A Safety Inspection Checklist Document Sample for Manufacturing provides a comprehensive guide to identifying potential hazards and ensuring compliance with industry safety standards. This document outlines specific inspection points related to machinery, employee protective equipment, and workplace environment to minimize risks and maintain a safe production area. Regular use of this checklist helps manufacturers prevent accidents and promote a culture of safety within the facility.

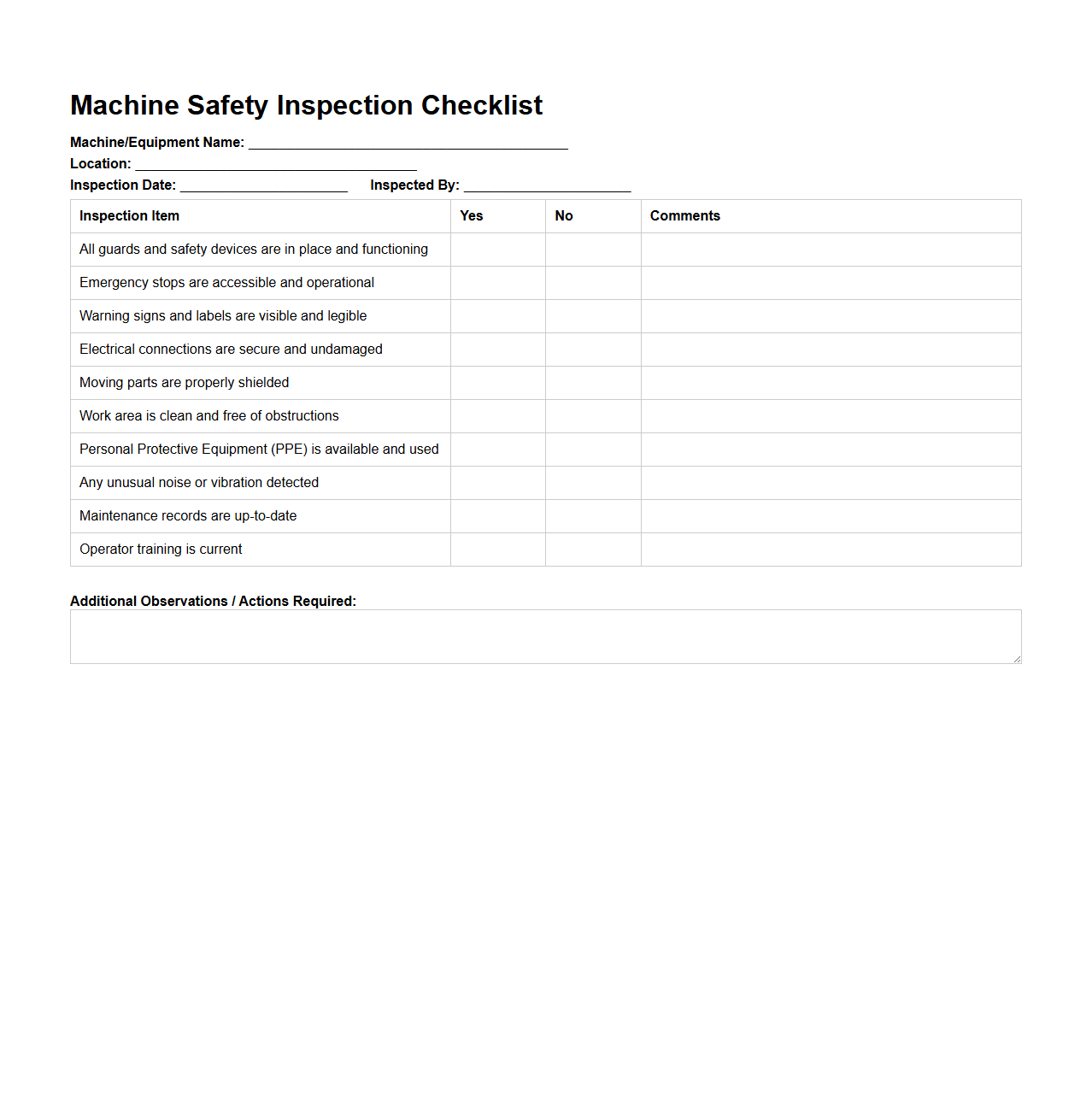

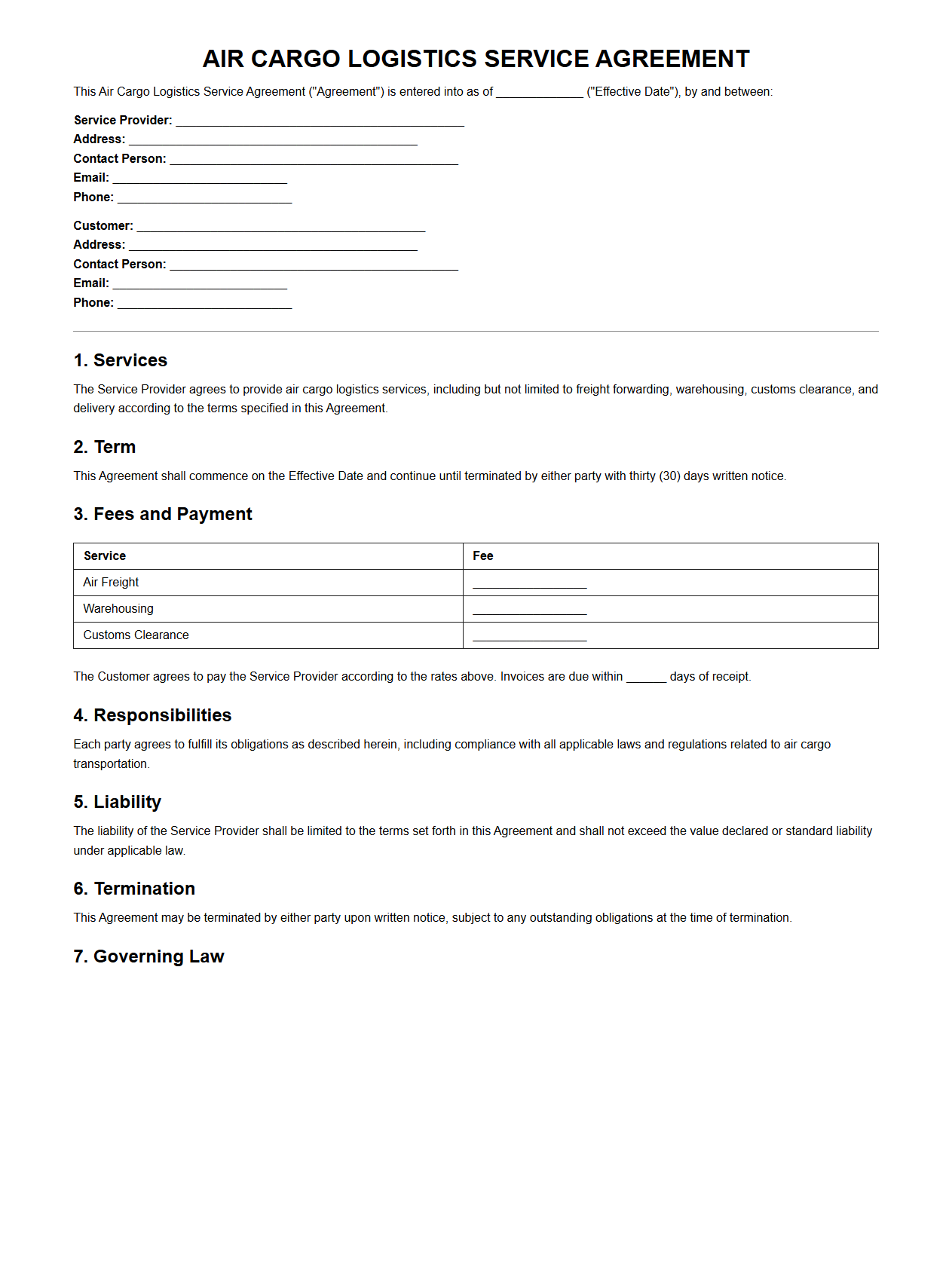

Machine Safety Inspection Checklist Template

The

Machine Safety Inspection Checklist Template is a structured document designed to ensure comprehensive evaluation of machinery for potential hazards, operational efficiency, and compliance with safety standards. It systematically guides inspectors through critical checkpoints such as emergency stop functions, guarding mechanisms, and electrical components, reducing the risk of accidents and equipment failure. This template facilitates consistent documentation, promoting workplace safety and regulatory adherence across industrial environments.

Electrical Safety Audit Checklist Example

An

Electrical Safety Audit Checklist Example document serves as a comprehensive tool to systematically evaluate electrical systems, equipment, and practices for potential hazards and compliance with safety standards. It typically includes detailed inspection items covering wiring, grounding, circuit protection, and emergency procedures to identify risks and ensure preventive measures are in place. Utilizing this checklist helps organizations maintain regulatory compliance, reduce electrical accidents, and promote a safe working environment.

