A Finished Goods Inspection Document Sample for Manufacturing outlines the criteria and standards used to evaluate the quality of products before shipment. This document ensures that all finished goods meet the specified requirements, including dimensions, functionality, and safety. It serves as a critical tool for quality control teams to maintain consistency and customer satisfaction.

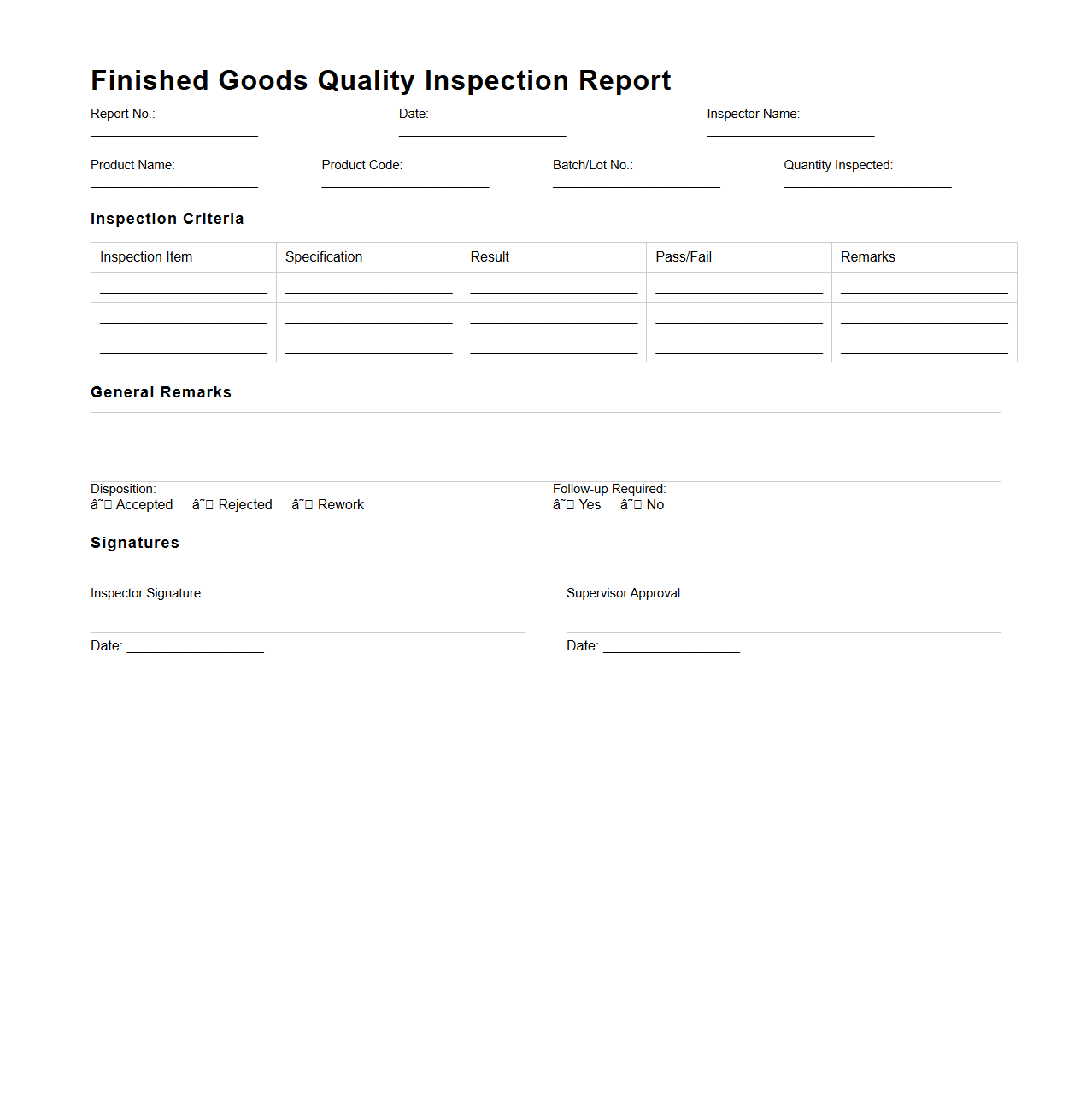

Finished Goods Quality Inspection Report Template

A

Finished Goods Quality Inspection Report Template document is a standardized form used to record and evaluate the quality of final products before they are shipped to customers. It includes detailed criteria such as product specifications, defect types, inspection results, and compliance with quality standards. This template helps ensure consistent quality control, facilitates traceability, and supports corrective actions in manufacturing processes.

