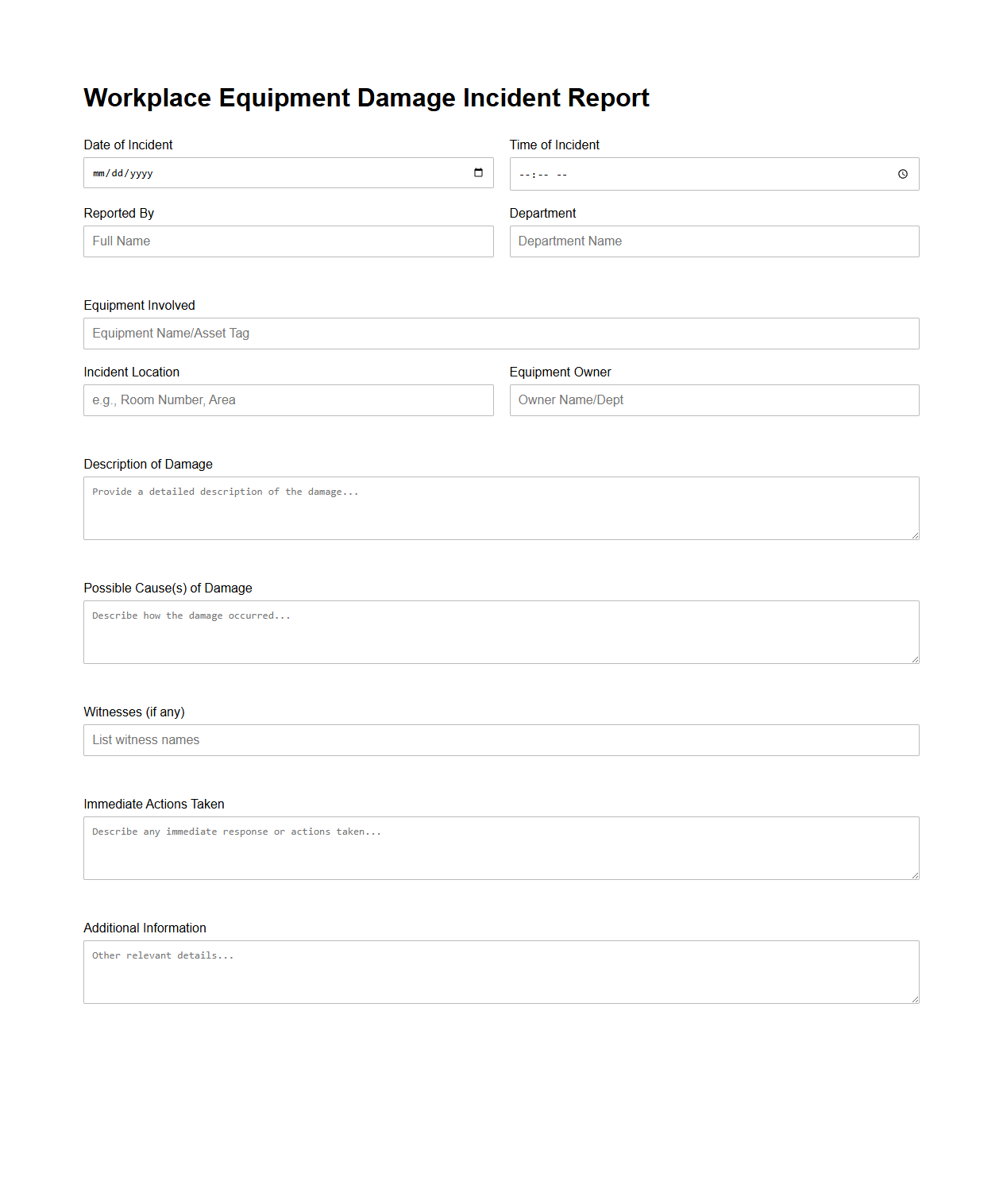

Workplace Equipment Damage Incident Report

A

Workplace Equipment Damage Incident Report document records detailed information about any damage sustained by machinery, tools, or other equipment during work operations. It includes specifics such as the date, time, location, parties involved, description of the damage, and potential causes to ensure accurate tracking and prompt resolution. This report aids in minimizing downtime, planning repairs, and preventing future incidents, thereby enhancing workplace safety and operational efficiency.

Employee Slip and Fall Incident Report

An

Employee Slip and Fall Incident Report document is a critical record used to detail the circumstances surrounding a workplace slip and fall accident involving an employee. This report captures essential information such as the date, time, location, cause of the fall, injury details, and witness statements to ensure accurate documentation for safety audits and insurance claims. Properly completed reports help employers identify hazards, improve workplace safety protocols, and comply with regulatory requirements.

