The First Article Inspection Document Sample for New Product ensures that the initial production meets specified requirements through detailed measurements and quality checks. This document includes comprehensive data, such as dimensions, materials, and performance criteria, to verify product conformity before full-scale manufacturing. Proper use of this sample helps identify and resolve potential defects early, reducing costly errors and improving overall product quality.

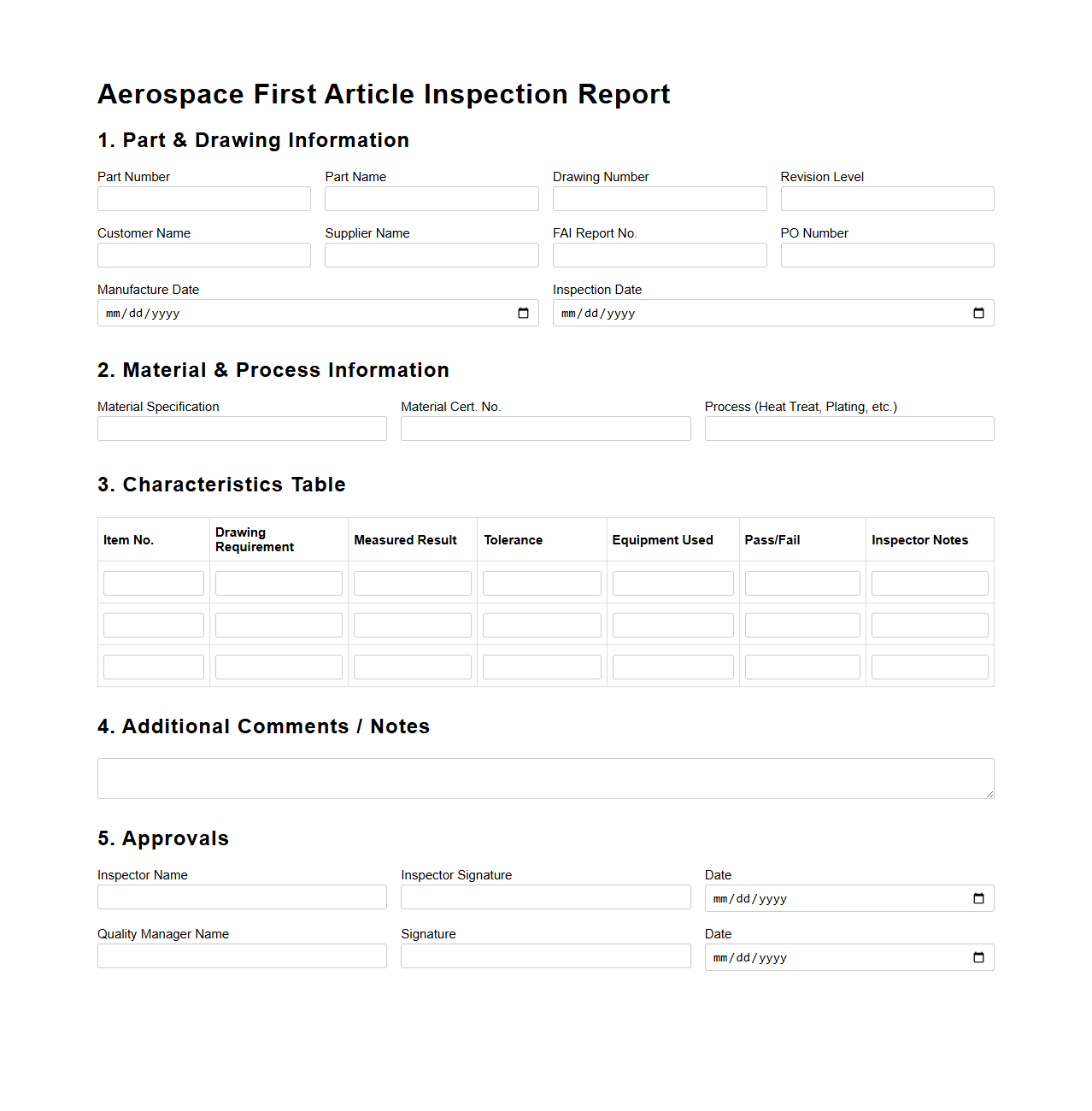

Aerospace First Article Inspection Report Template for New Product

The

Aerospace First Article Inspection Report Template for a new product document serves as a standardized format to verify and document that the initial production item meets all engineering specifications and quality requirements. This report ensures compliance with aerospace industry standards such as AS9102 and covers dimensions, materials, and functional testing results. Its thorough documentation supports traceability, quality assurance, and regulatory approval essential for certified aerospace manufacturing.