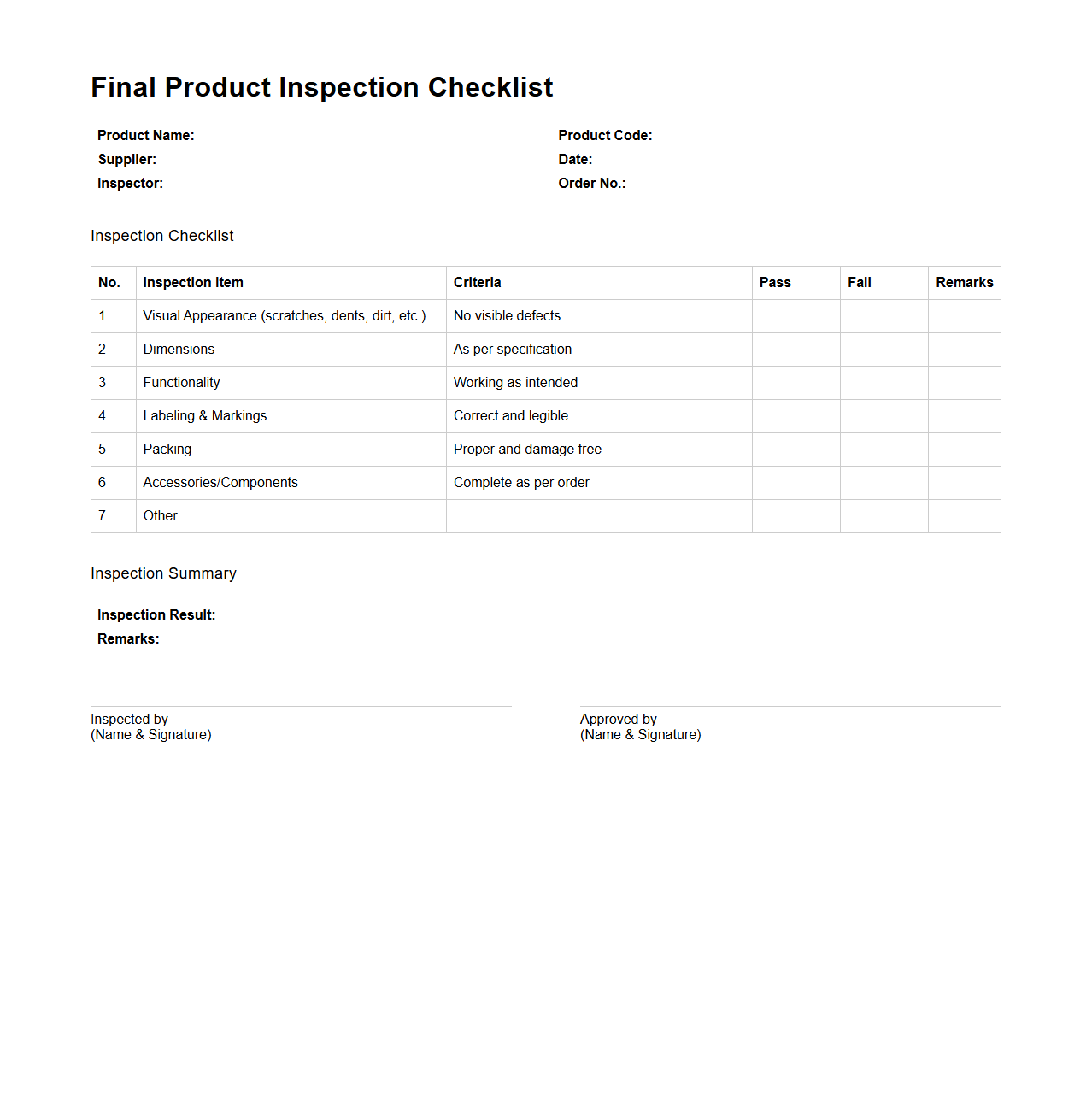

Final Product Inspection Checklist Example

A

Final Product Inspection Checklist example document serves as a detailed tool used by quality control teams to verify that products meet specified standards before shipment. It typically includes criteria such as dimensional accuracy, functionality, cosmetic appearance, and packaging integrity. Utilizing this checklist ensures consistent quality assurance, minimizes defects, and enhances customer satisfaction.

