A Root Cause Analysis Document Sample for Process Issues provides a structured approach to identify and address the underlying causes of process inefficiencies or failures. It typically includes a detailed problem description, analysis of contributing factors, and recommended corrective actions to prevent recurrence. This document helps organizations improve process performance and maintain quality standards effectively.

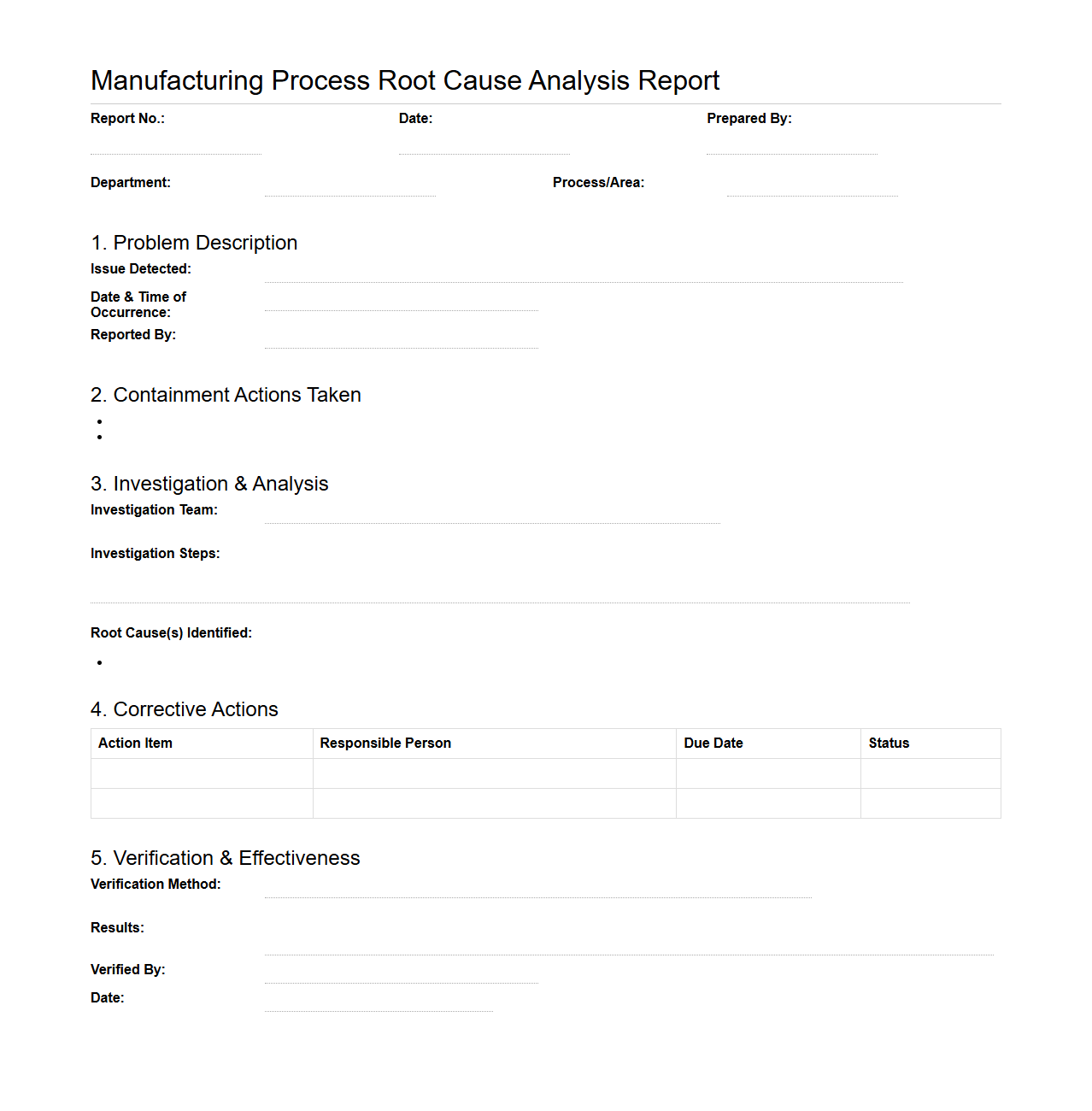

Manufacturing Process Root Cause Analysis Report

A

Manufacturing Process Root Cause Analysis Report document systematically identifies and examines the underlying causes of defects or failures within a manufacturing process. It includes detailed data collection, analysis techniques such as fishbone diagrams or 5 Whys, and corrective action recommendations to prevent recurrence. This report is essential for improving process efficiency, product quality, and minimizing downtime in production environments.