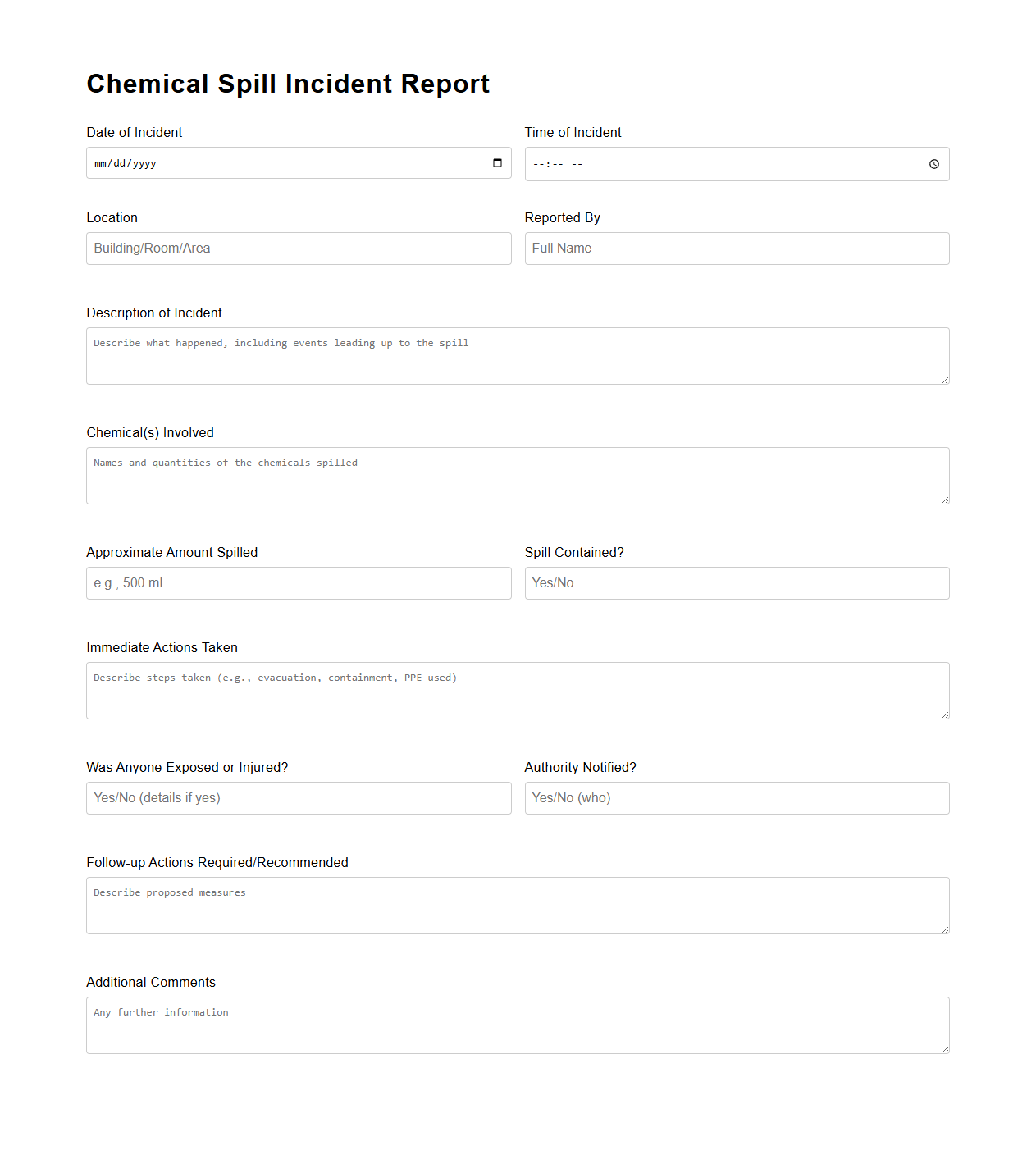

Chemical Spill Incident Report

A

Chemical Spill Incident Report document is a detailed record used to document the occurrence, causes, and consequences of a chemical spill within industrial or laboratory settings. It includes critical information such as the type of chemical involved, quantity spilled, affected area, personnel exposure, and immediate containment actions taken. This report is essential for regulatory compliance, risk assessment, and improving future spill prevention strategies.