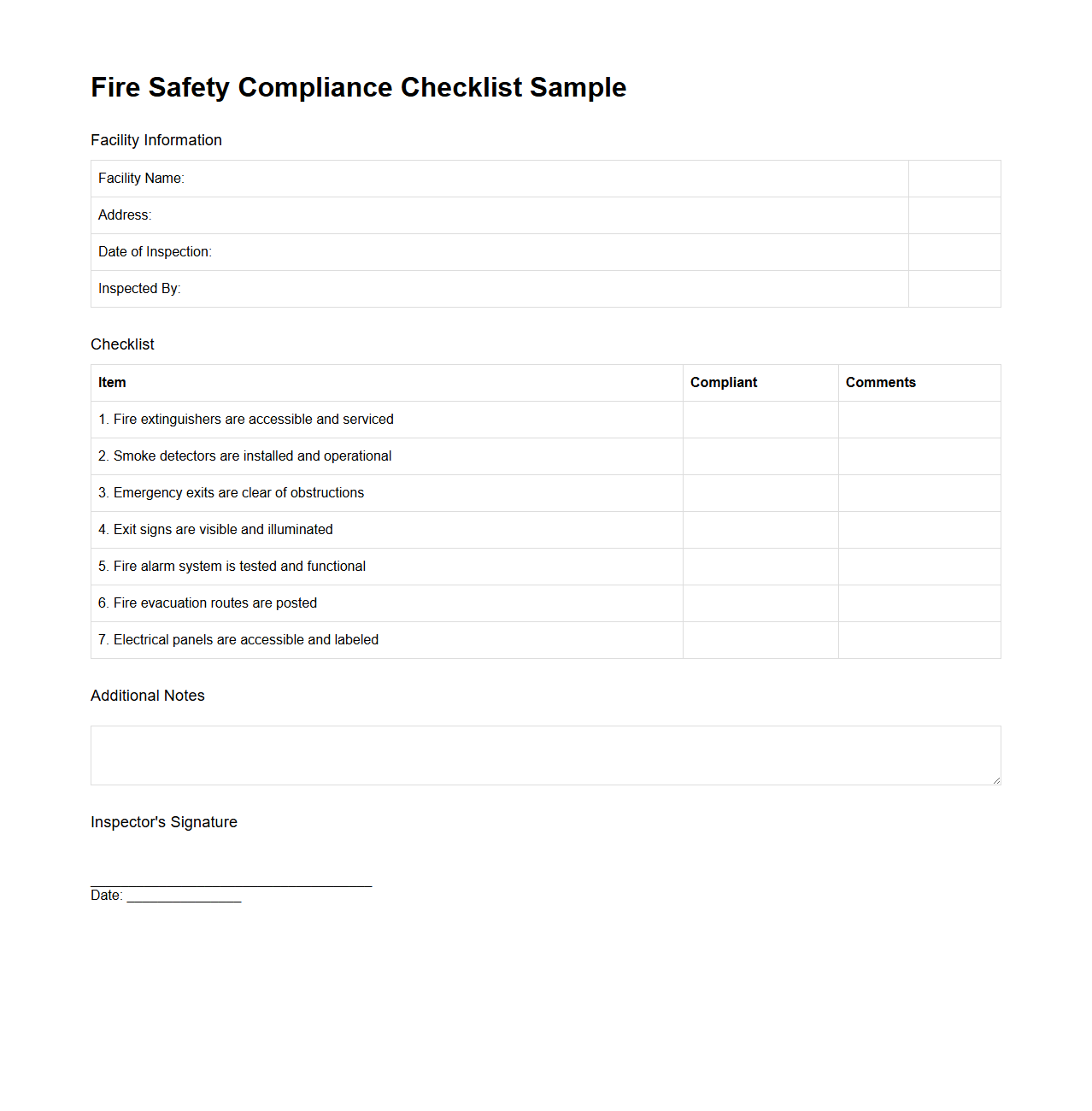

Fire Safety Compliance Checklist Sample

A

Fire Safety Compliance Checklist Sample document is a structured tool used to ensure all fire safety regulations and standards are met within a building or facility. It outlines crucial items such as fire extinguisher inspections, emergency exit accessibility, smoke alarm functionality, and proper storage of flammable materials. This checklist aids organizations in maintaining safety, preventing fire hazards, and complying with local fire codes and legal requirements.

