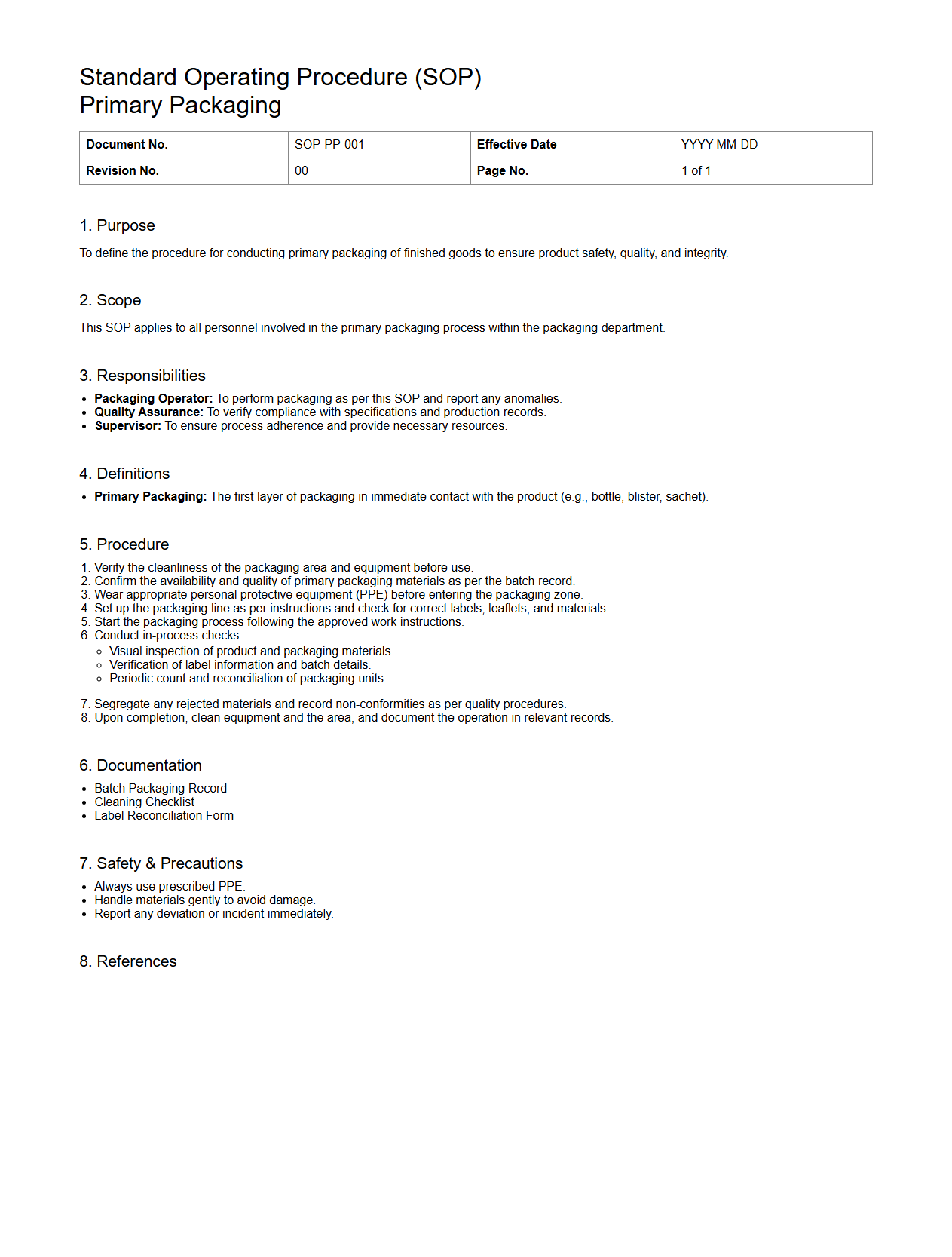

Standard Operating Procedure for Primary Packaging

A

Standard Operating Procedure (SOP) for Primary Packaging document outlines detailed, step-by-step instructions to ensure consistency and quality in the packaging of products at the initial stage. It defines critical parameters such as material specifications, equipment settings, hygiene protocols, and inspection criteria to prevent contamination and ensure product integrity. This document is essential for regulatory compliance and helps maintain efficiency and safety in manufacturing environments.