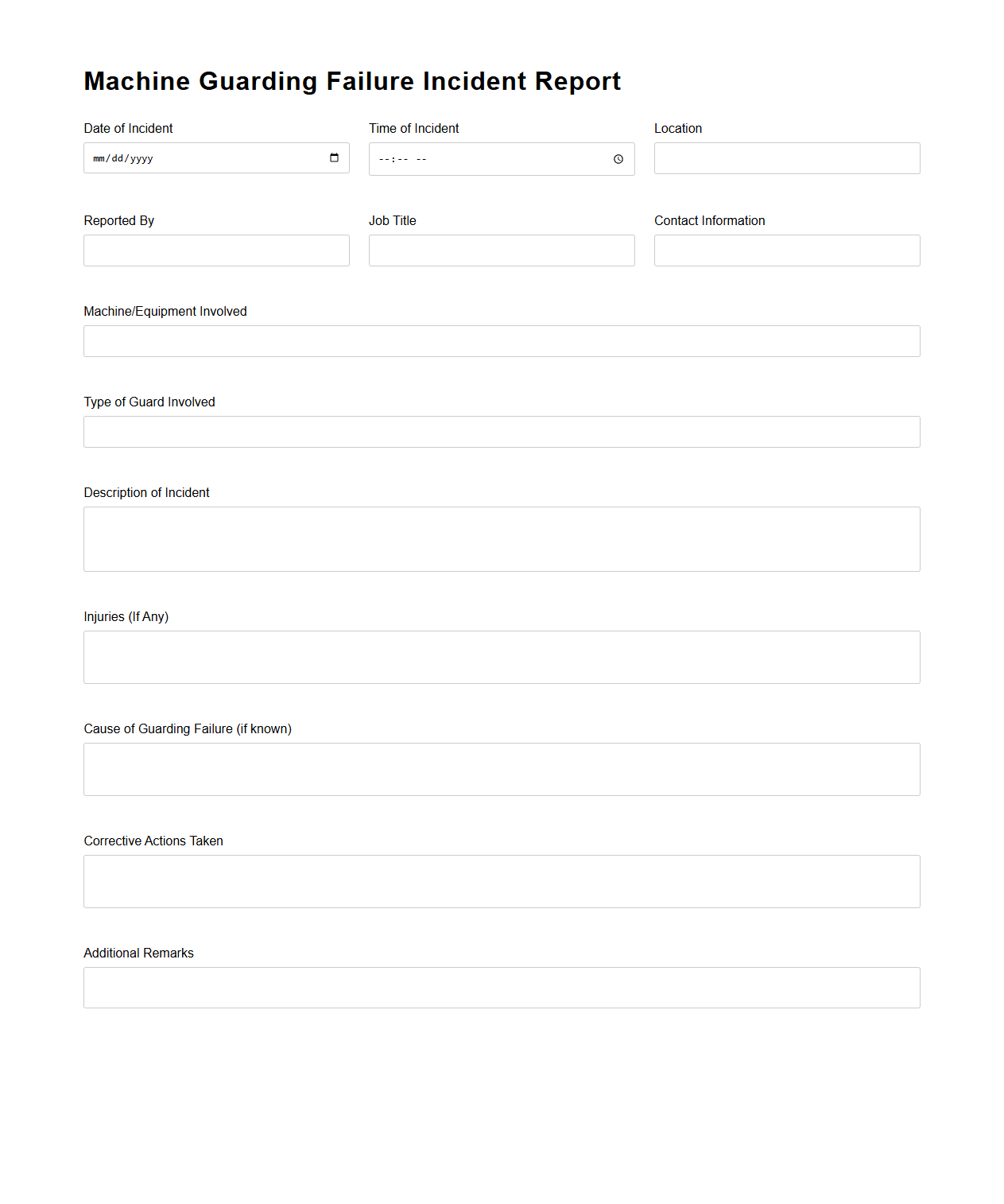

Machine Guarding Failure Incident Report

The

Machine Guarding Failure Incident Report document records detailed information about incidents where safety guards on machinery fail to protect operators or workers, causing potential or actual harm. It includes data on the type of machinery involved, description of the failure, contributing factors, and corrective actions taken to prevent recurrence. This report is essential for maintaining workplace safety compliance and reducing equipment-related accidents.