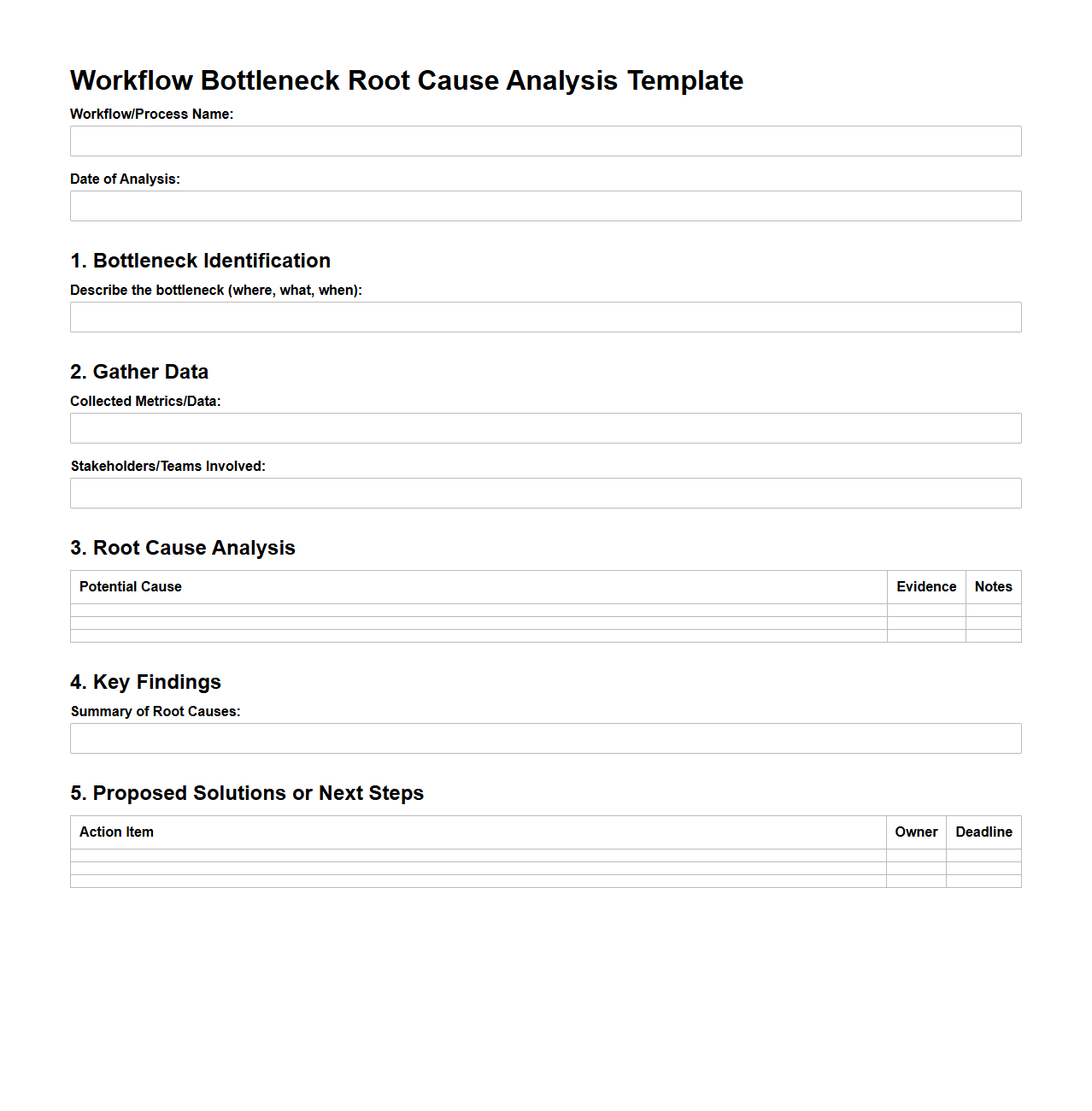

Workflow Bottleneck Root Cause Analysis Template

The

Workflow Bottleneck Root Cause Analysis Template document is a structured tool designed to identify and analyze the underlying causes of delays or inefficiencies in business processes. It helps teams systematically pinpoint specific workflow stages where bottlenecks occur, enabling targeted improvements. By documenting root causes, impact, and potential solutions, organizations can optimize productivity and reduce process downtime.