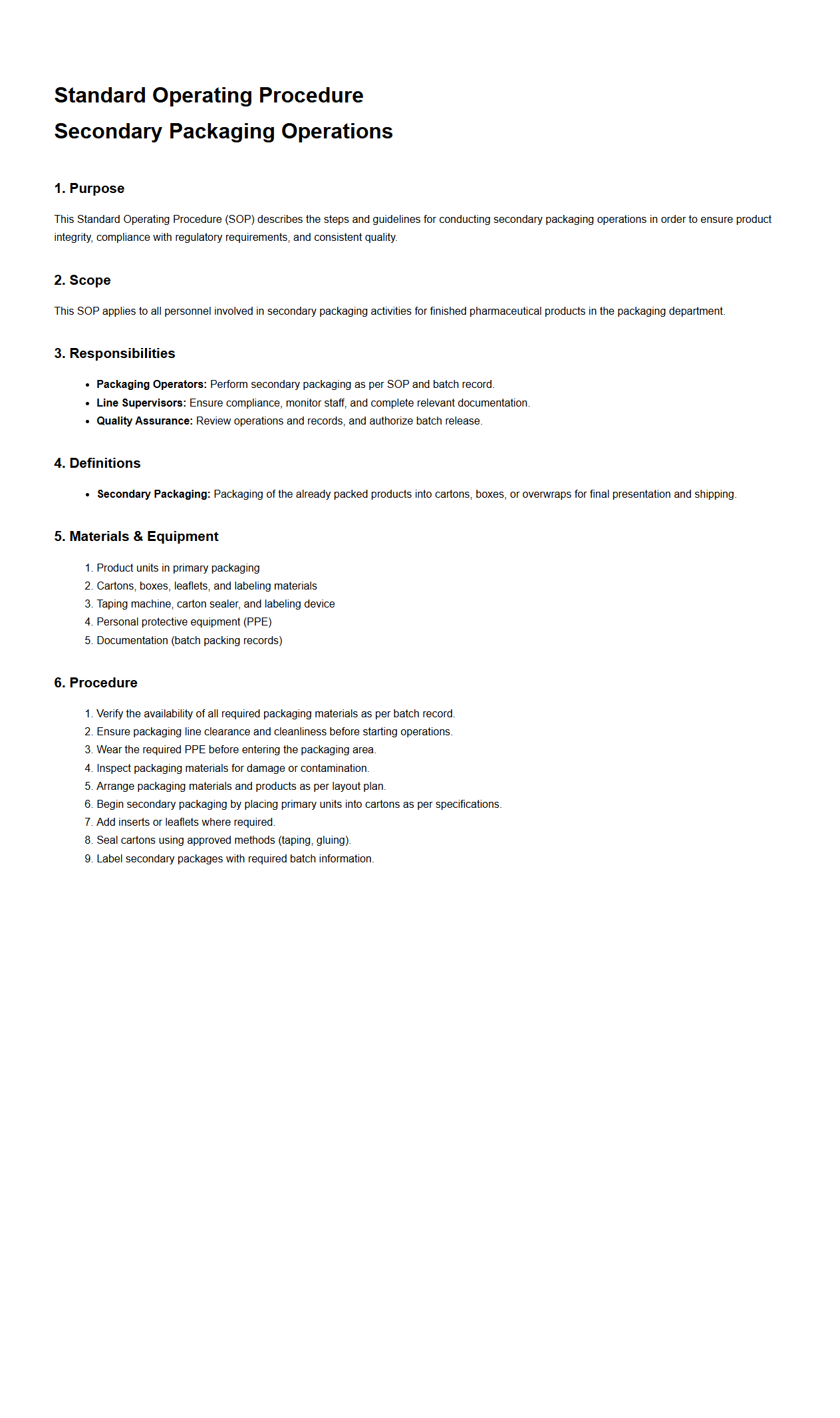

SOP for Secondary Packaging Operations

The

SOP for Secondary Packaging Operations outlines standardized procedures to ensure consistent, efficient, and compliant packaging of products after primary packaging. It details steps for labeling, boxing, palletizing, and quality checks to maintain product integrity and regulatory adherence. This document serves as a critical guide to minimize errors and streamline secondary packaging workflows in manufacturing environments.

