A Training Record Document Sample for Manufacturing Staff provides a structured template to track employee training sessions, skills acquired, and certifications earned within the manufacturing environment. This document ensures compliance with industry standards and helps managers monitor workforce development efficiently. Proper use of such records supports continuous improvement and enhances overall production quality.

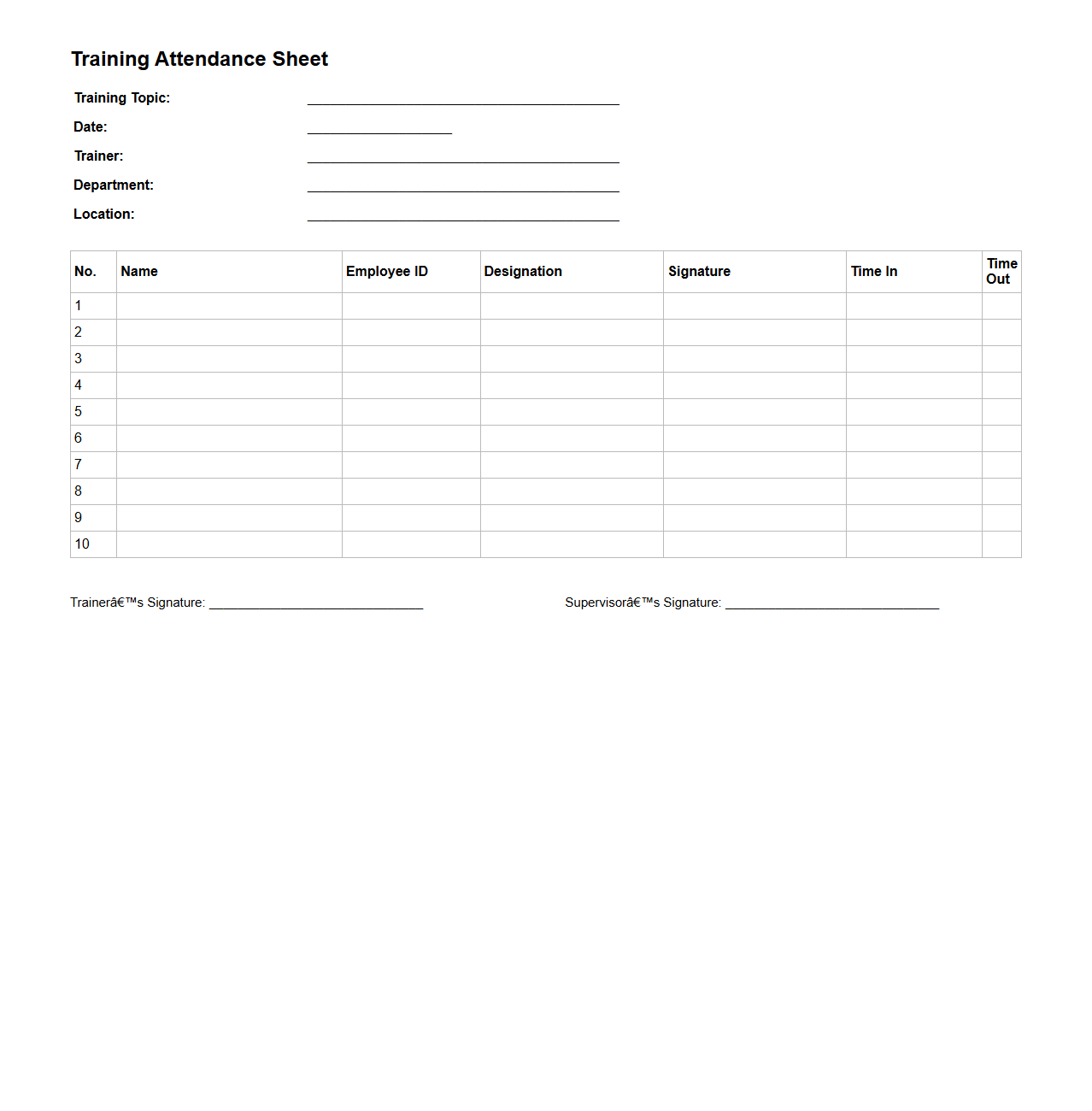

Training Attendance Sheet for Manufacturing Personnel

A

Training Attendance Sheet for Manufacturing Personnel is a document used to accurately record the participation of employees in training sessions specific to manufacturing processes and safety protocols. It helps track attendance, verify compliance with mandatory training requirements, and ensures that all personnel meet competency standards. This sheet supports workforce development and regulatory audits by providing documented proof of employee engagement in essential training activities.