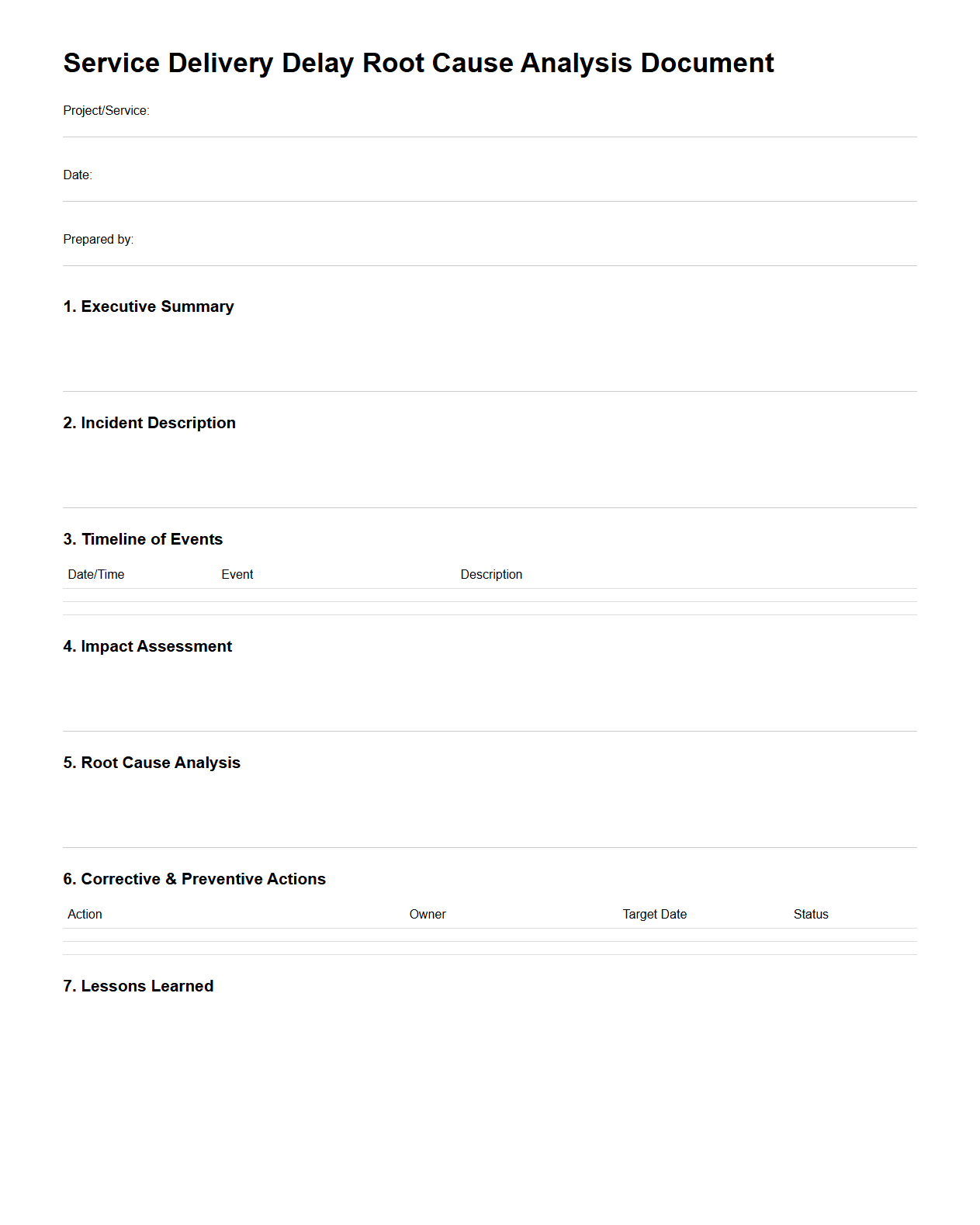

Service Delivery Delay Root Cause Analysis Document

The

Service Delivery Delay Root Cause Analysis Document systematically identifies underlying factors contributing to delays in delivering services, enabling organizations to pinpoint process inefficiencies and bottlenecks. This document includes detailed timelines, stakeholder inputs, and performance metrics to facilitate data-driven decision-making for corrective actions. It serves as a critical tool for improving operational efficiency and enhancing customer satisfaction by addressing and preventing future service delays.