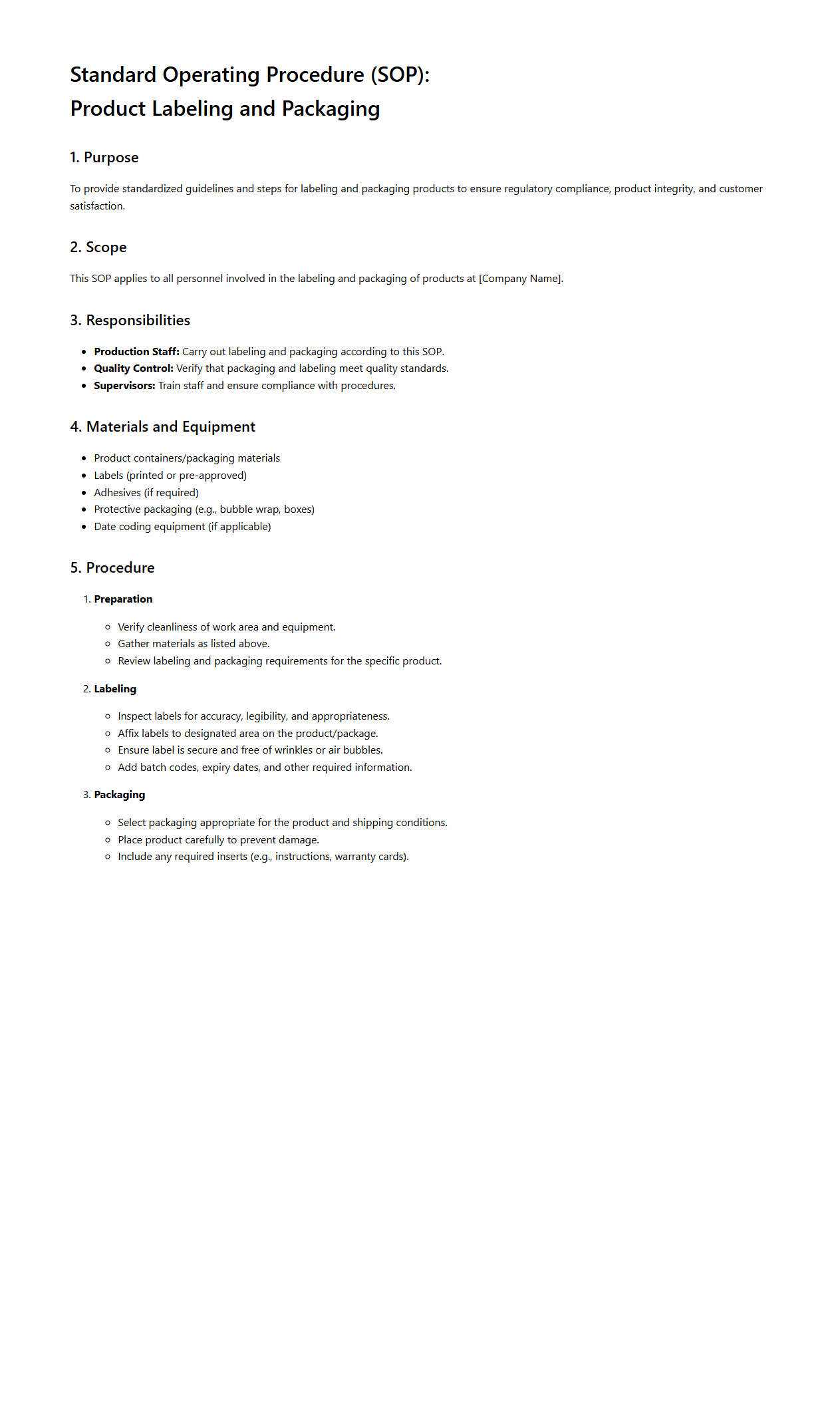

SOP for Product Labeling and Packaging

A

SOP for Product Labeling and Packaging document establishes standardized procedures to ensure consistency, compliance with regulatory requirements, and accuracy in labeling and packaging processes. It details the steps for verifying product information, artwork approval, packaging material selection, and quality checks to prevent errors and maintain brand integrity. This document is essential for minimizing risks, meeting industry standards, and enhancing customer trust through clear and accurate product presentation.

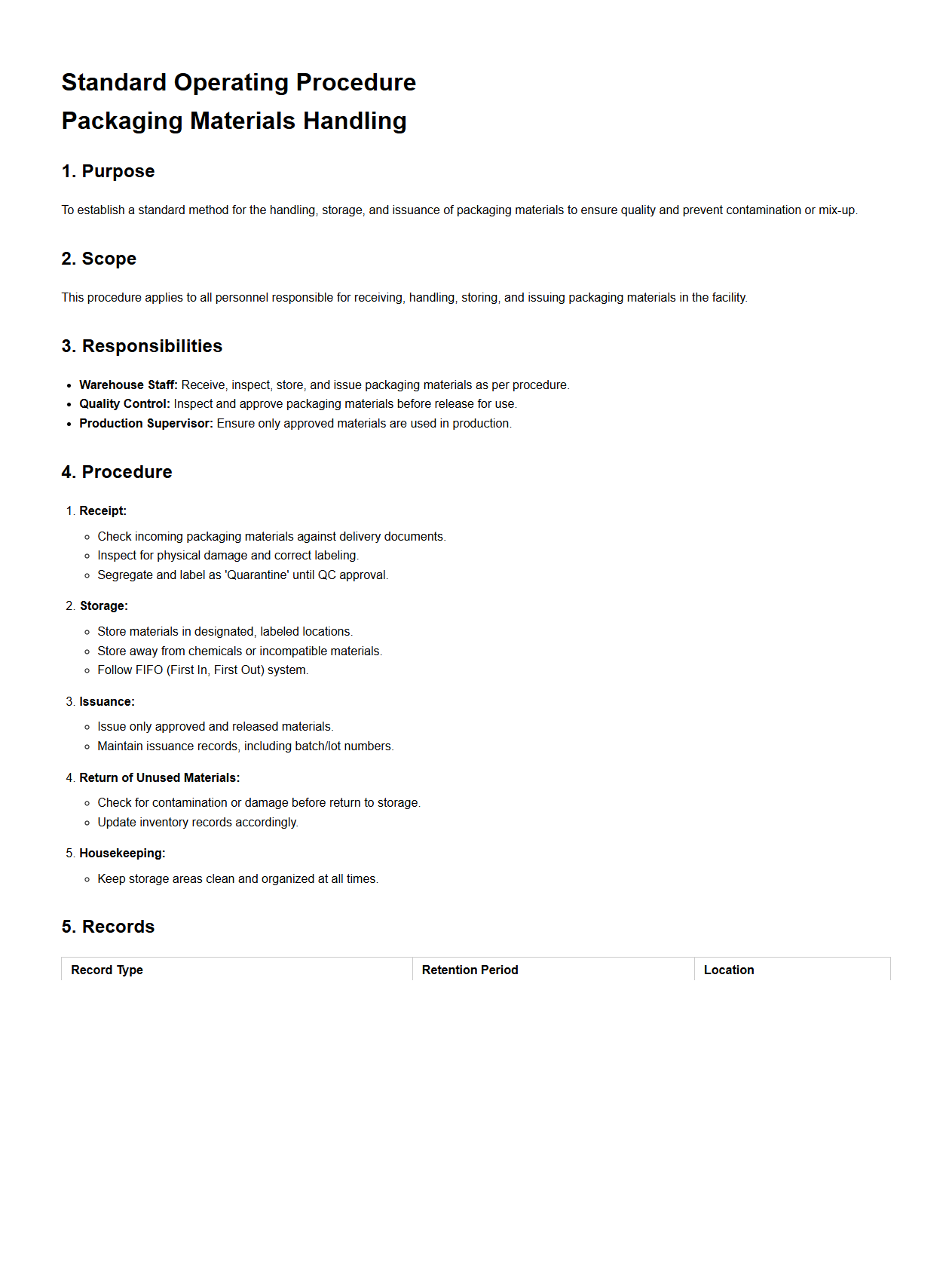

Packaging Materials Handling SOP

A

Packaging Materials Handling SOP document outlines standardized procedures for the efficient, safe, and consistent management of packaging materials within a facility. It details steps for receiving, storing, transporting, and using packaging supplies to minimize damage, waste, and delays. This document ensures compliance with industry regulations and supports optimal inventory control and workflow.

