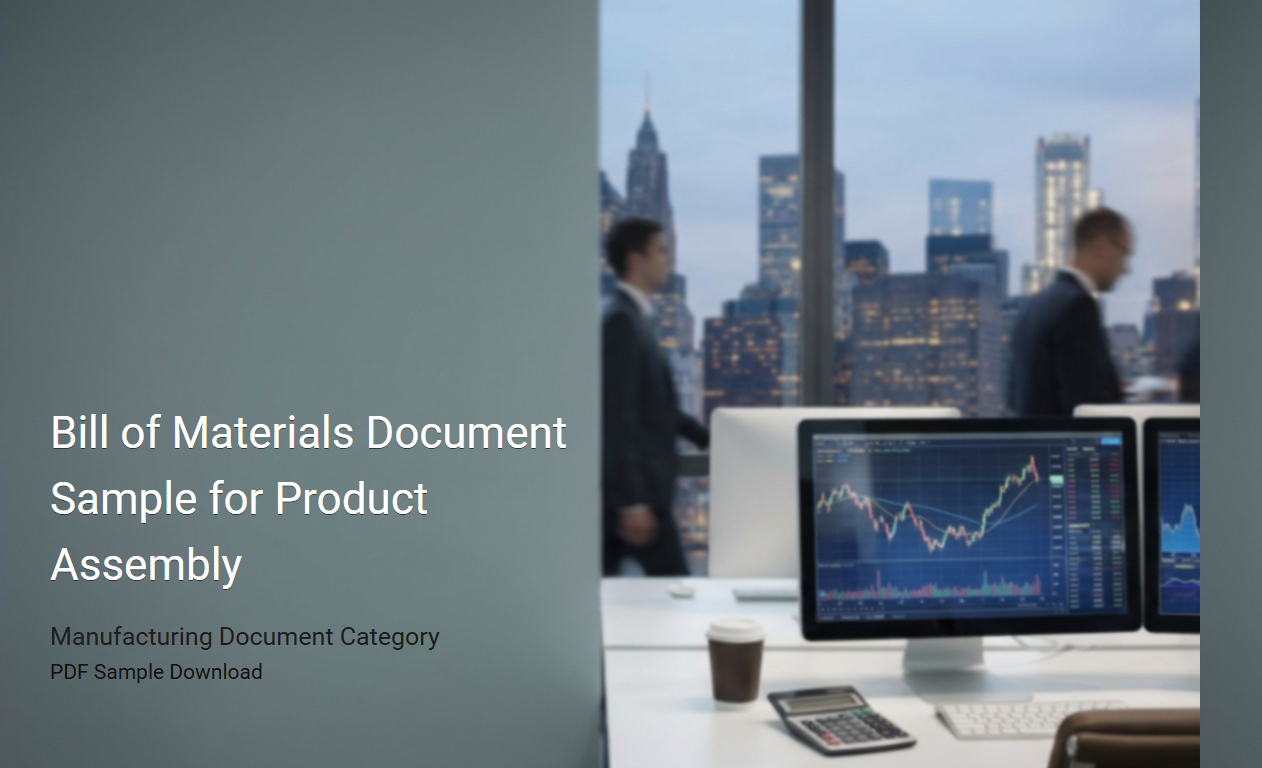

Electronic Device Bill of Materials Template

An

Electronic Device Bill of Materials Template document is a structured framework used to list all components, parts, and materials required to manufacture an electronic device. It includes detailed information such as part numbers, quantities, descriptions, suppliers, and cost data to ensure accurate procurement and inventory management. This template enhances efficiency in production planning, cost estimation, and quality control throughout the device manufacturing process.