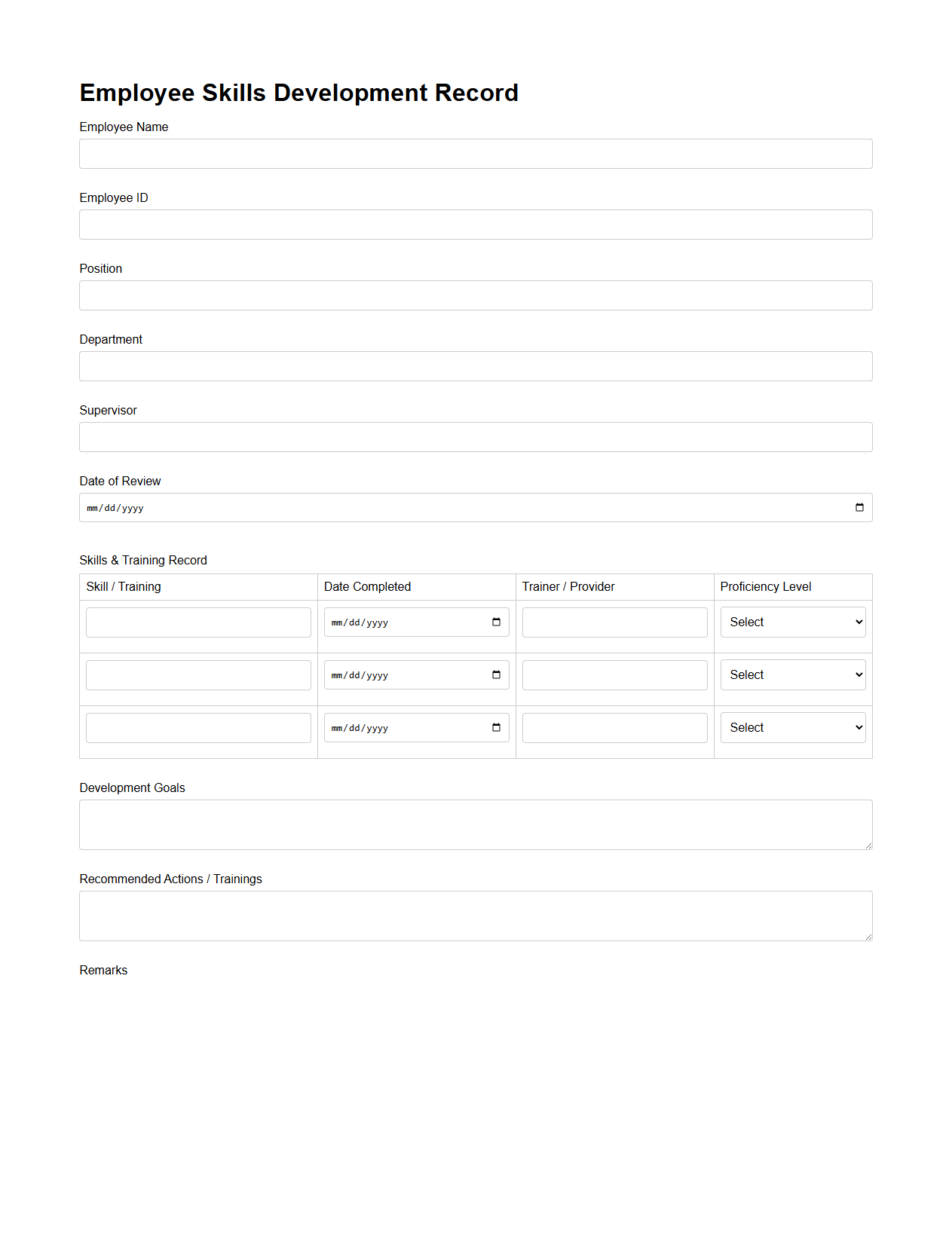

Employee Skills Development Record for Factory Staff

The

Employee Skills Development Record for factory staff is a comprehensive document that tracks the progress and acquisition of job-related competencies over time. It includes detailed information on training sessions attended, skill assessments, certifications earned, and areas requiring improvement. This record facilitates targeted workforce development, ensuring employees meet operational standards and contribute effectively to production goals.