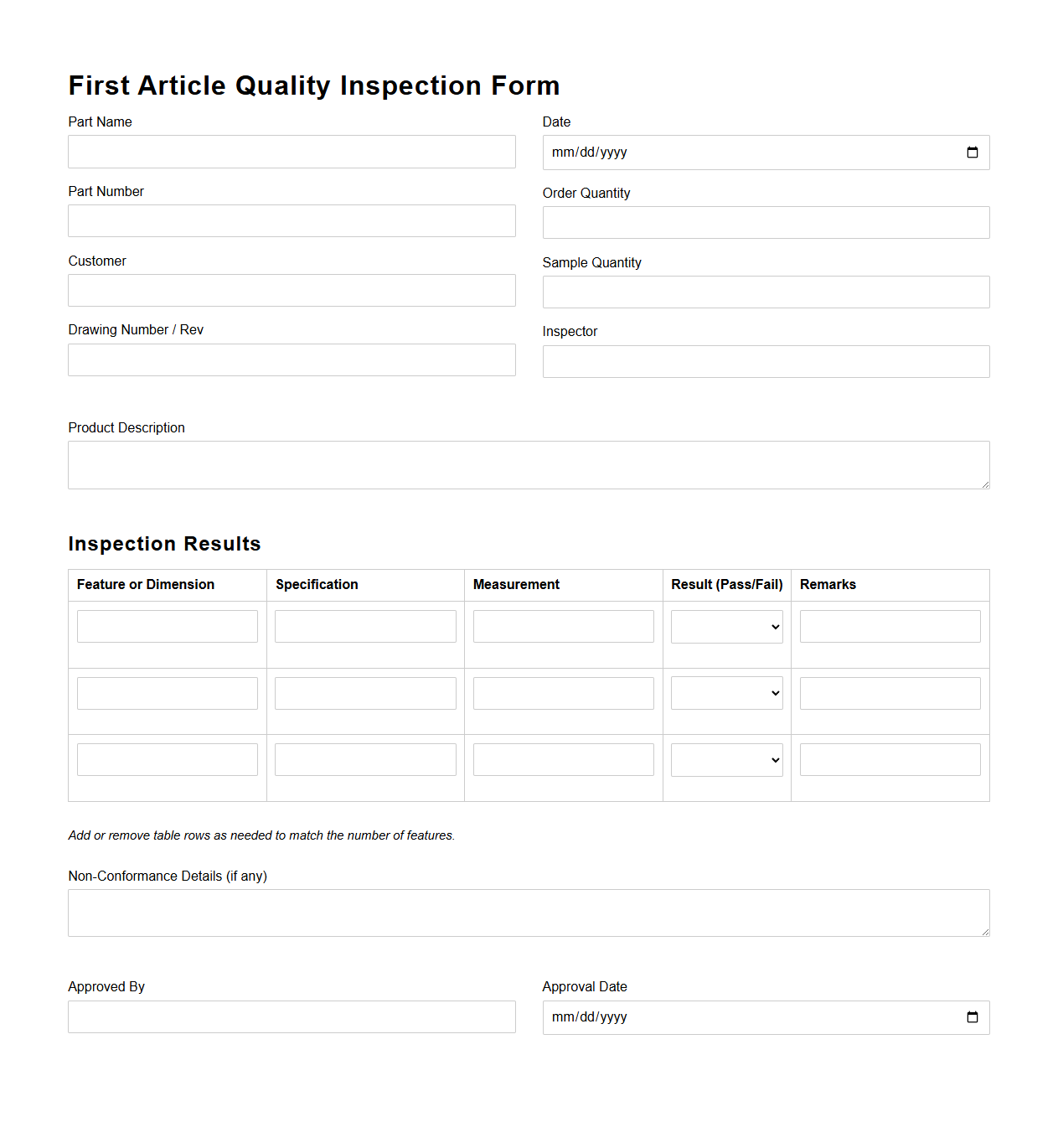

Manufacturing First Article Quality Inspection Form Example

A

Manufacturing First Article Quality Inspection Form is a critical document used to verify that a newly produced part or product meets specified design and quality requirements before mass production. This form records detailed measurements, material properties, and visual inspections to ensure compliance with engineering standards and customer specifications. It serves as an essential reference for quality control teams to identify and resolve potential issues early in the manufacturing process, thereby reducing defects and improving product reliability.

