a detailed guide that outlines standardized procedures to ensure safe and efficient use of welding equipment. It includes essential instructions on machine setup, operational steps, safety precautions, maintenance schedules, and troubleshooting tips. This document helps maintain consistent quality, reduces operational risks, and ensures compliance with industry standards.

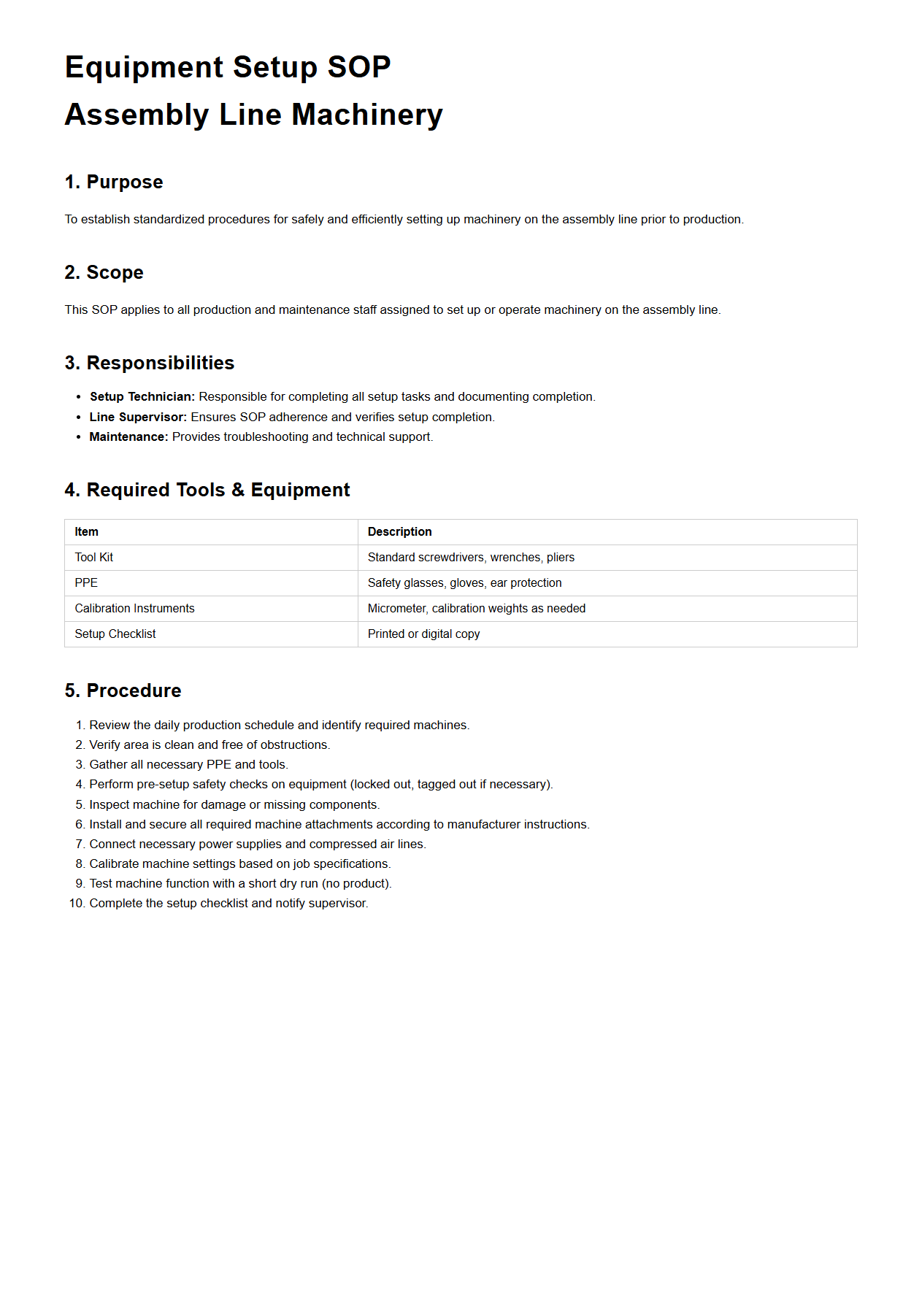

Equipment Setup SOP for Assembly Line Machinery

The

Equipment Setup SOP for Assembly Line Machinery document outlines standardized procedures to ensure accurate and efficient configuration of machines before production begins. It details step-by-step instructions, safety protocols, and quality checks to minimize downtime and maintain consistent product output. Following this SOP ensures proper calibration and alignment of assembly line equipment, reducing errors and increasing operational efficiency.