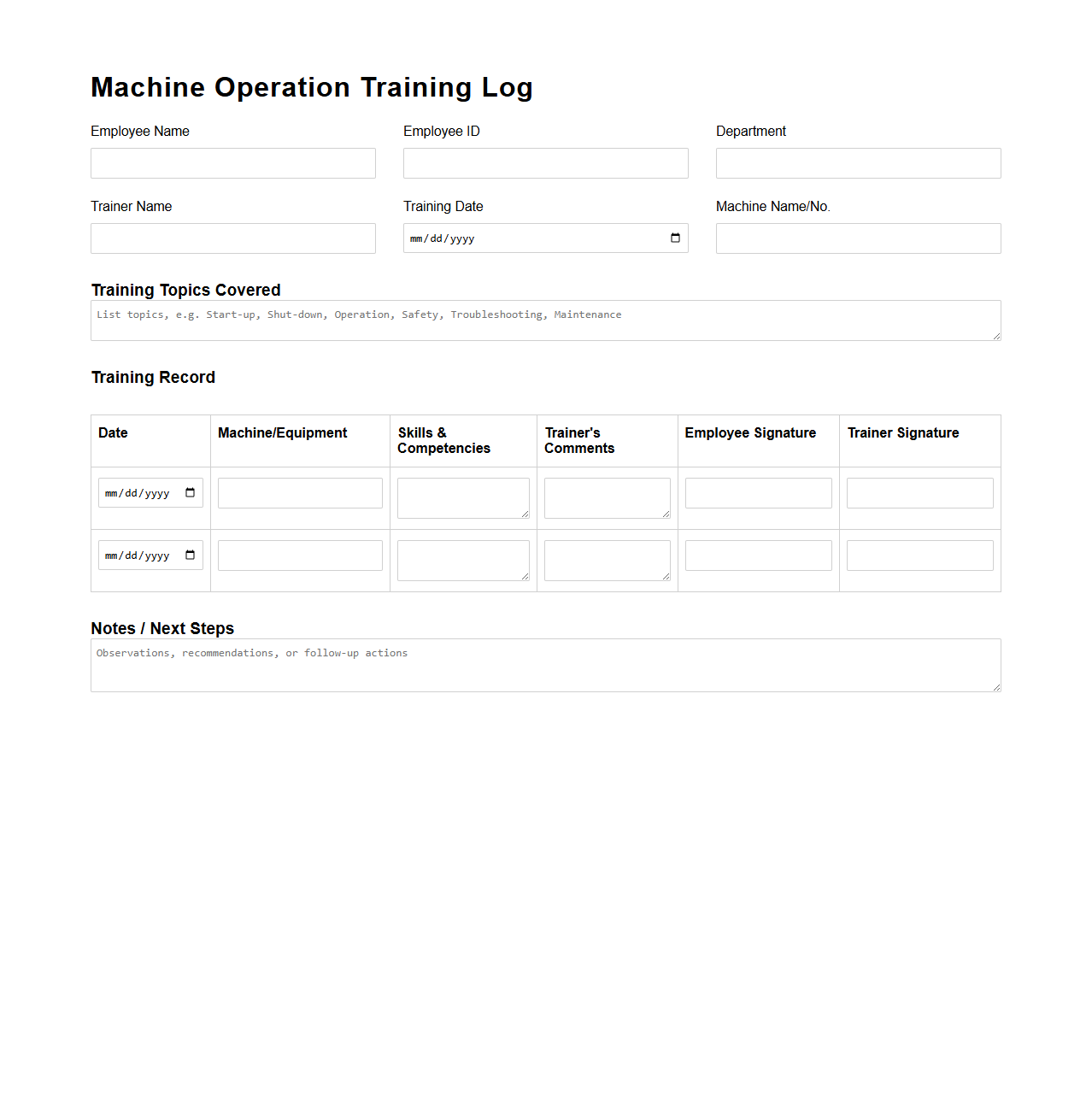

Machine Operation Training Log for Production Workers

A

Machine Operation Training Log for Production Workers is a detailed record documenting the training sessions, skills acquired, and competency assessments related to operating specific machinery. It ensures compliance with safety standards and helps track employee progress, skill gaps, and certification status. This log enhances operational efficiency and minimizes risks by verifying that workers are adequately trained before using production equipment.