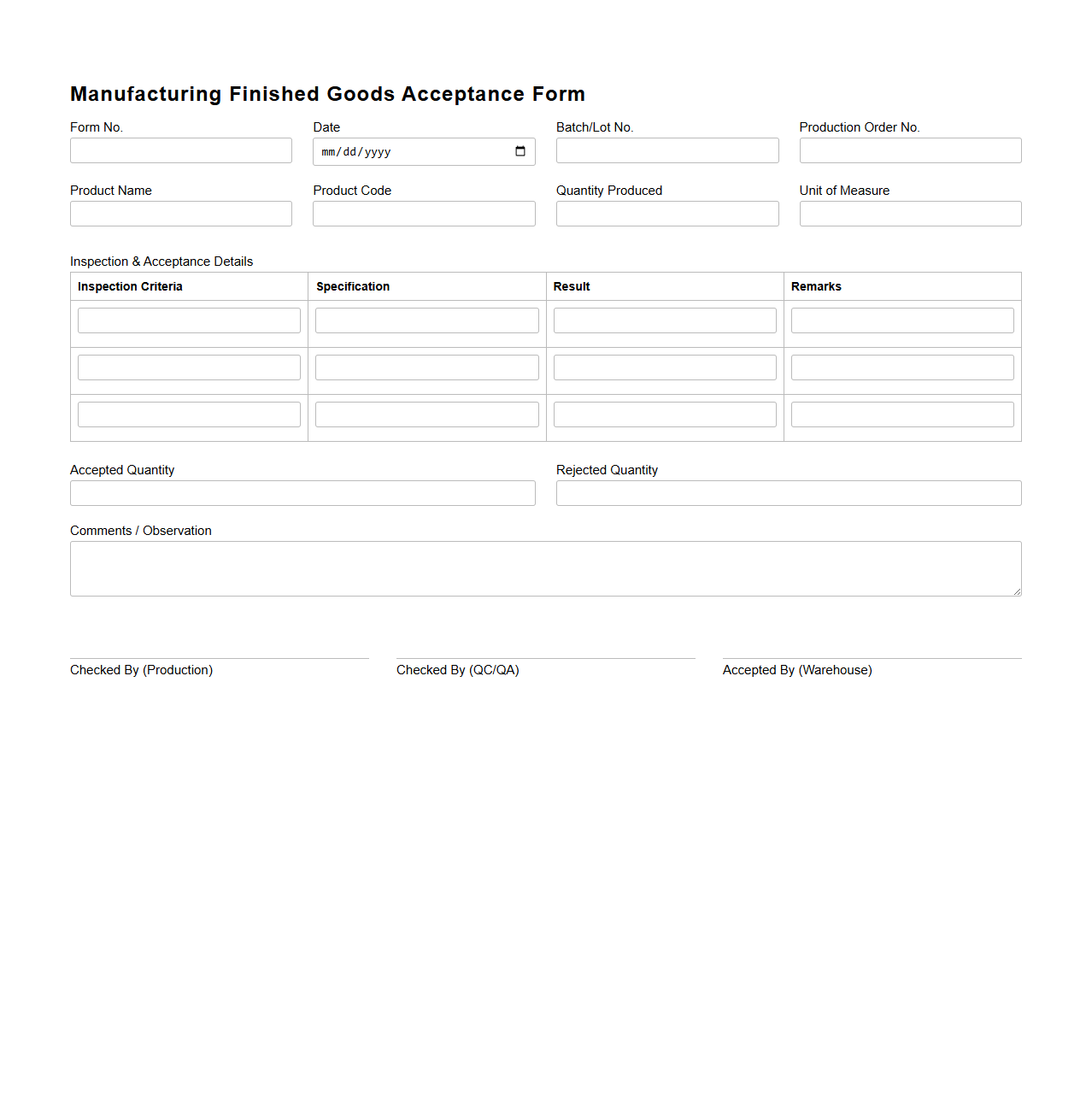

Manufacturing Finished Goods Acceptance Form

The

Manufacturing Finished Goods Acceptance Form is a critical document used to verify the quality and quantity of finished products before they are released for distribution or sale. It records inspection results, compliance with production standards, and any discrepancies found during the acceptance process. This form ensures accountability and traceability in manufacturing operations, facilitating quality control and inventory management.

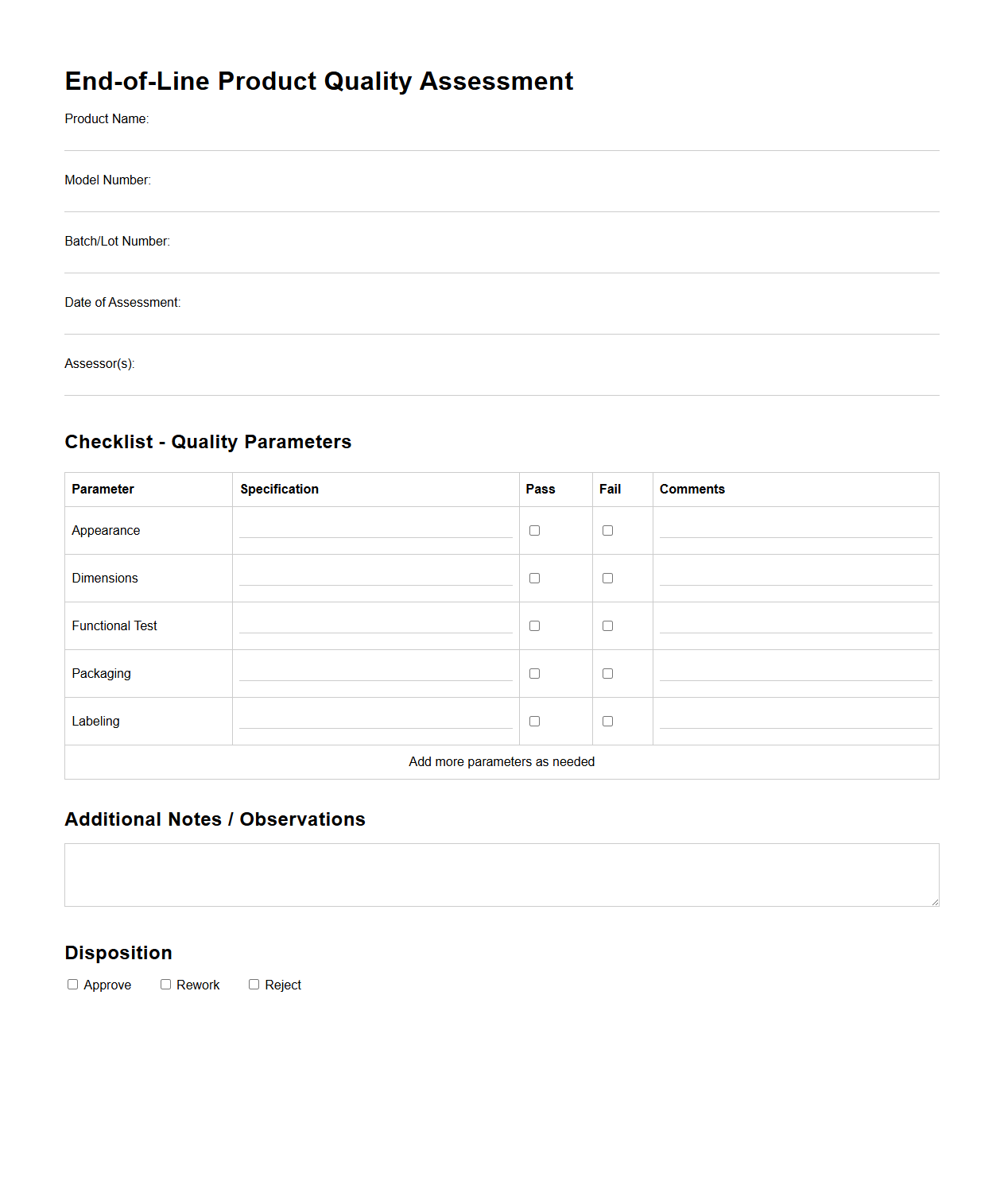

End-of-Line Product Quality Assessment Template

The End-of-Line Product Quality Assessment Template document serves as a structured framework to evaluate and ensure the final product meets established quality standards before shipment. It includes critical checkpoints such as dimensional accuracy, functional testing, and visual inspections, enabling consistent verification of product integrity. This document plays a vital role in reducing defects and increasing customer satisfaction by standardizing the

quality control process at the production line's conclusion.