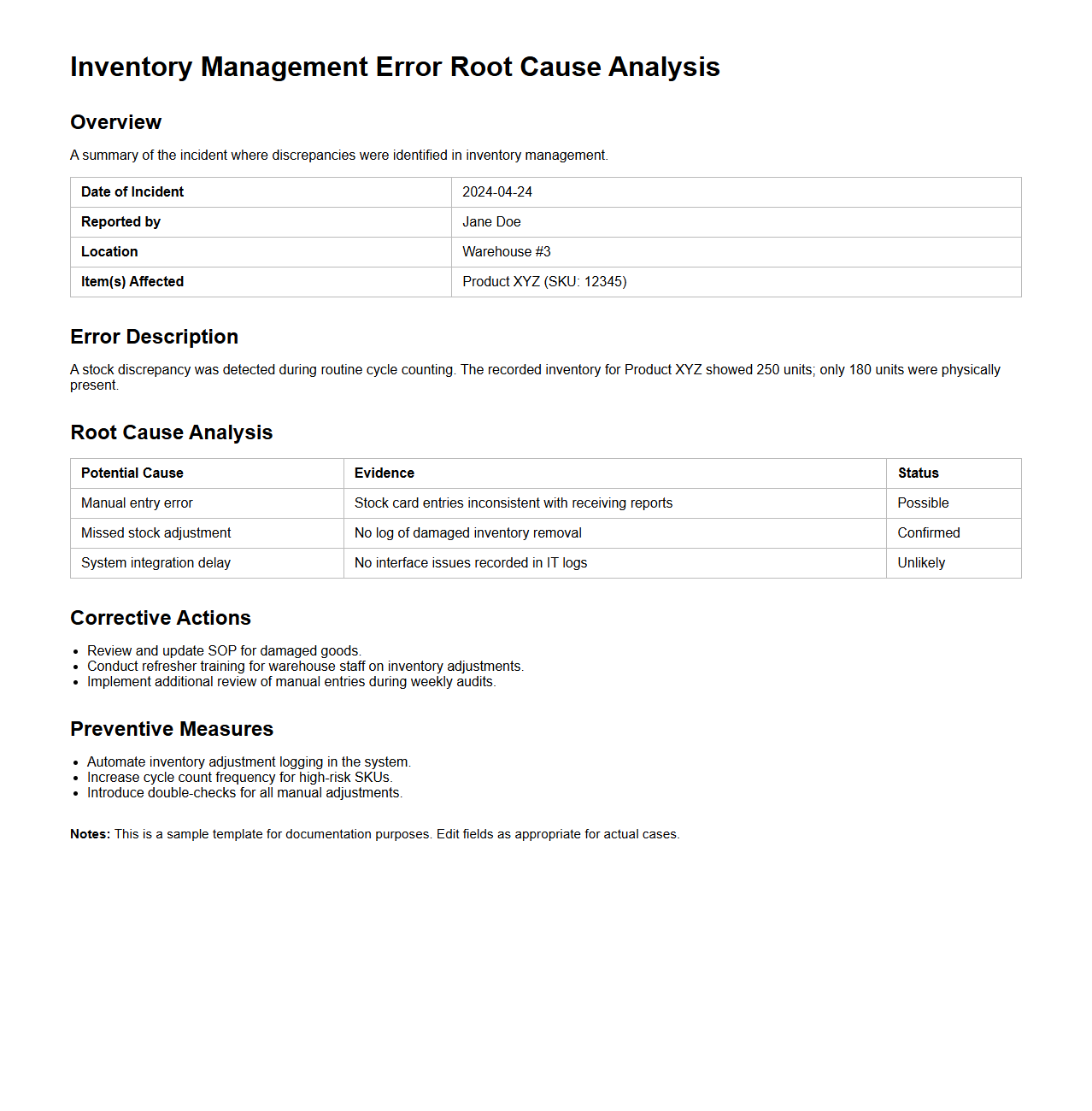

Inventory Management Error Root Cause Analysis Example

An

Inventory Management Error Root Cause Analysis Example document systematically identifies the underlying causes of errors in inventory tracking and control processes. It provides a detailed examination of inventory discrepancies, highlighting factors such as data entry mistakes, system integration issues, or procedural lapses. This document serves as a practical reference to improve accuracy, reduce stockouts, and enhance overall supply chain efficiency.

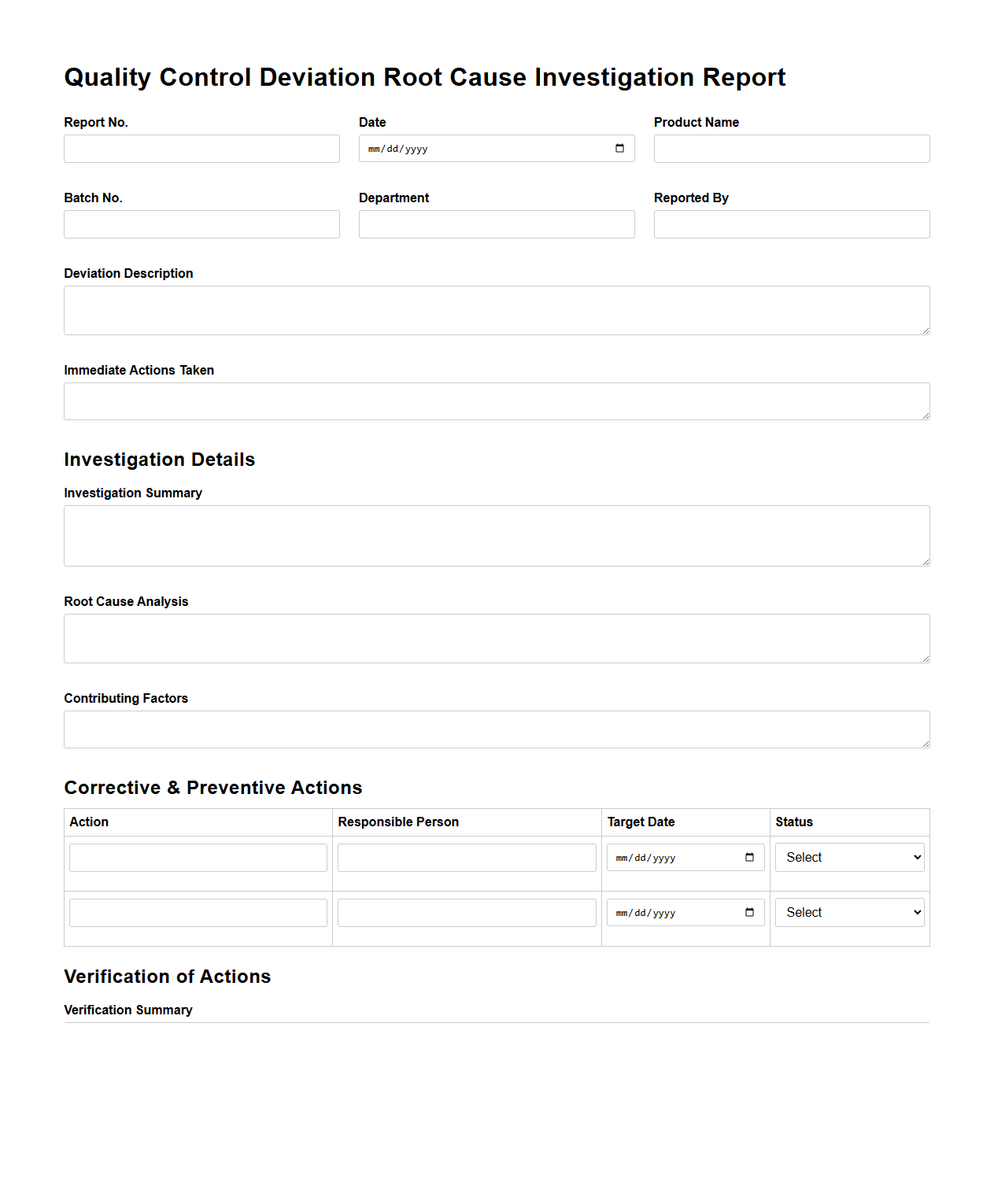

Quality Control Deviation Root Cause Investigation Report

A

Quality Control Deviation Root Cause Investigation Report document is a formal record used to identify and analyze the underlying causes of deviations from established quality standards during production or testing processes. It provides detailed documentation of the investigation findings, corrective actions, and preventive measures to ensure compliance and avoid recurrence. This report is essential for maintaining product integrity, regulatory adherence, and continuous quality improvement in manufacturing environments.