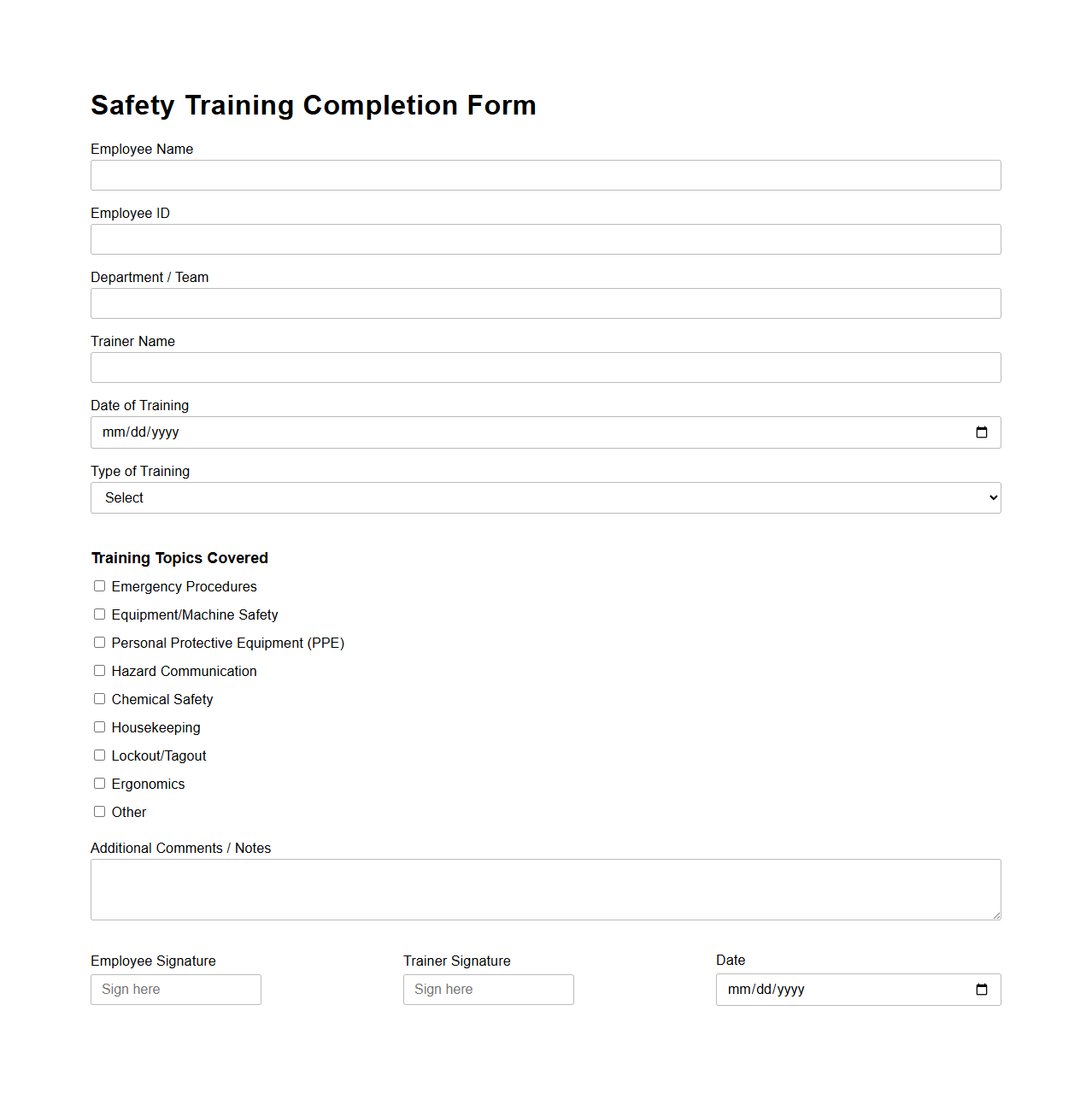

Safety Training Completion Form for Manufacturing Team

The

Safety Training Completion Form for Manufacturing Team document serves as an official record confirming that employees have successfully completed required safety training specific to manufacturing processes. It outlines essential safety protocols, procedures, and compliance standards to ensure workplace safety and reduce risk of accidents. This document is critical for regulatory compliance and helps track employee readiness to handle manufacturing equipment safely.

