A Equipment Calibration Record Document Sample for Manufacturing Machines ensures precise tracking of calibration activities, maintaining machine accuracy and compliance with industry standards. This document typically includes details such as equipment identification, calibration dates, technician signatures, and measurement results. Properly maintained calibration records support quality control and operational efficiency in manufacturing processes.

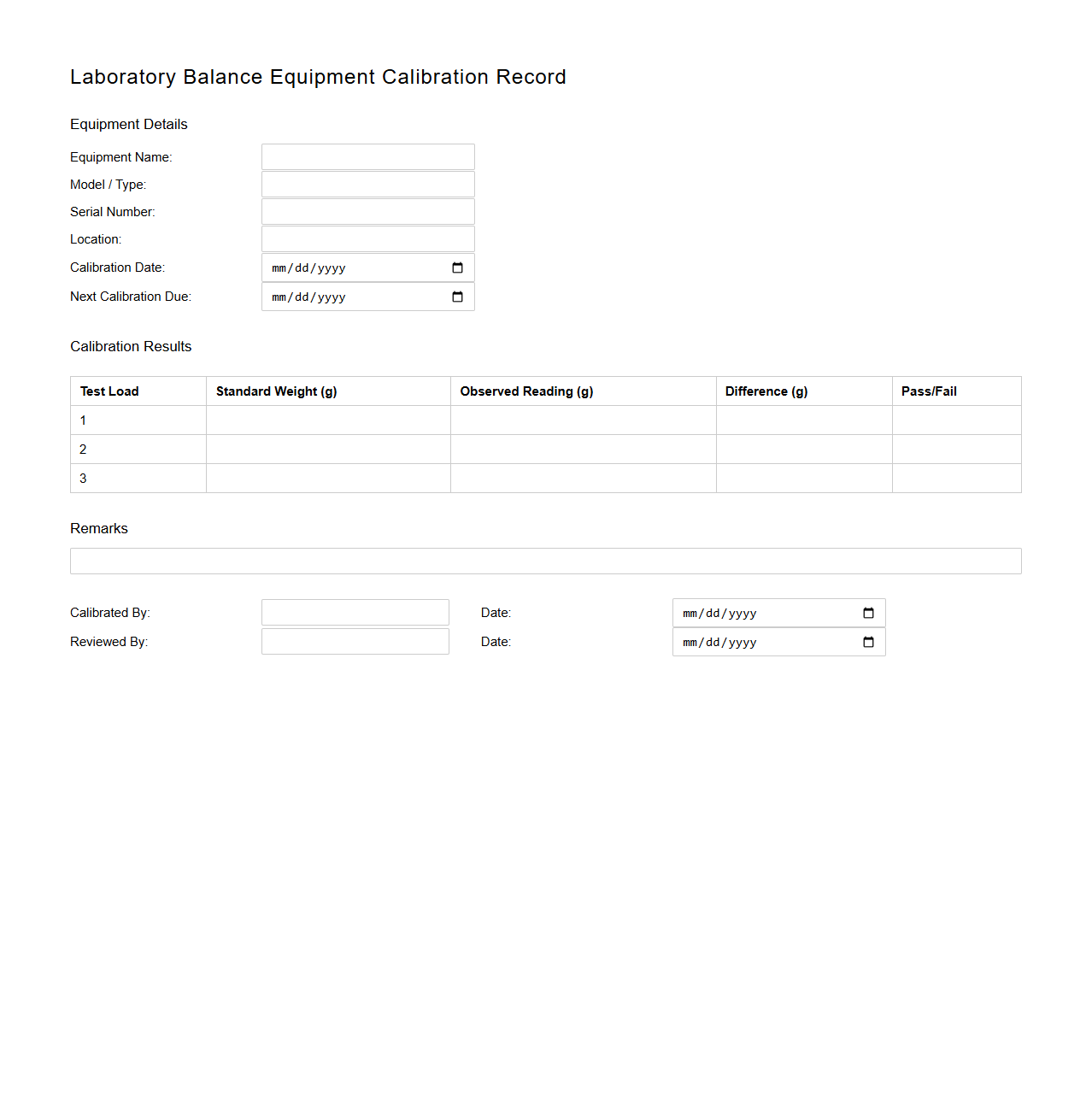

Laboratory Balance Equipment Calibration Record Sample

A

Laboratory Balance Equipment Calibration Record Sample document is a standardized form used to log the calibration details of laboratory balances, ensuring precision and accuracy in measurements. It typically includes data such as calibration date, technician name, balance identification, calibration results, and any necessary adjustments or repairs. Maintaining this record supports compliance with quality control standards and facilitates traceability for audits and inspections.