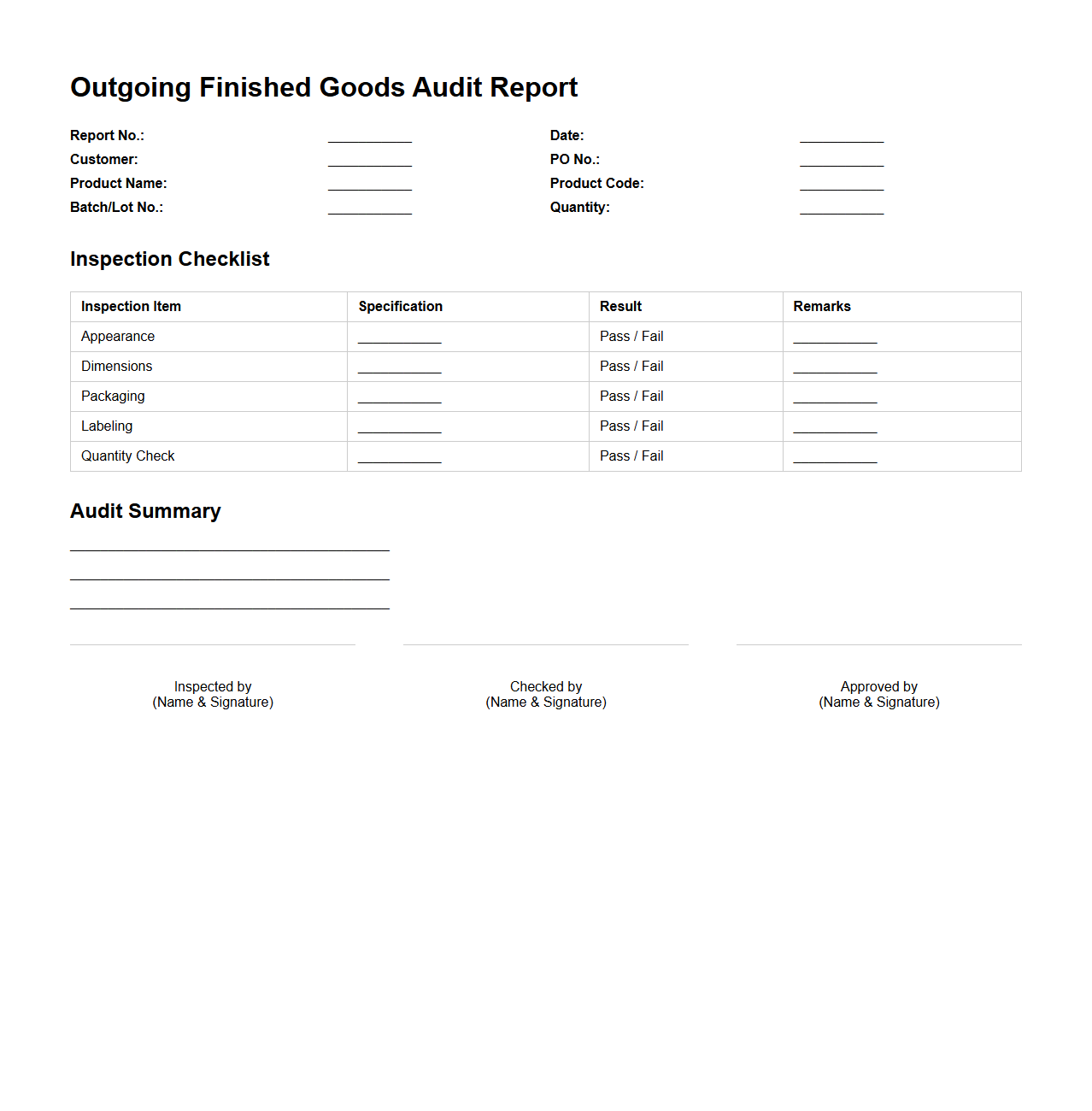

Outgoing Finished Goods Audit Report Sample

The

Outgoing Finished Goods Audit Report Sample document provides a structured template used to evaluate and verify the quality, quantity, and compliance of finished products before shipment. It includes detailed checklists for product specifications, packaging integrity, and record accuracy, ensuring that all goods meet company standards and customer requirements. This report helps in maintaining quality control, reducing errors, and supporting traceability in the supply chain process.