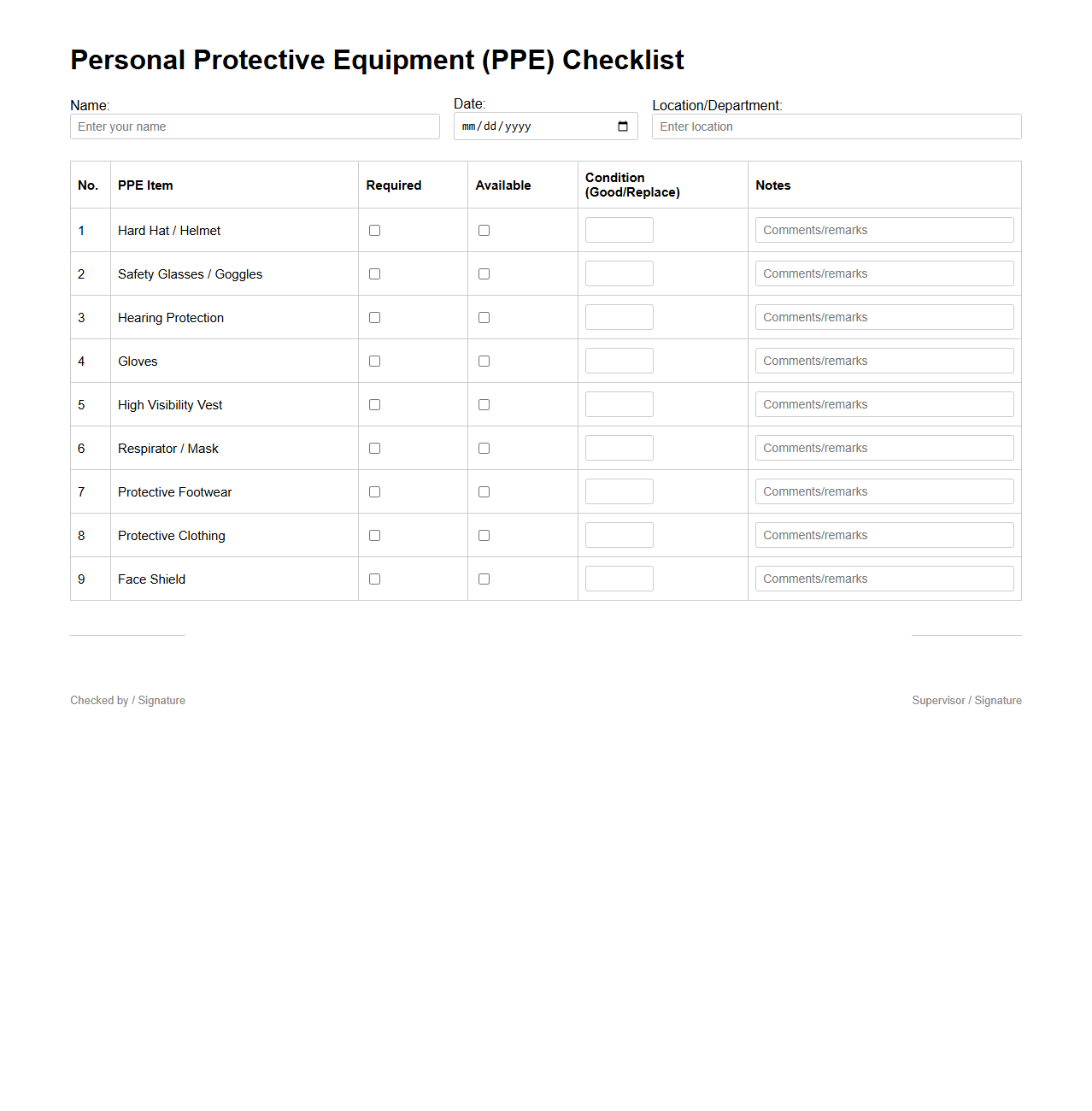

Personal Protective Equipment (PPE) Checklist Format

A

Personal Protective Equipment (PPE) Checklist Format document is a structured tool designed to ensure all required safety gear is properly inspected and available before workplace activities begin. It systematically lists specific PPE items such as helmets, gloves, goggles, and respirators, allowing for easy verification of compliance with safety standards. This checklist helps minimize workplace hazards by promoting consistent equipment use and maintenance.