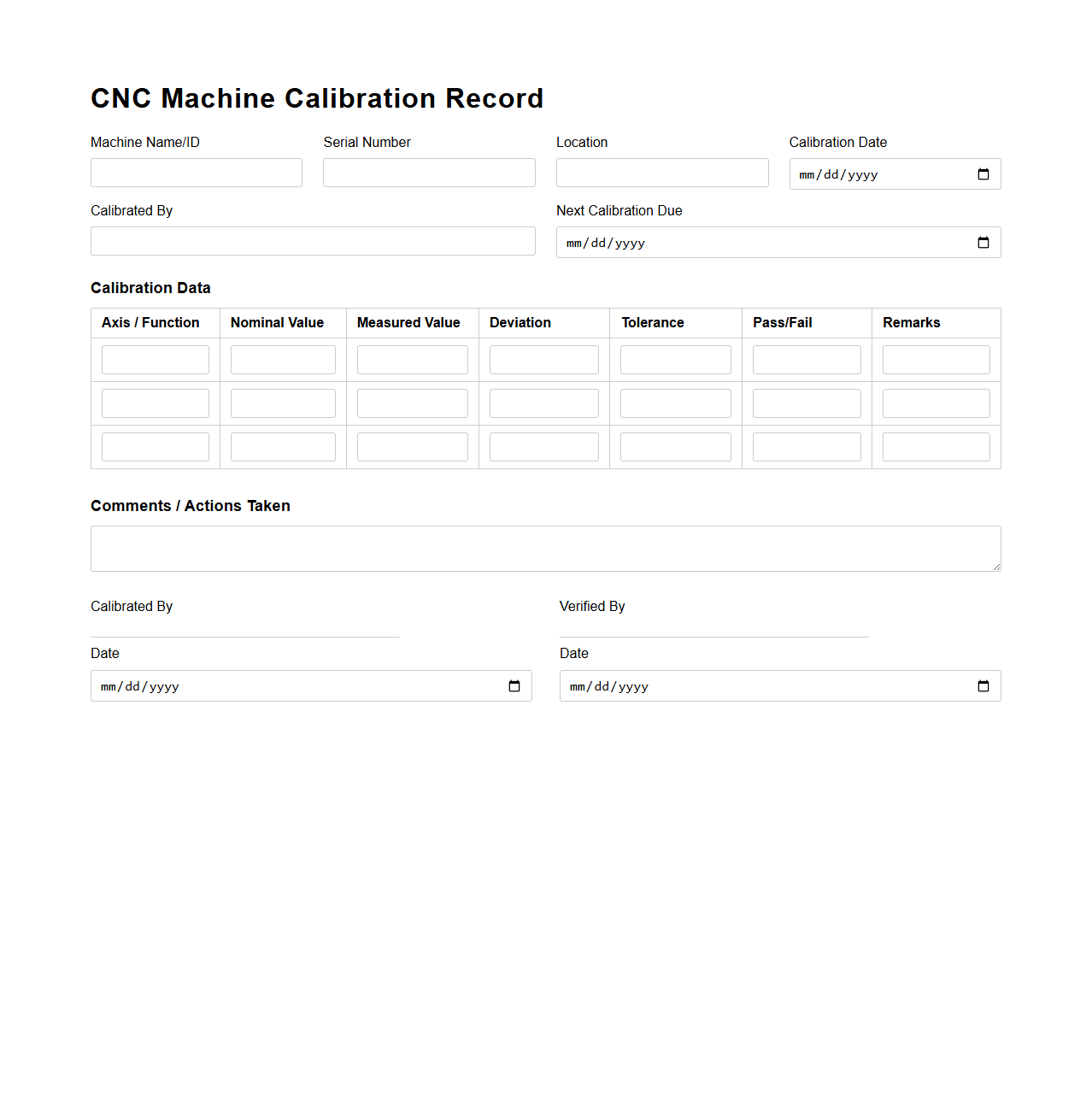

CNC Machine Calibration Record Template Example

A

CNC Machine Calibration Record Template Example document is used to systematically document the calibration process of CNC machines, ensuring accuracy and consistency in production. It typically includes fields for machine details, calibration dates, technician information, measured values, and acceptable tolerance ranges. Maintaining this record helps in verifying machine precision, complying with quality standards, and facilitating regular maintenance audits.