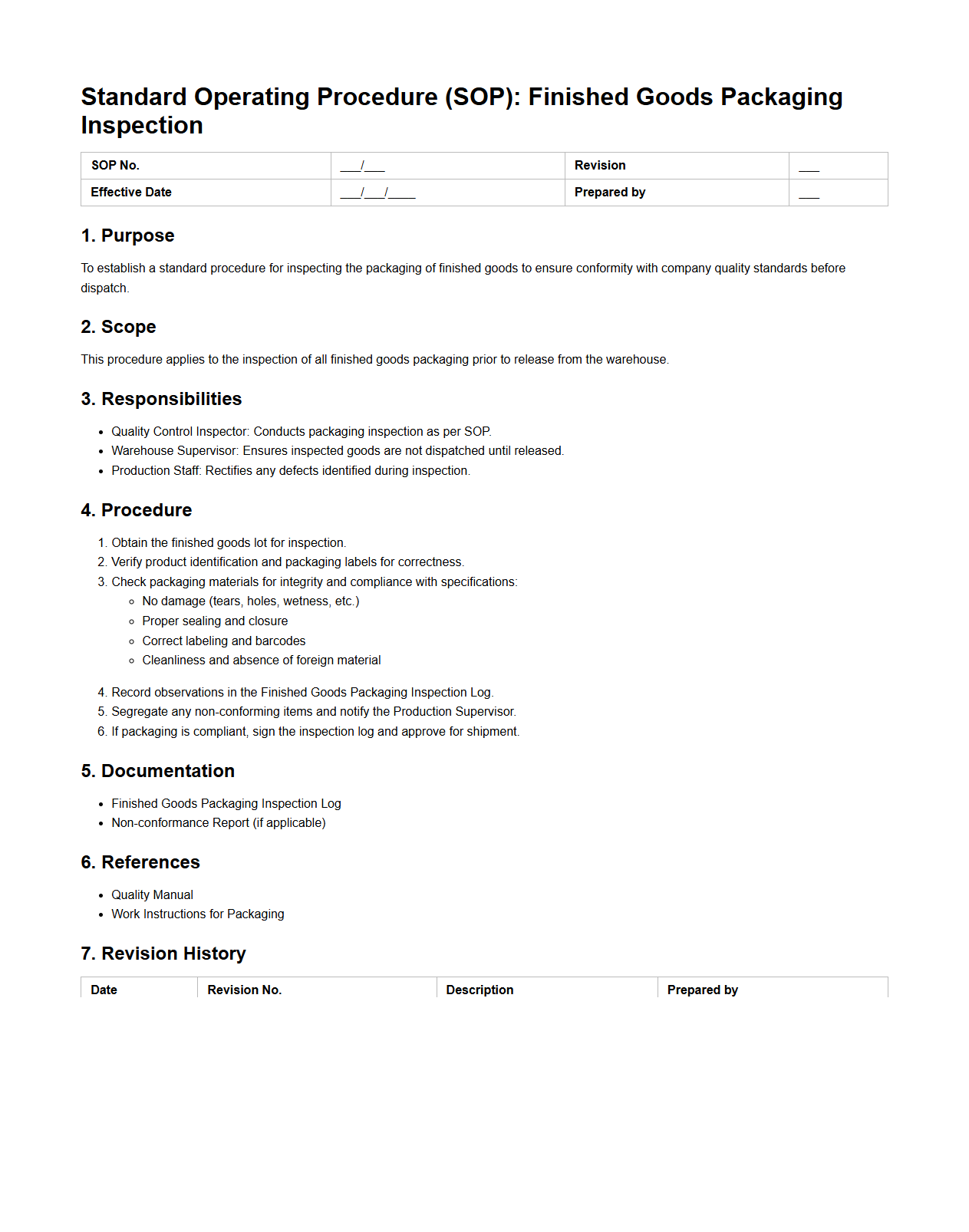

SOP for Finished Goods Packaging Inspection

The

SOP for Finished Goods Packaging Inspection document outlines standardized procedures to ensure packaging meets quality, safety, and regulatory standards before shipment. It specifies inspection criteria such as packaging integrity, labeling accuracy, and compliance with customer requirements. This procedure helps minimize product damage during transit and ensures consistent presentation to end customers.