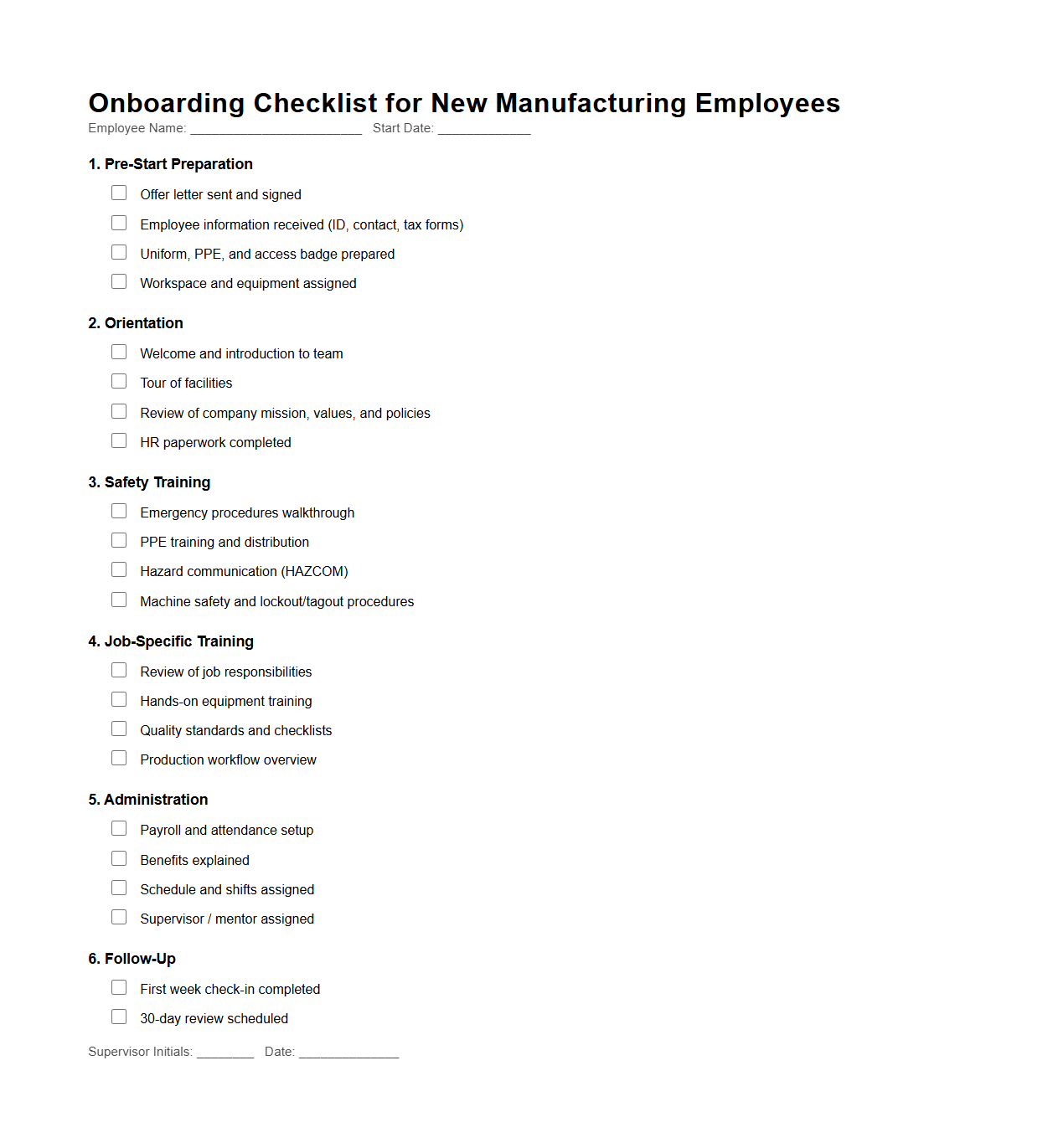

Onboarding Checklist for New Manufacturing Employees

An

Onboarding Checklist for New Manufacturing Employees is a structured document designed to guide the integration process of new hires into a manufacturing environment. It typically includes essential tasks such as safety training, equipment orientation, company policies review, and role-specific procedures to ensure compliance and productivity. This checklist helps standardize onboarding, reducing errors and accelerating employee readiness in the manufacturing sector.

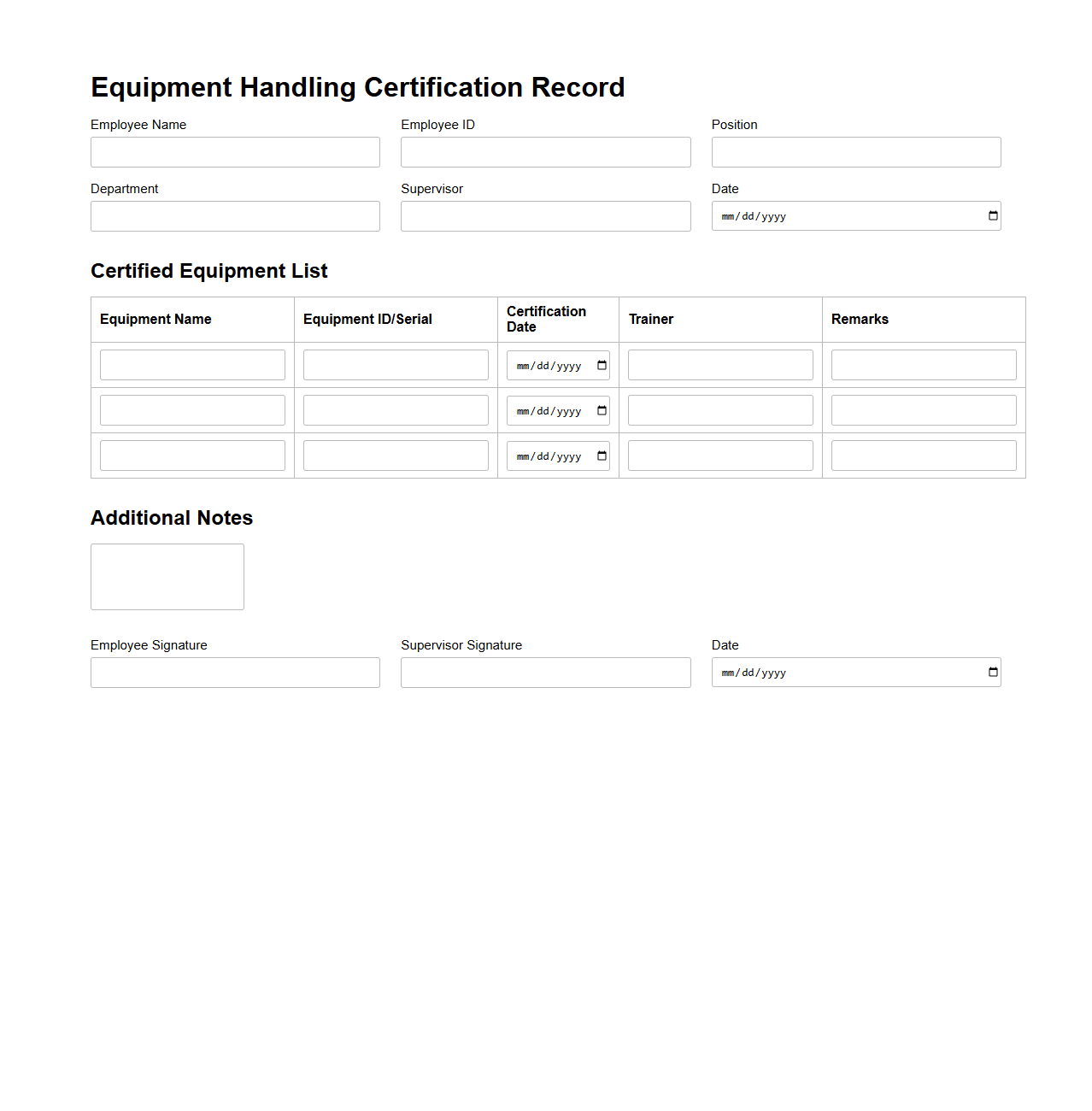

Equipment Handling Certification Record for Assembly Line Staff

The

Equipment Handling Certification Record for Assembly Line Staff is a formal document that verifies an employee's training and competency in operating specific machinery safely and efficiently. This record ensures compliance with workplace safety standards and helps reduce the risk of accidents by confirming staff have demonstrated proper equipment handling skills. Maintaining this certification is crucial for quality control and operational efficiency on the assembly line.