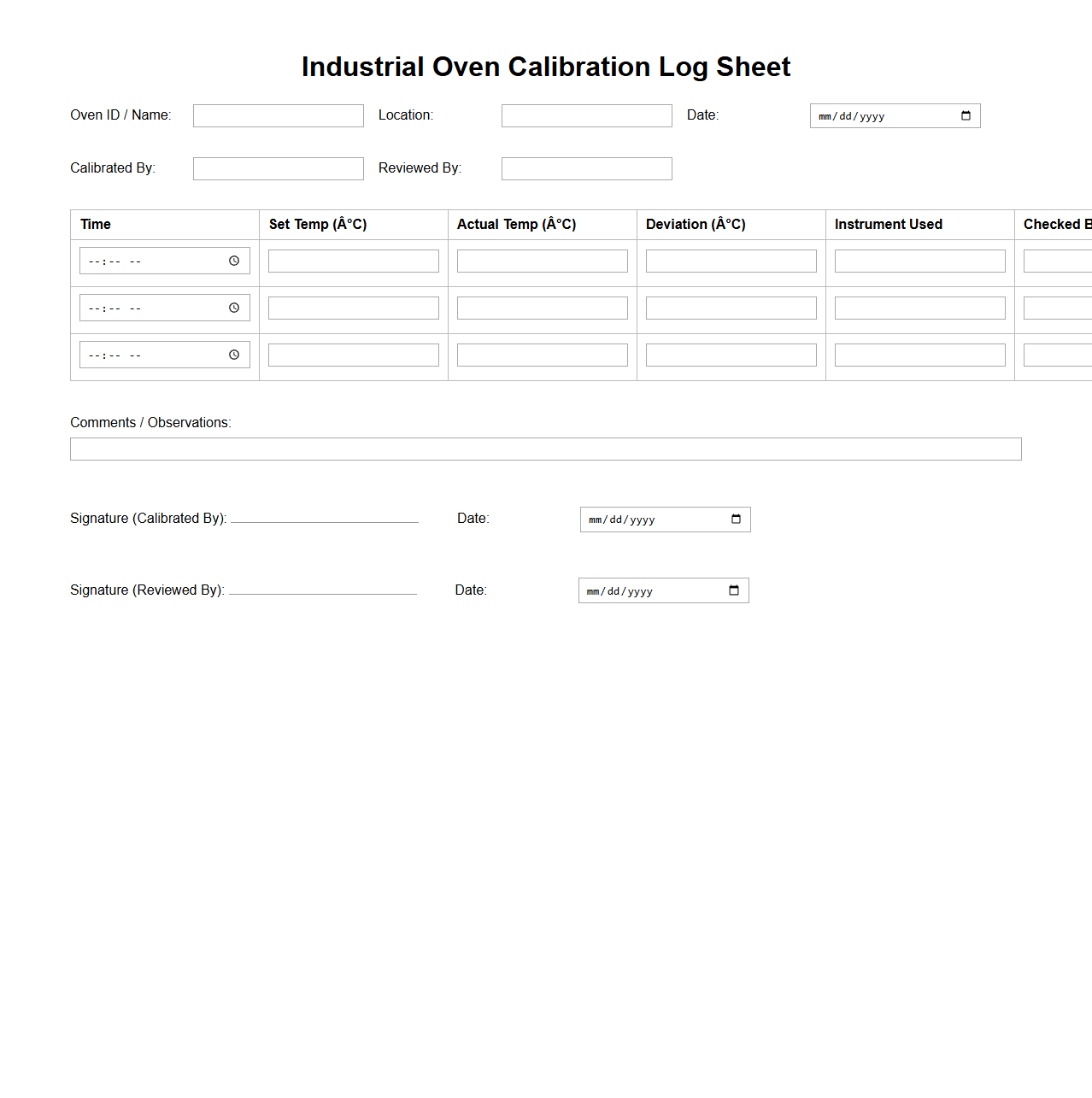

Industrial Oven Calibration Log Sheet Example

An Industrial Oven Calibration Log Sheet Example document is a detailed record used to track the calibration process of industrial ovens, ensuring accurate temperature control and consistent performance. This log sheet typically includes essential data such as calibration dates, technician names, oven serial numbers, temperature settings, measured values, and any adjustments made during calibration. Maintaining a

calibration log sheet is crucial for quality assurance, regulatory compliance, and optimal oven operation in manufacturing or laboratory environments.