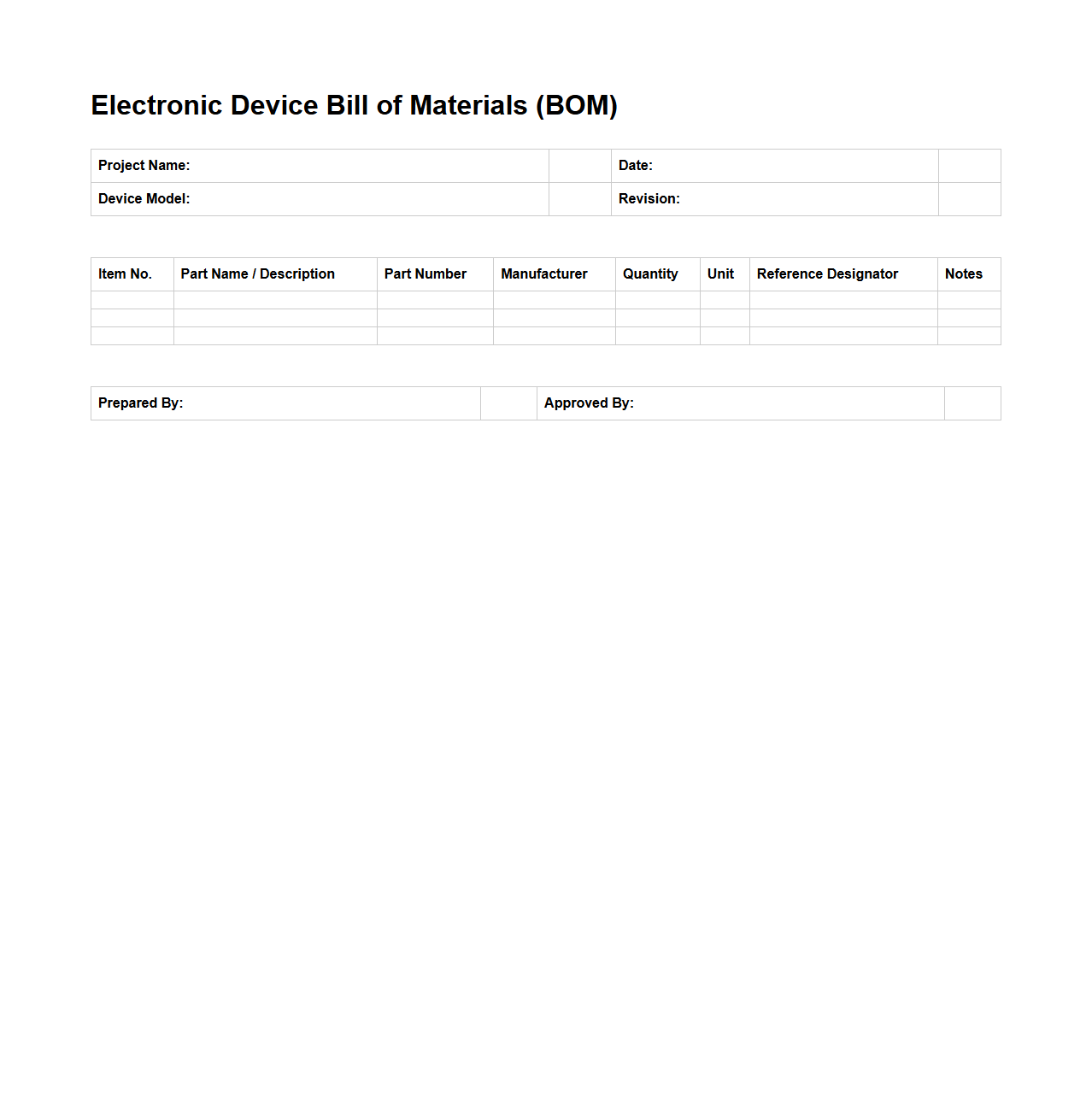

Furniture Product Assembly BOM Example

A

Furniture Product Assembly BOM Example document outlines the detailed list of components, materials, and sub-assemblies required to assemble a furniture product. It includes specifications such as part numbers, quantities, descriptions, and assembly instructions to ensure accurate production and inventory management. This document serves as a critical reference for manufacturing teams to maintain consistency and quality in the assembly process.

