A Equipment Maintenance Log Document Sample for Manufacturing helps track routine inspections, repairs, and servicing of machinery to ensure optimal performance and minimize downtime. This log provides detailed entries including dates, technician names, and maintenance actions taken, enhancing accountability and traceability. Proper use of this document improves equipment lifespan and supports compliance with industry standards.

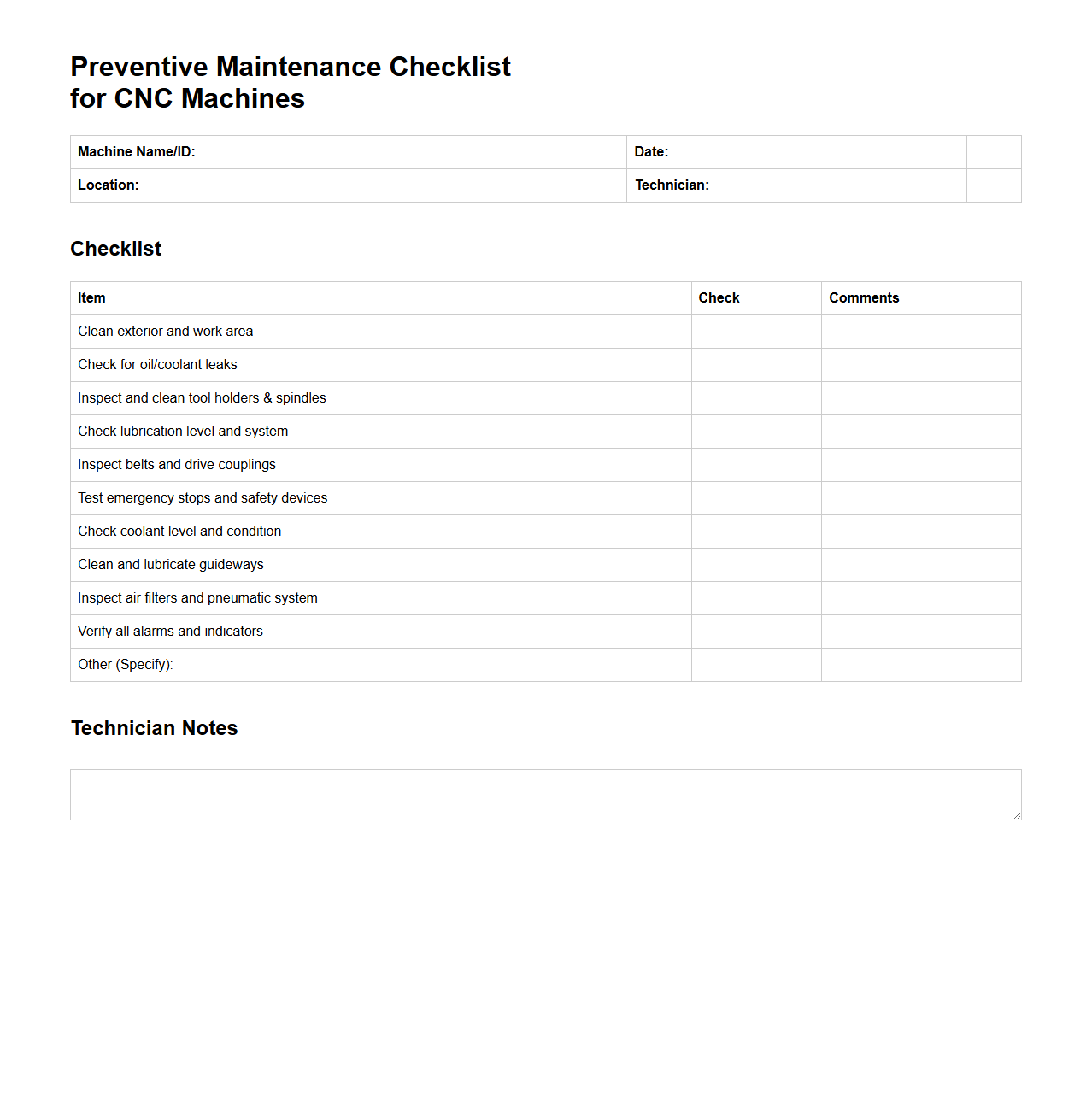

Preventive Maintenance Checklist Template for CNC Machines

A

Preventive Maintenance Checklist Template for CNC Machines is a structured document designed to systematically outline routine inspection and servicing tasks essential for the optimal performance of CNC equipment. This template helps technicians track regular maintenance activities such as lubrication, calibration, and component wear assessment, reducing machine downtime and minimizing costly repairs. Utilizing this checklist ensures adherence to manufacturer guidelines and extends the operational lifespan of CNC machines.