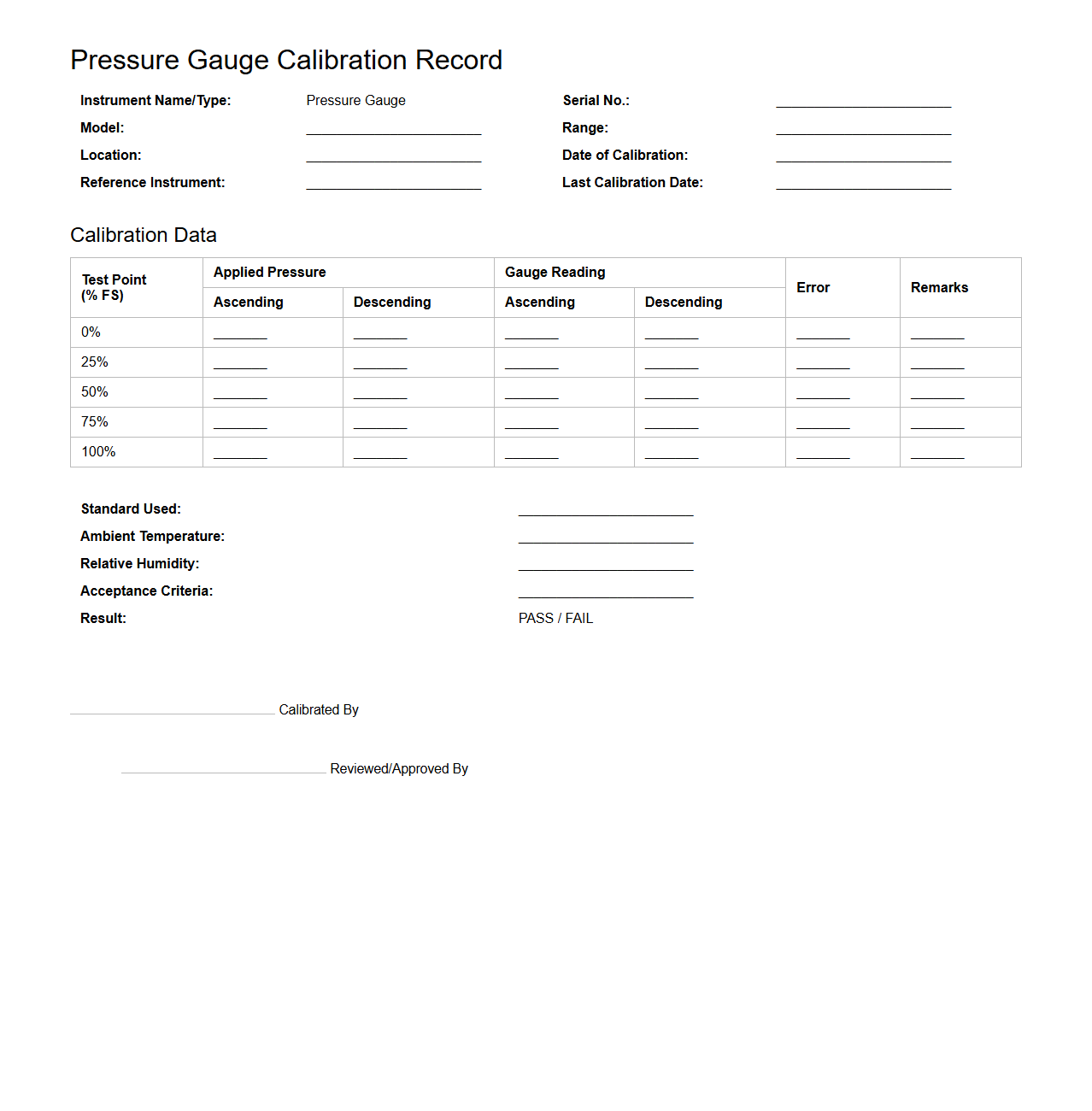

Pressure Gauge Calibration Record Document Sample

A

Pressure Gauge Calibration Record Document Sample is a standardized form used to capture detailed information during the calibration process of pressure gauges, ensuring accuracy and traceability. It typically includes fields for date, technician details, calibration results, equipment identification, and reference standards used. Maintaining these records supports compliance with quality control standards and helps in tracking the performance and reliability of pressure measurement instruments over time.