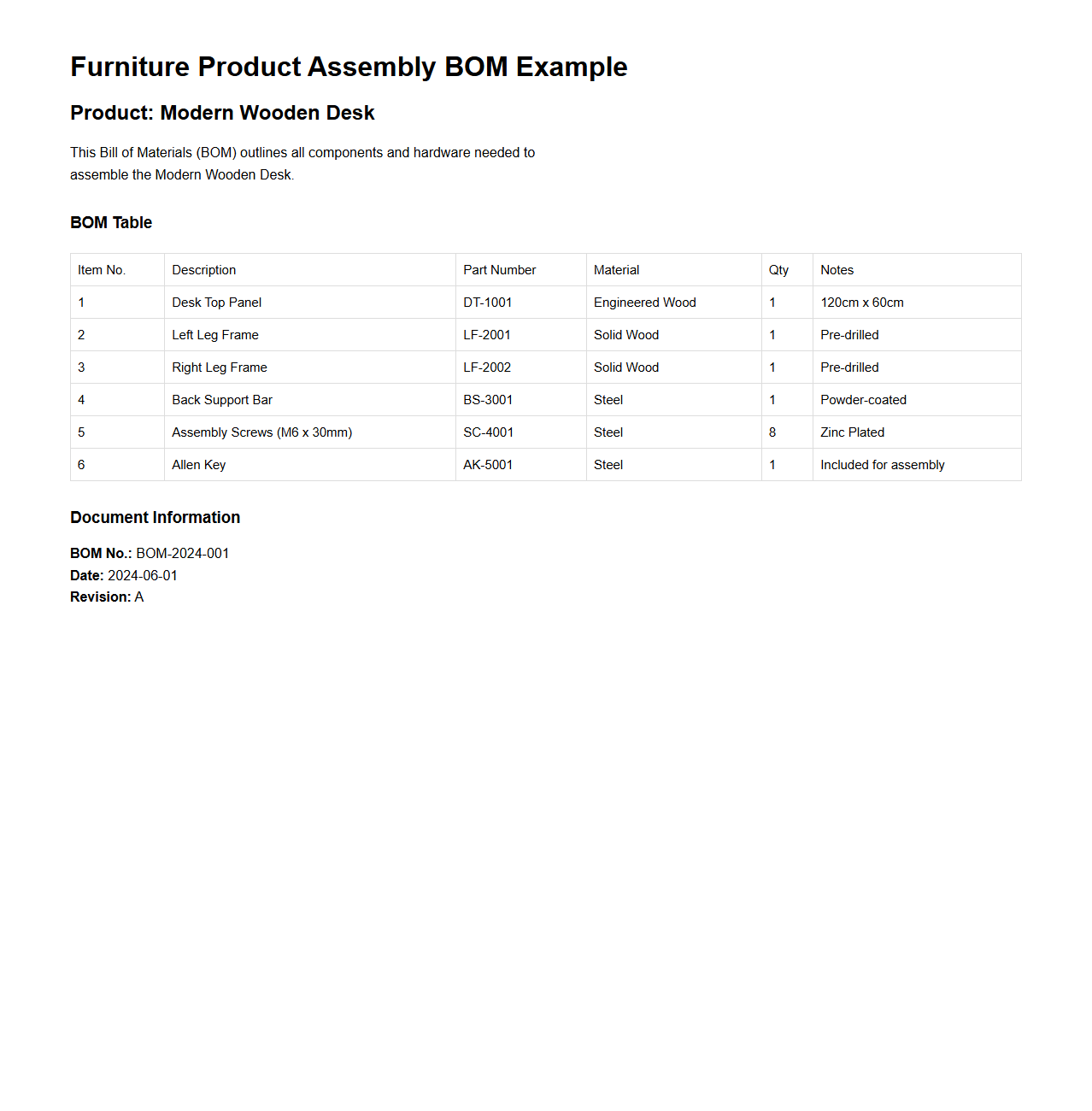

Mechanical Equipment BOM Format

A

Mechanical Equipment BOM Format document is a structured list that details all components, sub-assemblies, and raw materials required for the manufacturing or assembly of mechanical equipment. This document includes part numbers, descriptions, quantities, and specifications to ensure accurate procurement and inventory management. It plays a critical role in supporting project planning, cost estimation, and efficient communication among engineering, purchasing, and production teams.

Consumer Appliance Assembly BOM

The

Consumer Appliance Assembly BOM document is a detailed list of all components, parts, and materials required to assemble a consumer appliance product. It serves as a critical reference for manufacturing teams to ensure accurate procurement, inventory management, and production scheduling. This document includes part numbers, quantities, descriptions, and supplier details to streamline the assembly process and maintain product quality.

Automotive Parts Bill of Materials Layout

The

Automotive Parts Bill of Materials (BOM) Layout document details the hierarchical structure and components required to assemble a specific automotive part, ensuring accurate tracking of quantities, part numbers, and specifications. It serves as a critical reference for manufacturing, procurement, and quality control teams, enhancing production efficiency and reducing errors. By providing clear visibility into each sub-assembly and material needed, the BOM layout streamlines inventory management and supports compliance with industry standards.

