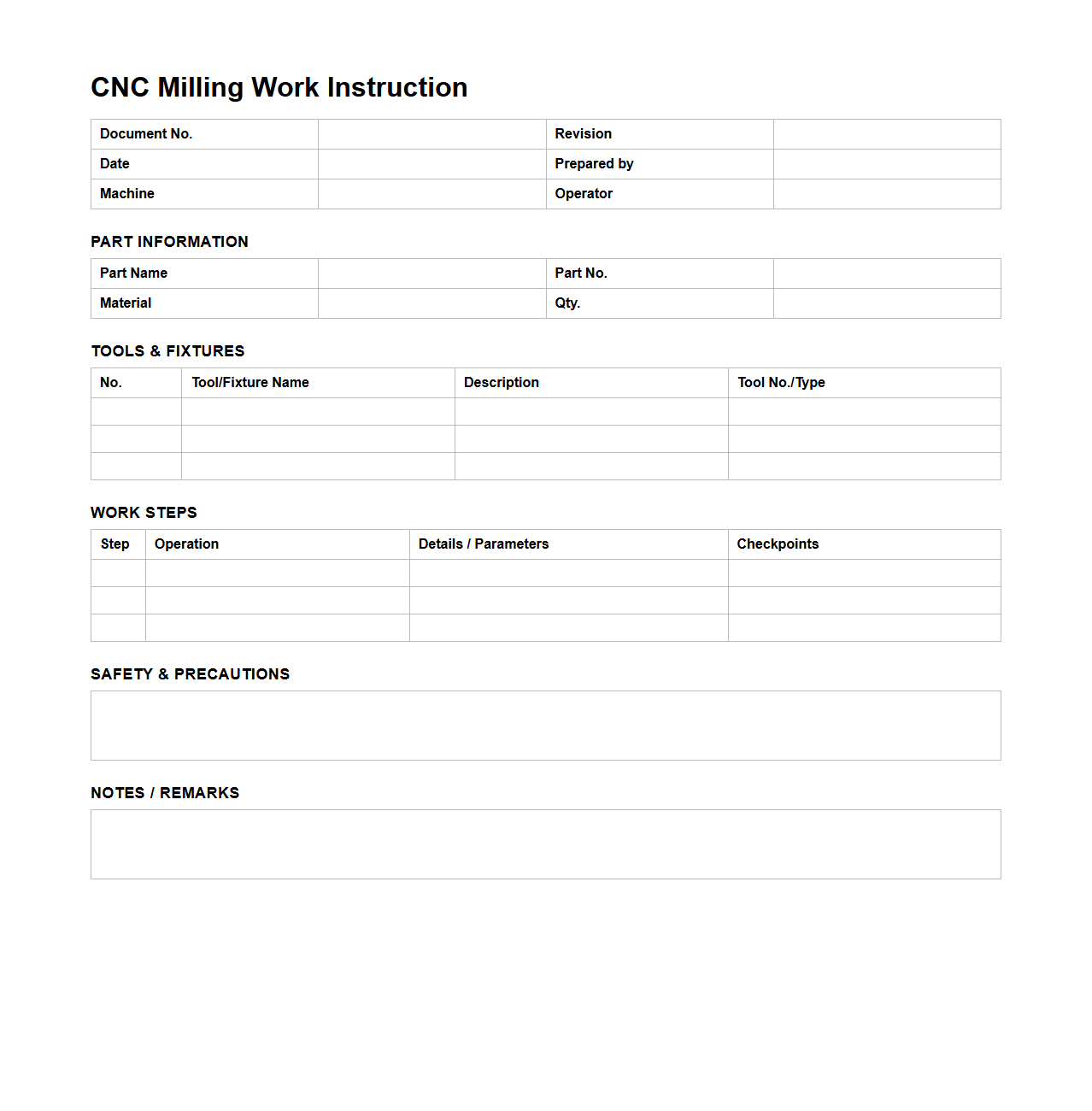

CNC Milling Work Instruction Template

A

CNC Milling Work Instruction Template document provides a standardized guide outlining step-by-step procedures for operating CNC milling machines efficiently and safely. It includes detailed instructions on machine setup, tooling selection, operational parameters, maintenance checks, and quality control measures to ensure consistent production outcomes. This template enhances communication between operators and engineers, reduces errors, and optimizes manufacturing processes.