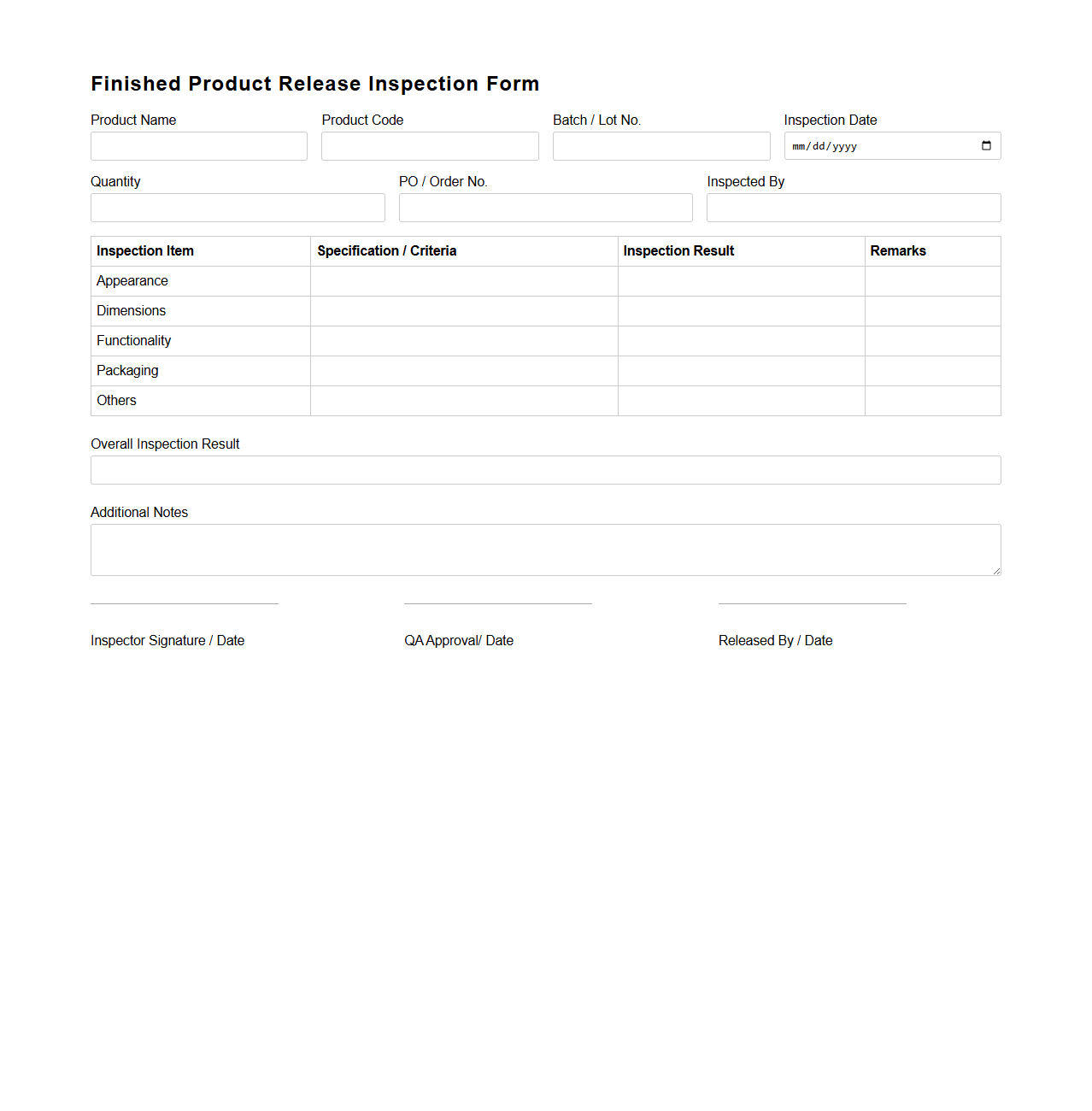

Finished Product Release Inspection Form

The

Finished Product Release Inspection Form document serves as a critical quality control tool used to verify that a final product meets all specified standards and regulatory requirements before distribution. It records detailed inspection results, including physical, chemical, and functional tests, ensuring compliance with manufacturing protocols and customer expectations. This form helps maintain product consistency, traceability, and accountability throughout the release process.