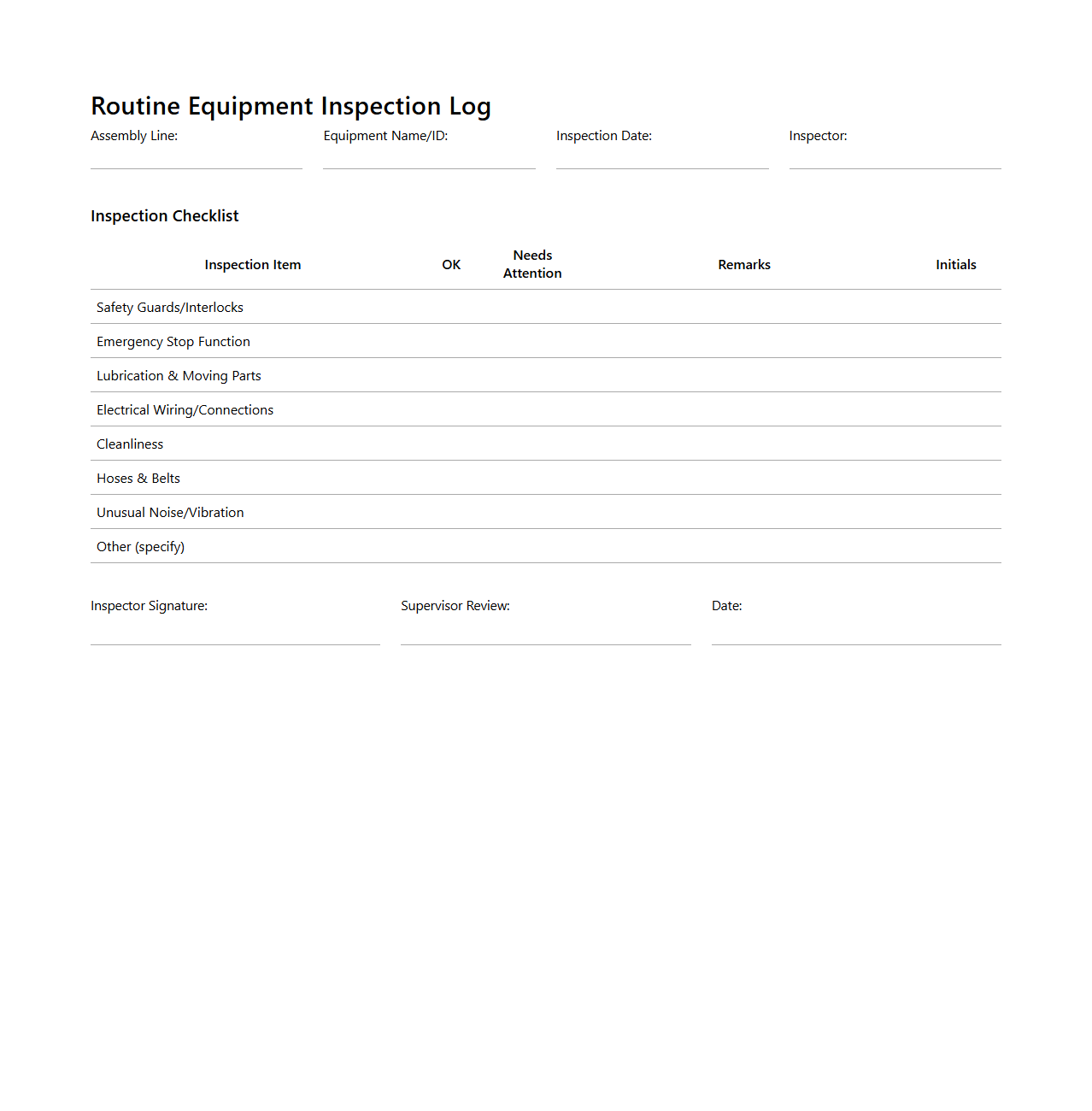

Routine Equipment Inspection Log for Assembly Lines

A

Routine Equipment Inspection Log for Assembly Lines document is a vital record that tracks the regular checks performed on machinery and equipment to ensure operational safety and efficiency. This log helps identify wear, malfunctions, or potential hazards early, minimizing downtime and maintaining product quality. Accurate entries in the log support compliance with industry standards and facilitate preventive maintenance scheduling.