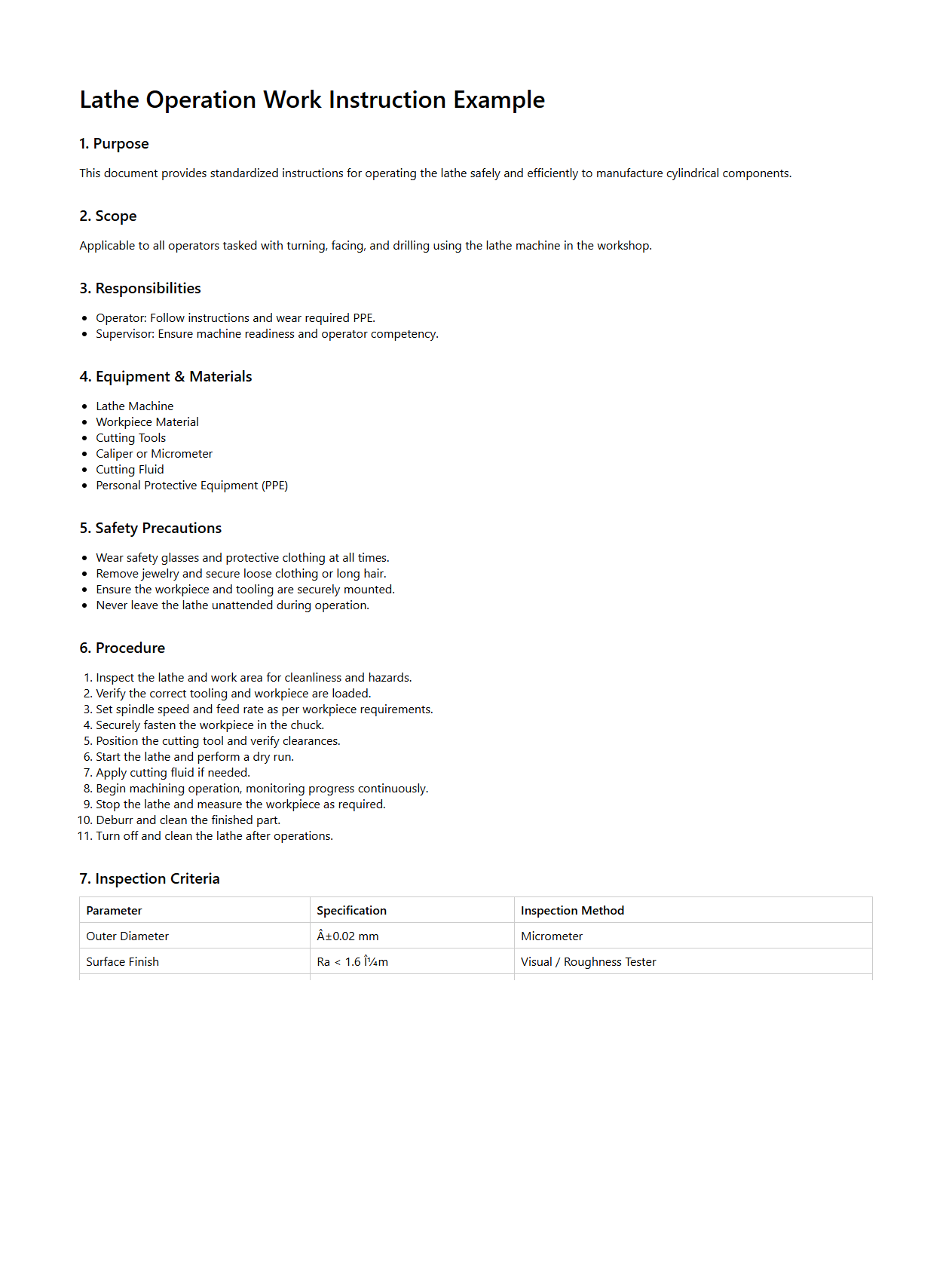

Lathe Operation Work Instruction Example

A

Lathe Operation Work Instruction Example document provides clear, step-by-step guidelines for safely and accurately performing machining tasks on a lathe machine. It includes detailed instructions on machine setup, tool selection, operational procedures, safety precautions, and quality checks to ensure consistent production output. This document is essential for training operators and maintaining standardized manufacturing processes in metalworking industries.