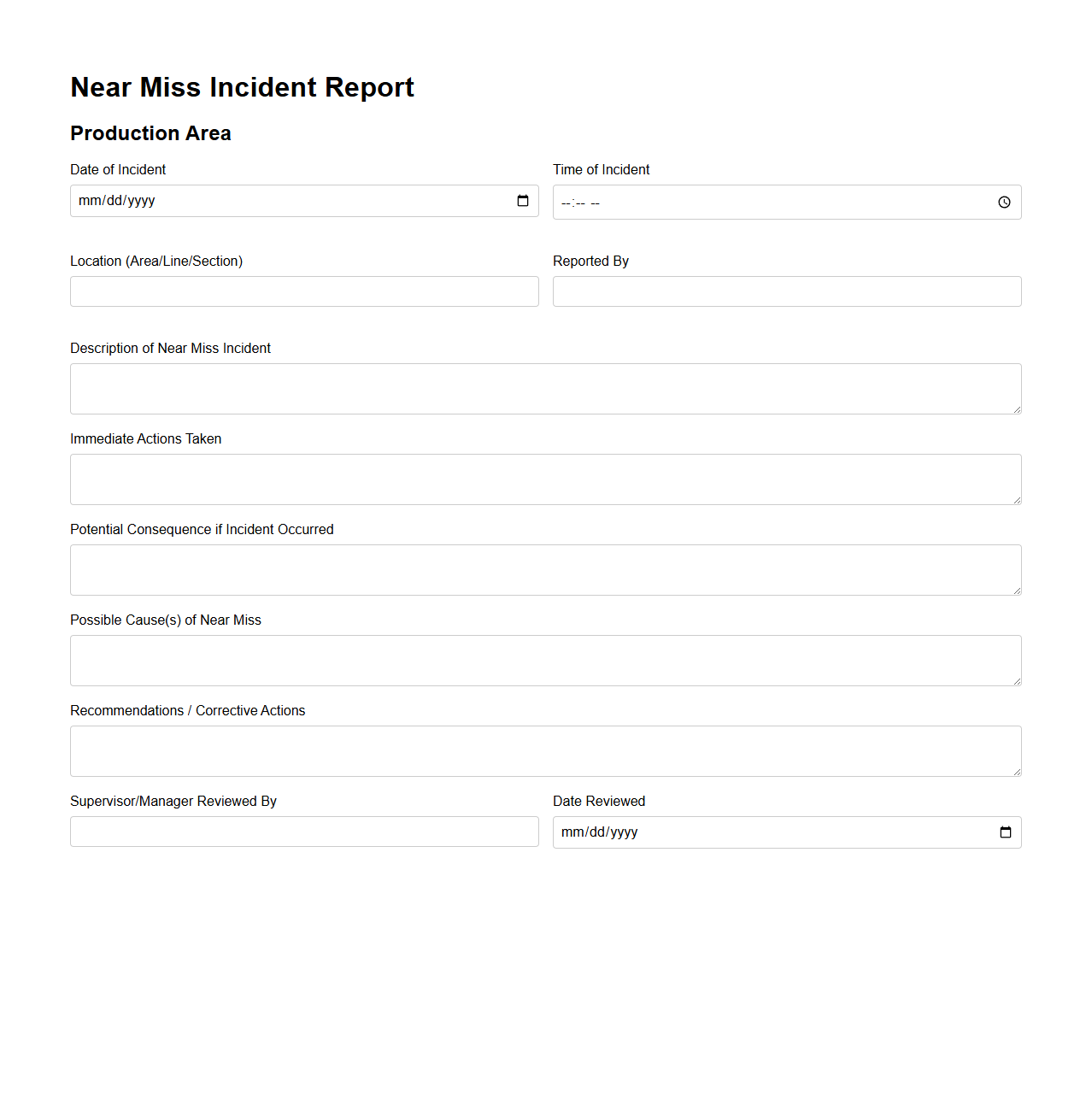

Near Miss Incident Report in Production Area

A

Near Miss Incident Report in the production area documents events where an accident or injury was narrowly avoided, highlighting potential hazards that could cause harm. This report captures detailed information about the incident, including location, time, involved personnel, and contributing factors, enabling organizations to analyze and mitigate risks effectively. By proactively identifying these near misses, companies enhance workplace safety and prevent future accidents.