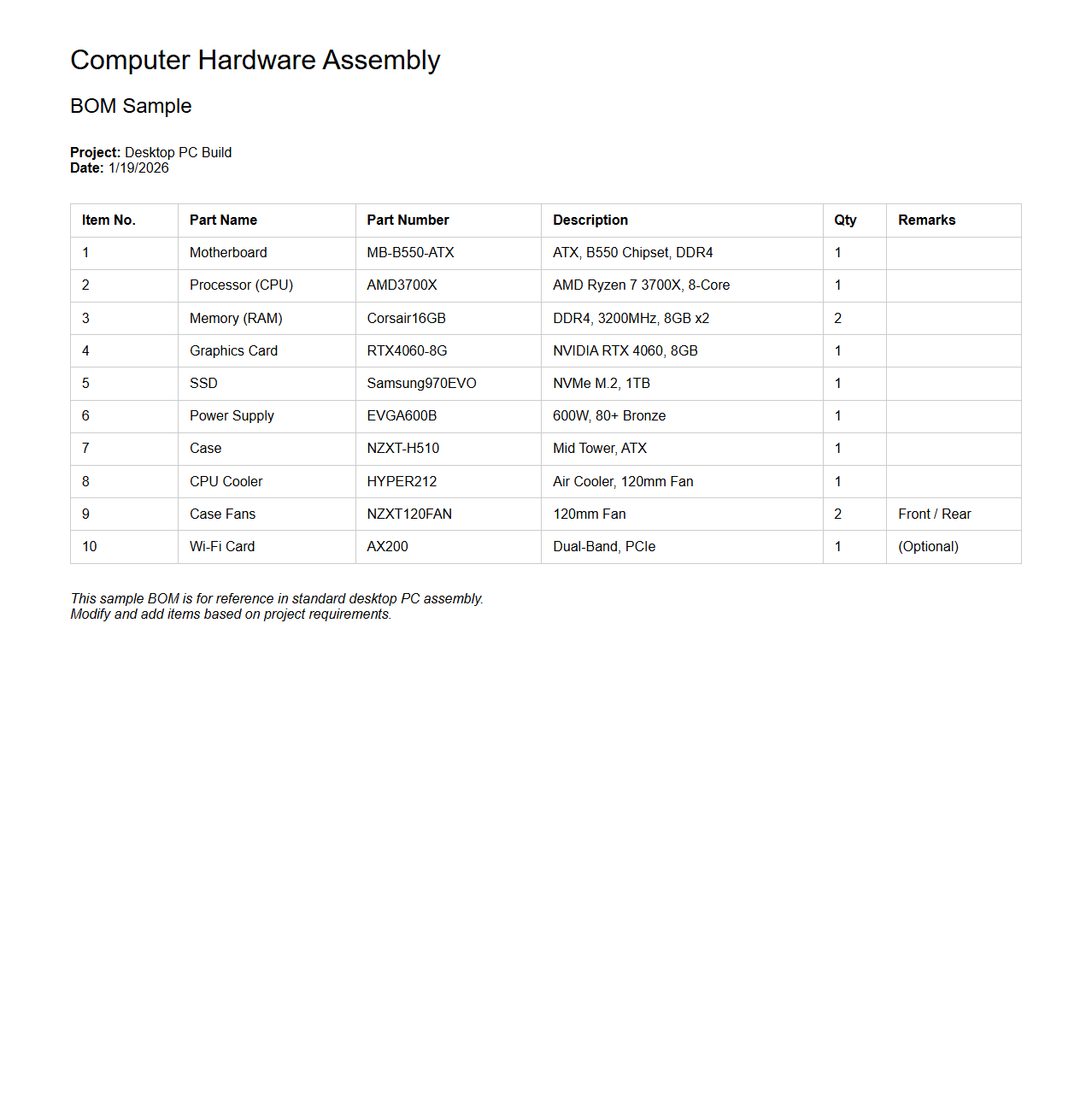

Computer Hardware Assembly BOM Sample

A

Computer Hardware Assembly BOM Sample document lists all components, parts, and materials required to assemble a computer system, including quantities, specifications, and part numbers. It organizes critical hardware elements such as processors, memory modules, storage devices, and circuit boards to facilitate accurate procurement and efficient assembly processes. This document serves as an essential reference for manufacturing teams, inventory management, and quality control in computer hardware production.