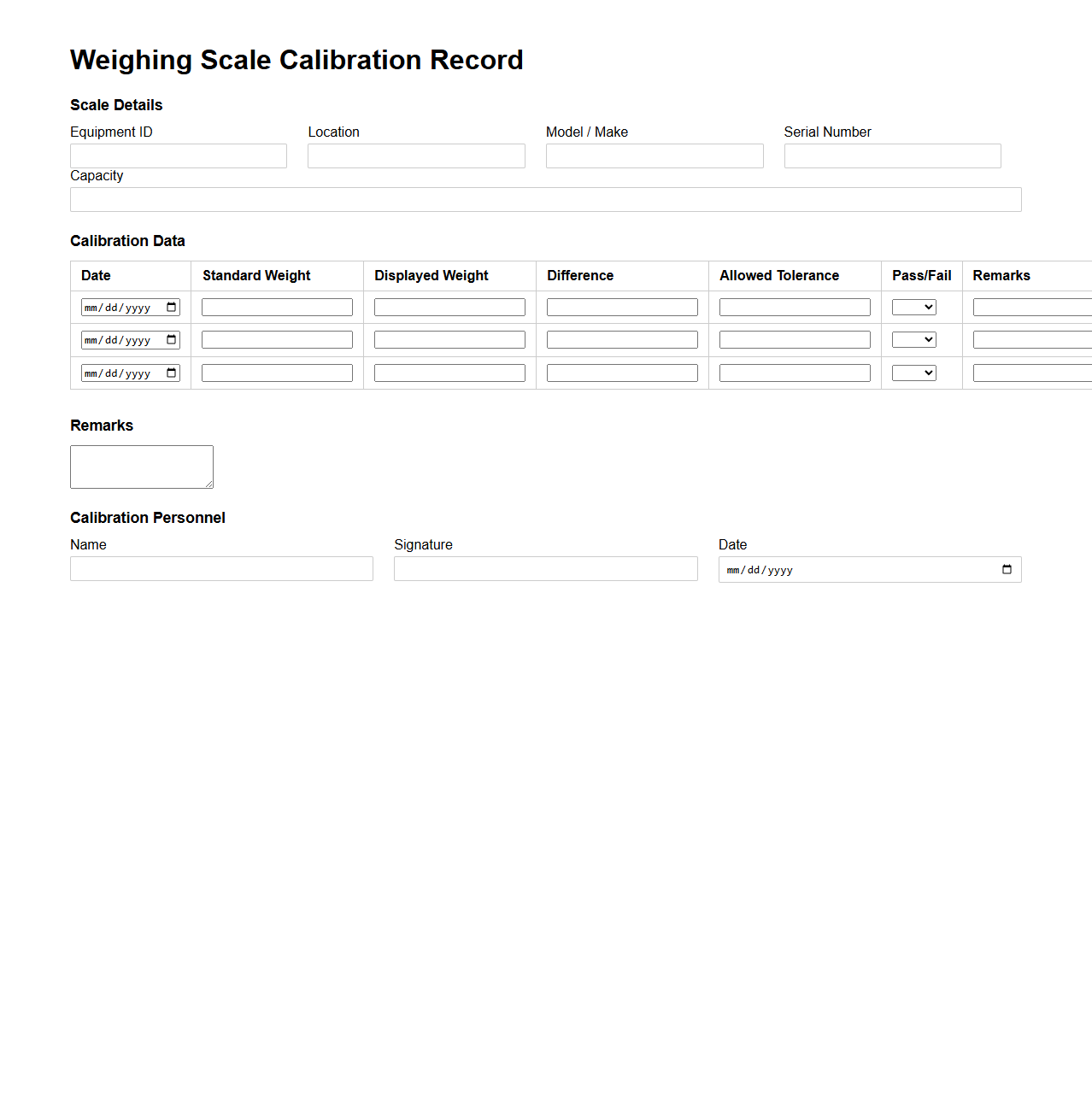

Weighing Scale Calibration Record For Manufacturing

A

Weighing Scale Calibration Record for Manufacturing document is a critical record that tracks the calibration status and accuracy of weighing scales used in production processes. It ensures compliance with industry standards by documenting calibration dates, methods, results, and corrective actions if measurements deviate from specified tolerances. Maintaining accurate calibration records helps guarantee product quality, consistency, and regulatory adherence within manufacturing operations.

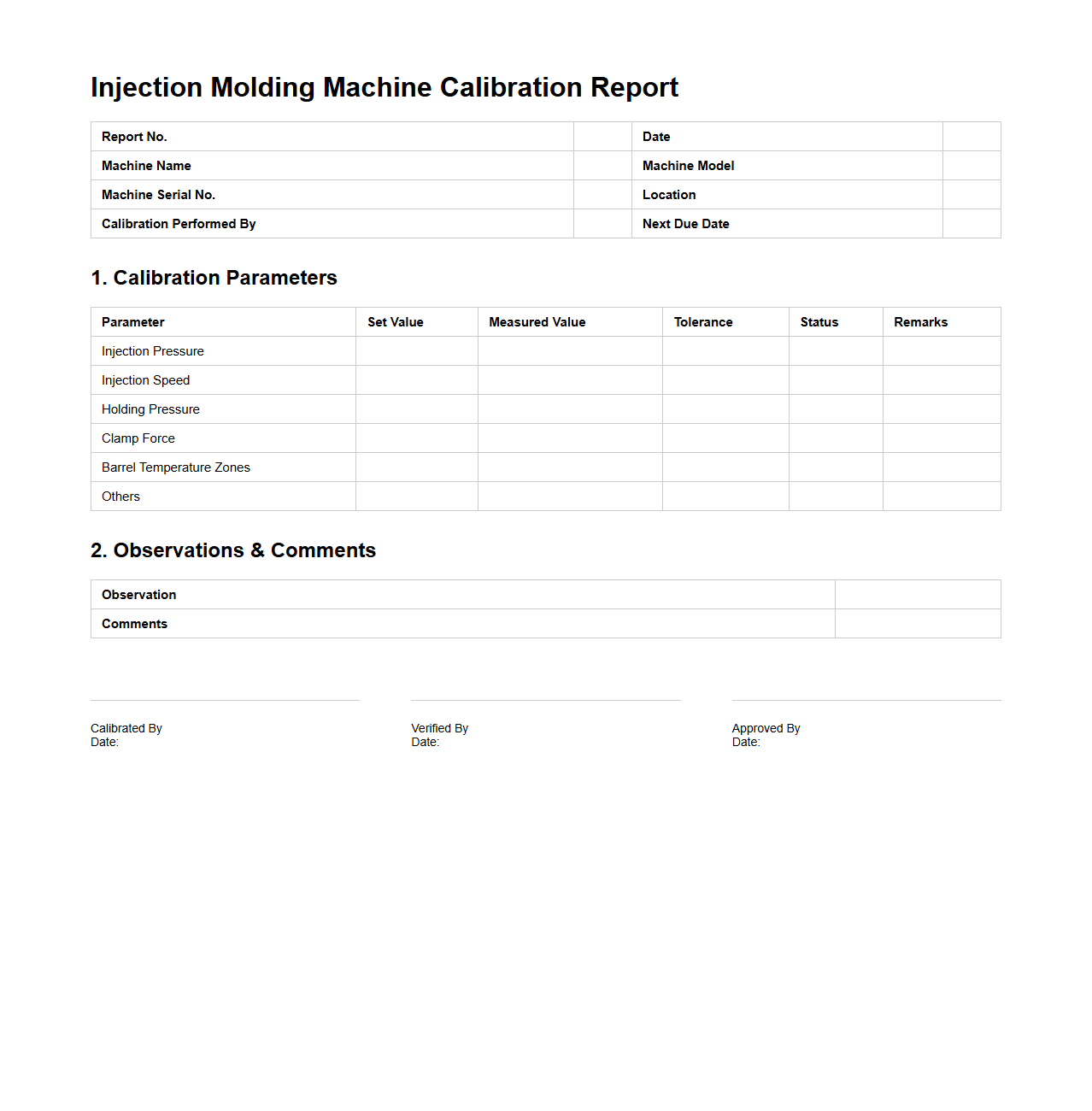

Injection Molding Machine Calibration Report Format

Injection Molding Machine Calibration Report Format document outlines the standardized procedure for recording and verifying the accuracy of pressure, temperature, and injection speed settings on the