Refresher Training Tracking Form for Plant Workers

The

Refresher Training Tracking Form for Plant Workers is a critical document designed to monitor and record the ongoing training sessions provided to employees within an industrial plant setting. It ensures compliance with safety regulations by documenting the completion dates, topics covered, and employee attendance, helping to maintain high standards of operational safety and efficiency. This form serves as a key tool for HR and safety managers to track skill updates and identify training gaps among plant workers effectively.

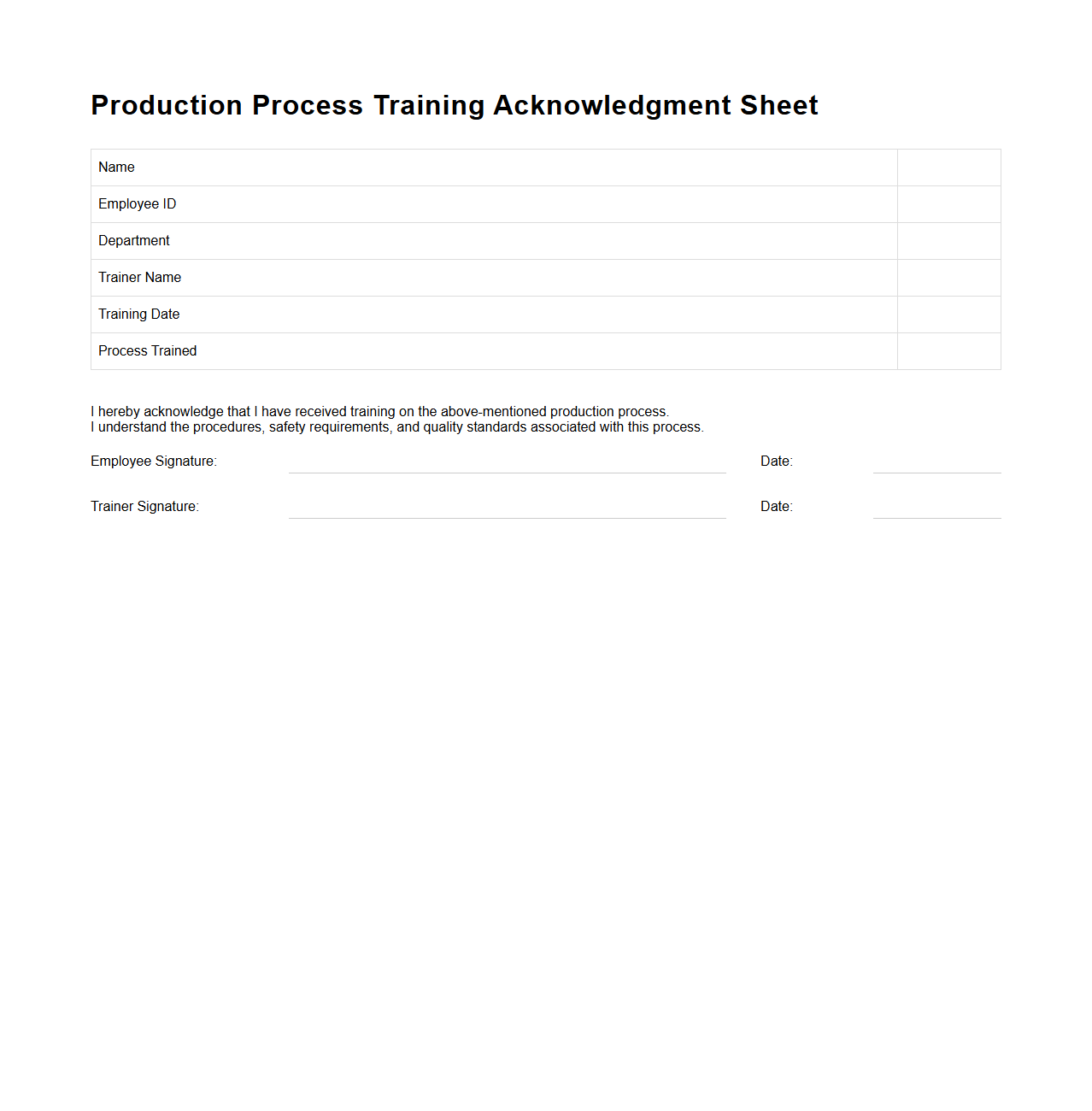

Production Process Training Acknowledgment Sheet

The

Production Process Training Acknowledgment Sheet document serves as a formal record confirming that employees have completed training related to specific production processes. It details the training topics covered, dates, and the trainee's acknowledgment of understanding and compliance with the procedures. This document is essential for maintaining quality control, ensuring workplace safety, and demonstrating regulatory compliance in manufacturing environments.