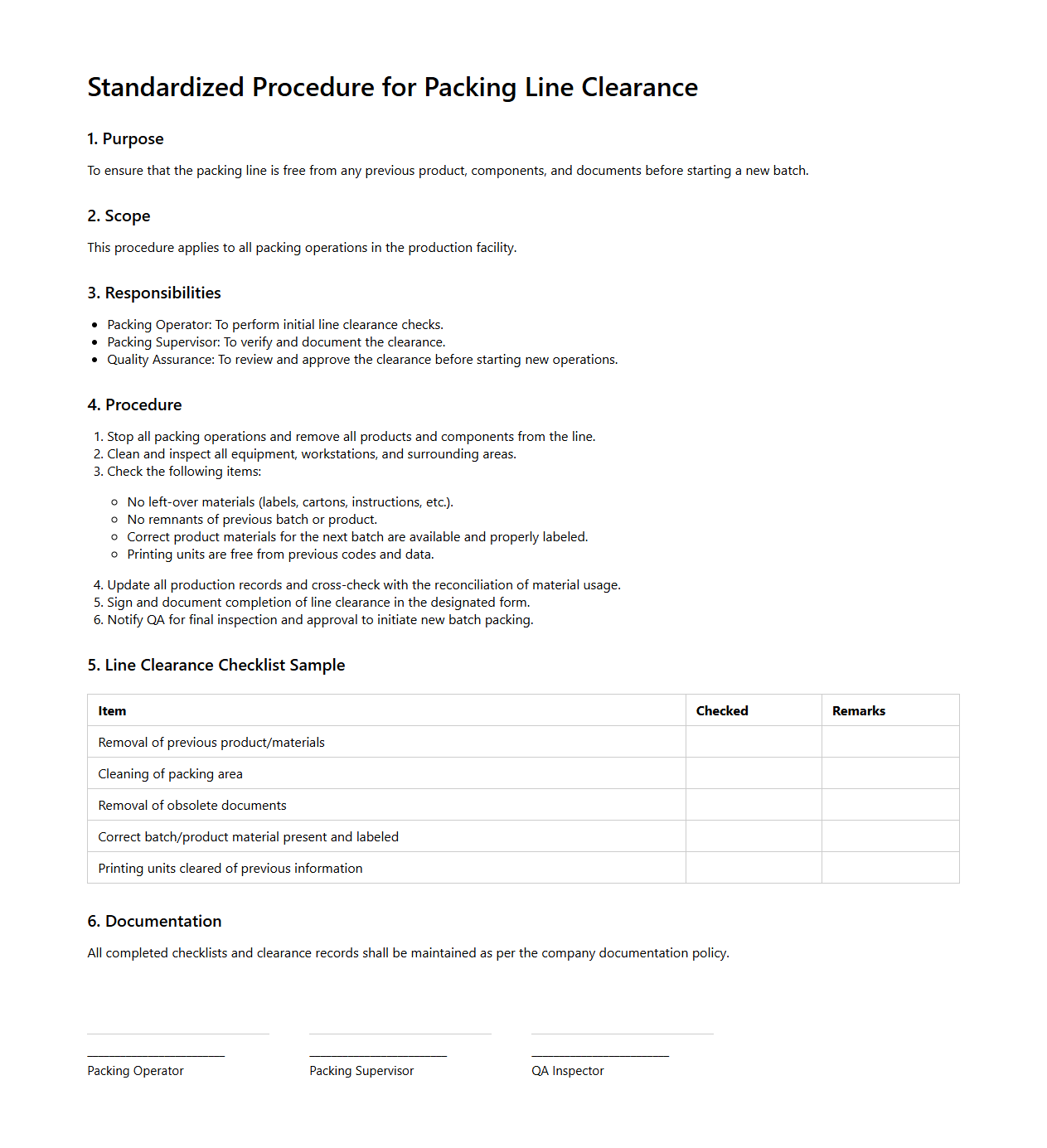

Standardized Procedure for Packing Line Clearance

The

Standardized Procedure for Packing Line Clearance document outlines the systematic steps to ensure that packaging equipment and materials are free from contamination or mix-ups before production begins. It provides clear criteria for inspecting and verifying cleanliness, proper setup, and the correct changeover of batch-specific components. This procedure is critical for maintaining product integrity, regulatory compliance, and minimizing the risk of cross-contamination in manufacturing environments.