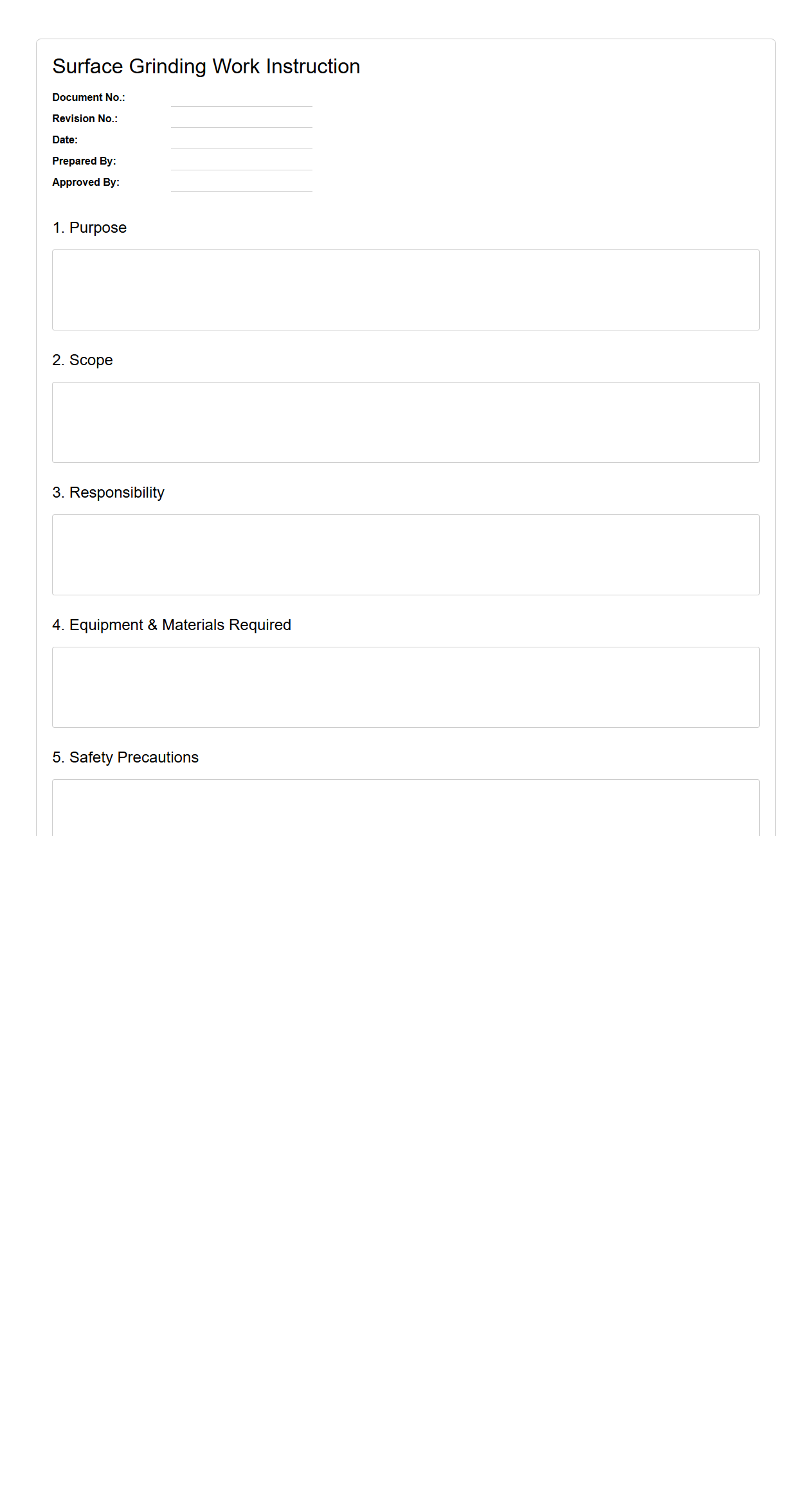

Surface Grinding Work Instruction Format

A

Surface Grinding Work Instruction Format document provides a standardized template outlining the step-by-step procedures, safety guidelines, and equipment specifications necessary for performing surface grinding tasks. It ensures consistency in operational methods, quality control, and adherence to industry standards, enabling operators to achieve precise surface finishes. This document typically includes details on machine setup, grinding wheel selection, workpiece handling, and inspection criteria to optimize performance and safety.

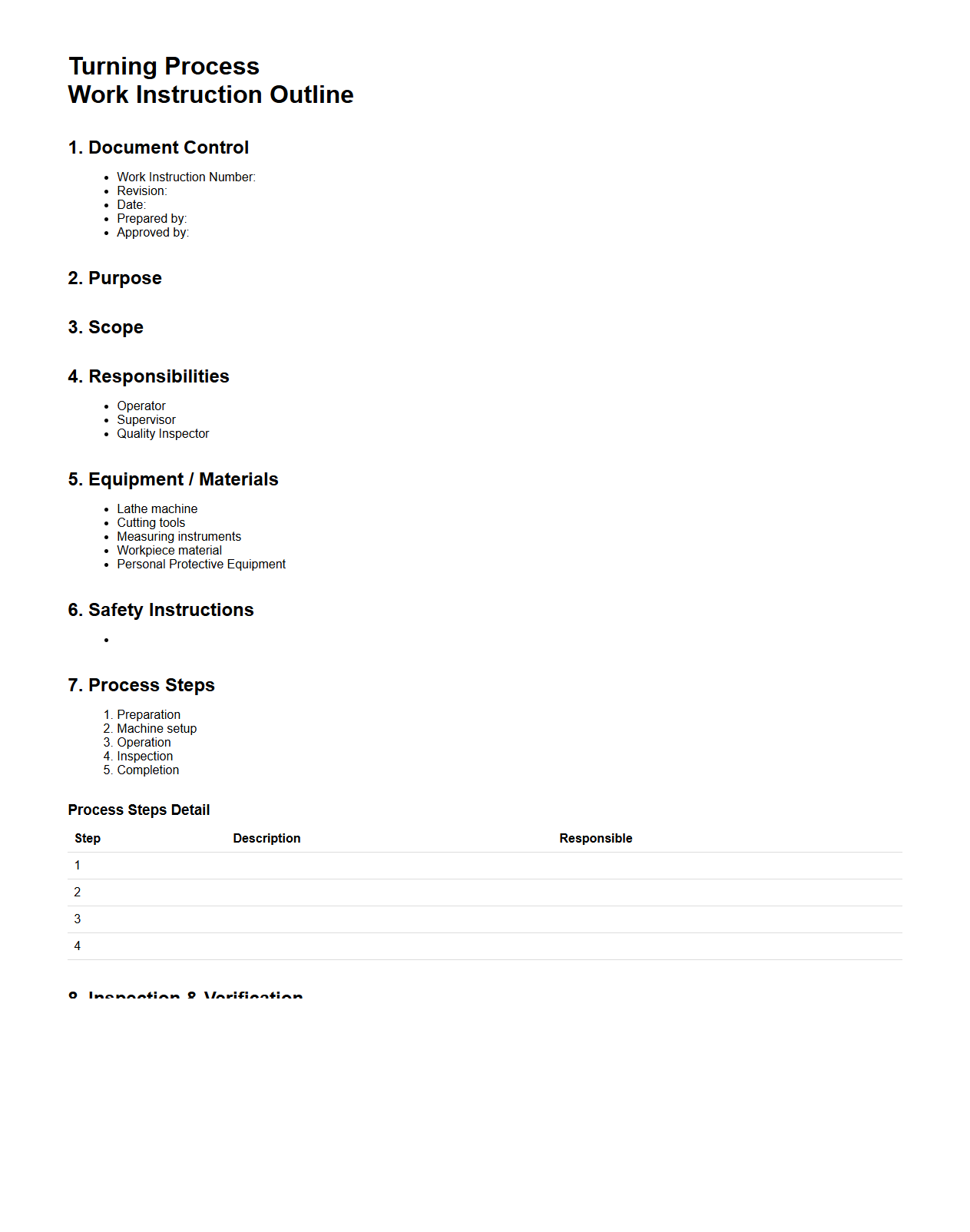

Turning Process Work Instruction Outline

The Turning Process Work Instruction Outline document provides detailed, step-by-step guidance for performing lathe machining operations efficiently and safely. It includes specifications for tool setup, machine parameters, cutting speeds, and quality control measures to ensure consistent production output. This document serves as a vital reference to maintain

operational accuracy and reduce variability in turning processes across manufacturing teams.