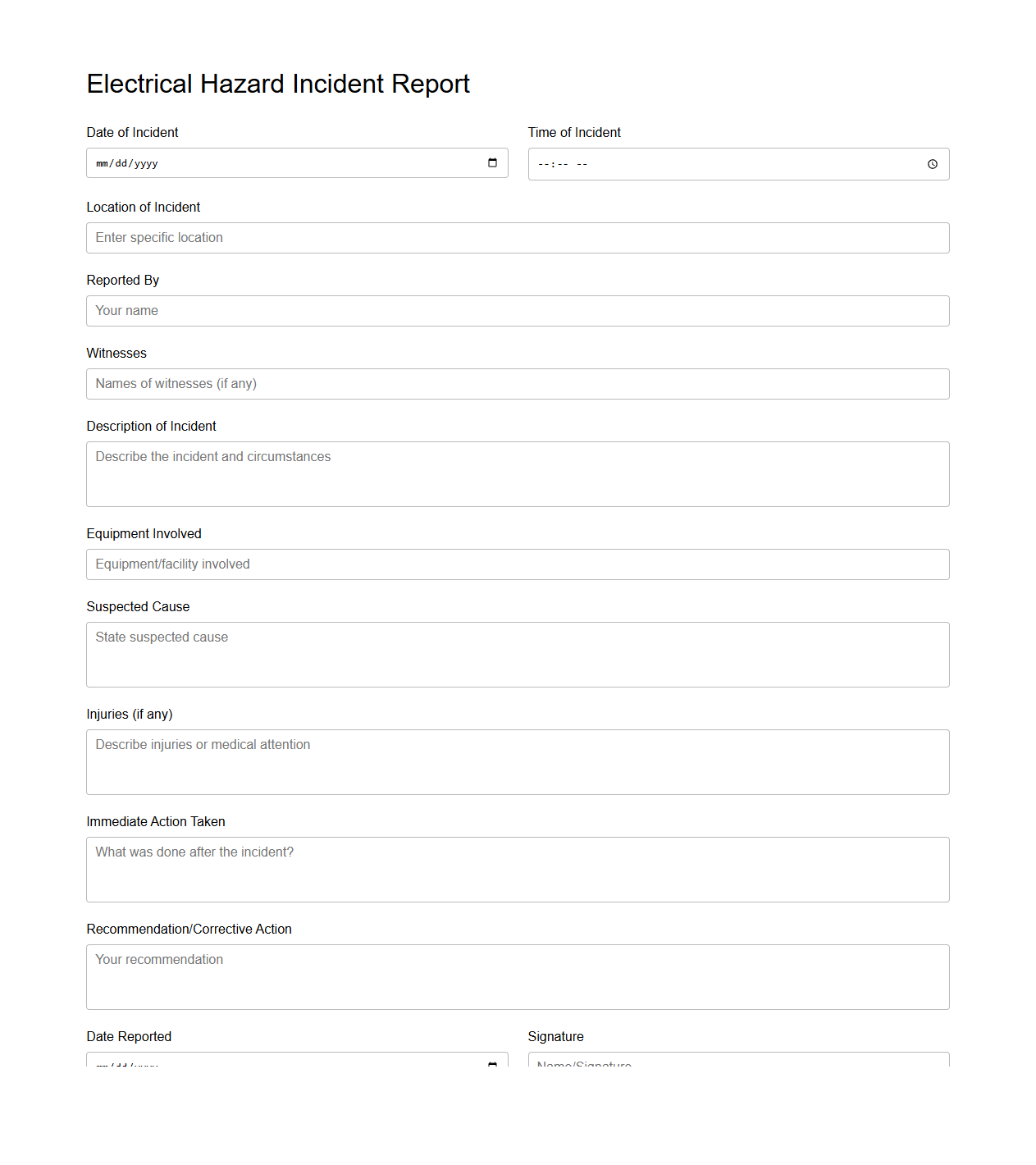

Electrical Hazard Incident Report

An

Electrical Hazard Incident Report document is a formal record used to detail any electrical-related accidents or near-misses in the workplace. It captures essential information such as the nature of the hazard, the specific location, equipment involved, and the individuals affected to ensure proper investigation and preventive measures. This report is crucial for maintaining safety standards, regulatory compliance, and minimizing future electrical risks.