injection molding machine. This format ensures consistent documentation of calibration data, including measurement results, tolerances, and equipment identification details. Proper calibration reporting is essential for maintaining machine performance, product quality, and regulatory compliance in manufacturing processes.

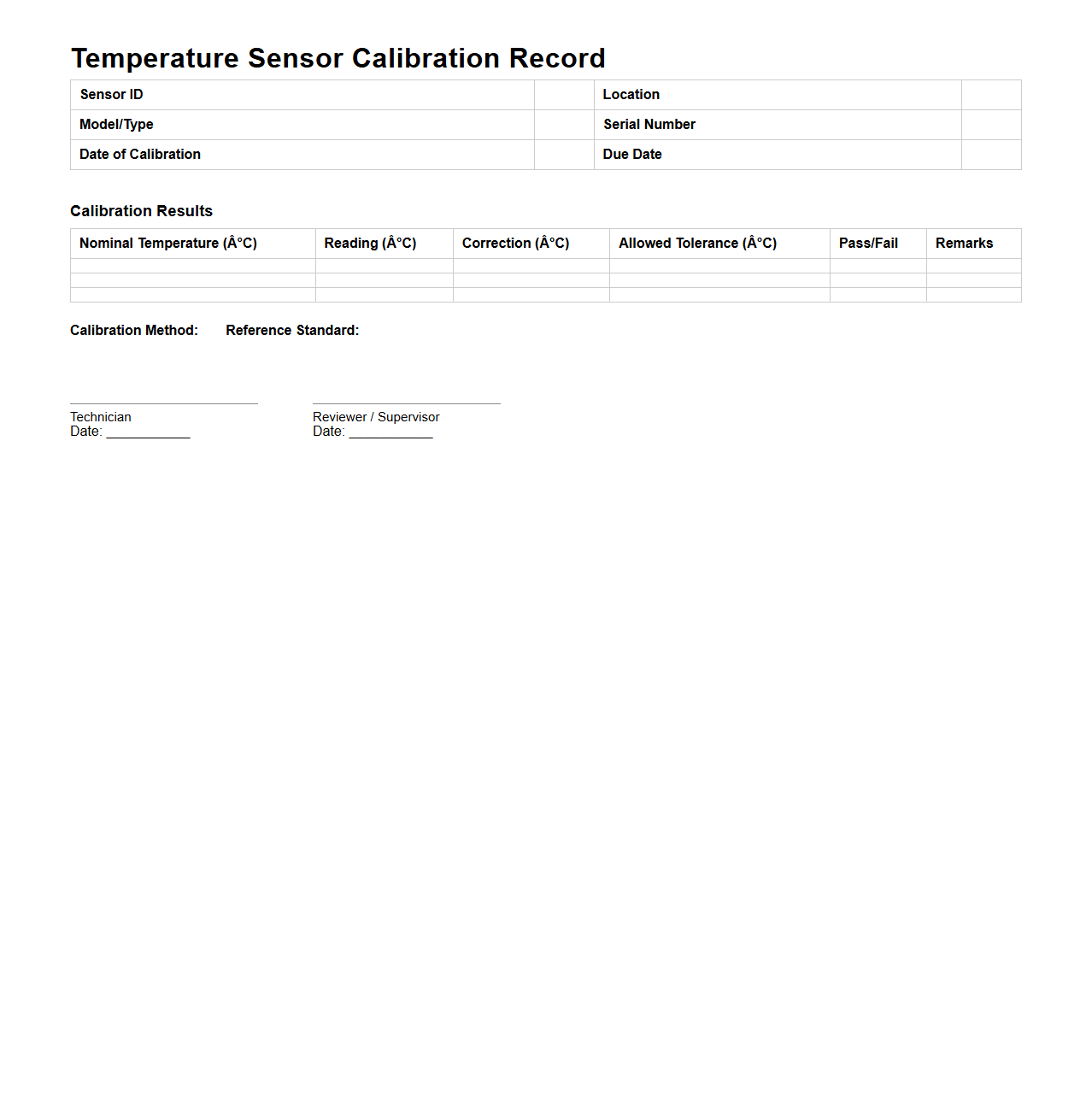

Temperature Sensor Calibration Record Example

A

Temperature Sensor Calibration Record Example document serves as a detailed log verifying the accuracy and performance of temperature sensors over time. It includes essential data such as sensor identification, calibration dates, reference standards, measured values, and any adjustments made during the calibration process. This record ensures compliance with industry standards and supports quality control in environments where precise temperature measurement is critical.