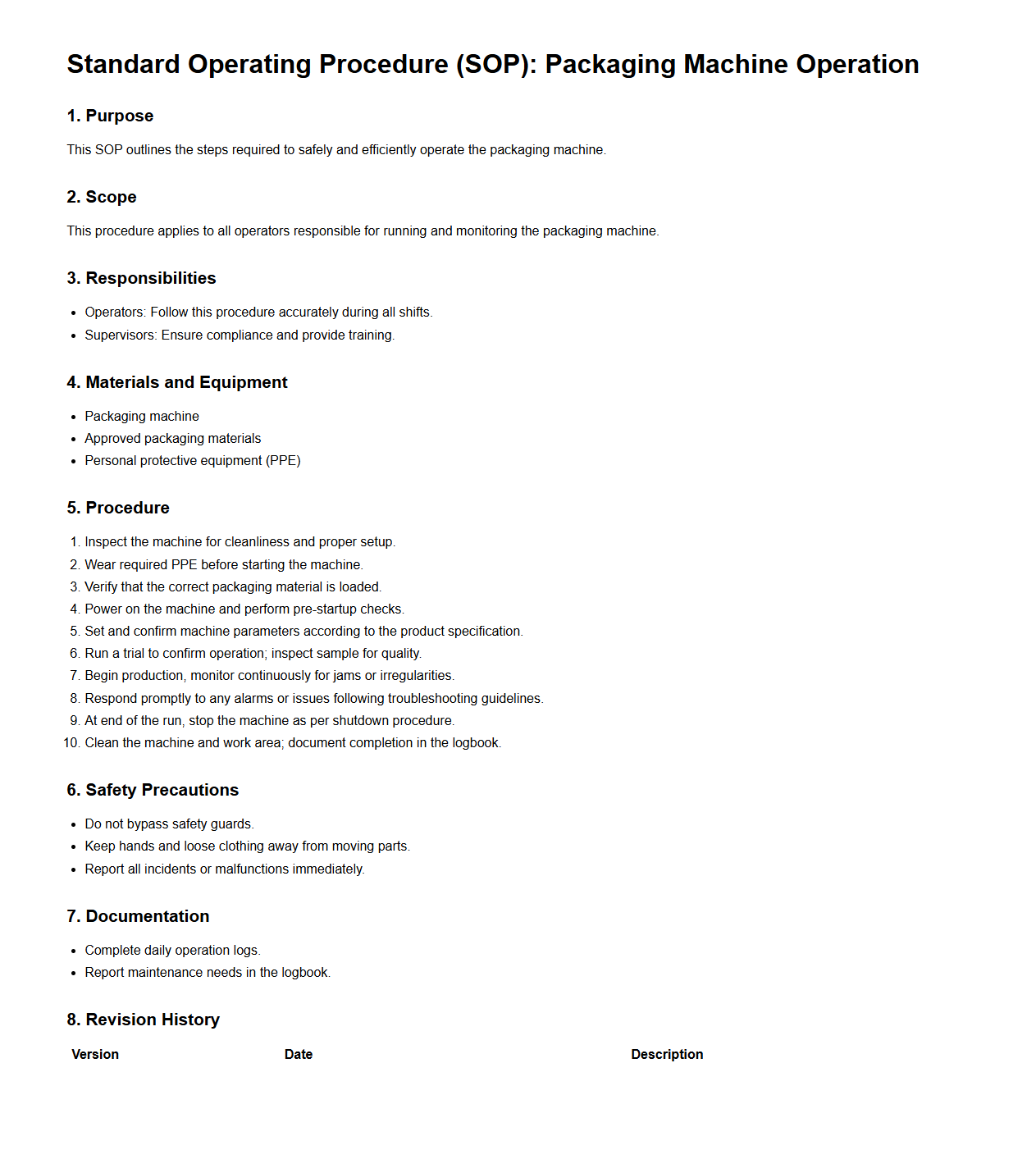

SOP for Packaging Machine Operation

The

SOP for Packaging Machine Operation document outlines standardized procedures to ensure consistent, safe, and efficient use of packaging machinery. It details step-by-step instructions for machine setup, operation, maintenance, and safety checks to minimize errors and downtime. This document supports quality control and regulatory compliance in packaging processes across manufacturing environments.