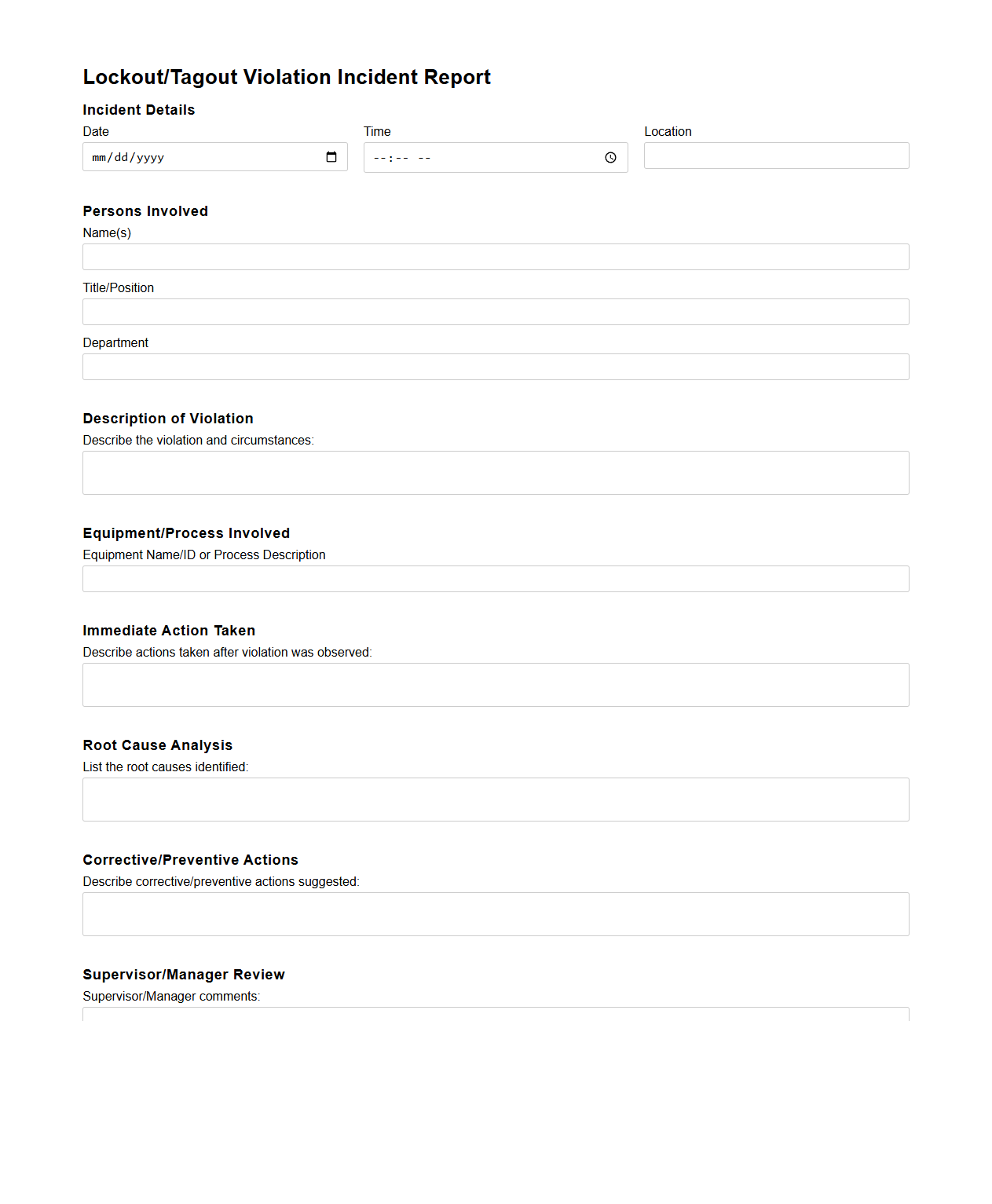

Lockout/Tagout Violation Incident Report

A

Lockout/Tagout Violation Incident Report document records instances where safety procedures to control hazardous energy during equipment maintenance were not properly followed. It details the nature of the violation, affected personnel, equipment involved, and corrective actions taken to prevent recurrence. This report is essential for compliance with OSHA standards and improving workplace safety protocols.

Fire or Smoke Incident Report

A

Fire or Smoke Incident Report document records detailed information about the occurrence, including the time, location, cause, and response actions taken during a fire or smoke event. It serves as a critical resource for emergency responders, insurance claims, and safety investigations, helping to identify hazards and prevent future incidents. Accurate documentation in this report supports regulatory compliance and improves overall fire safety protocols.