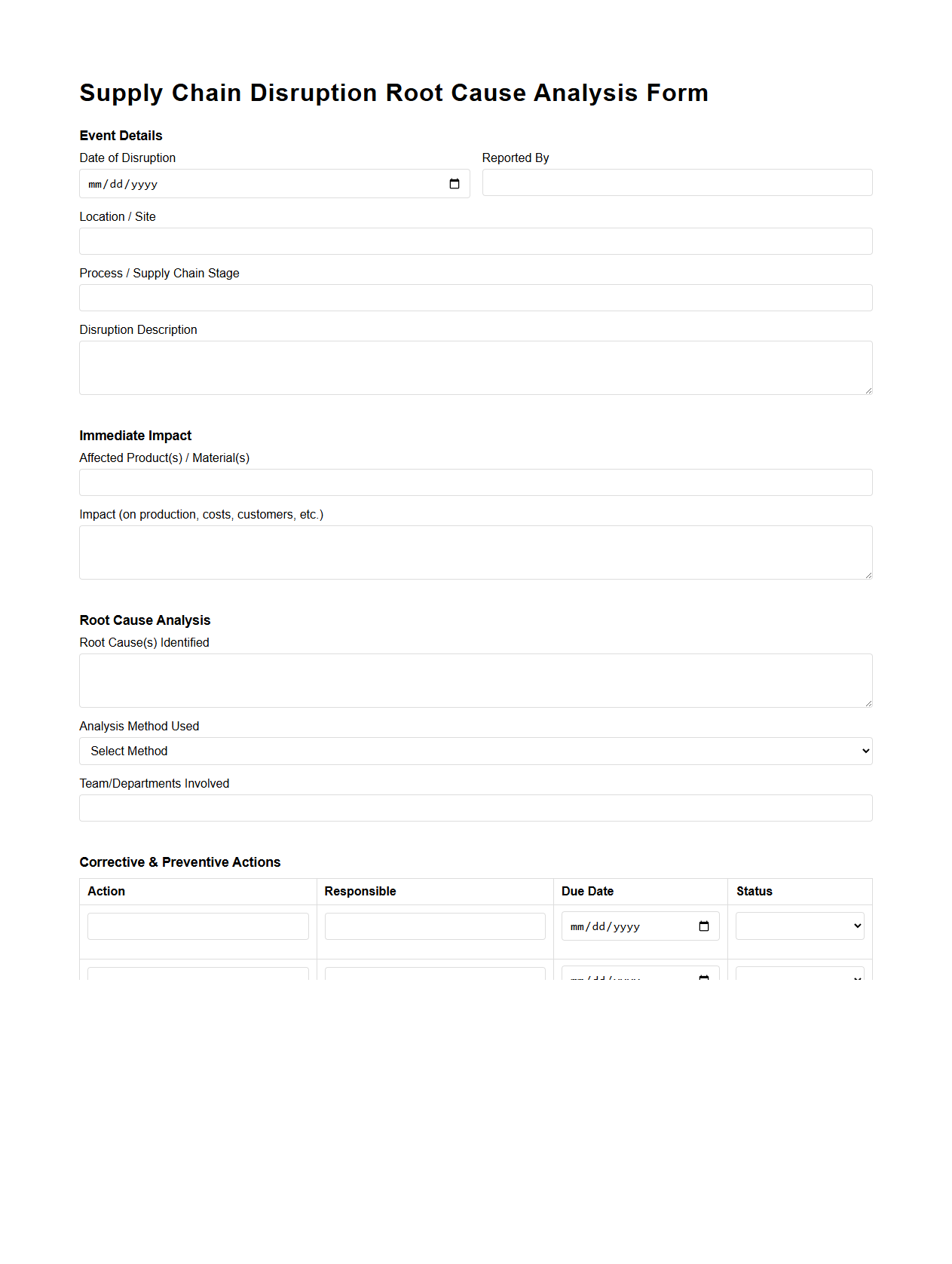

Supply Chain Disruption Root Cause Analysis Form

A

Supply Chain Disruption Root Cause Analysis Form document systematically identifies and records the fundamental reasons behind interruptions in the supply chain process. It captures data on variables such as supplier delays, logistics failures, or inventory inaccuracies to facilitate targeted corrective actions. This form is essential for improving supply chain resilience and minimizing future operational risks.