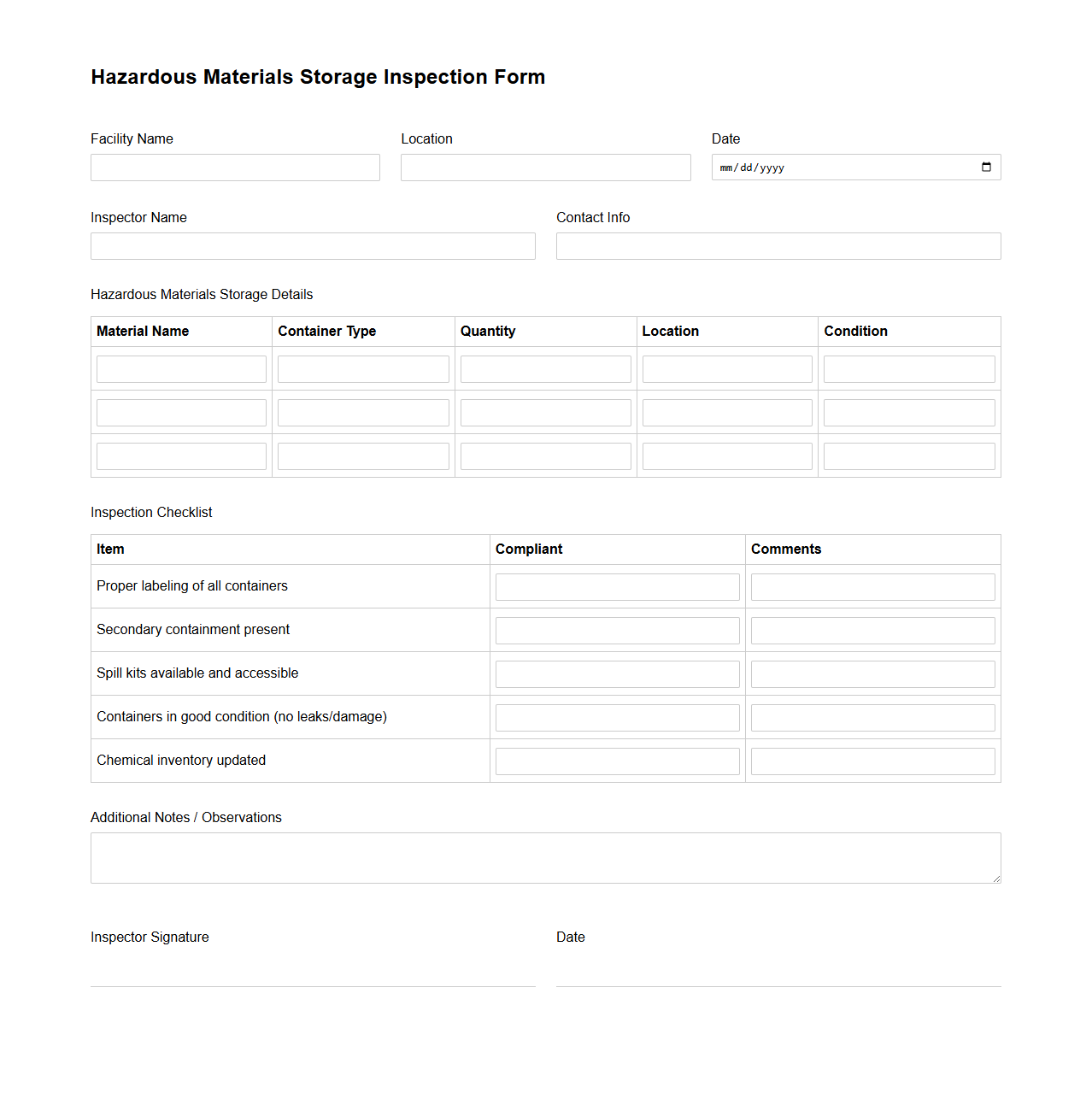

Hazardous Materials Storage Inspection Form

The

Hazardous Materials Storage Inspection Form document is used to systematically record the condition and compliance of hazardous materials storage areas with safety regulations. It ensures proper containment, labeling, and segregation of dangerous substances to prevent accidents and environmental contamination. Regular inspections documented through this form help identify potential risks and maintain workplace safety standards.

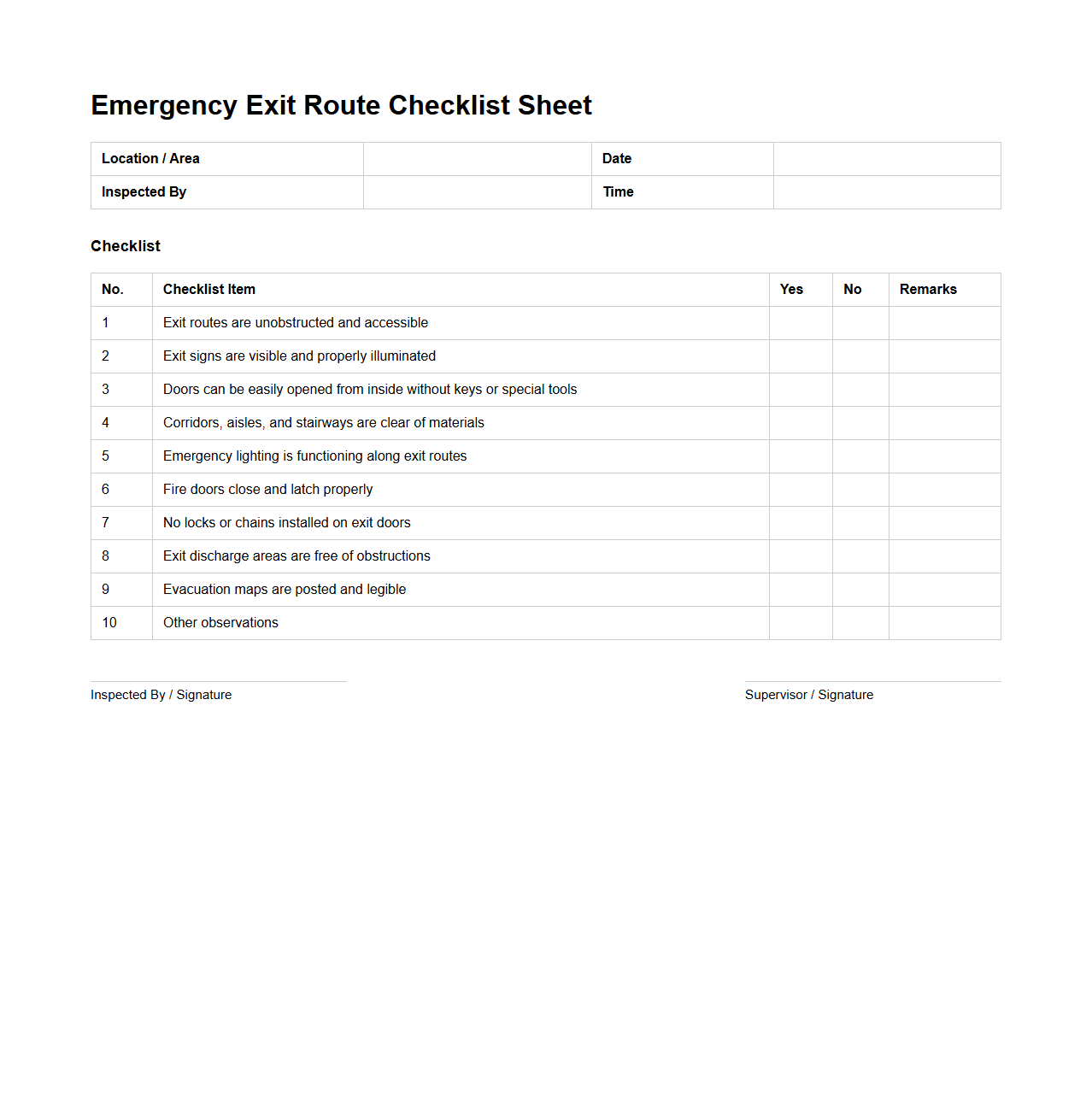

Emergency Exit Route Checklist Sheet

An

Emergency Exit Route Checklist Sheet document systematically outlines all essential safety measures and clearances required for exit paths during emergencies. It ensures compliance with fire safety regulations by verifying unobstructed routes, properly illuminated exit signs, and functional emergency lighting. Regular use of this checklist enhances workplace safety by facilitating quick evacuation and minimizing risks during critical situations.