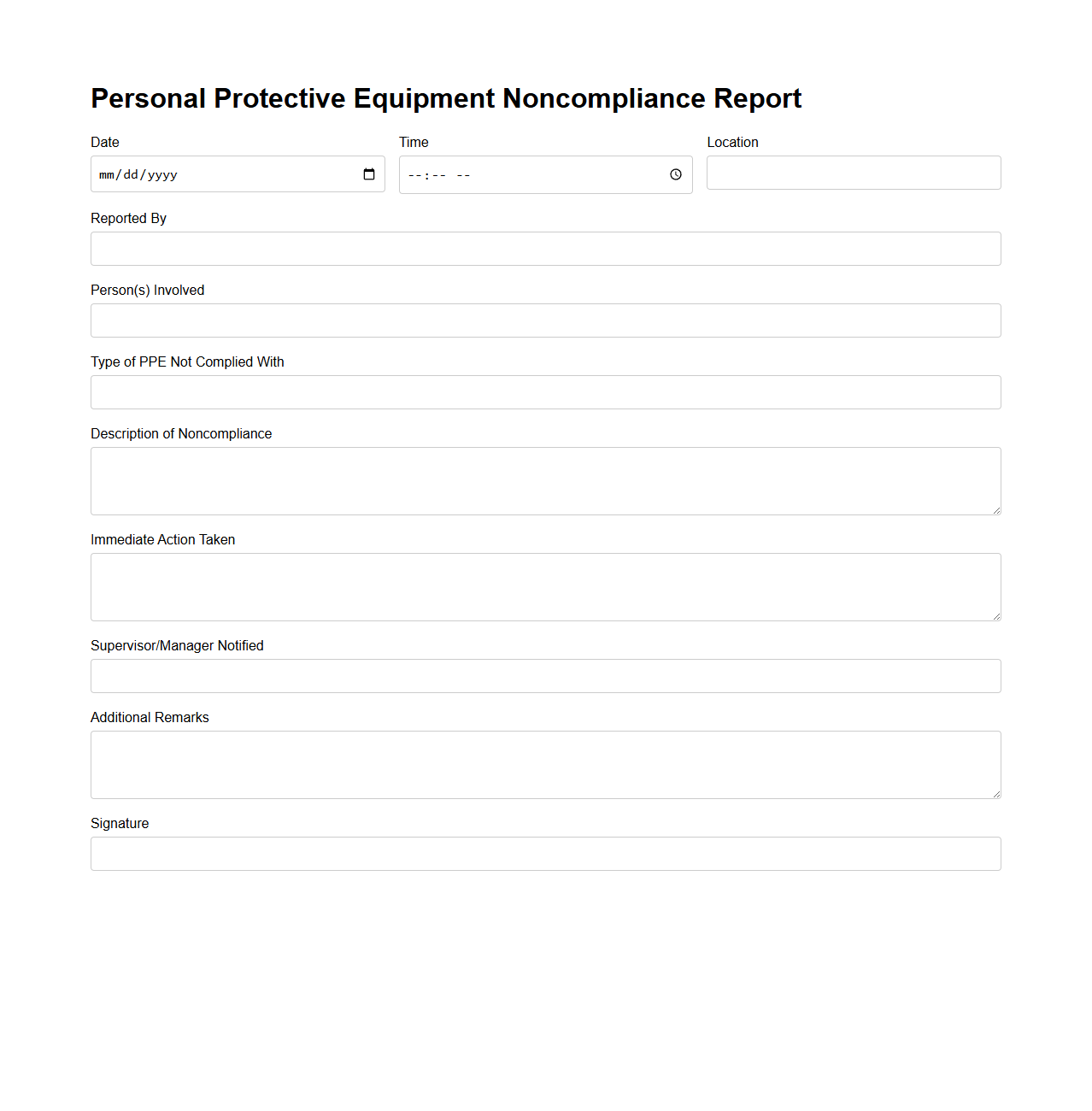

Personal Protective Equipment Noncompliance Report

A

Personal Protective Equipment Noncompliance Report document records instances where employees or personnel fail to wear or properly use required safety gear in the workplace. It details the nature of the noncompliance, involved individuals, and potential safety risks resulting from the oversight. The report serves as a critical tool for enforcing safety protocols and improving overall workplace health and safety standards.