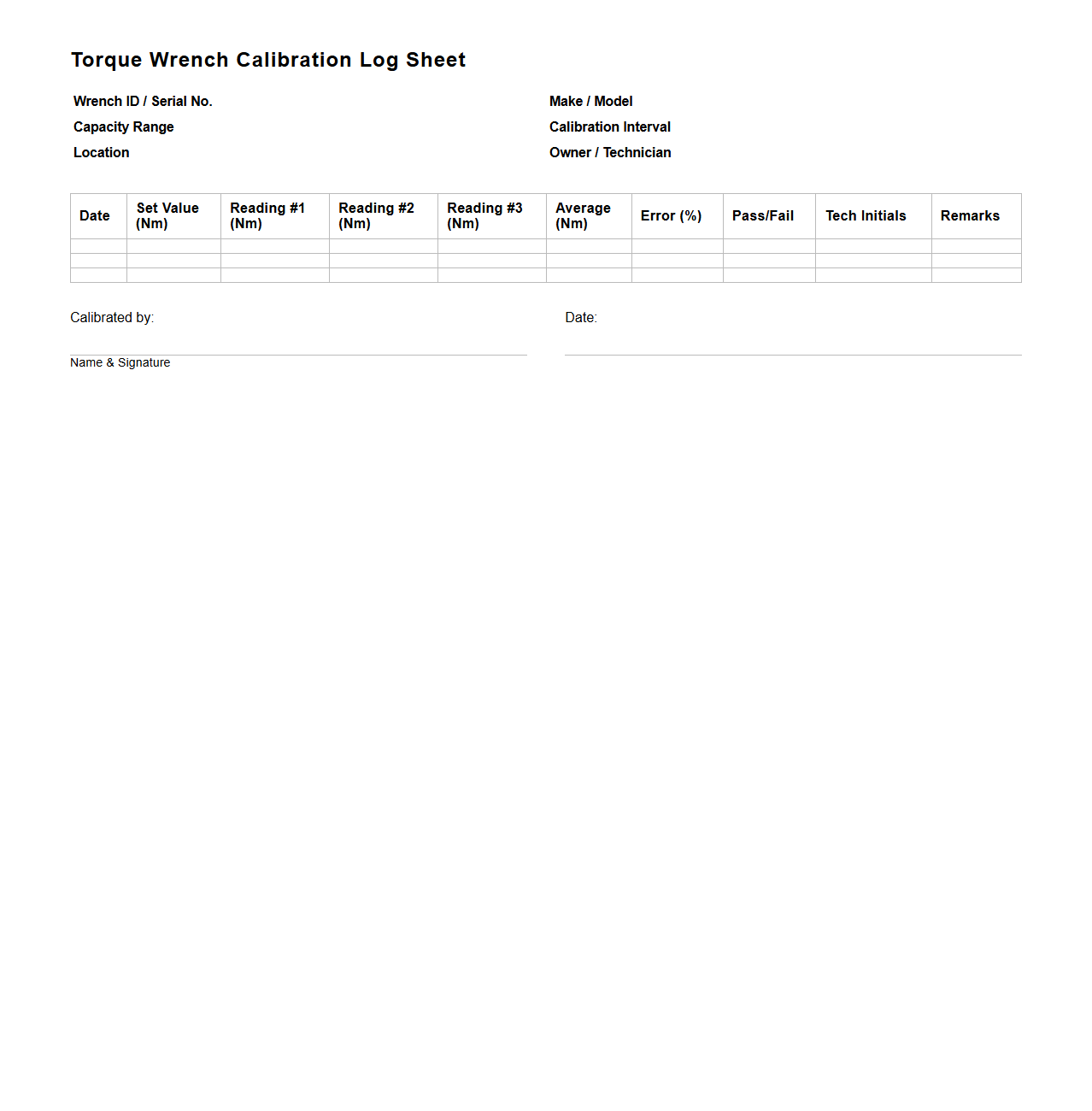

Torque Wrench Calibration Log Sheet Sample

A

Torque Wrench Calibration Log Sheet Sample is a standardized document used to record the calibration details of torque wrenches, ensuring the accuracy and reliability of torque measurements. It typically includes fields for wrench identification, calibration date, applied torque values, measured torque values, and technician signatures. Maintaining this log sheet enhances quality control and compliance with industry standards such as ISO 6789.

Conveyor Belt Speed Calibration Record Form

The

Conveyor Belt Speed Calibration Record Form document is used to systematically log and verify the speed measurements of conveyor belts during calibration processes. It helps ensure that the conveyor system operates at accurate speeds, maintaining efficiency and safety in material handling. This form typically includes fields for recorded speed values, calibration dates, equipment identification, and technician signatures for traceability.