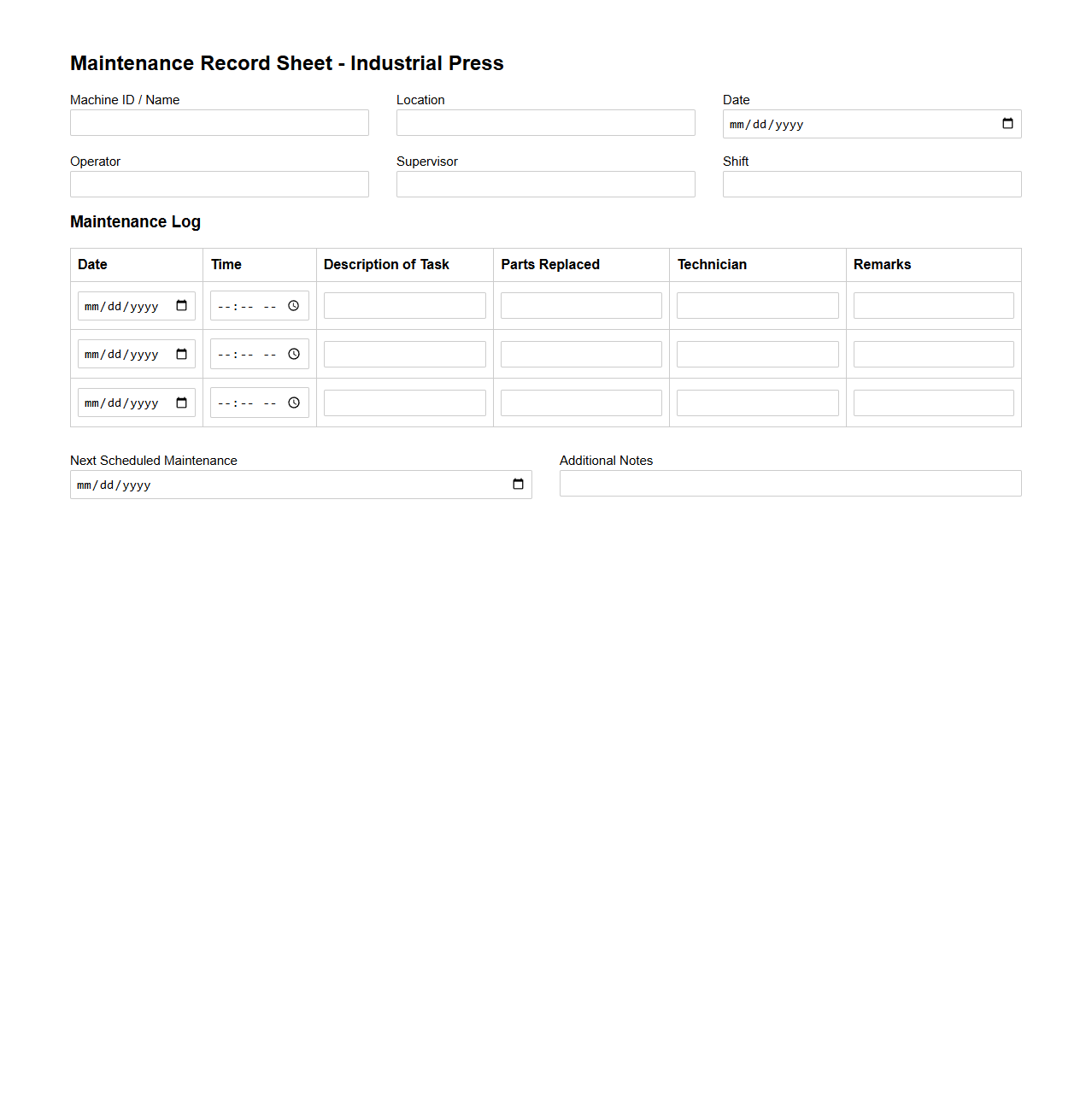

Maintenance Record Sheet for Industrial Presses

A

Maintenance Record Sheet for Industrial Presses is a critical document used to track all maintenance activities performed on industrial pressing machines. It logs details such as inspection dates, types of maintenance conducted, parts replaced, and any identified issues, ensuring machine reliability and compliance with safety standards. This sheet supports preventive maintenance strategies, reduces downtime, and extends the operational lifespan of industrial presses.