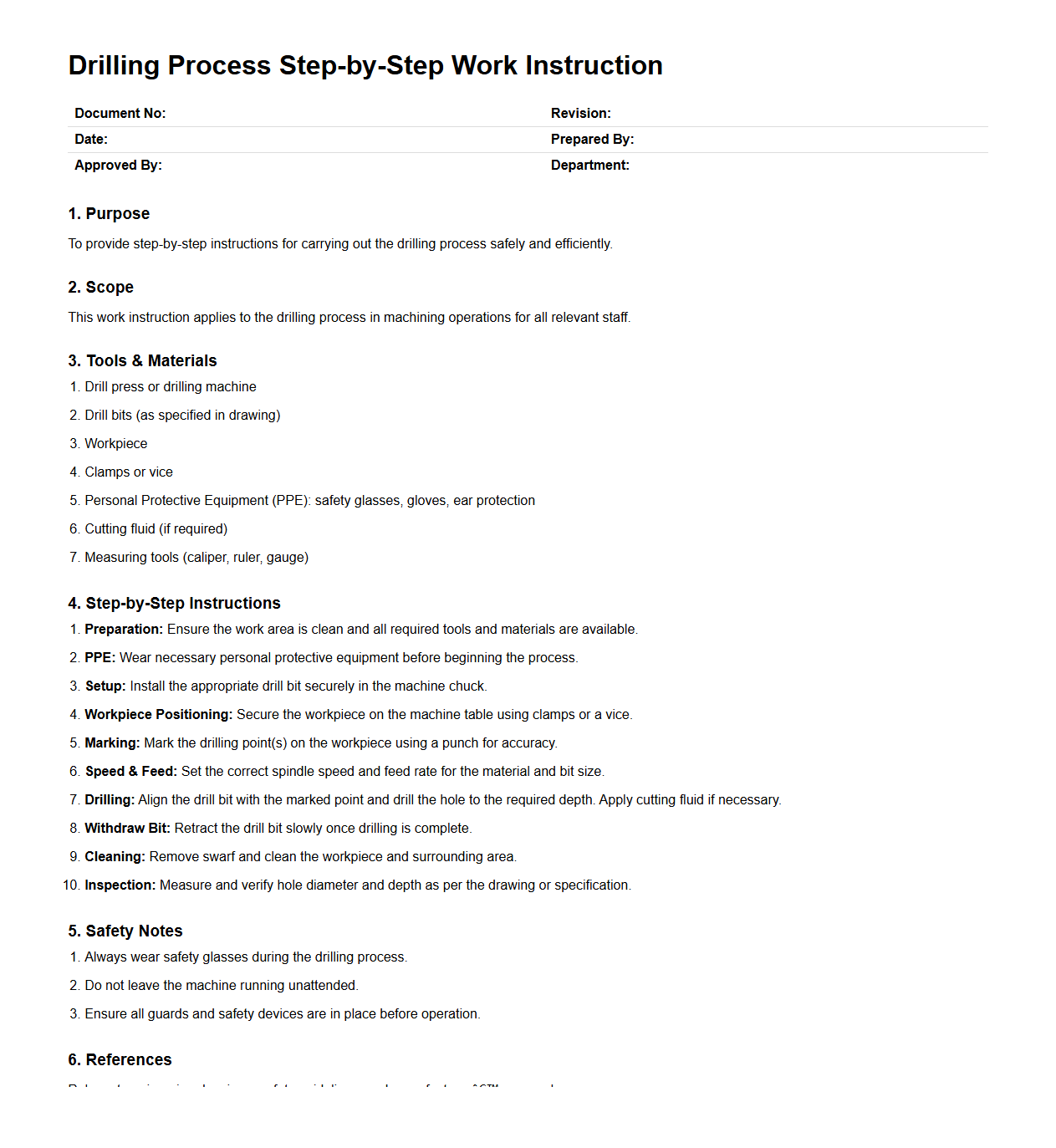

Drilling Process Step-by-Step Work Instruction

A

Drilling Process Step-by-Step Work Instruction document provides detailed guidelines outlining each phase of the drilling operation to ensure safety, efficiency, and consistency. It includes precise instructions on equipment setup, operational parameters, and safety checks to minimize errors and hazards. This document serves as a critical reference for on-site personnel to maintain standardization and optimize drilling performance.