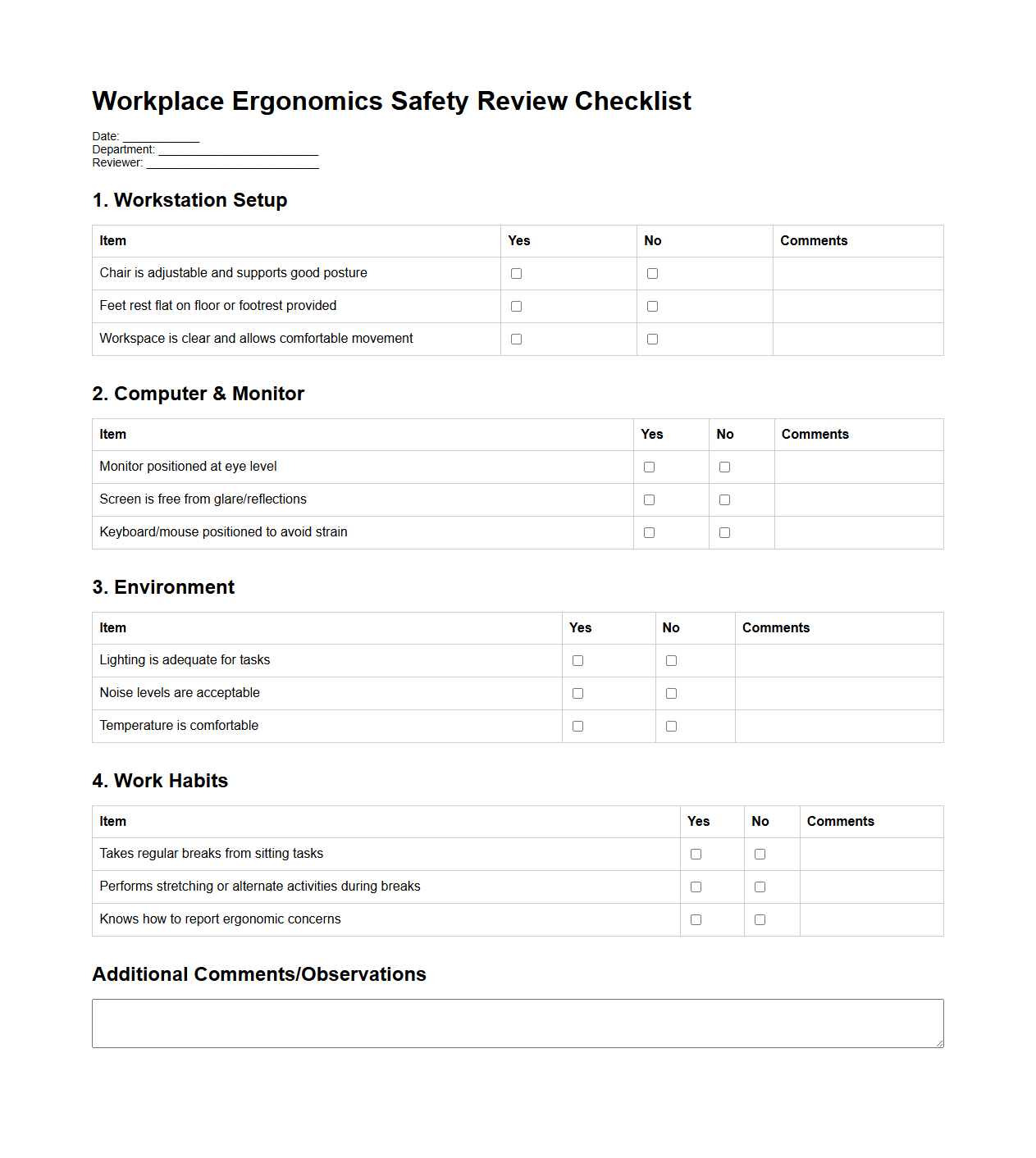

Workplace Ergonomics Safety Review Checklist

The

Workplace Ergonomics Safety Review Checklist document serves as a crucial tool for identifying and mitigating ergonomic risks in the work environment. It systematically evaluates factors such as workstation design, employee posture, and repetitive motion hazards to ensure compliance with occupational safety standards. This checklist helps organizations enhance employee comfort, reduce injury rates, and improve overall productivity by promoting ergonomic best practices.