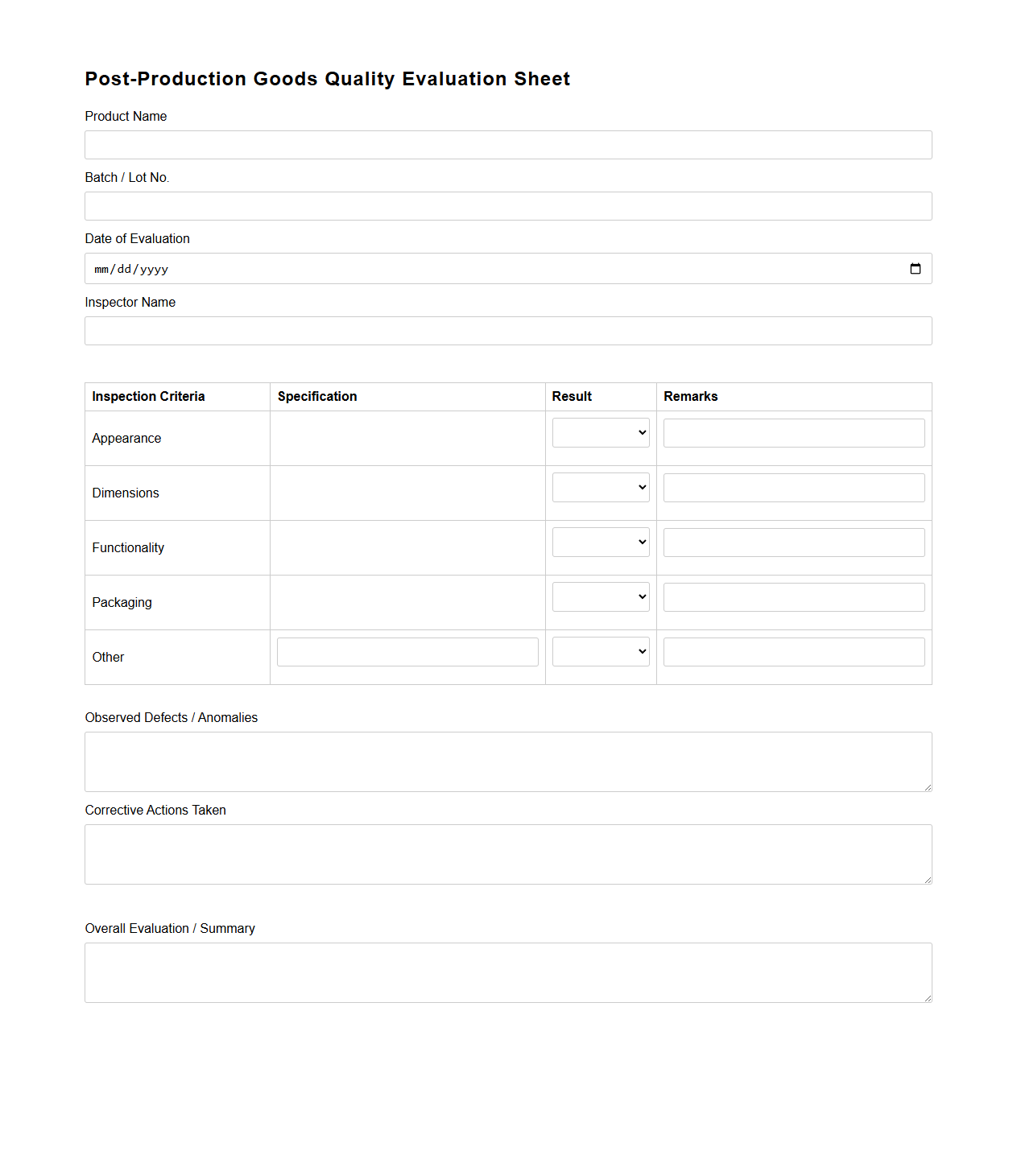

Post-Production Goods Quality Evaluation Sheet

The

Post-Production Goods Quality Evaluation Sheet is a detailed document used to assess the quality of products after the manufacturing process. It records inspection results, identifies defects, and ensures products meet established quality standards before shipment. This sheet plays a crucial role in maintaining product consistency, reducing returns, and enhancing customer satisfaction.