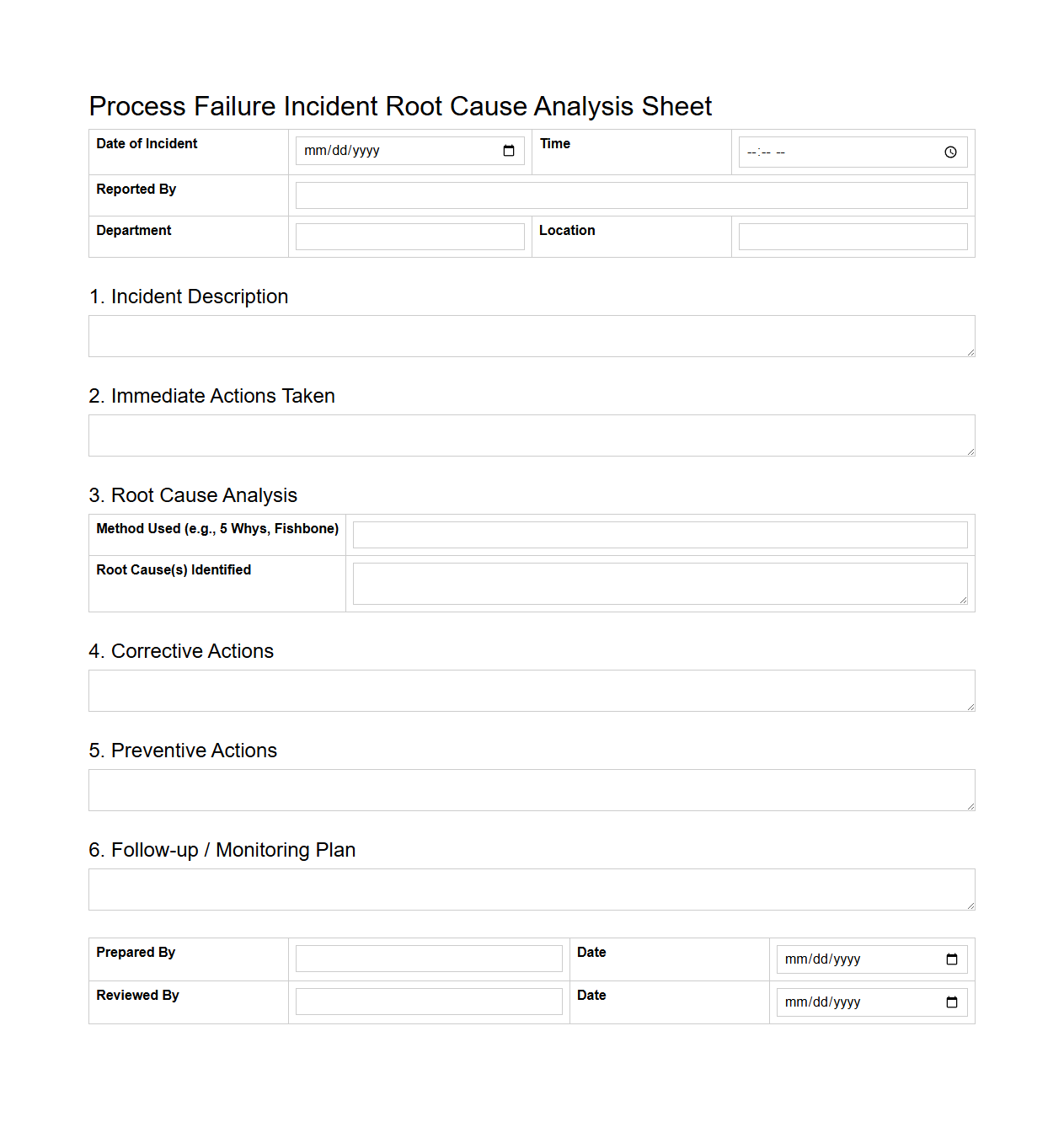

Process Failure Incident Root Cause Analysis Sheet

The

Process Failure Incident Root Cause Analysis Sheet is a structured document designed to systematically identify, analyze, and document the underlying causes of process failures within an organization. It enables teams to capture critical details such as failure type, contributing factors, and corrective actions, facilitating continuous improvement and preventing recurrence. This tool is essential in quality management systems, enhancing operational efficiency and ensuring compliance with industry standards.