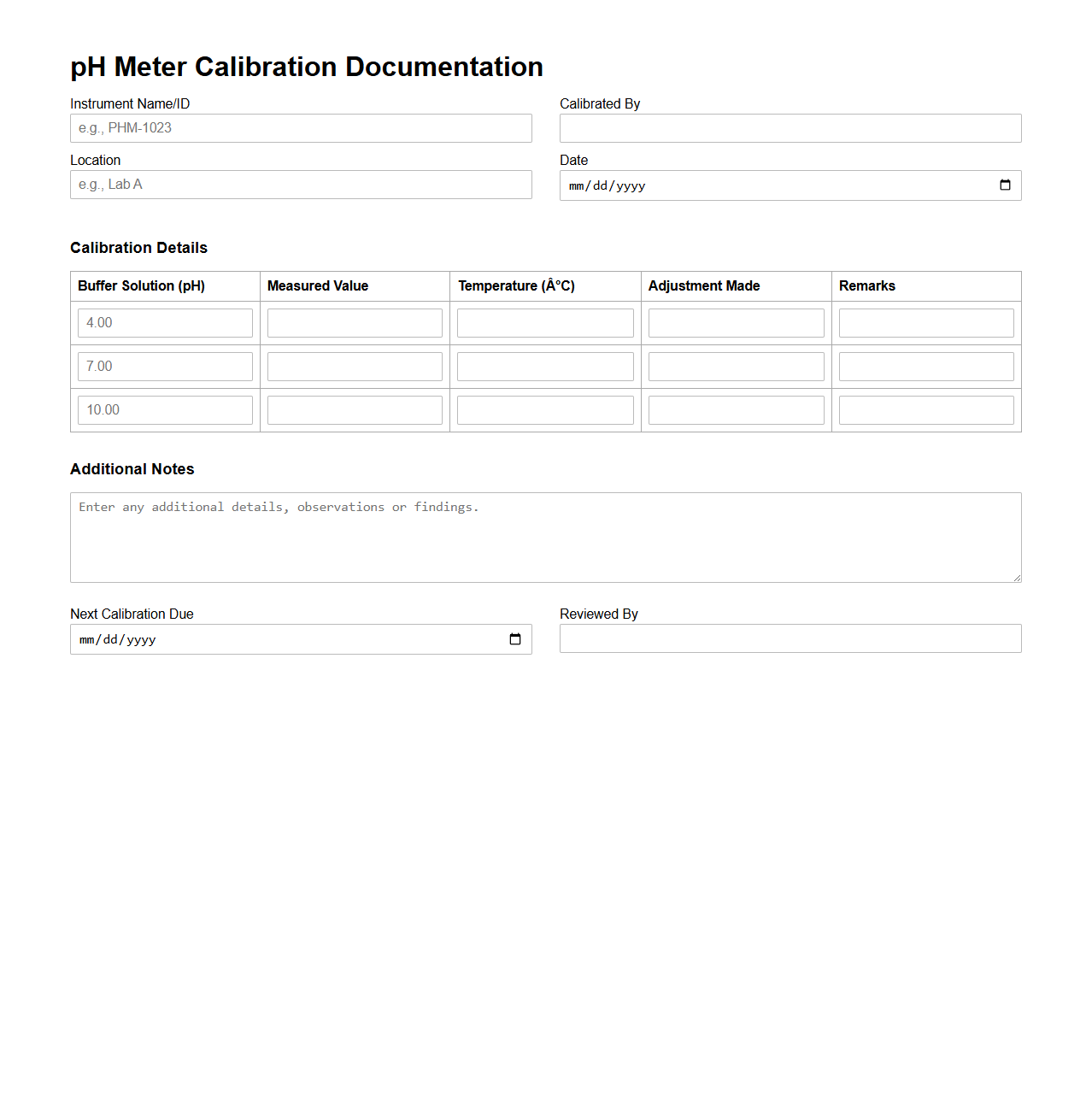

pH Meter Calibration Documentation Example

accurate pH meter calibration records enhances traceability and supports laboratory audits and validation procedures.What is the primary purpose of the Equipment Calibration Record Document in manufacturing?

The primary purpose of the Equipment Calibration Record Document is to maintain accurate and verifiable data regarding the calibration status of manufacturing equipment. This ensures that all machines operate within specified tolerances, guaranteeing product quality and compliance. It serves as an official record to demonstrate that calibration activities have been systematically performed.

Which critical information fields must be included in a calibration record for compliance?

A compliant calibration record must include fields such as equipment identification, calibration date, results achieved, and the name of the technician performing the calibration. It should also document the calibration standards used and the next scheduled calibration date. This information is vital for audits and regulatory inspections.

How does the calibration record document ensure traceability for each manufacturing machine?

The calibration record provides traceability by linking each machine to its unique calibration history and standards employed. By detailing dates, responsible personnel, and specific calibration outcomes, the document creates a transparent audit trail. This assists in identifying potential issues and maintaining quality consistency over time.

What procedures are specified for handling non-conforming calibration results in the document?

The document outlines corrective actions for non-conforming calibration results, including equipment quarantine, investigation, and re-calibration. It mandates documentation of findings and authorization before returning equipment to service. These procedures prevent faulty equipment from impacting production quality.

How does the document guide the scheduling and frequency of equipment calibration tasks?

The calibration record document specifies the frequency and scheduling of calibration tasks based on manufacturer recommendations, usage, and regulatory requirements. It maintains a calibration calendar to ensure timely completion and avoid lapses. This proactive scheduling helps sustain equipment accuracy and reliability.

More Manufacturing Templates