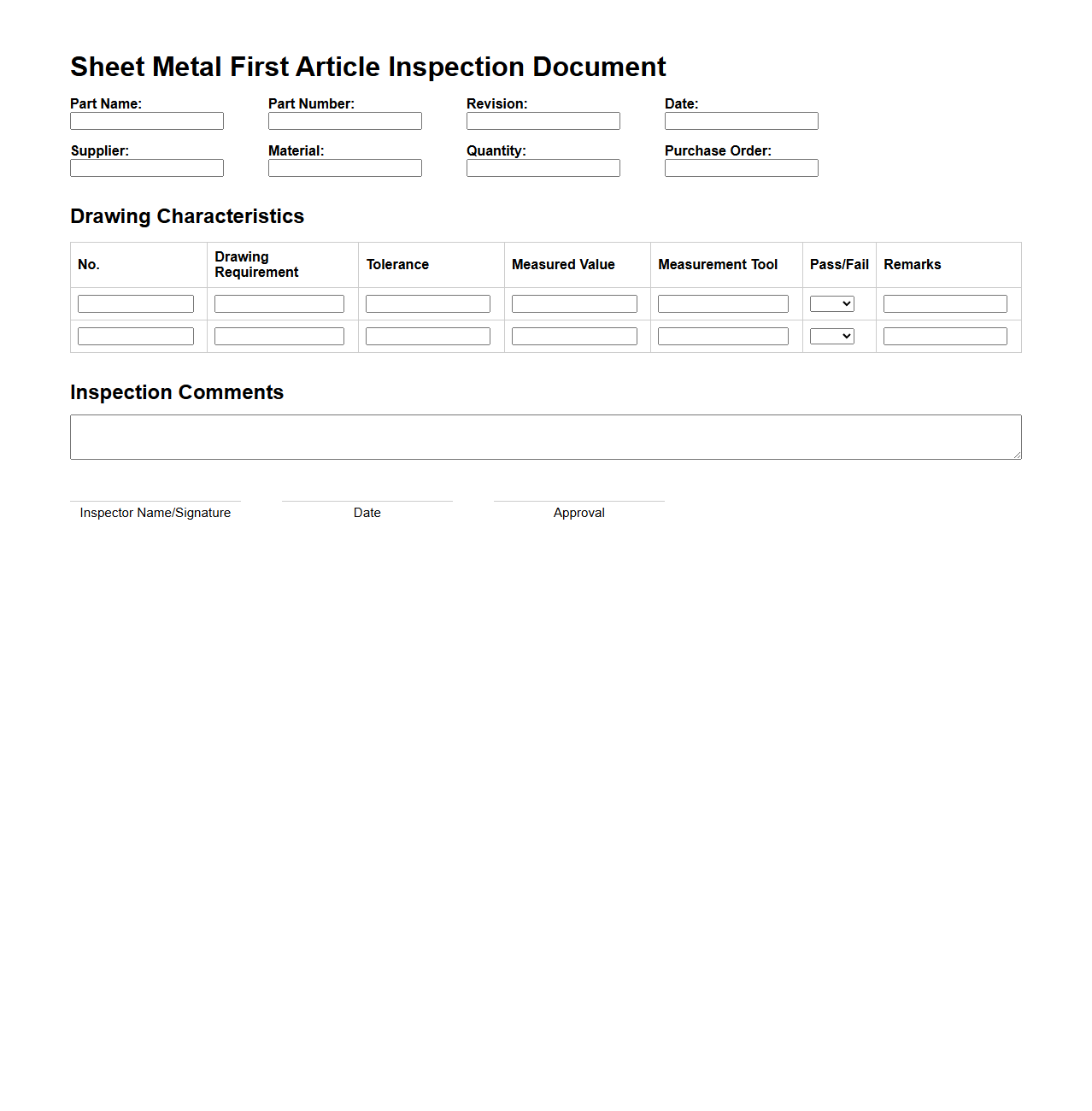

Sheet Metal First Article Inspection Document for New Parts

The

Sheet Metal First Article Inspection Document for new parts serves as a comprehensive report that verifies the dimensional accuracy and quality compliance of manufactured sheet metal components against specified engineering drawings and standards. This document includes detailed measurements, material certifications, and inspection results to ensure the first produced part meets all design requirements before full-scale production begins. It is essential for quality control and process validation in industries such as automotive, aerospace, and manufacturing.

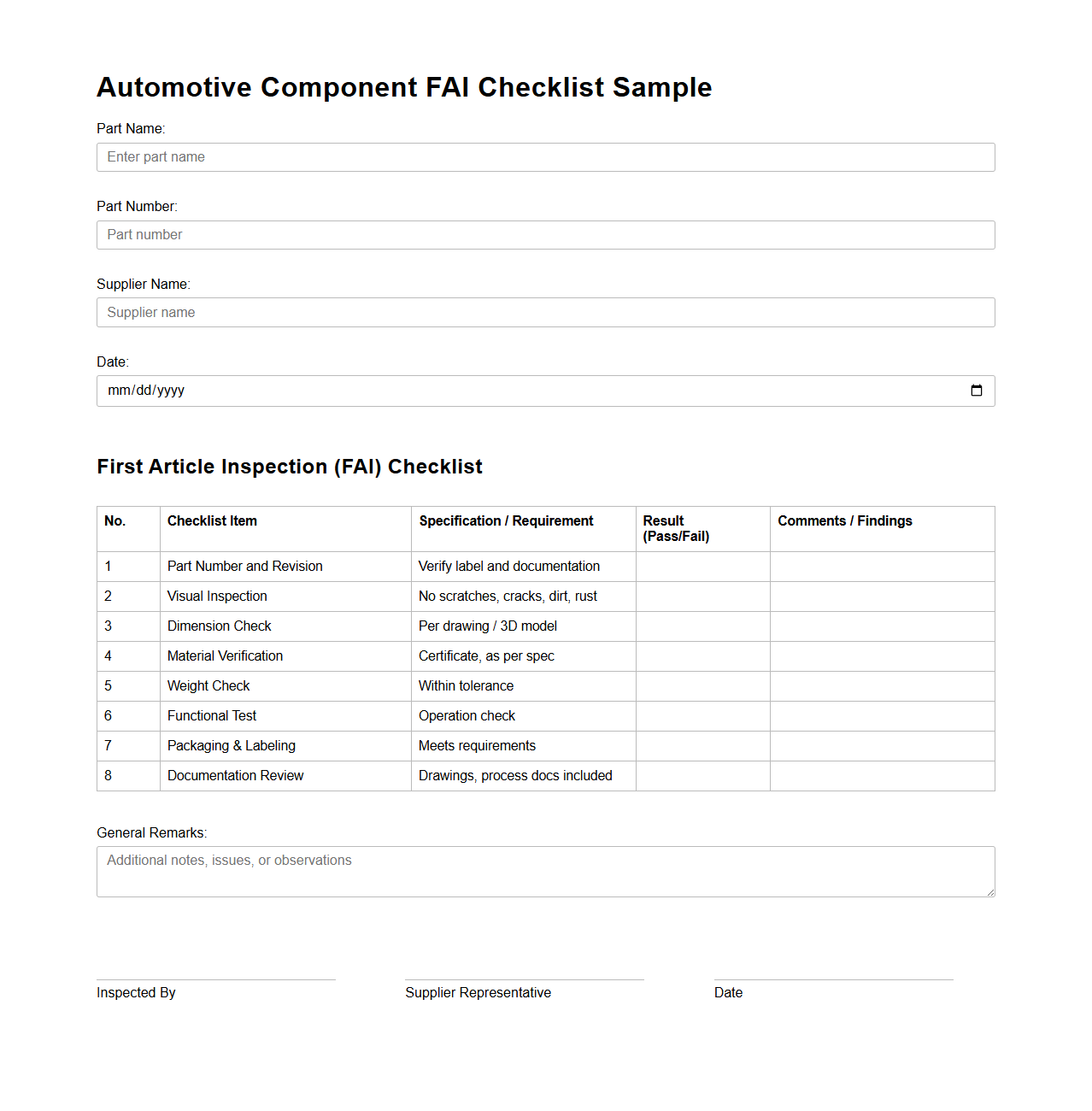

Automotive Component FAI Checklist Sample

The

Automotive Component FAI (First Article Inspection) Checklist Sample document is a structured tool used to verify the quality and compliance of automotive parts during the initial production run. It outlines specific criteria and measurements that components must meet to ensure they conform to design specifications, industry standards, and customer requirements. This checklist helps manufacturers identify defects early, reduce errors, and maintain consistency in automotive component production.