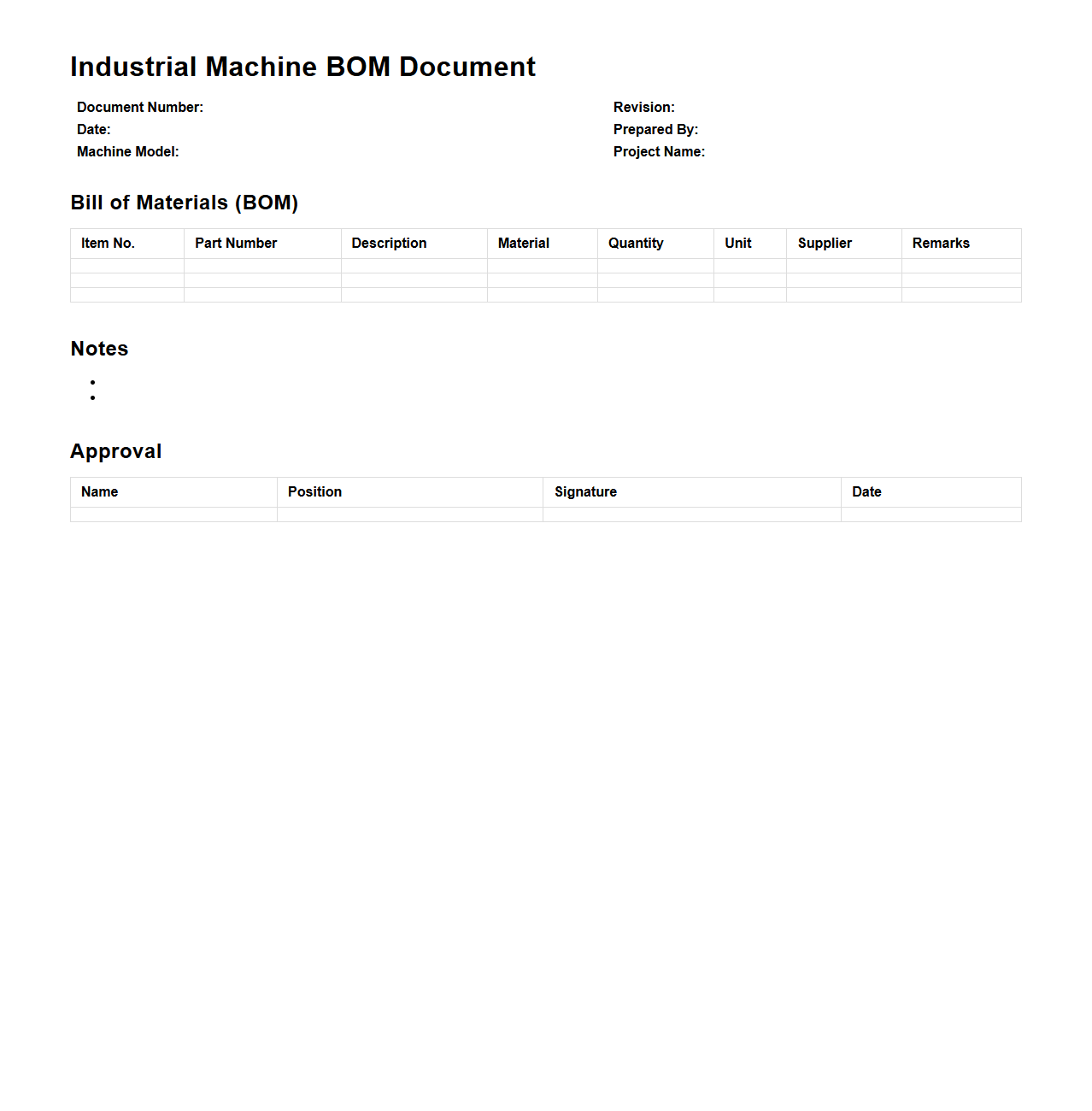

Industrial Machine BOM Document

The

Industrial Machine BOM Document is a comprehensive list detailing all components, parts, and assemblies required to manufacture or assemble an industrial machine. It includes part numbers, quantities, descriptions, and suppliers, serving as a critical reference for procurement, manufacturing, and maintenance teams. Accurate BOM documentation ensures efficient production planning, cost estimation, and inventory management within industrial operations.