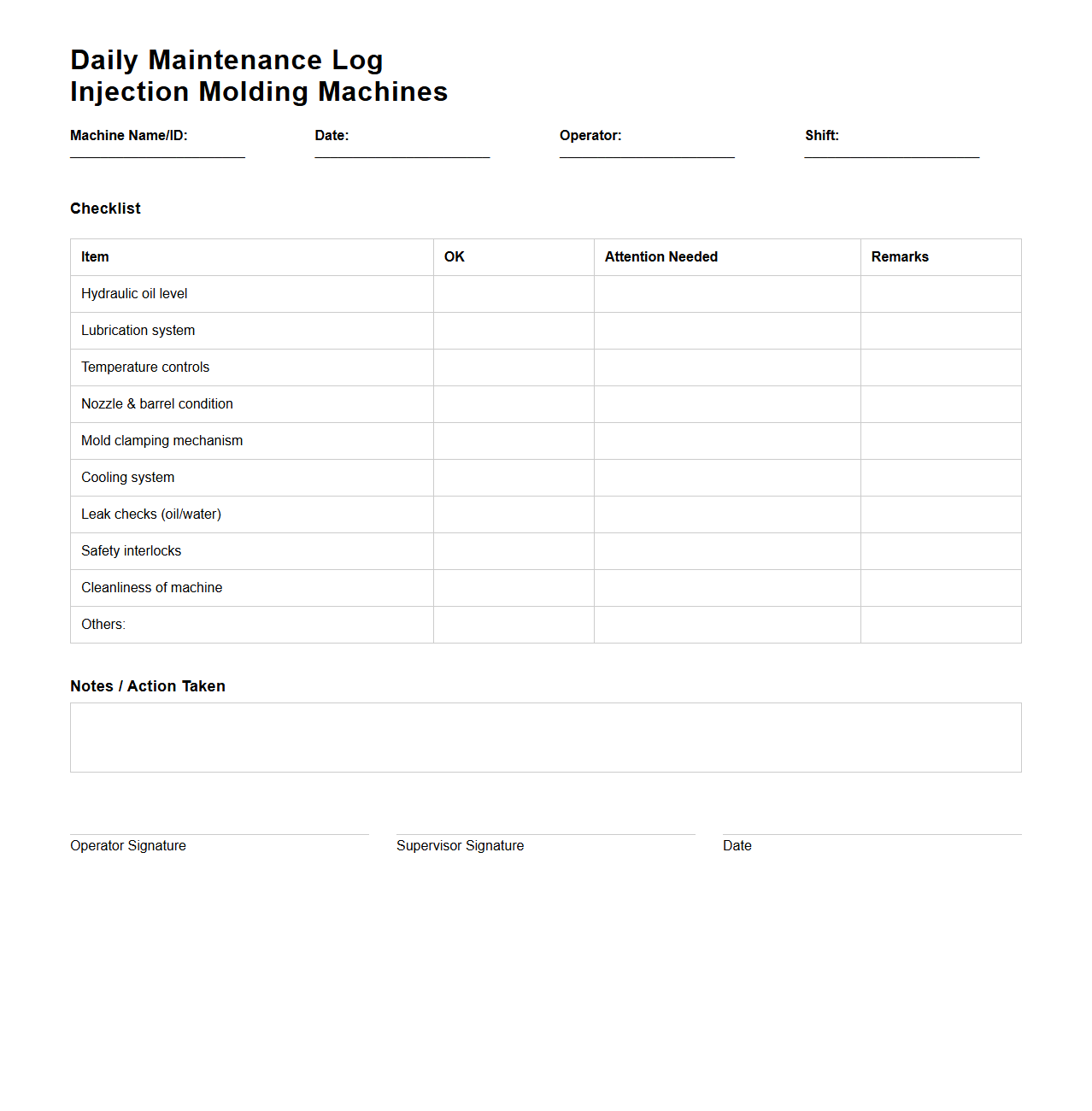

Daily Maintenance Log for Injection Molding Machines

A

Daily Maintenance Log for Injection Molding Machines document systematically records routine inspections, cleaning, lubrication, and minor repairs performed each day. This log ensures consistent machine performance, helps identify recurring issues early, and supports compliance with industry quality standards. Detailed entries improve operational efficiency by enabling predictive maintenance and reducing unexpected downtime.

Corrective Action Tracker for Manufacturing Equipment

The

Corrective Action Tracker for Manufacturing Equipment document is a vital tool used to monitor, record, and manage the resolution of equipment-related issues in manufacturing processes. It helps ensure timely identification, root cause analysis, and implementation of corrective measures to prevent recurrence of equipment failures or malfunctions. This document enhances equipment reliability, minimizes downtime, and supports continuous improvement initiatives within manufacturing operations.