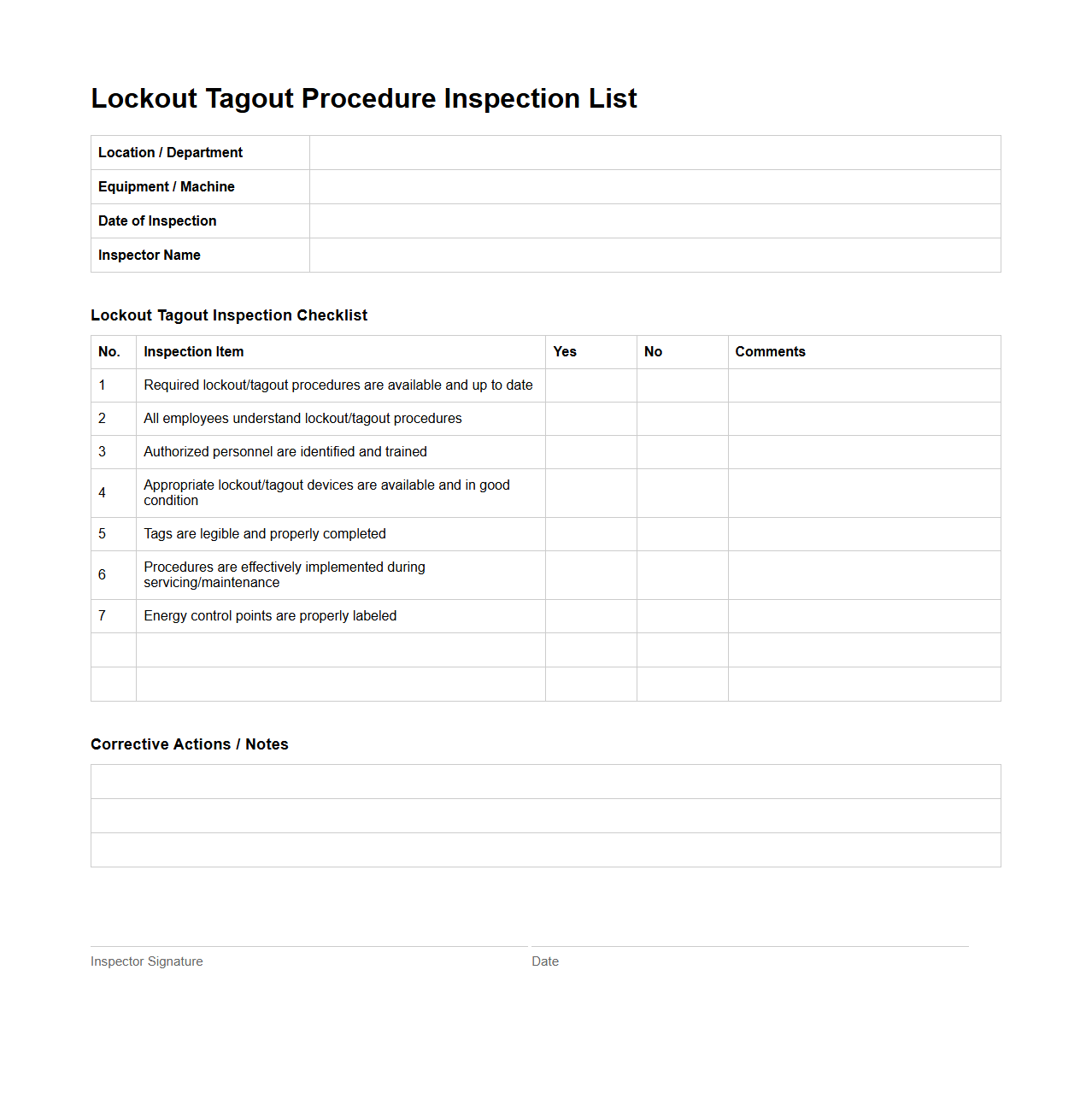

Lockout Tagout Procedure Inspection List

The

Lockout Tagout Procedure Inspection List document serves as a critical safety tool designed to ensure that all energy control procedures are properly implemented and maintained. It systematically verifies the effectiveness of lockout/tagout devices, employee training, and compliance with OSHA standards to prevent accidental machinery startup during maintenance. Regular use of this inspection list helps minimize workplace injuries by identifying potential hazards and ensuring corrective actions are taken promptly.

Chemical Spill Response Checklist Outline

The

Chemical Spill Response Checklist Outline document serves as a structured guide to efficiently manage and mitigate chemical spill incidents. It provides clear, step-by-step procedures to ensure safety, minimize environmental impact, and comply with regulatory requirements such as OSHA and EPA standards. This checklist typically includes identification of chemicals involved, emergency contacts, containment methods, personal protective equipment (PPE) usage, and cleanup protocols.