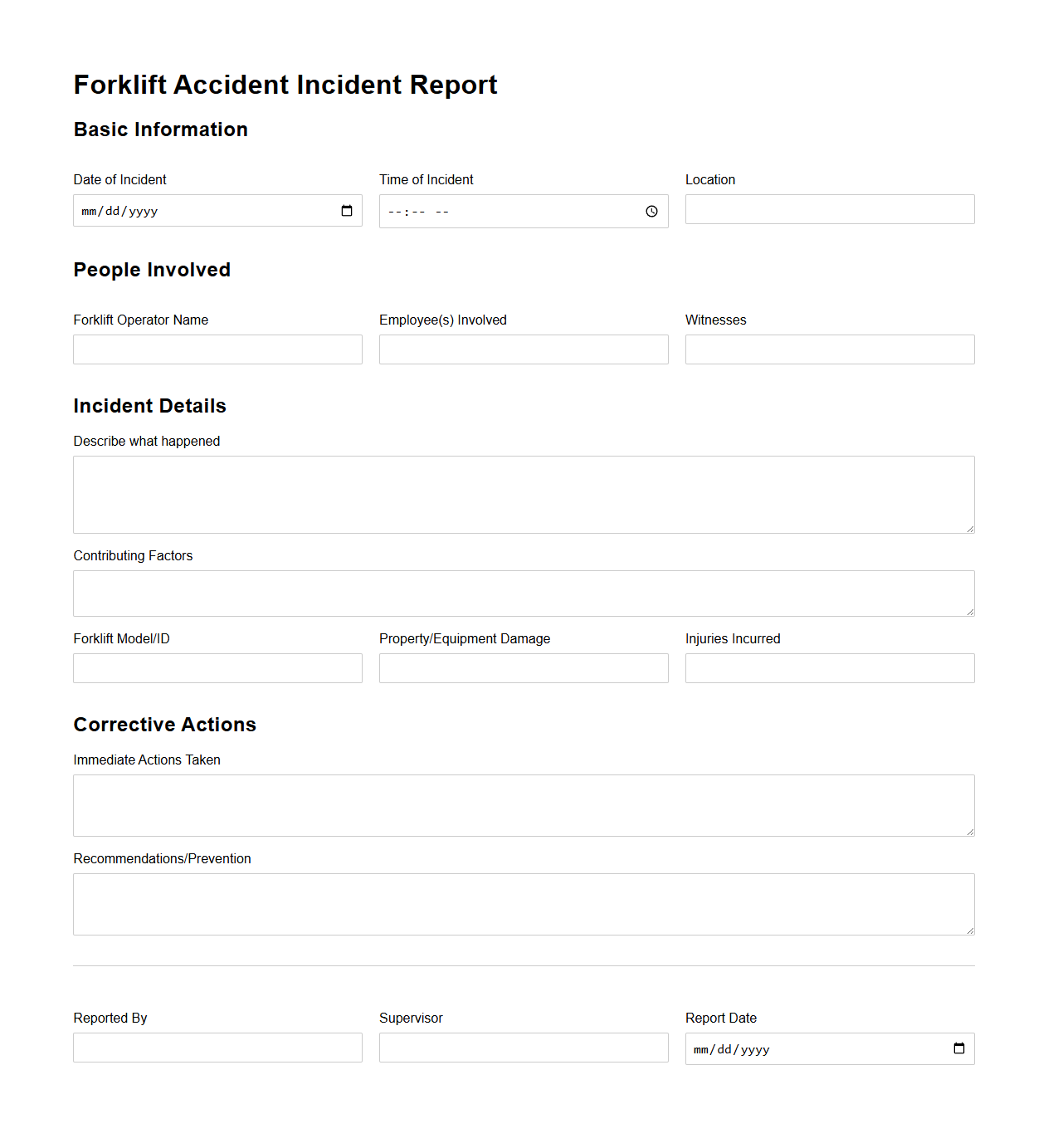

Forklift Accident Incident Report

A

Forklift Accident Incident Report document records essential details of accidents involving forklifts in the workplace, including the date, time, location, personnel involved, and a description of the incident. This report helps identify root causes, assess damages, and implement corrective measures to improve safety protocols. It serves as a critical tool for compliance with occupational health and safety regulations and supports insurance claims and internal investigations.

Commonly Reported Safety Incidents in Manufacturing

The most frequently reported safety incidents in the manufacturing document sample include slips, trips, and falls, equipment malfunctions, and material handling accidents. These incidents often result in injuries ranging from minor cuts to severe trauma. Tracking these common incidents is critical for implementing targeted safety measures.

Essential Sections for Effective Incident Analysis

Key sections of the Safety Incident Report necessary for thorough analysis include the incident description, root cause analysis, and corrective actions. Accurate documentation in these areas ensures a comprehensive understanding of the incident. This facilitates effective prevention strategies and continuous safety improvements.

Defined Roles and Responsibilities in Incident Reporting

The document clearly outlines the roles and responsibilities of employees, supervisors, and safety officers in reporting and investigating incidents. Employees must promptly report incidents, while supervisors are responsible for initial assessments. Safety officers lead detailed investigations and implement remedial measures.

Corrective and Preventive Actions Outlined

The safety incident report sample specifies corrective actions such as equipment repairs and updated safety training programs. Preventive measures include regular safety audits and hazard identification processes. Together, these actions aim to reduce incident recurrence and improve workplace safety.

Ensuring Compliance with Safety Standards and Regulations

The document ensures compliance by aligning incident reporting procedures with OSHA regulations and industry-specific safety standards. It mandates regular employee training on regulatory requirements. This proactive approach helps maintain a safe work environment and legal compliance.