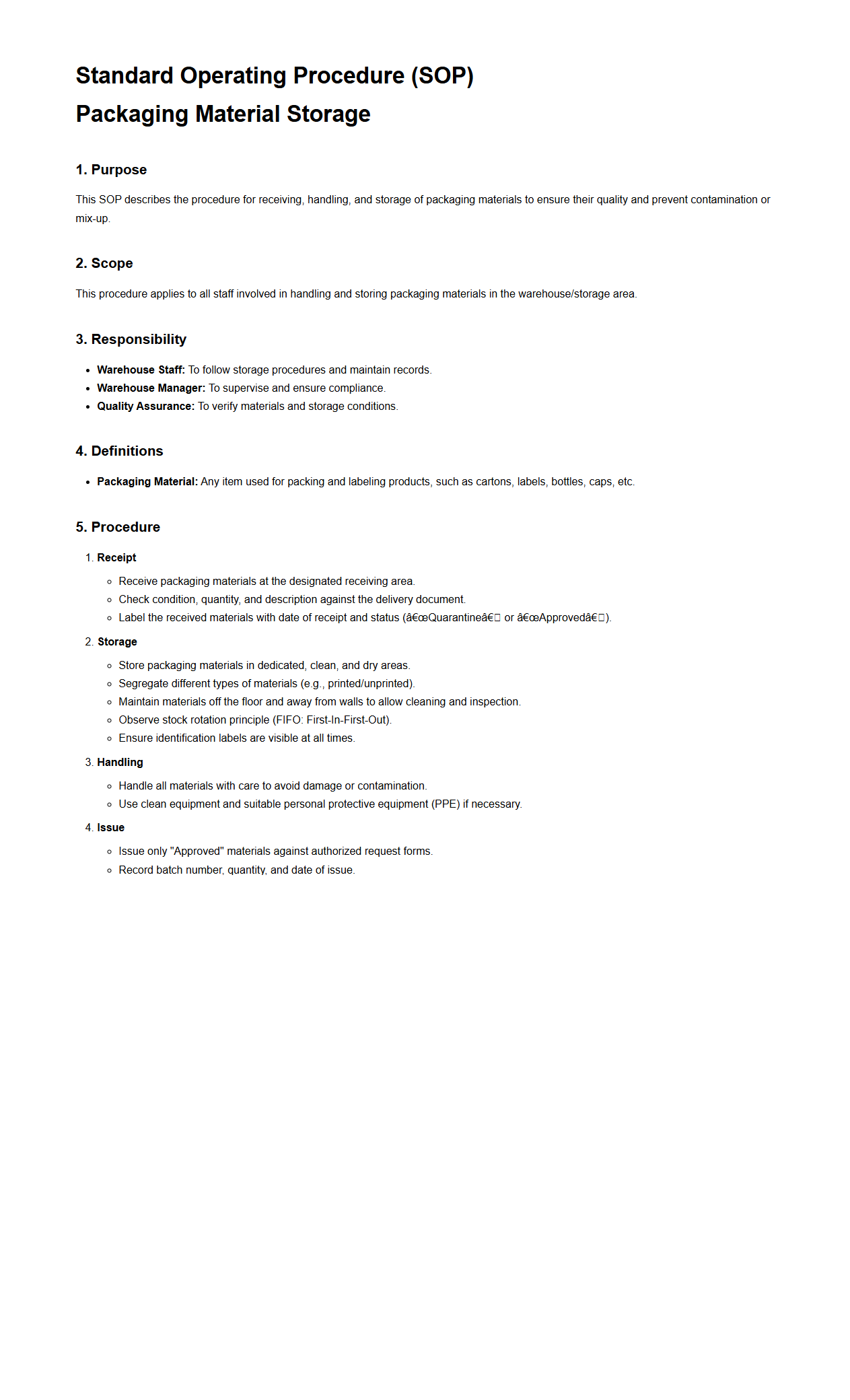

SOP for Packaging Material Storage

The

SOP for Packaging Material Storage document outlines standardized procedures to ensure the proper handling, storage, and preservation of packaging materials, maintaining their quality and compliance with regulatory standards. It details guidelines on inventory management, environmental controls, and safety measures to prevent contamination, damage, or deterioration. This document is essential for maintaining operational efficiency and product integrity throughout the supply chain.

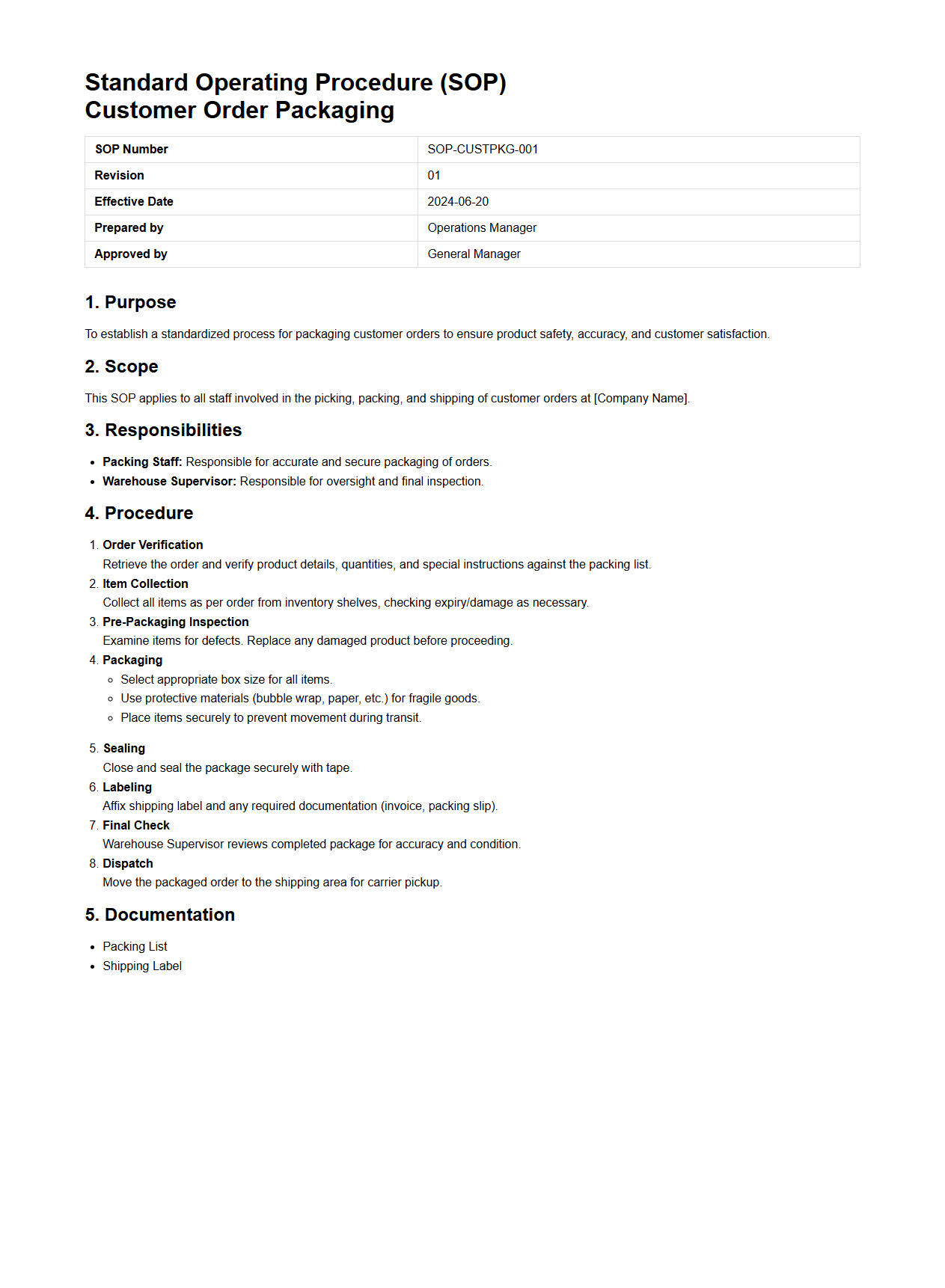

SOP for Customer Order Packaging

A

Standard Operating Procedure (SOP) for Customer Order Packaging document outlines the step-by-step process to ensure consistent, accurate, and secure packaging of customer orders. It includes guidelines on packaging materials, labeling requirements, quality checks, and handling instructions to maintain product integrity during shipment. This SOP helps streamline operations, reduce errors, and enhance customer satisfaction by delivering orders in optimal condition.