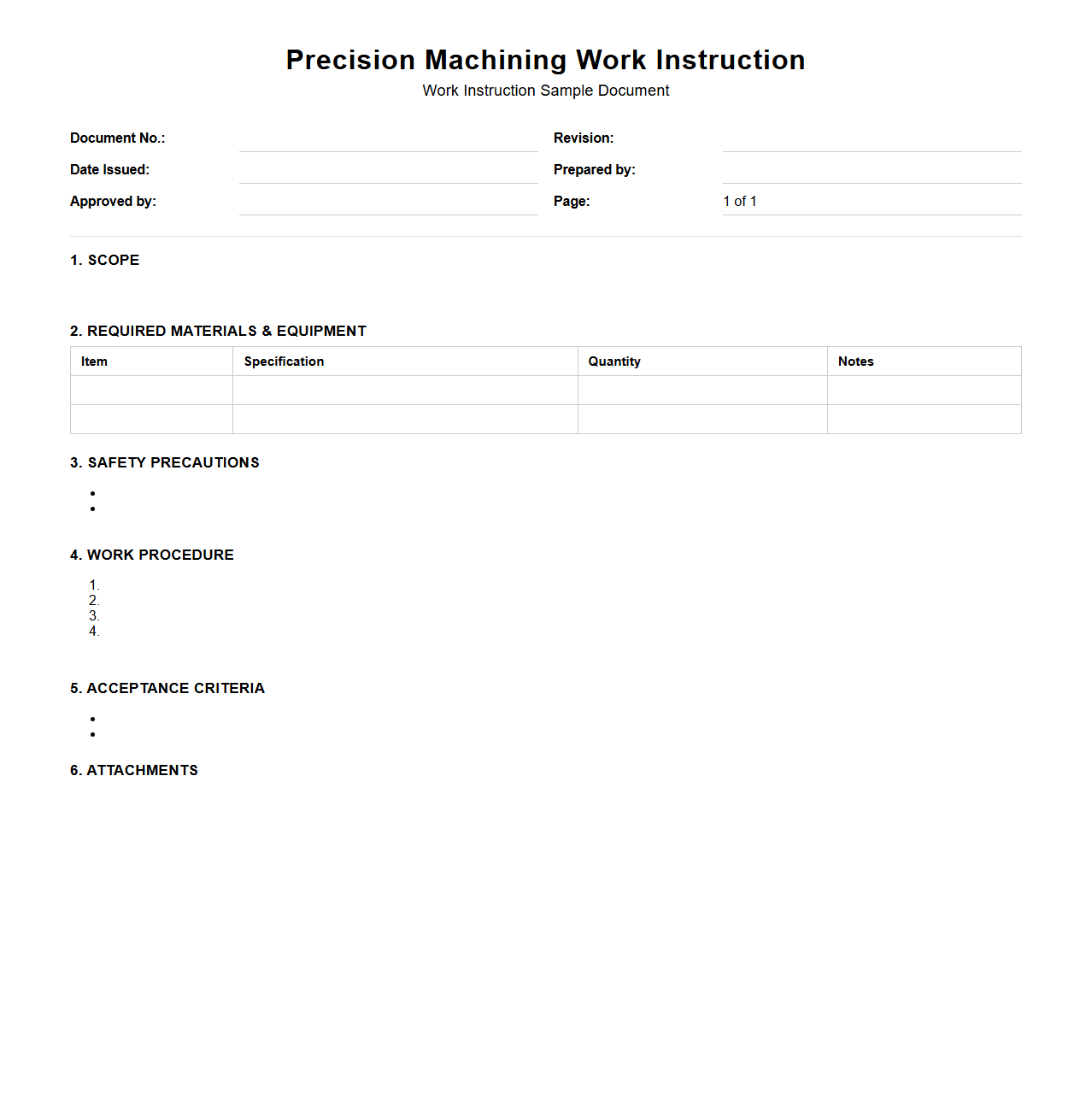

Precision Machining Work Instruction Sample

A

Precision Machining Work Instruction Sample document provides detailed, step-by-step guidelines for accurately manufacturing components with tight tolerances. It includes essential information such as tooling specifications, machine settings, quality control checkpoints, and safety protocols to ensure consistent and high-quality output. This document serves as a standardized reference to optimize production efficiency and reduce errors in precision machining processes.