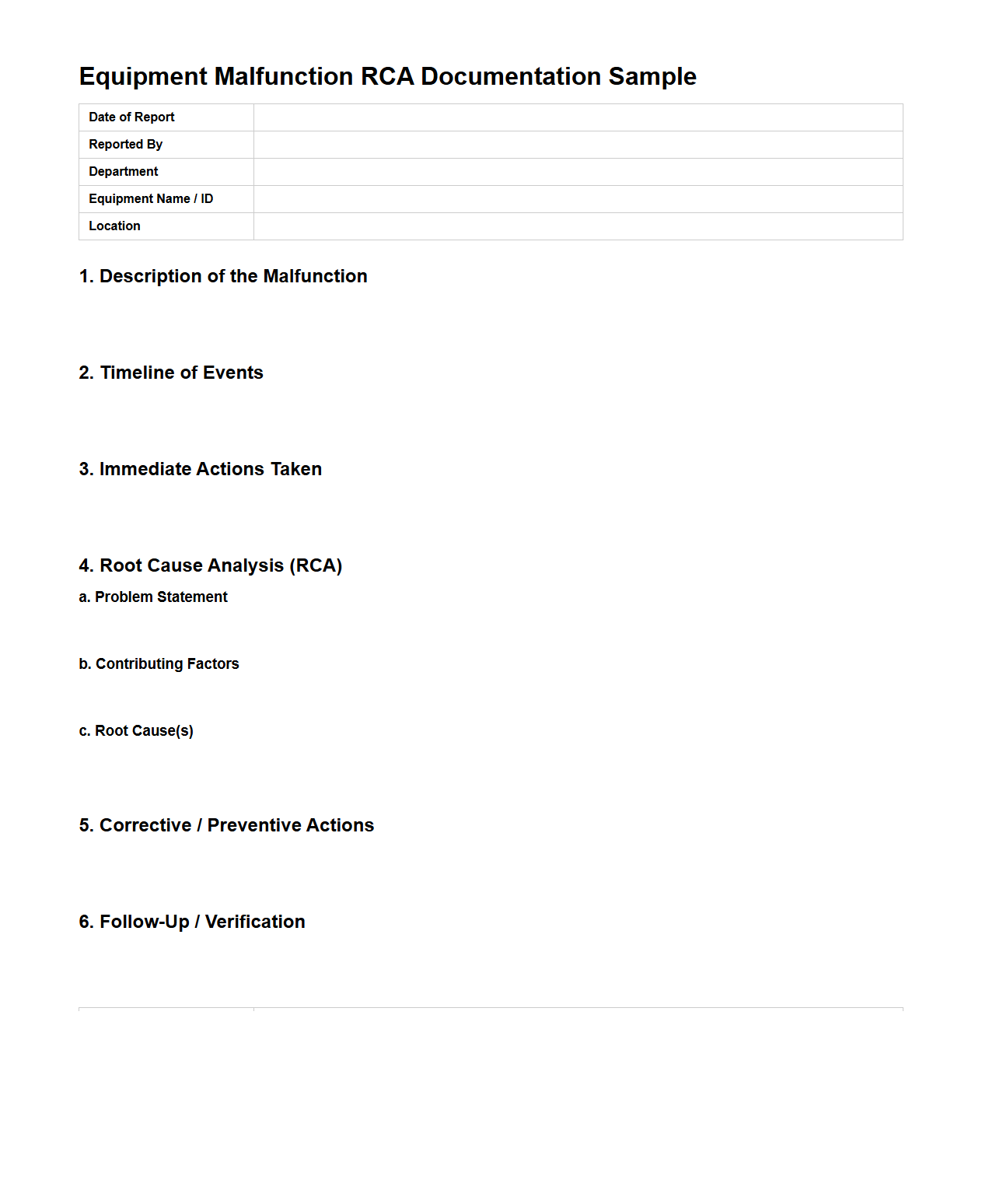

Equipment Malfunction RCA Documentation Sample

Equipment Malfunction RCA Documentation Sample document serves as a systematic record detailing the root cause analysis of an equipment failure. It includes key components such as problem identification, investigation procedures, cause analysis, corrective actions, and preventive measures to avoid recurrence. This document is essential for

enhancing maintenance strategies and improving operational reliability in industrial settings.

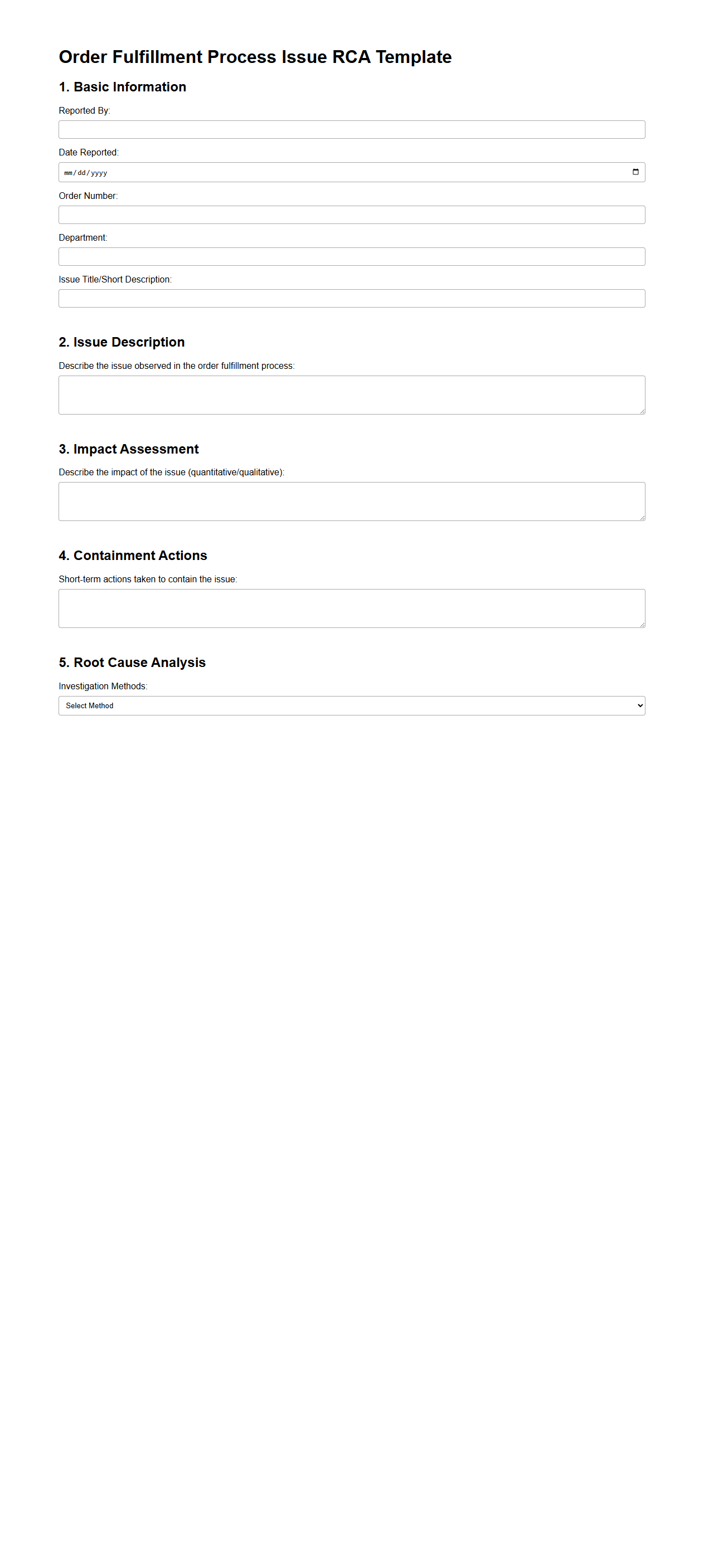

Order Fulfillment Process Issue RCA Template

The

Order Fulfillment Process Issue RCA Template document is designed to systematically identify the root causes of problems occurring during the order fulfillment cycle. It helps organizations analyze delays, errors, or inefficiencies by breaking down the process stages and pinpointing bottlenecks or failures. Utilizing this template improves operational efficiency, enhances customer satisfaction, and supports continuous process improvement initiatives.