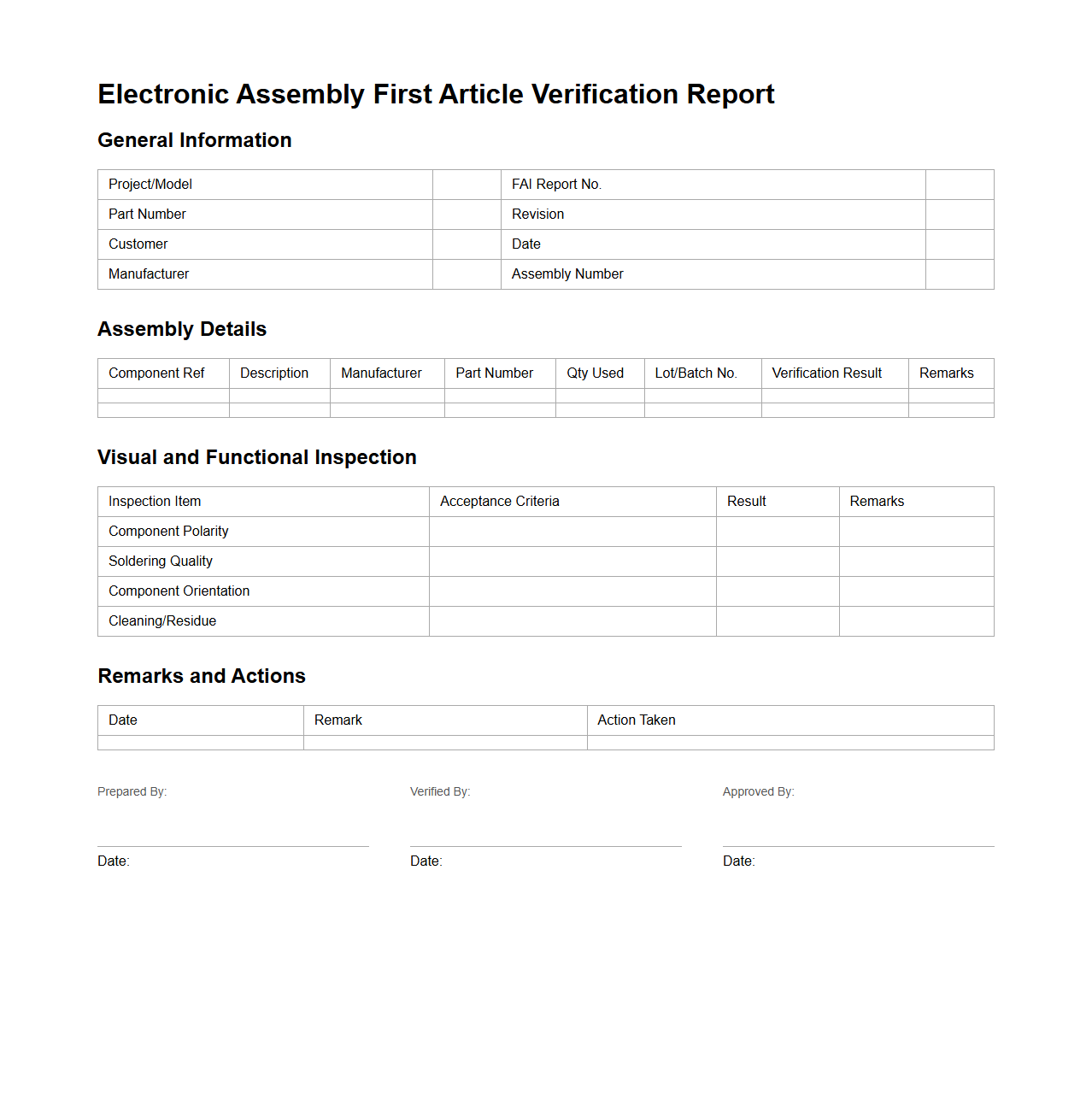

Electronic Assembly First Article Verification Report Format

The

Electronic Assembly First Article Verification Report Format document is a standardized template used to capture comprehensive inspection results of a newly assembled electronic product or prototype. It ensures that each component and assembly process meets specified design requirements and quality standards by systematically recording measurements, materials, and test outcomes. This documentation is crucial for validating production readiness and maintaining traceability throughout the manufacturing lifecycle.