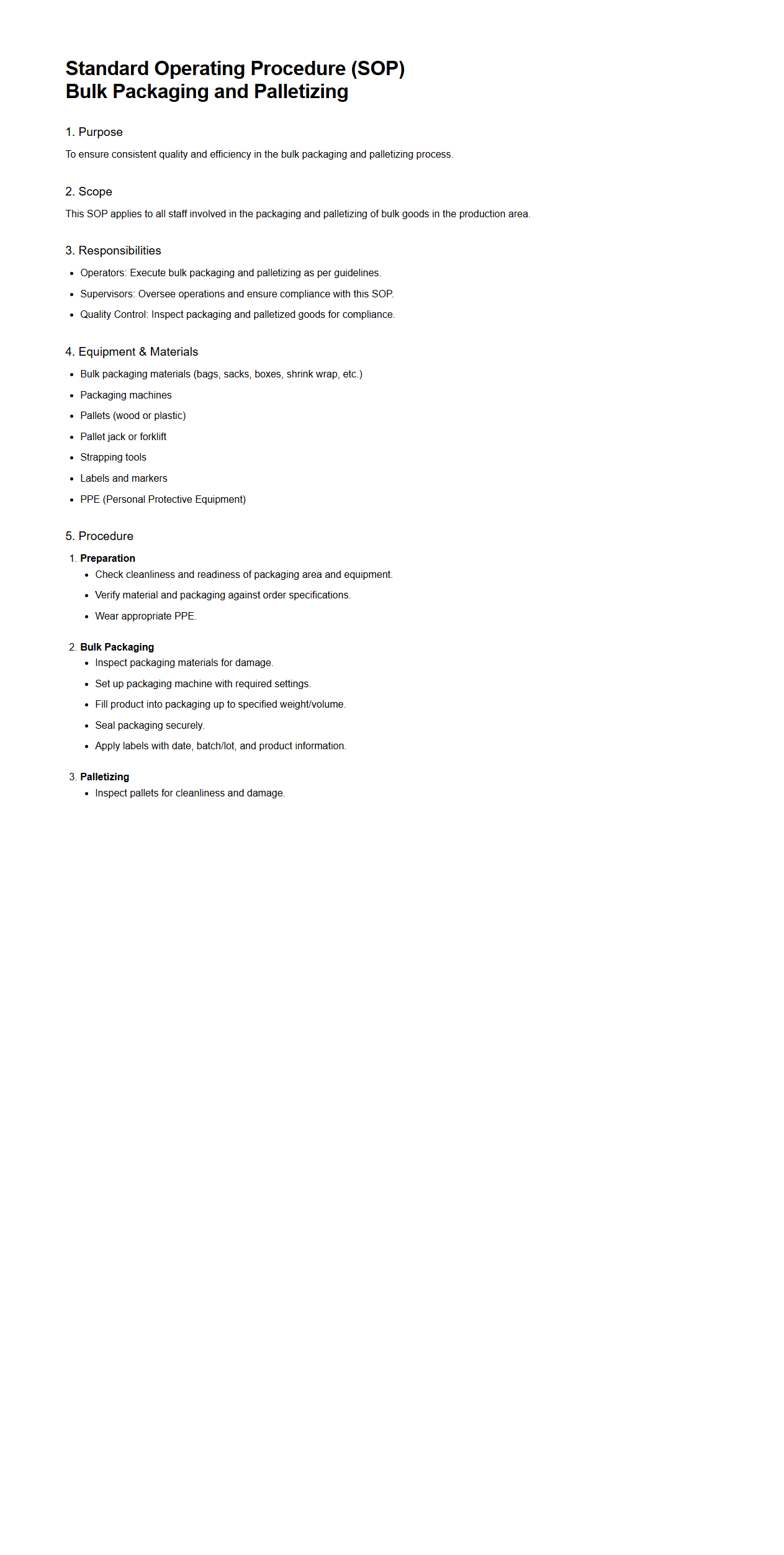

SOP for Bulk Packaging and Palletizing

The

SOP for Bulk Packaging and Palletizing document outlines standardized procedures for efficiently packaging and stacking bulk products to ensure safety, quality, and compliance with industry regulations. It details specific methods for packaging materials, handling equipment, weight limits, and secure palletization techniques to optimize storage and transportation. This document serves as a critical reference to minimize product damage, streamline logistics, and maintain consistency across production facilities.

What is the primary objective of the Standard Operating Procedure (SOP) outlined in this document for packaging?

The primary objective of the SOP is to establish a consistent and efficient packaging process that ensures product integrity and customer satisfaction. It aims to minimize errors and streamline packaging tasks for operational excellence. This is achieved by outlining clear instructions and standards applicable to all packaging activities.

Which specific materials and equipment are required according to this packaging SOP?

The SOP specifies the use of quality packaging materials such as durable boxes, seals, and cushioning items to protect the product during transit. Essential equipment includes sealing machines, label printers, and weighing scales to ensure accuracy. Using the prescribed materials and equipment supports compliance with packaging standards and product safety.

What are the sequential steps detailed for the packaging process in this document?

The packaging process begins with product inspection followed by selecting appropriate packaging materials. Subsequently, the product is carefully packed, sealed, and labeled according to guidelines. Each step is designed to maintain product quality and traceability throughout the packaging cycle.

What quality control checks are mandated in the SOP before final packaging?

The SOP mandates rigorous quality control checks including verification of product condition, weight accuracy, and proper labeling. These checks ensure that no defective or incorrectly packaged items proceed to shipment. Maintaining these standards helps uphold the brand's reputation and compliance with regulatory requirements.

How does the document address safety and compliance regulations for packaging procedures?

The document emphasizes adherence to safety and compliance regulations such as proper handling of materials and equipment to prevent accidents. It includes guidelines on personal protective equipment (PPE) usage and environmental safety practices. Compliance with these regulations ensures a safe workplace and meets legal packaging standards.