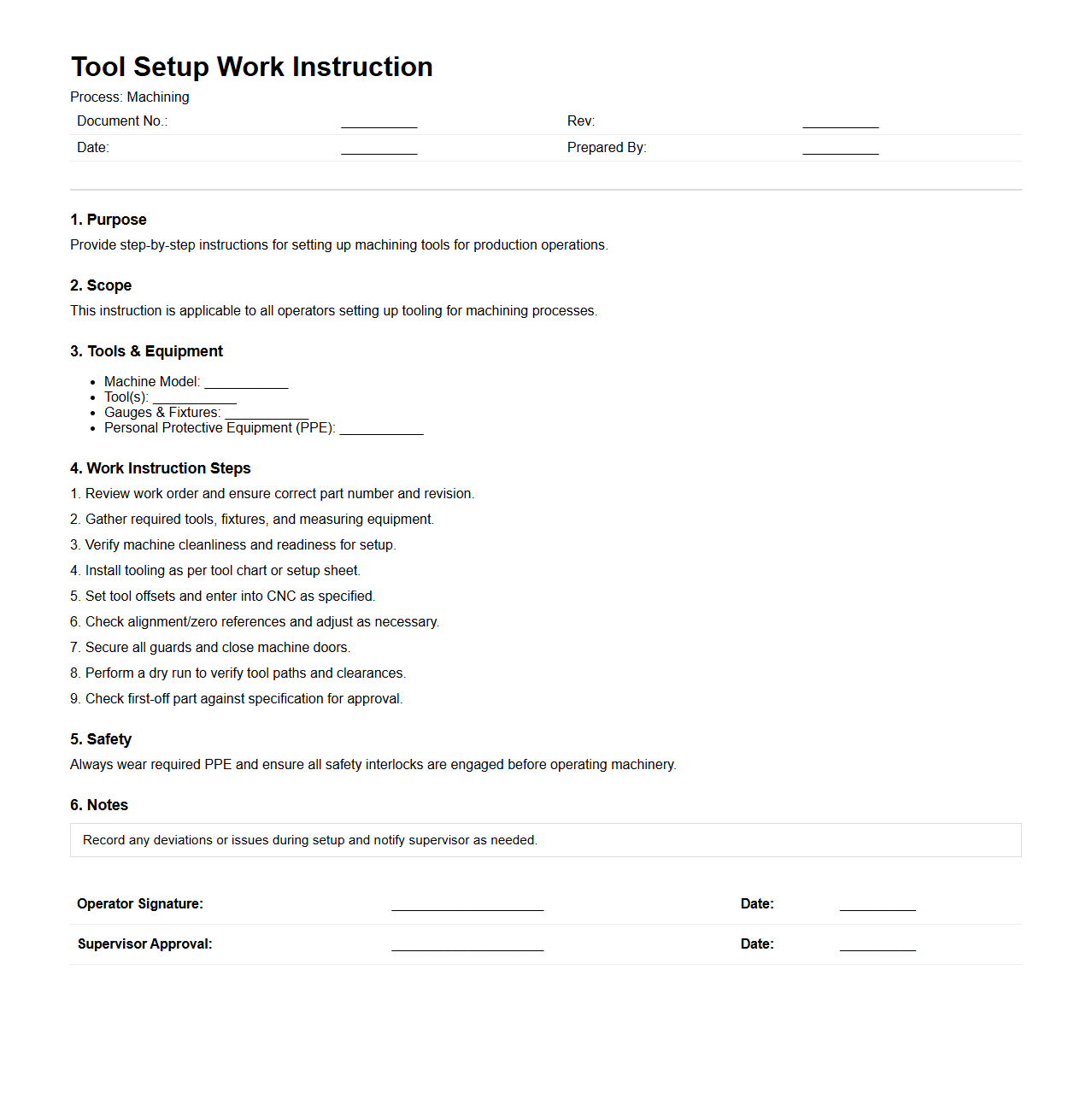

Tool Setup Work Instruction for Machining

The

Tool Setup Work Instruction for Machining document provides detailed guidelines on preparing and configuring tools required for machining operations. It includes step-by-step procedures to ensure accurate tool alignment, calibration, and verification to optimize machining precision and efficiency. This document is essential for reducing setup time, minimizing errors, and maintaining consistent quality in manufacturing processes.