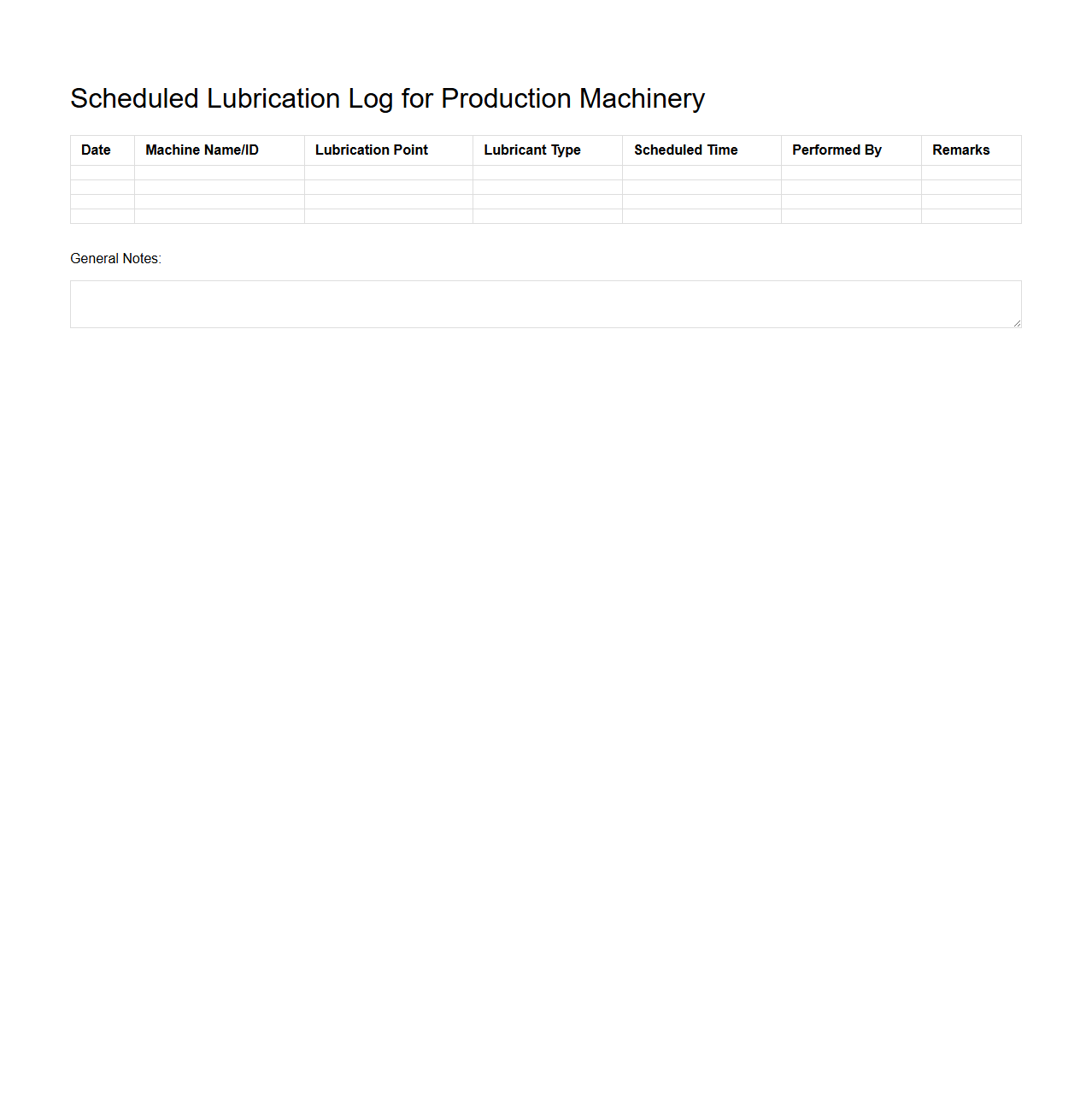

Scheduled Lubrication Log for Production Machinery

A

Scheduled Lubrication Log for Production Machinery document records the regular lubrication activities performed on manufacturing equipment to ensure optimal performance and prevent mechanical failures. It details the dates, types of lubricants used, specific machinery parts serviced, and responsible personnel, facilitating maintenance tracking and compliance. Maintaining this log supports equipment longevity, reduces downtime, and enhances overall production efficiency.