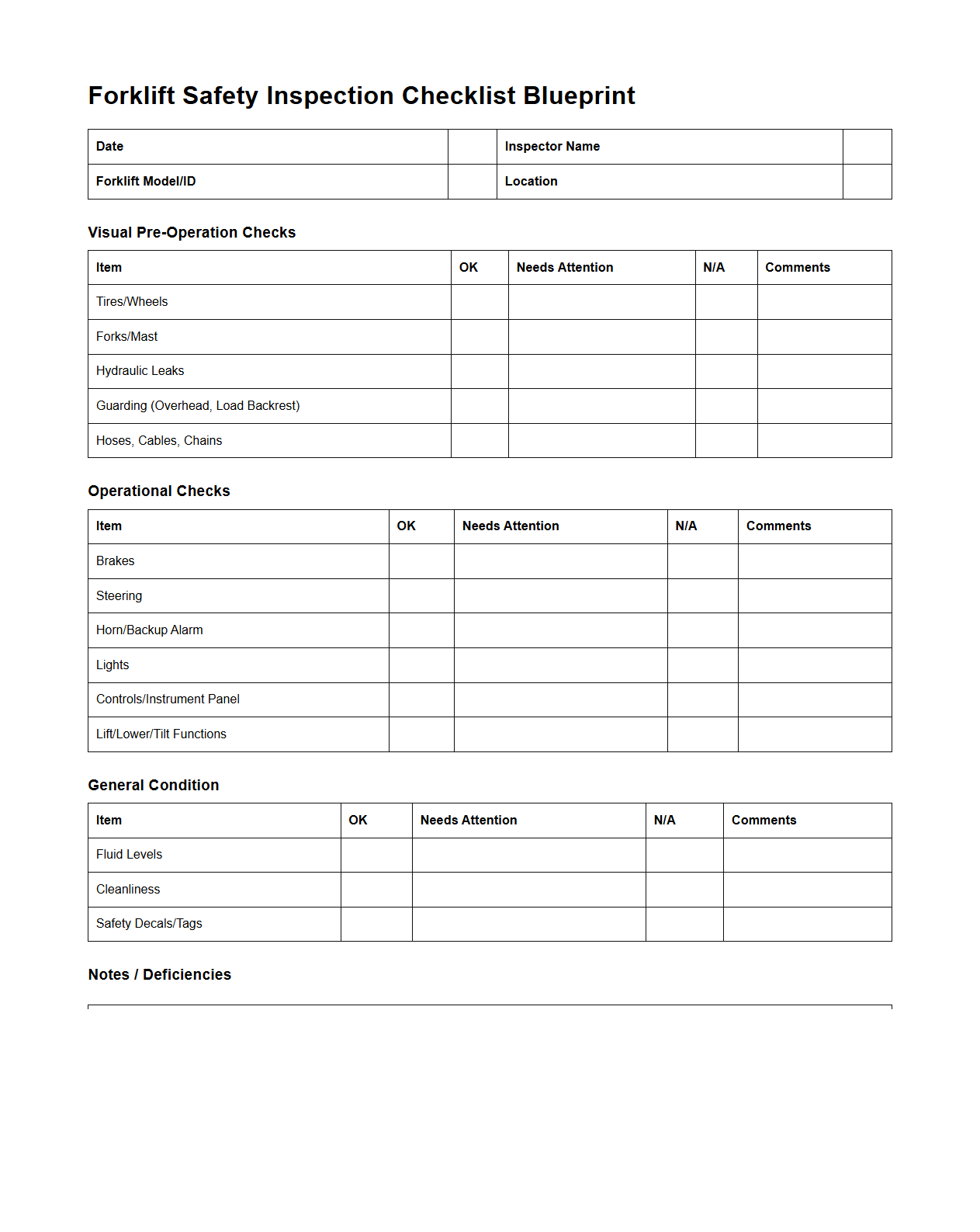

Forklift Safety Inspection Checklist Blueprint

A

Forklift Safety Inspection Checklist Blueprint document serves as a comprehensive guide to systematically evaluate the operational condition and safety features of forklifts before use. It ensures compliance with OSHA and ANSI safety standards by covering critical components such as brakes, steering, controls, and safety devices. Regular use of this checklist reduces the risk of workplace accidents and enhances overall forklift safety management.

What key hazards are identified and documented in the Safety Inspection Checklist for the manufacturing site?

The Safety Inspection Checklist identifies critical hazards such as machinery malfunctions, electrical risks, and chemical exposure. It also highlights ergonomic concerns and potential slip, trip, and fall hazards. This comprehensive approach ensures all significant risks within the manufacturing environment are systematically documented for action.

How does the checklist ensure compliance with relevant occupational safety standards and regulations?

The checklist is aligned with OSHA regulations and other pertinent local safety standards to promote full compliance. It incorporates specific audit points that correspond to legal requirements, facilitating regulatory adherence. Regular updates to the checklist ensure ongoing alignment with evolving occupational safety laws.

What specific personal protective equipment (PPE) requirements are outlined in the document?

The document specifies mandatory use of PPE including safety helmets, gloves, eye protection, and respiratory masks where necessary. It also emphasizes proper PPE maintenance and correct usage protocols. These detailed requirements help minimize employee exposure to workplace hazards effectively.

How are maintenance and housekeeping practices addressed within the checklist?

The checklist mandates routine maintenance inspections and timely repairs of equipment to prevent safety failures. It also enforces strict housekeeping standards to keep work areas clean and free of obstacles. These practices are crucial for reducing the risk of accidents and ensuring a safe operational environment.

What procedures are included in the checklist for reporting and correcting identified safety issues?

The checklist outlines a clear reporting procedure for employees to notify supervisors about hazards promptly. It includes steps for immediate corrective actions and documentation to track resolution progress. This systematic approach ensures that safety concerns are efficiently addressed and mitigated.

More Manufacturing Templates