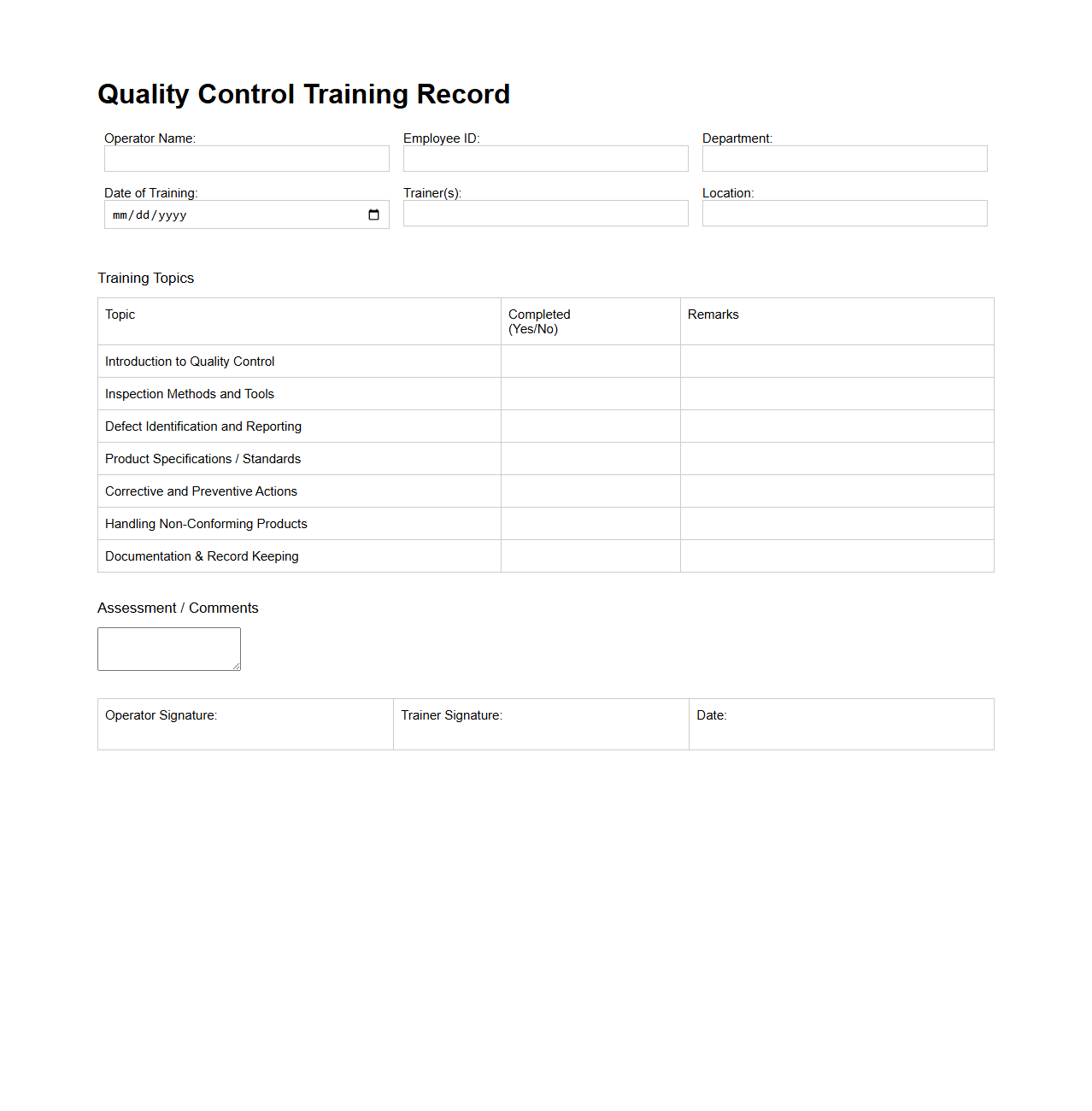

Quality Control Training Record for Manufacturing Operators

A

Quality Control Training Record for Manufacturing Operators document systematically tracks the completion and proficiency of quality control training sessions specific to manufacturing processes. This record ensures operators are qualified to perform their tasks in compliance with industry standards and regulatory requirements, minimizing product defects and maintaining consistent production quality. Maintaining accurate training records aids in audits and continuous improvement initiatives by providing verifiable evidence of operator competencies and training history.