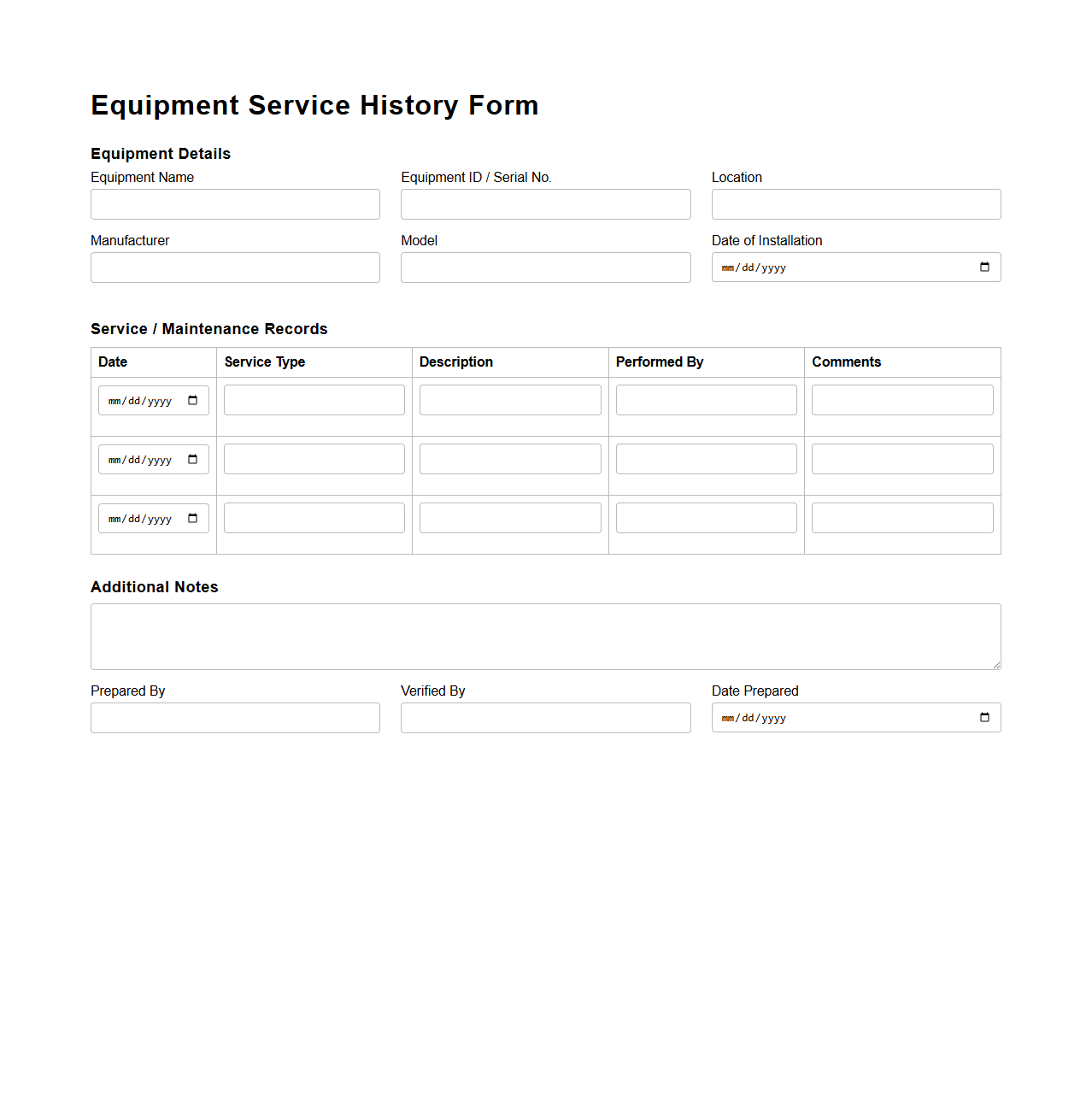

Equipment Service History Form for Factory Operations

The

Equipment Service History Form for Factory Operations documents all maintenance, repairs, and inspections performed on machinery, ensuring accurate tracking of equipment performance and reliability. This form helps factory managers monitor service intervals, identify recurring issues, and plan preventative maintenance to minimize downtime. Maintaining detailed service histories supports compliance with safety standards and enhances operational efficiency.

Machine Downtime Tracking Spreadsheet for Manufacturing Plants

A

Machine Downtime Tracking Spreadsheet for manufacturing plants is a tool designed to systematically record and analyze periods when machinery is not operational. It captures essential data such as downtime duration, causes, and affected equipment, enabling managers to identify patterns and improve maintenance schedules. This document enhances operational efficiency by reducing unexpected stoppages and optimizing production workflows.

Calibration Record Template for Process Equipment

A

Calibration Record Template for Process Equipment document is a standardized form used to systematically document the calibration details of machinery and instruments within a manufacturing or industrial process. It captures essential data such as calibration date, equipment identification, calibration results, technician's name, and any adjustments made to ensure accuracy and compliance with quality standards. Maintaining accurate calibration records helps in traceability, regulatory audits, and ensures the process equipment operates within specified parameters to maintain product quality and safety.