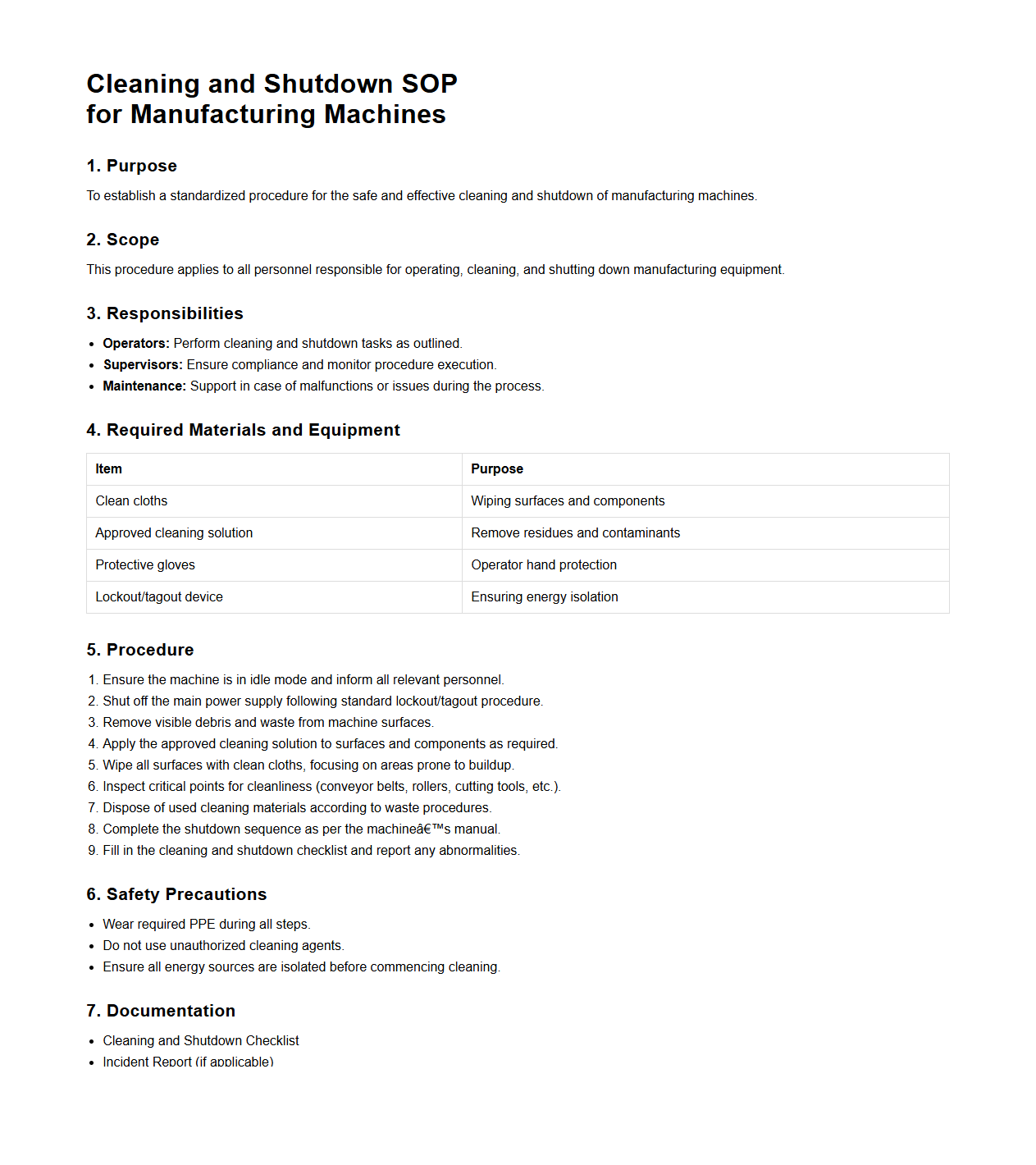

Cleaning and Shutdown SOP for Manufacturing Machines

The

Cleaning and Shutdown SOP for Manufacturing Machines document outlines standardized procedures to ensure machines are properly cleaned and safely powered down to maintain operational efficiency and prevent contamination or damage. It specifies step-by-step actions, safety precautions, and required cleaning agents to guarantee consistent hygiene and equipment longevity. Adhering to this SOP minimizes downtime, enhances workplace safety, and supports regulatory compliance in manufacturing environments.

What is the primary objective of the Standard Operating Procedure (SOP) for this machine operation?

The primary objective of the SOP is to ensure consistent and safe machine operation. It aims to minimize errors and enhance productivity by providing clear guidelines. Compliance with the SOP supports both operational efficiency and safety standards.

Which safety protocols are mandatory before initiating the machine operation?

Before starting the machine, operators must follow mandatory safety protocols such as wearing personal protective equipment (PPE). Checking emergency stop functions and inspecting the machine for hazards are essential steps. These protocols prevent accidents and ensure a safe working environment.

What are the step-by-step instructions outlined for starting and stopping the machine?

The SOP details precise step-by-step instructions to start the machine, including power checks and control system verification. Stopping the machine requires following the shutdown procedure to avoid damage and maintain safety. Adhering strictly to these instructions ensures smooth and reliable machine operation.

Which troubleshooting procedures are specified in case of operational issues?

The specified troubleshooting procedures include identifying common faults such as power failure, mechanical jams, or sensor errors. The SOP guides operators through systematic diagnosis and corrective actions to restore function. Prompt troubleshooting minimizes downtime and maintains production flow.

What documentation or logs must be completed after performing the machine operation?

After operation, operators must complete comprehensive documentation or logs to record performance data and any incidents. These records help in tracking machine efficiency and support preventive maintenance. Accurate logs contribute to continuous improvement and regulatory compliance.

More Manufacturing Templates