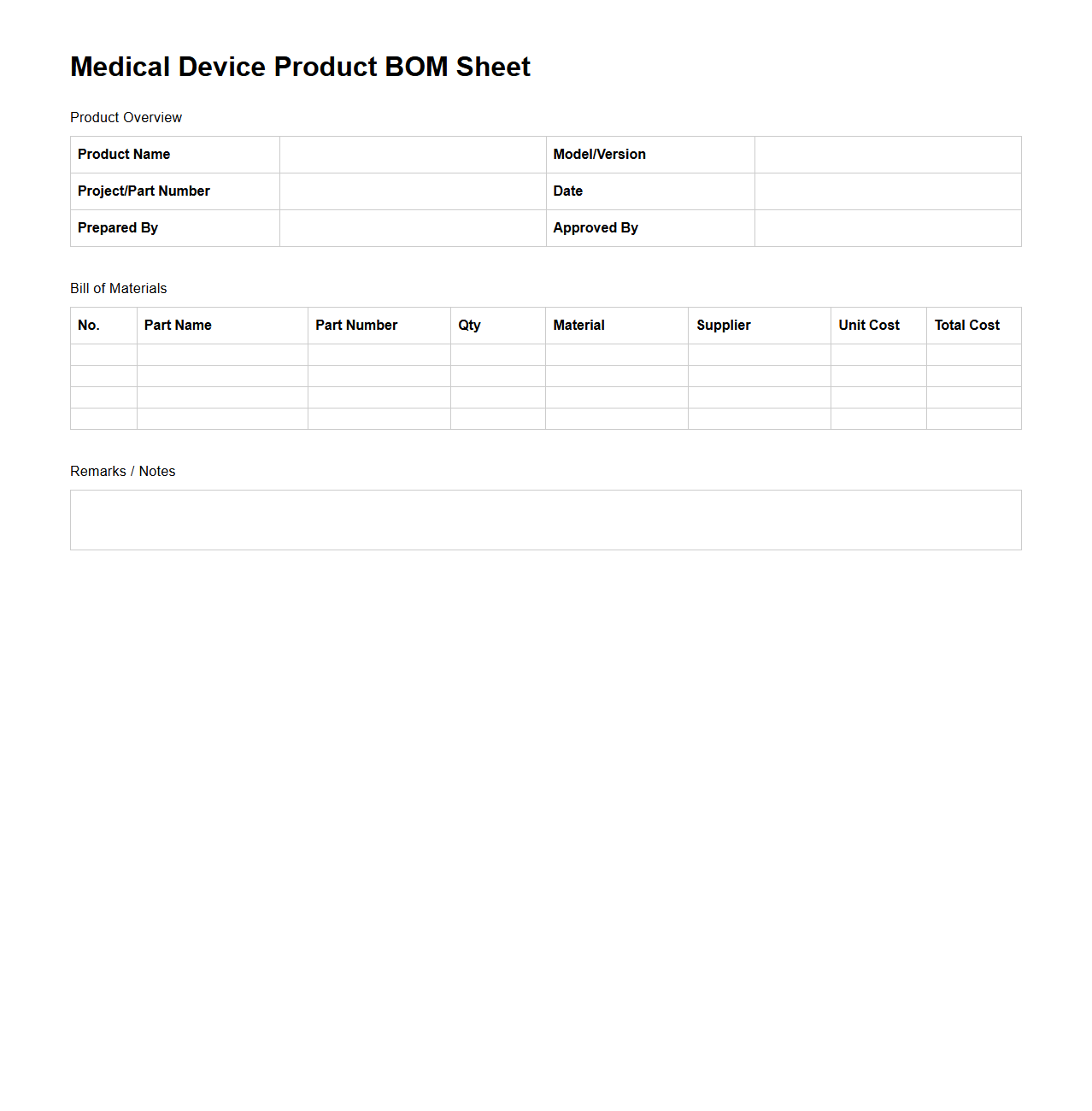

Medical Device Product BOM Sheet

A

Medical Device Product BOM Sheet is a detailed document that lists all components, materials, and subassemblies required to manufacture a medical device. It includes specific part numbers, quantities, suppliers, and specifications to ensure compliance with regulatory standards and quality control. This sheet facilitates accurate production planning, traceability, and cost management throughout the product lifecycle.