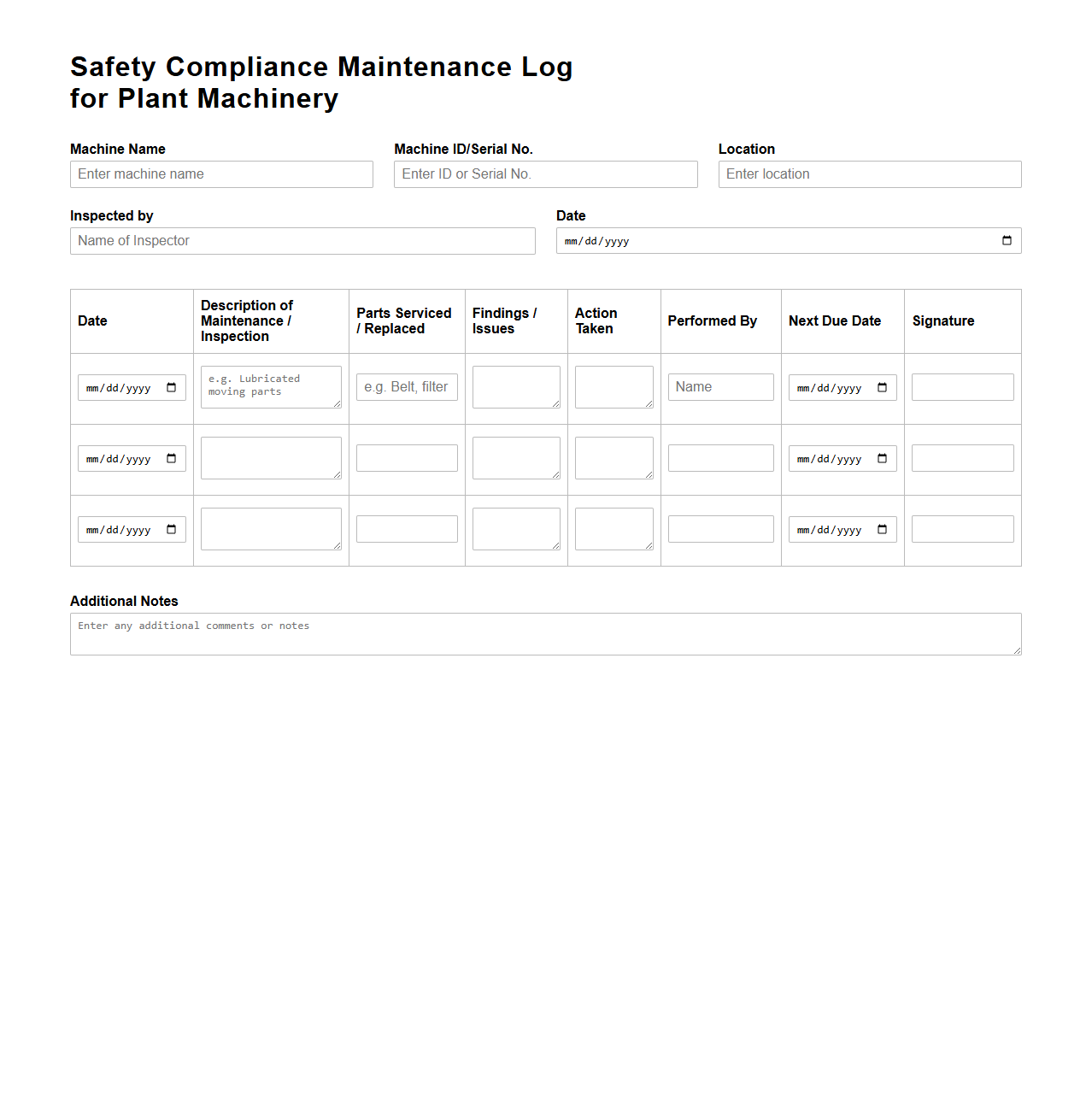

Safety Compliance Maintenance Log for Plant Machinery

The

Safety Compliance Maintenance Log for plant machinery is a detailed record documenting regular inspections, maintenance activities, and safety checks to ensure equipment operates within regulatory standards. This log helps track compliance with occupational safety regulations and promotes proactive identification of potential hazards or mechanical failures. Keeping accurate maintenance records enhances plant safety, reduces downtime, and supports audit readiness.

What key data fields should be included in an Equipment Maintenance Log for manufacturing?

An effective Equipment Maintenance Log must capture essential data fields such as equipment ID, maintenance date, description of the service performed, and the technician's name. It should also include information on parts replaced, time taken, and maintenance type (preventive or corrective). These fields ensure detailed tracking and facilitate efficient maintenance management.

How does the log document track scheduled versus unscheduled equipment maintenance?

The log distinguishes between scheduled and unscheduled maintenance by clearly marking each entry with the type of maintenance performed. Scheduled maintenance entries correspond to planned activities laid out in a maintenance calendar, while unscheduled logs reflect unexpected repairs or breakdowns. This classification helps in analyzing equipment reliability and planning future maintenance strategies.

Which sections record compliance with safety and regulatory standards in the maintenance log?

Compliance with safety and regulatory standards is recorded in dedicated sections of the maintenance log, including safety checks, inspection results, and regulatory audit remarks. These sections ensure that all maintenance actions adhere to industry regulations and internal safety protocols. Documenting compliance protects the organization from legal liabilities and promotes workplace safety.

How is equipment downtime information documented and analyzed in the log?

Equipment downtime is meticulously documented by noting the start and end times of equipment inactivity, along with reasons for the downtime. This downtime data is analyzed to identify patterns, causes, and impacts on production efficiency. Such analysis enables targeted improvements to reduce future downtime and optimize operational availability.

In what way does the log facilitate traceability of maintenance actions and personnel involvement?

The maintenance log facilitates traceability by recording detailed information about each maintenance action, including the responsible technician's name, date, and specific tasks performed. This accountability allows for performance assessment, troubleshooting, and quality control. Comprehensive logs also support audits and continuous improvement initiatives effectively.

More Manufacturing Templates