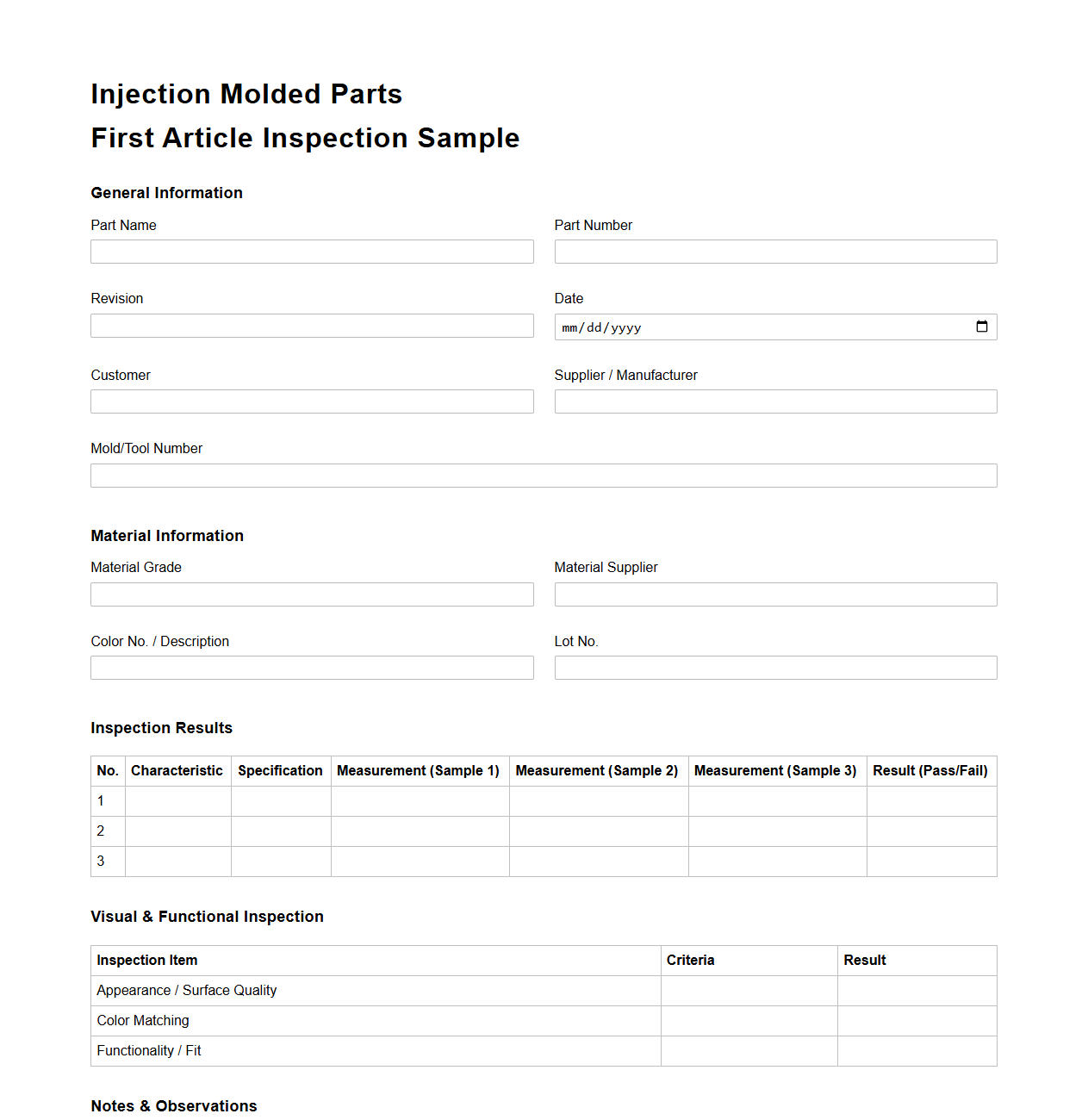

Injection Molded Parts First Article Inspection Sample Document

The

Injection Molded Parts First Article Inspection Sample Document provides a detailed record of the initial production run's dimensional and visual verification against design specifications. This document ensures that the injection molded components meet quality standards, confirming critical measurements, material consistency, and functional performance. Manufacturers and quality control teams use this sample document to identify potential defects early and validate production processes before full-scale manufacturing.