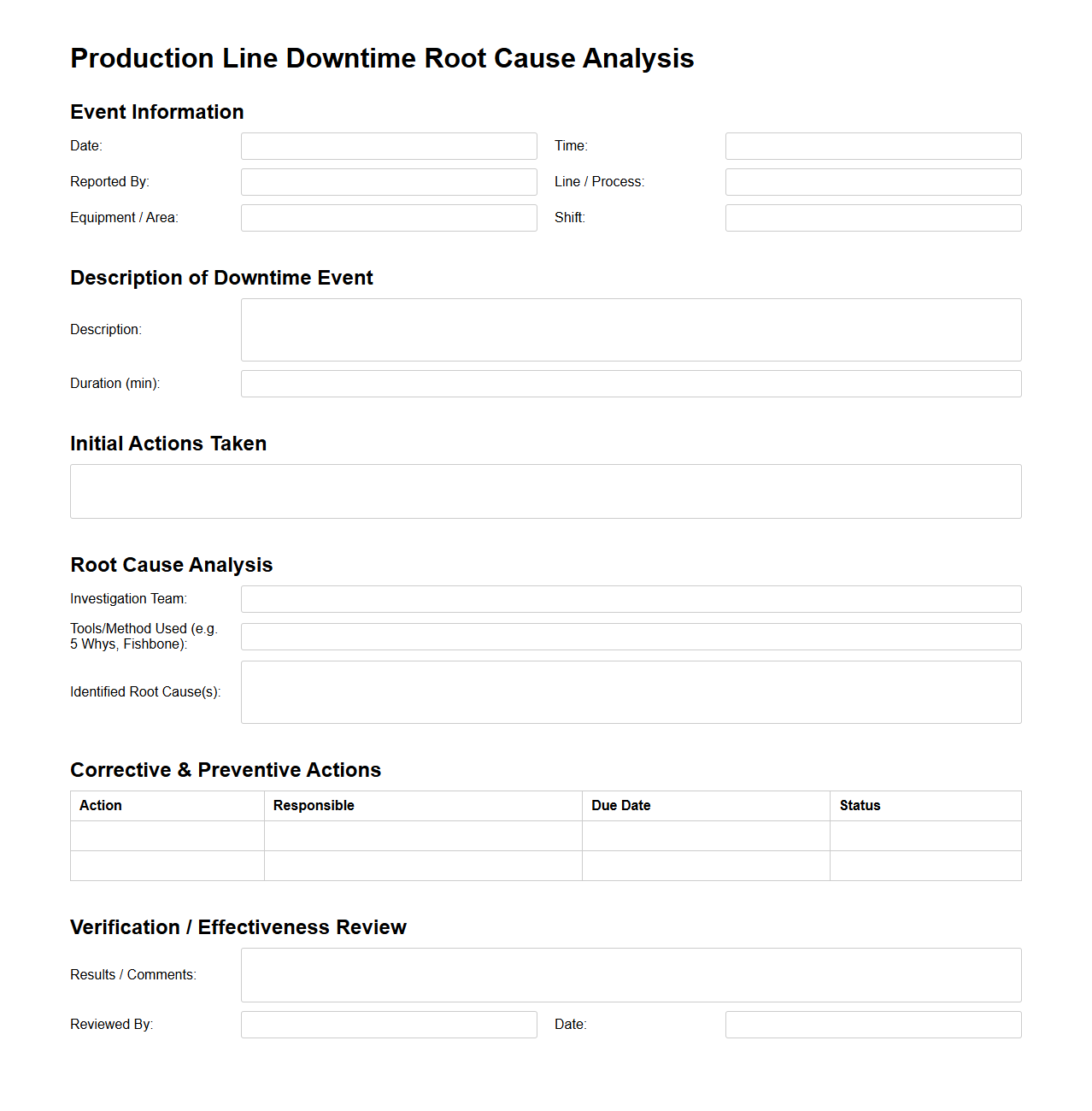

Production Line Downtime Root Cause Analysis File

The

Production Line Downtime Root Cause Analysis File document systematically records, investigates, and identifies the underlying causes of production line stoppages to minimize unplanned downtime. It includes detailed data such as incident descriptions, timestamps, equipment involved, and corrective actions taken to improve operational efficiency. This file serves as a critical tool for continuous improvement, helping manufacturing teams to implement preventative measures and optimize production flow.

What specific process issue is being analyzed in this Root Cause Analysis document?

The analysis focuses on a critical process inefficiency causing delayed product delivery. This delay negatively impacts customer satisfaction and operational costs. Identifying the root cause aims to restore timely and reliable delivery schedules.

Which data sources and methods were used to identify the root cause(s) of the issue?

The investigation employed process flowcharts, performance metrics, and employee interviews as primary data sources. Analytical methods such as the 5 Whys and Fishbone diagrams were utilized to systematically pinpoint causes. These tools helped in triangulating data for comprehensive insight.

What key contributing factors are highlighted in the analysis?

The analysis highlights inefficient workflow coordination, outdated equipment, and insufficient employee training as major contributors. Additionally, communication breakdowns between departments exacerbate delays. These factors collectively result in process bottlenecks.

Which corrective actions are recommended in the document to address the root cause(s)?

The document recommends upgrading key machinery, implementing standardized training programs, and enhancing interdepartmental communication protocols. These interventions aim to streamline operations and reduce errors. A phased implementation plan ensures manageable transition and resource allocation.

How will the effectiveness of the proposed solutions be monitored and measured?

Effectiveness will be tracked using key performance indicators (KPIs) such as delivery time, error rates, and customer feedback scores. Regular audits and progress reviews will ensure adherence to corrective measures. Continuous improvement will be supported through data-driven adjustments.

More Manufacturing Templates