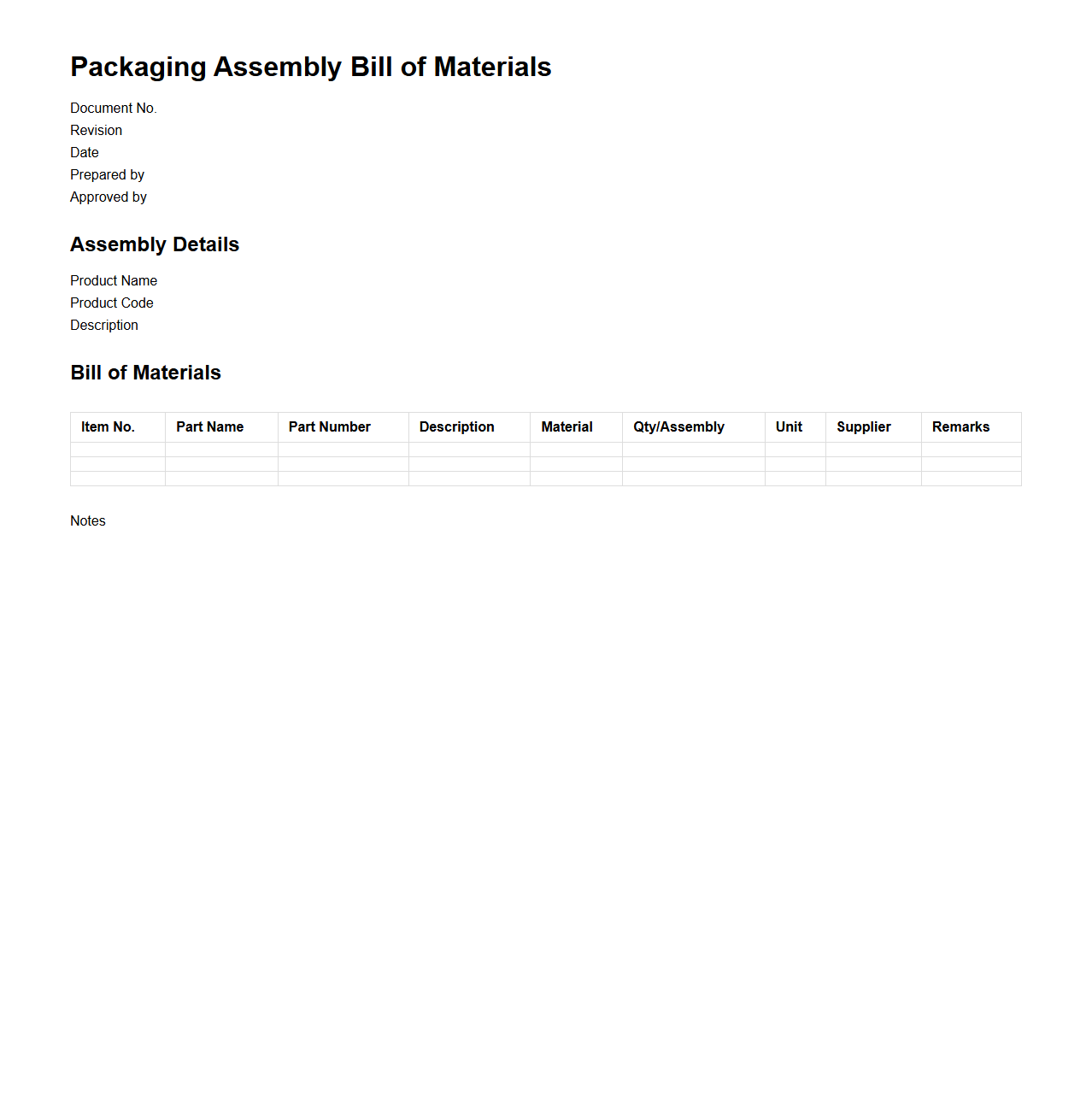

Packaging Assembly Bill of Materials

A

Packaging Assembly Bill of Materials (BOM) document is a detailed list that specifies all components, materials, and sub-assemblies required to manufacture and assemble a packaging product. It includes precise quantities, part numbers, descriptions, and supplier information to ensure accurate production and inventory management. This document serves as a critical reference for procurement, production planning, and quality control within packaging manufacturing processes.