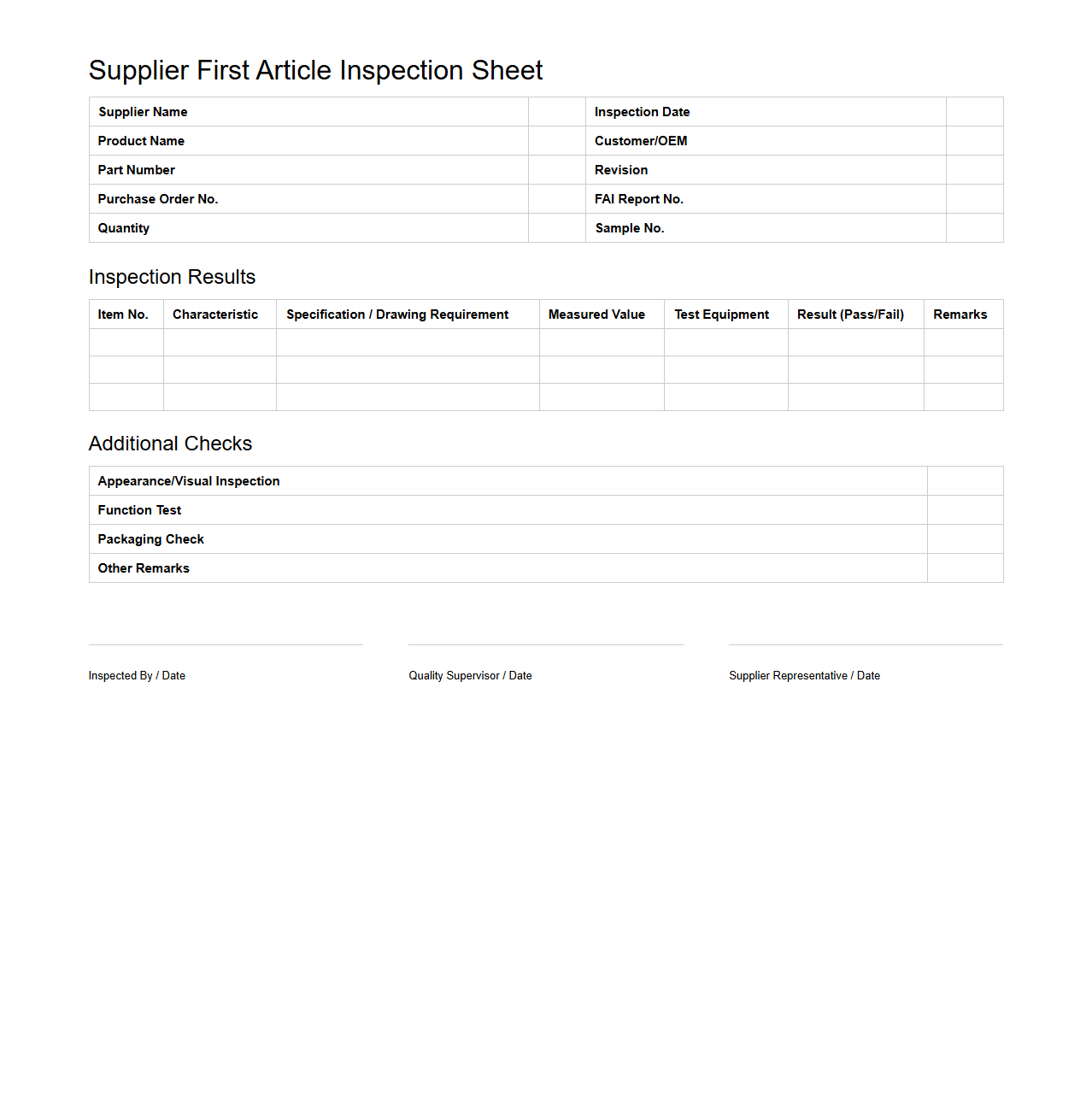

Supplier First Article Inspection Sheet for OEM Products

The

Supplier First Article Inspection Sheet for OEM products is a critical quality control document used to verify that a supplier's initial production batch meets the specified engineering and design requirements. It includes detailed measurements, material certifications, and compliance checks aligned with OEM standards, ensuring product accuracy before full-scale manufacturing. This sheet facilitates early detection of deviations, reduces the risk of defective components, and supports continuous quality improvement in the supply chain.