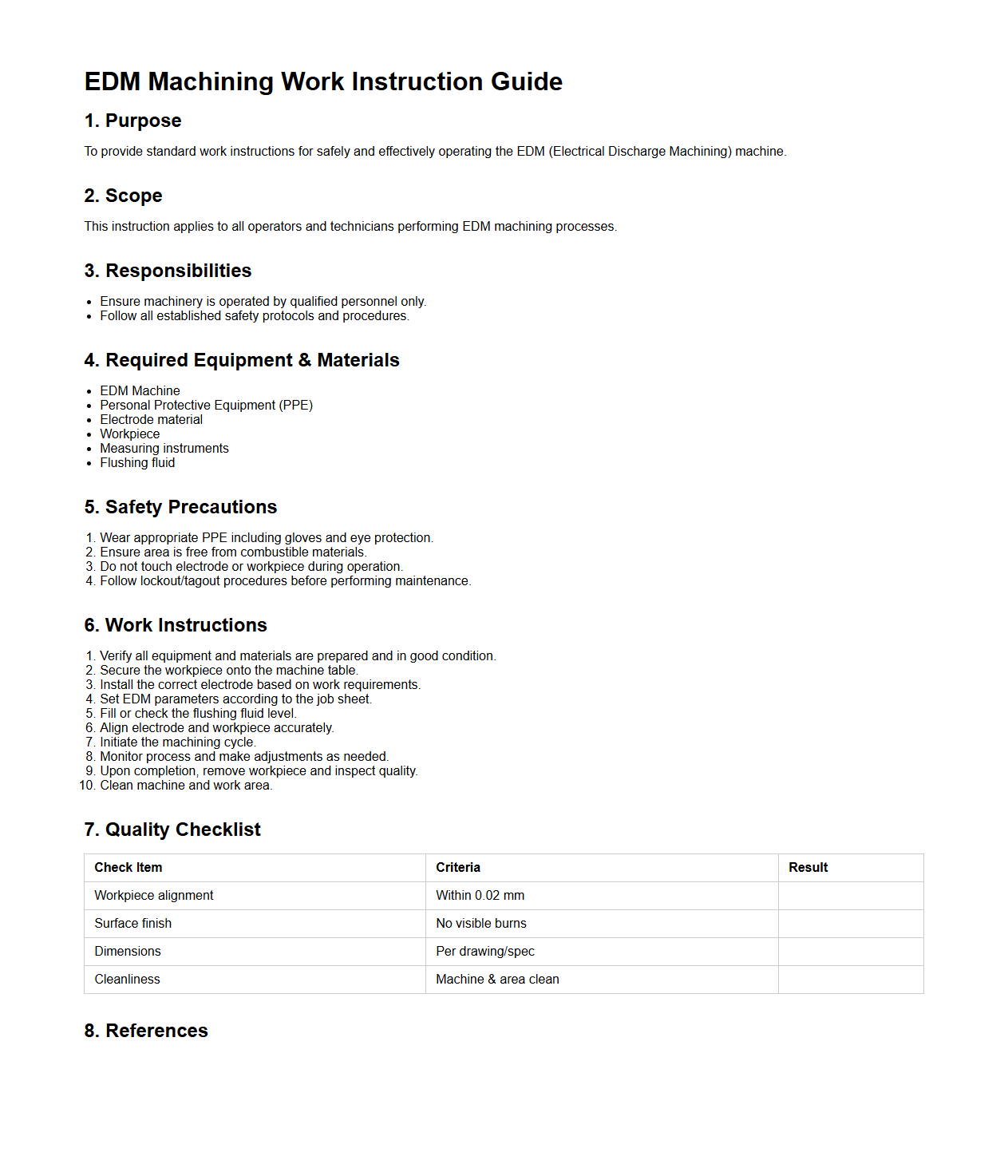

EDM Machining Work Instruction Guide

The

EDM Machining Work Instruction Guide document provides detailed, step-by-step procedures for Electrical Discharge Machining operations, ensuring precision and consistency in manufacturing. It outlines safety protocols, machine setup parameters, electrode selection, and maintenance schedules essential for optimized performance. This guide supports machinists in achieving high-quality surface finishes and dimensional accuracy while minimizing machine downtime.

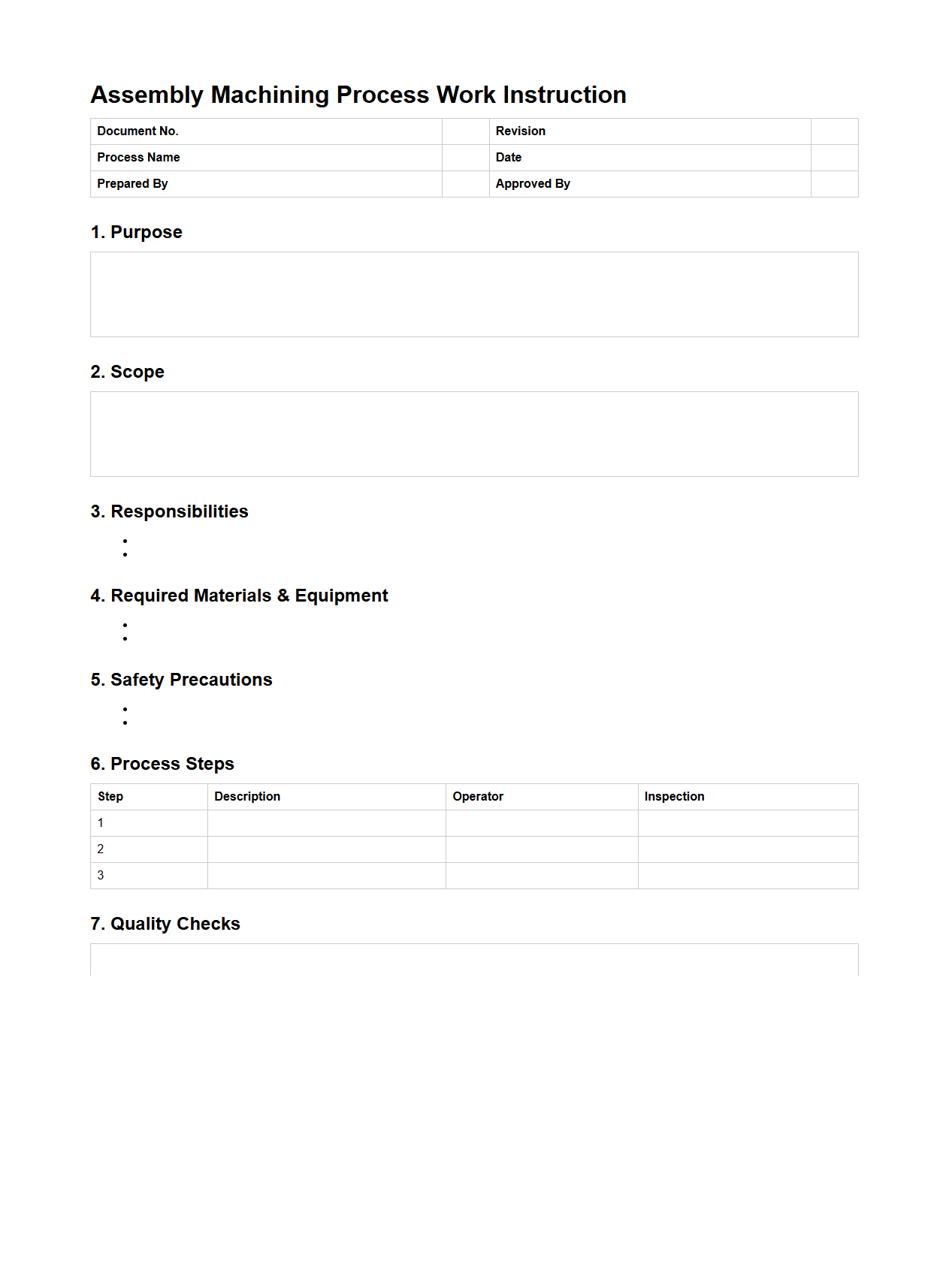

Assembly Machining Process Work Instruction

An

Assembly Machining Process Work Instruction document provides detailed, step-by-step guidelines for operators to accurately perform machining tasks during the assembly process. It includes specifications such as tooling requirements, machine settings, machining sequences, quality control checks, and safety protocols to ensure consistent product quality and operational efficiency. This document serves as a critical reference for minimizing errors, maintaining compliance with manufacturing standards, and optimizing production workflow.