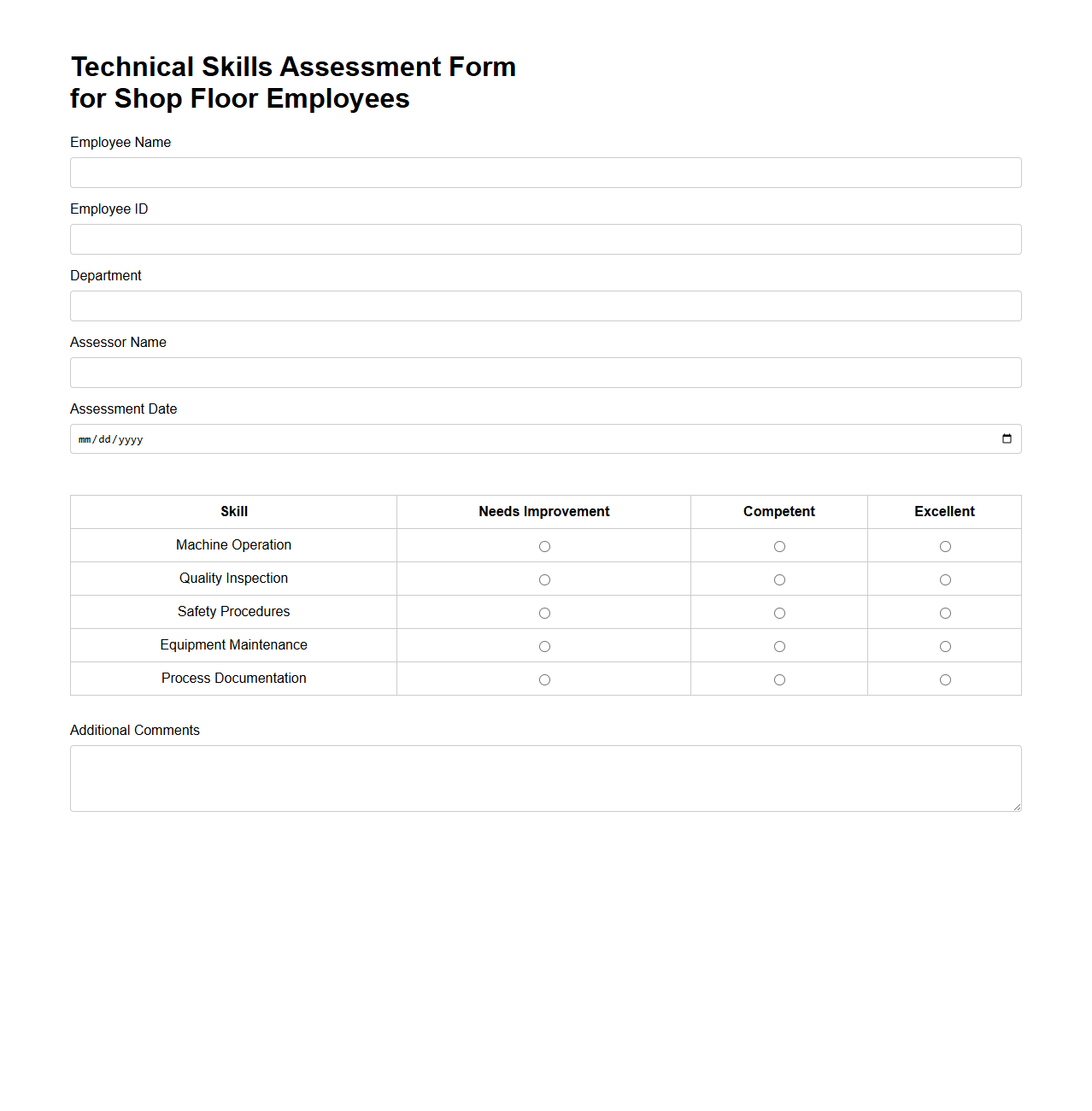

Technical Skills Assessment Form for Shop Floor Employees

The

Technical Skills Assessment Form for shop floor employees is a structured document used to evaluate and document the specific technical abilities and competencies required for various operational tasks. It measures proficiency in critical skills such as machinery operation, safety protocols, quality control, and equipment maintenance. This form ensures consistent skill validation and helps identify training needs to enhance overall workforce performance on the shop floor.

What essential information must be included in a manufacturing staff training record document?

A manufacturing staff training record document must include the employee's full name, job title, and identification number. It should detail the specific training modules completed, including dates and duration. Additionally, the document must record the training provider and any certifications earned.

How does the document verify staff competency and completion of specific training modules?

The document verifies staff competency through documented assessments, test results, or supervisor sign-offs upon training completion. It includes signatures or digital confirmations from both the trainee and trainer to confirm participation. Competency evidence may also incorporate practical evaluations and refresher course completions.

Which roles and responsibilities are outlined in maintaining and updating the training record?

Typically, the Human Resources department or designated training coordinator is responsible for maintaining and updating the training record. Supervisors must ensure staff attend required training and report any changes promptly. Employees are also accountable for participating in training and providing accurate information about their progress.

How is document approval, review, and revision history tracked for training record compliance?

A proper approval and review system includes documented signatures from management confirming the validity of records. Revision history logs must capture the date of changes, the person authorizing them, and the nature of updates. Regular audits are conducted to ensure ongoing compliance with regulatory and company standards.

What methods are in place within the document for tracking mandatory and refresher trainings?

The document uses automated alerts and checklists to track mandatory and refresher trainings for each employee. Scheduled reminders notify staff and supervisors when retraining is due to maintain competency. Detailed logs of past training ensure transparency and facilitate timely compliance with organizational policies.

More Manufacturing Templates