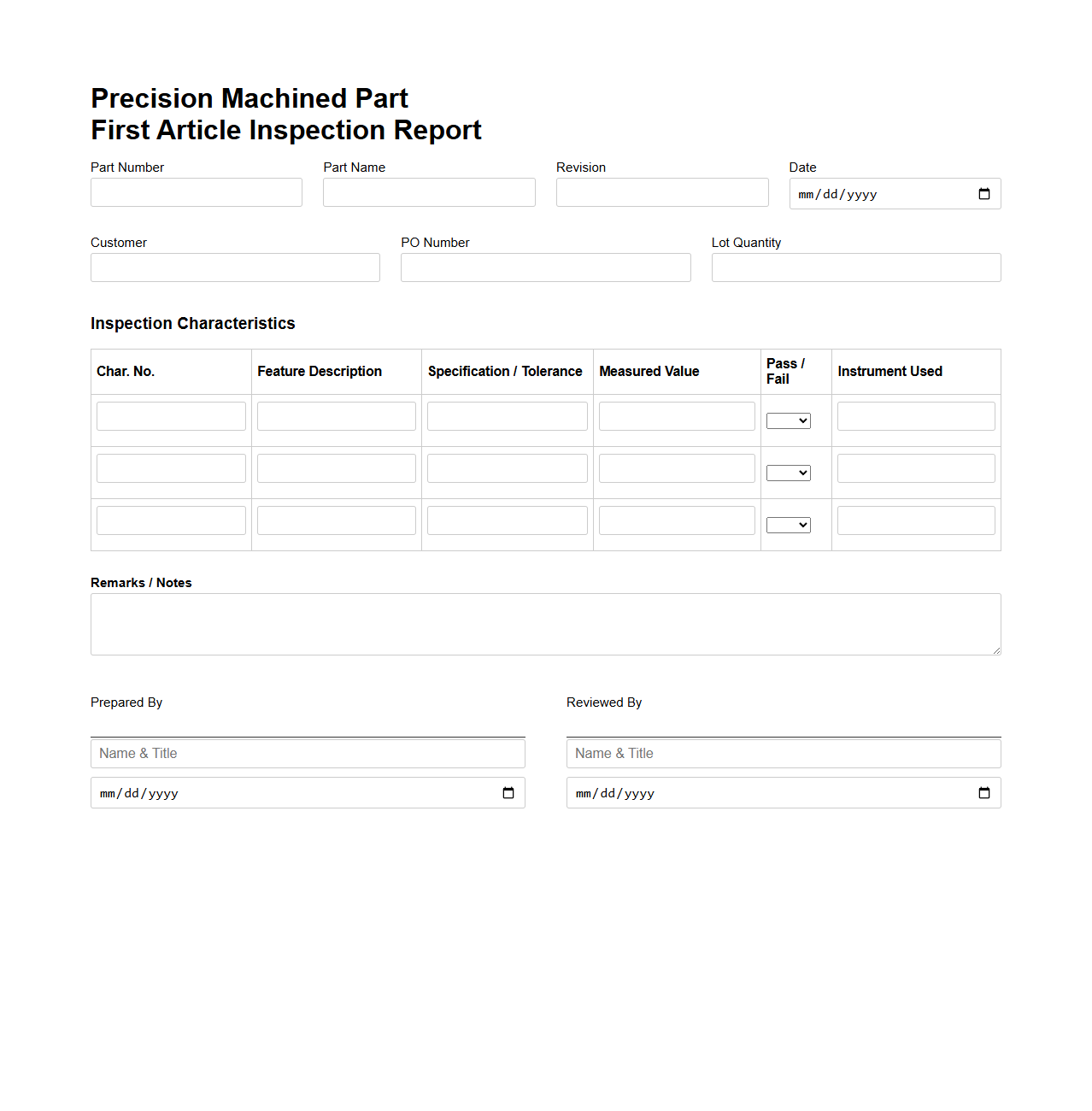

Precision Machined Part First Article Inspection Example

A

Precision Machined Part First Article Inspection Example document serves as a detailed record that verifies the accuracy and compliance of a machined component against specified design and engineering requirements. It typically includes measurements, material certifications, and inspection results to ensure the part meets quality standards before full-scale production. This document is crucial for identifying any deviations early in the manufacturing process, reducing errors, and maintaining consistent product quality.

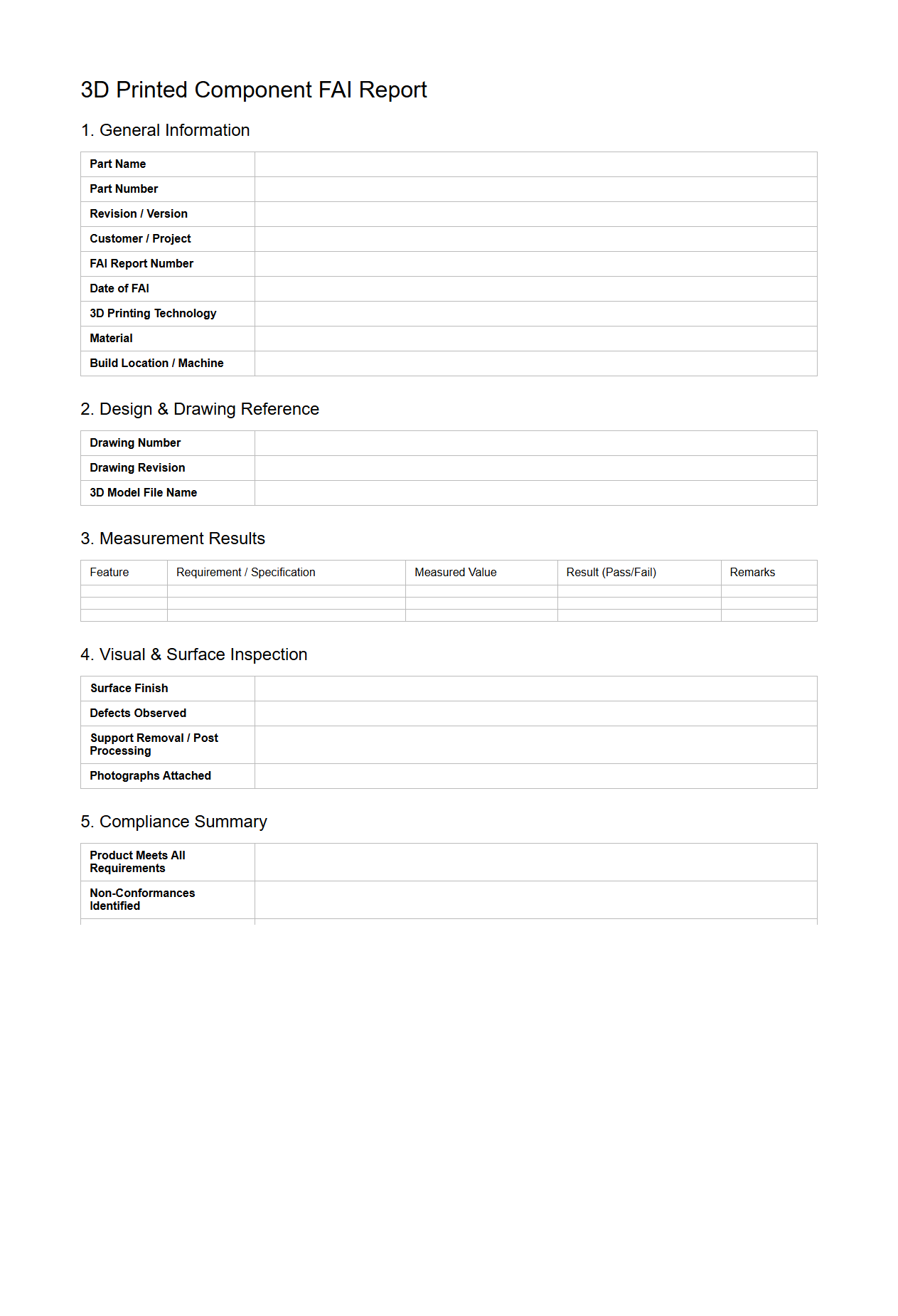

3D Printed Component FAI Report Template

A

3D Printed Component FAI Report Template document serves as a standardized format for conducting First Article Inspections (FAI) on 3D printed parts, ensuring dimensional accuracy and conformance to design specifications. It systematically records critical inspection data such as material properties, geometry verification, and process parameters to validate manufacturing quality. This template helps manufacturers and quality control teams maintain consistency and traceability throughout the production workflow.