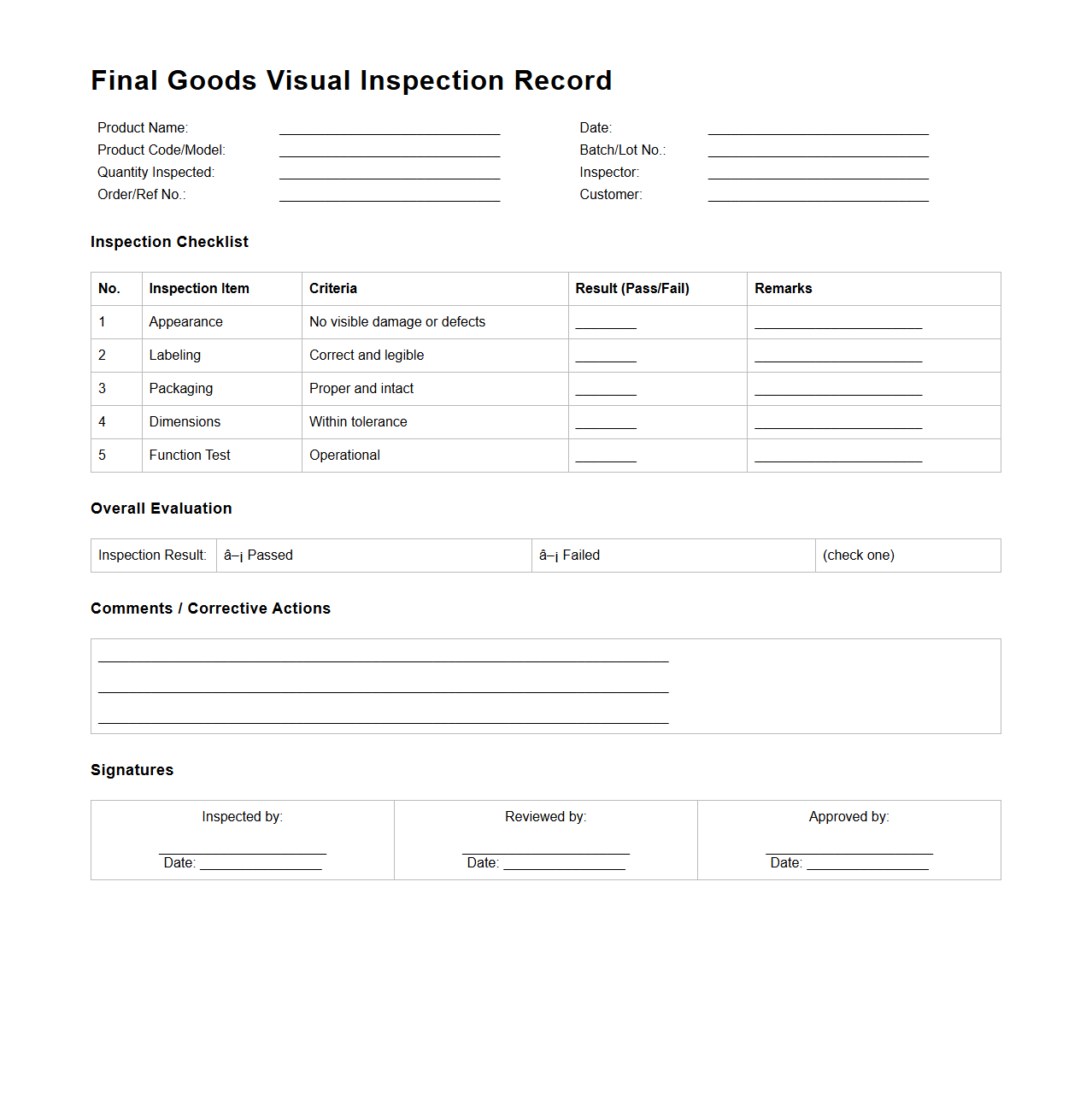

Final Goods Visual Inspection Record

The

Final Goods Visual Inspection Record document is a vital quality control tool used to verify the physical condition and compliance of finished products before shipment. It systematically captures detailed observations regarding defects, packaging integrity, and adherence to specified standards, ensuring that only products meeting quality criteria proceed to distribution. Maintaining accurate records supports traceability, facilitates quality audits, and helps prevent defective goods from reaching customers.

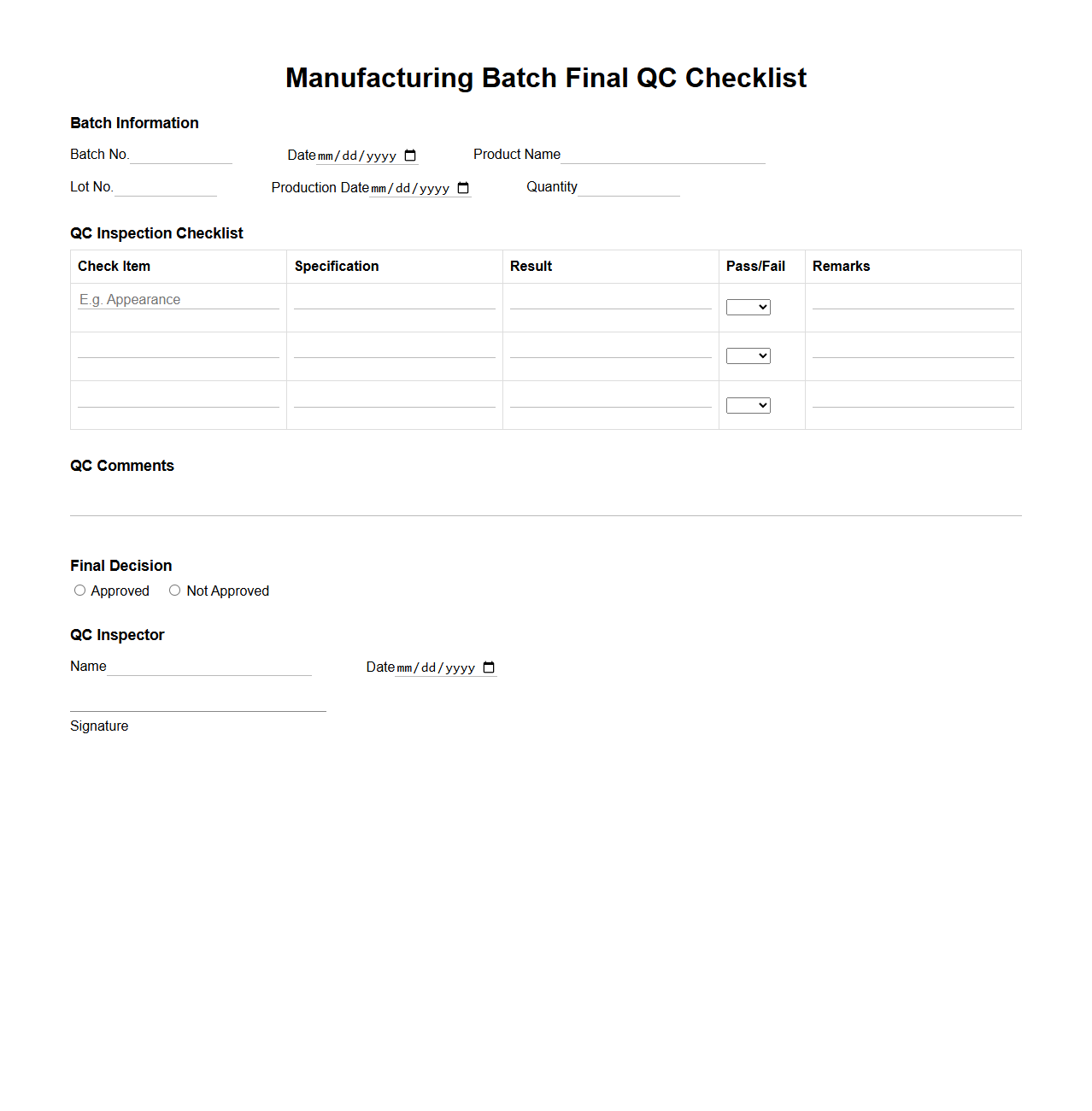

Manufacturing Batch Final QC Checklist

The

Manufacturing Batch Final QC Checklist document serves as a critical tool to ensure that every product batch meets predefined quality standards before release. It systematically records inspection results, verifies compliance with manufacturing specifications, and confirms that all quality control tests have been completed successfully. This checklist helps prevent defective products from reaching customers, thereby maintaining product integrity and regulatory compliance.