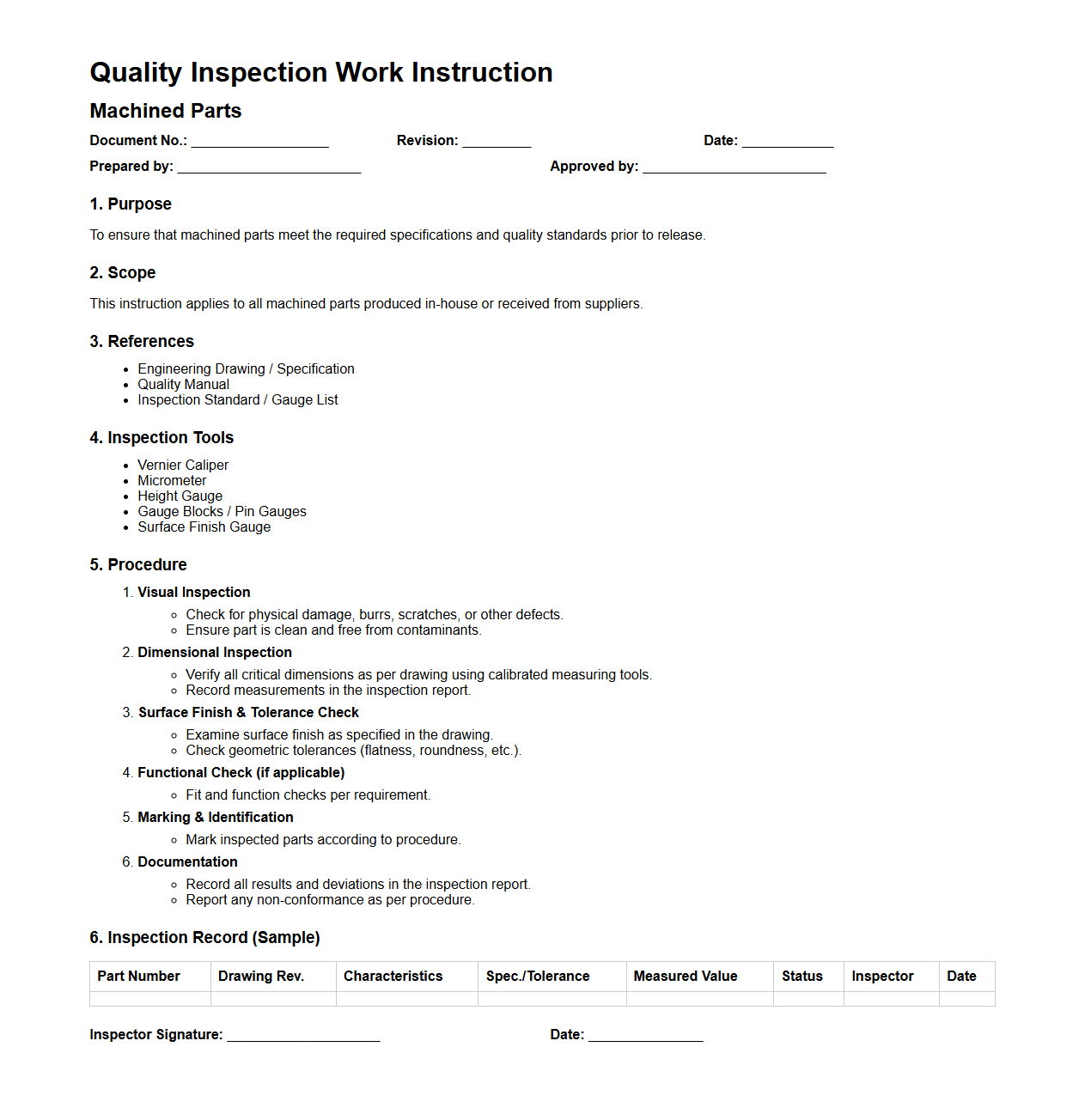

Quality Inspection Work Instruction for Machined Parts

A

Quality Inspection Work Instruction for Machined Parts document outlines detailed procedures and criteria to verify the dimensional accuracy, surface finish, and material integrity of machined components. It serves as a standardized guide for quality inspectors to consistently measure, evaluate, and record inspection results using specific tools and techniques, ensuring compliance with manufacturing specifications. This document is essential for minimizing defects, improving product reliability, and maintaining quality standards throughout the production process.

What is the primary objective of the machining process described in the work instruction document?

The primary objective of the machining process is to accurately shape and finish materials to meet specified design standards. This process ensures that parts achieve precise dimensions and surface quality. Consistency and efficiency in production are key goals throughout the operation.

Which specific safety precautions must be followed according to the document?

The document mandates strict adherence to safety precautions such as wearing appropriate personal protective equipment (PPE) like gloves and safety goggles. Operators must also ensure that machine guards are correctly installed before starting work. Additionally, maintaining a clean workspace and following lockout/tagout procedures are essential for safe operation.

What are the key steps outlined for machine setup and operation?

The key steps for machine setup include verifying tool alignment, securing the workpiece firmly, and calibrating the machine to desired settings. Operators must then perform a test run to confirm correct operation before proceeding with production. Proper documentation of setup parameters is emphasized for quality control purposes.

How does the document specify measurement and quality verification procedures?

The document specifies using precision measuring instruments such as calipers and micrometers to verify part dimensions. Quality checks are to be performed at regular intervals to detect deviations early. Recording measurement data ensures traceability and compliance with quality standards.

What troubleshooting actions are recommended for common machining issues?

Recommended troubleshooting actions include inspecting cutting tools for wear and replacing them if necessary to avoid defects. Operators should also check machine settings and recalibrate when parts do not meet specifications. Cleaning and lubricating machine components regularly helps prevent mechanical failures.