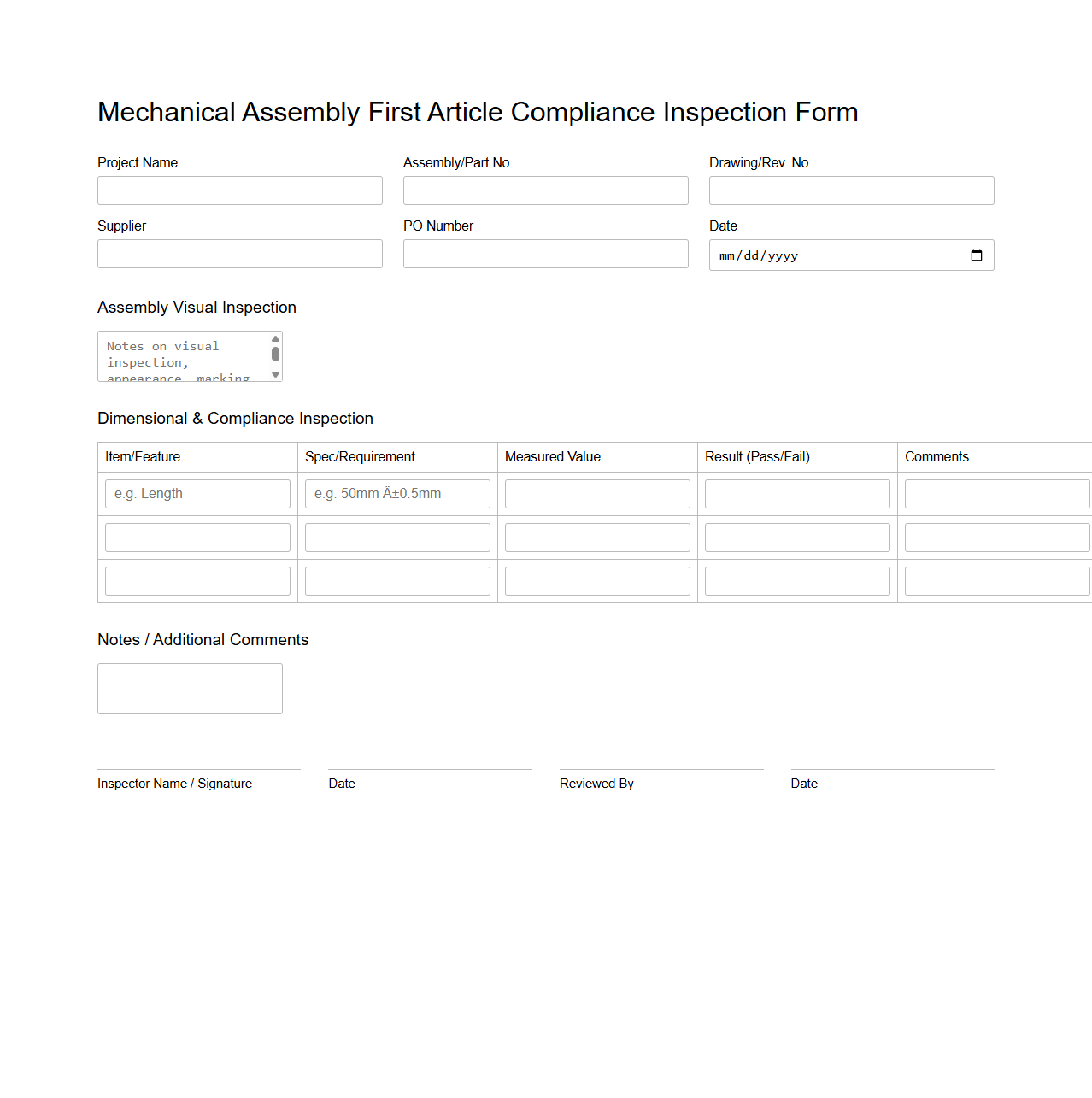

Mechanical Assembly First Article Compliance Inspection Form

The

Mechanical Assembly First Article Compliance Inspection Form document serves as a critical quality assurance tool used to verify that the initial production run of a mechanical assembly meets all specified design and manufacturing standards. This form systematically records inspection results, ensuring components and assemblies conform to engineering drawings, dimensional tolerances, and functional requirements before full-scale production continues. Maintaining this documentation aids in identifying discrepancies early, reducing potential defects, and ensuring compliance with industry regulations and customer specifications.

Essential Sections in a First Article Inspection Document

The First Article Inspection Document primarily includes product identification, dimensional inspection results, and material certification data. It also contains detailed information on the manufacturing and inspection methods used to ensure compliance. This structure guarantees a comprehensive review of the product's conformity to specifications.

Product Characteristics and Dimensions Verification

The document verifies critical dimensions, functional features, and tolerances essential to the product's performance. Each characteristic is measured against design drawings and specifications to confirm accuracy. This ensures that the finished product meets all specified requirements before mass production.

Material Certifications and Supplier Information Tracking

Material certifications are recorded with unique batch numbers and supplier details to maintain traceability. The document includes supplier contact information and signed attestations to validate material authenticity. This traceability is crucial for quality assurance and audit purposes.

Criteria for Product Conformity in Inspection Reports

Product conformity is determined by adherence to design tolerances and functional requirements as outlined in the inspection checklist. Only features meeting specified criteria are accepted, while deviations trigger further review. This strict evaluation ensures consistency and product reliability.

Documentation and Follow-Up of Non-Conformities

All non-conformities are thoroughly documented with descriptions, photos, and immediate corrective actions. The First Article Inspection process includes a formal follow-up to verify corrective measures and prevent recurrence. This systematic approach ensures continuous improvement and compliance.

More Manufacturing Templates