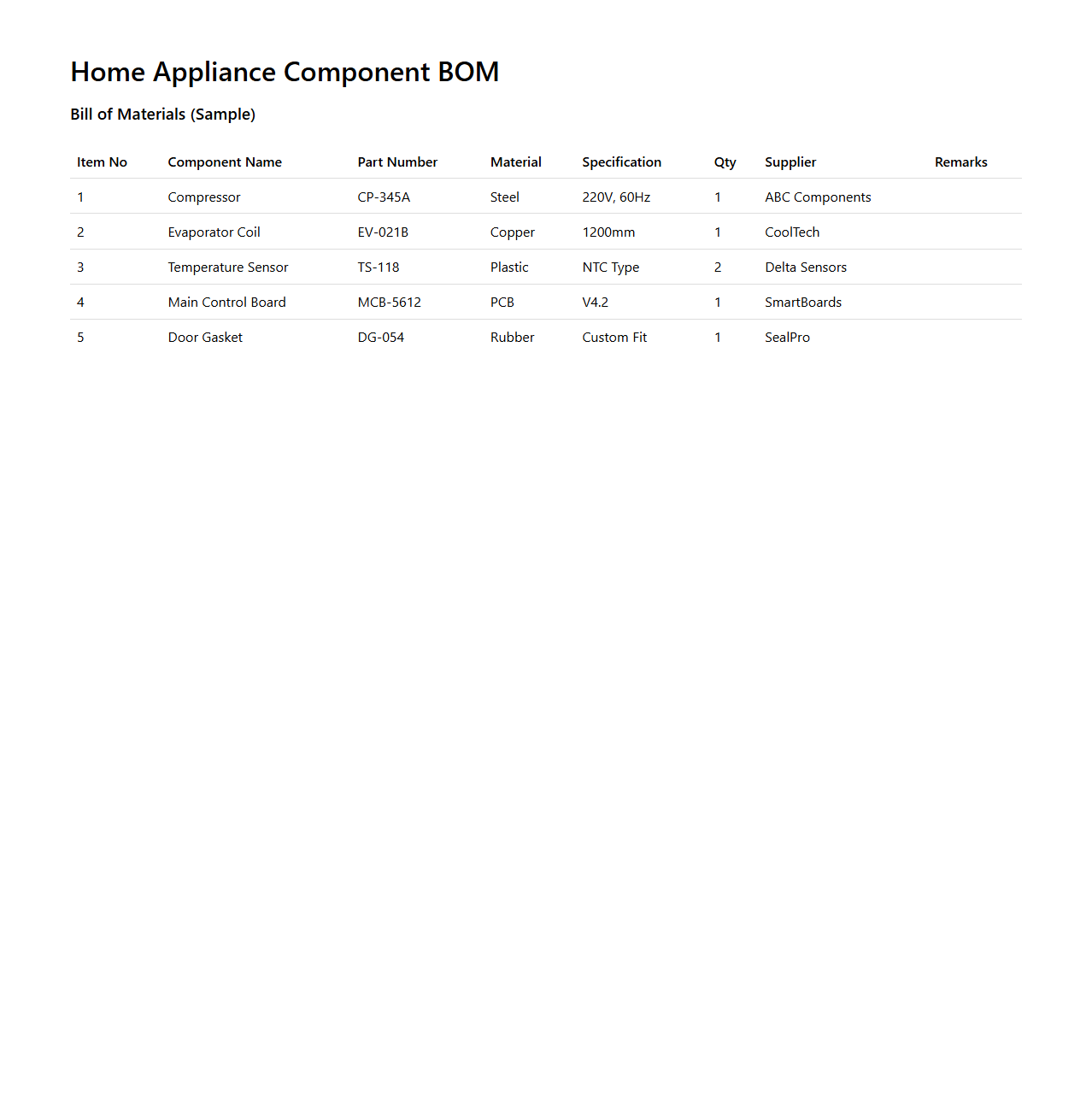

Home Appliance Component BOM

A

Home Appliance Component BOM document details the comprehensive list of parts and materials required for manufacturing a specific home appliance. It includes component specifications, quantities, part numbers, and supplier information to ensure accurate procurement and assembly. This document is essential for streamlining production, managing inventory, and maintaining quality control throughout the manufacturing process.

What specific components and quantities are detailed in the Bill of Materials (BOM) for the product assembly?

The Bill of Materials (BOM) includes a comprehensive list of all components required for product assembly, specifying each item's type and description. Quantities for each part are precisely detailed to ensure accurate procurement and inventory management. This helps streamline the assembly process by providing a clear and organized component breakdown.

How are part numbers and descriptions organized within the BOM document sample?

Part numbers in the BOM are typically arranged in a sequential or categorized order, facilitating easy identification and reference. Each part number is paired with a detailed description that explains the component's function or specifications. This structure enhances clarity and aids in efficient communication across teams.

What information does the BOM provide regarding supplier or manufacturer sources for each part?

The BOM includes critical data about the supplier or manufacturer for every component, ensuring traceability and quality control. This information often contains supplier names, contact details, and sometimes part-specific sourcing notes. Such details enable procurement teams to source parts reliably and maintain consistent product standards.

How does the BOM document indicate the hierarchy or assembly sequence of the product?

The BOM uses a hierarchical structure to illustrate the relationship between subassemblies and individual components, reflecting the overall product assembly. Indentation or numbering systems highlight the sequence and dependencies among parts. This organized representation ensures smooth assembly workflows and accurate build processes.

What revision control or version information is included in the BOM for effective product management?

The BOM document typically contains revision control details such as version numbers, revision dates, and summary of changes. This enables teams to track updates and maintain alignment with the latest product specifications. Proper version management within the BOM supports quality assurance and regulatory compliance throughout the product lifecycle.