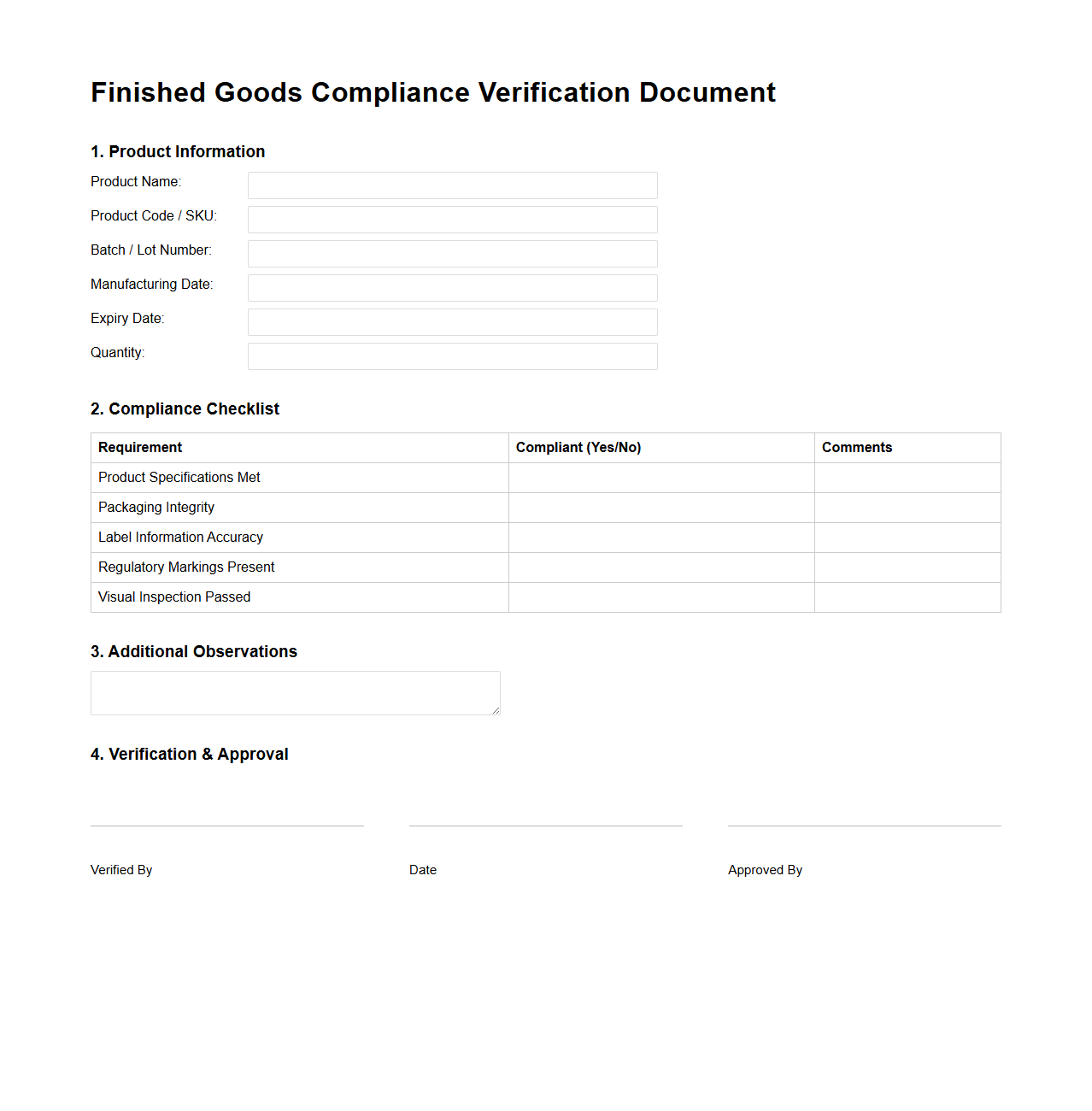

Finished Goods Compliance Verification Document

A

Finished Goods Compliance Verification Document serves as a critical record ensuring that final products meet all regulatory, safety, and quality standards before distribution. It typically includes detailed inspections, certification of adherence to industry regulations, and confirmation that all manufacturing processes comply with established guidelines. This document is essential for traceability, preventing non-compliant goods from reaching the market and minimizing legal liabilities.

What key information must be included in a Finished Goods Inspection Document for manufacturing?

The Finished Goods Inspection Document must include detailed product specifications to ensure accuracy. It should also record the batch or serial number for traceability. Additionally, the document must capture inspection dates and the inspector's identification for accountability.

Which quality control criteria are evaluated during the finished goods inspection process?

During the inspection, dimensional accuracy is verified to meet design tolerances. The functionality and performance standards are tested to confirm product reliability. Visual inspections assess for defects such as surface finish quality and packaging integrity.

How are non-conformance findings documented and addressed in the inspection sample?

Non-conformance issues are recorded in detail within the inspection report, specifying the defect type and severity. Corrective actions are proposed based on the documented findings to prevent recurrence. Follow-up inspections ensure that all non-conformities are effectively resolved.

What roles and responsibilities are outlined for personnel in completing the inspection document?

The quality inspector is responsible for conducting the inspection and accurately completing the document. Supervisors review and validate the inspection results to ensure compliance. Additionally, corrective action teams address any issues identified during the inspection process.

Which approval and verification steps are required before finished goods are released?

Final approval requires a thorough review by the quality assurance manager to confirm all criteria are met. Verification includes cross-checking inspection results with product specifications. Only after successful approval and verification are the finished goods authorized for release and distribution.

More Manufacturing Templates