A Quality Control Checklist Document Sample for Assembly Line ensures accuracy and consistency throughout the manufacturing process by outlining specific inspection criteria. This checklist helps identify defects or deviations early, reducing errors and maintaining product standards. It is a vital tool for enhancing efficiency and delivering high-quality finished goods.

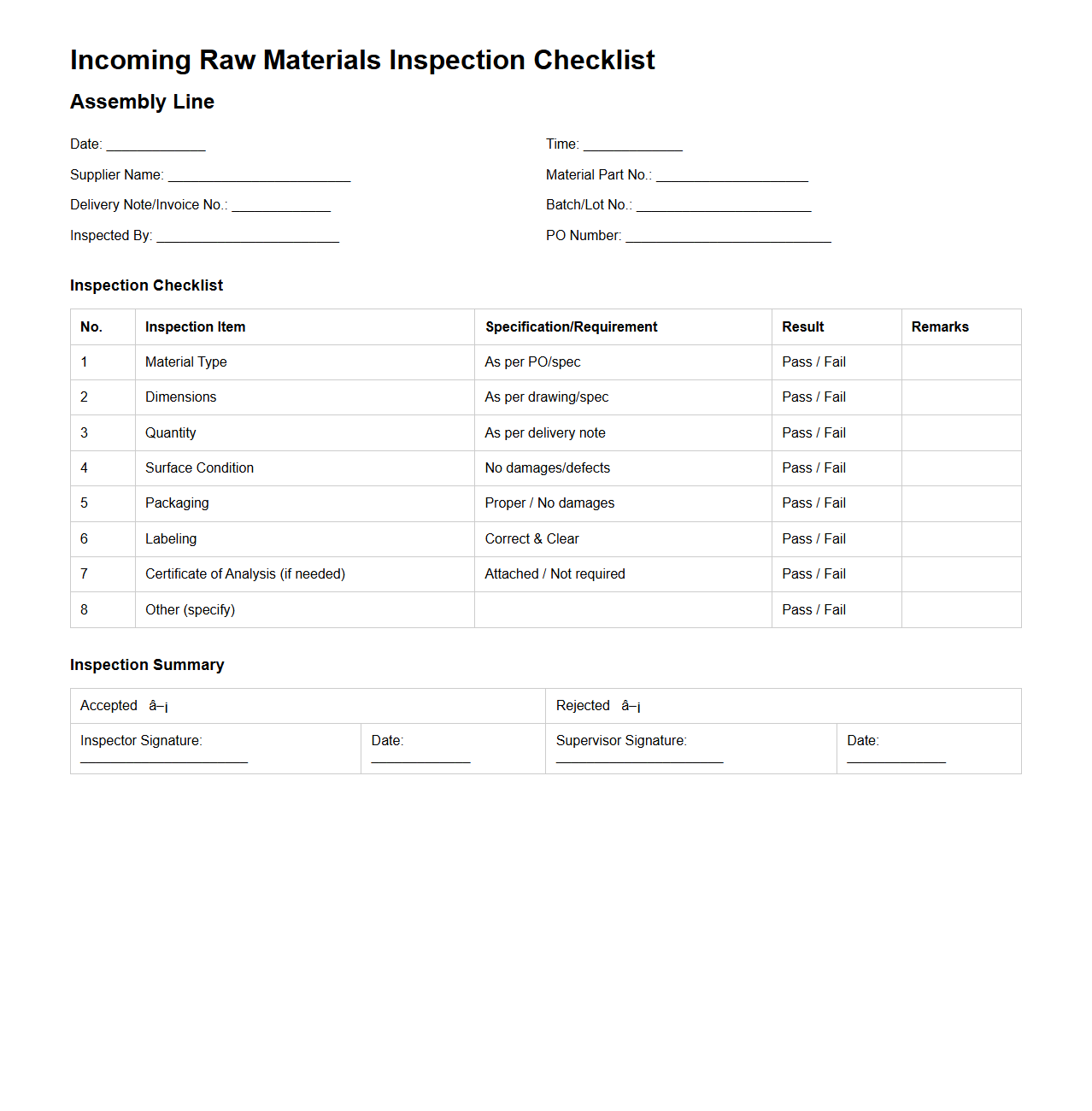

Incoming Raw Materials Inspection Checklist for Assembly Line

The

Incoming Raw Materials Inspection Checklist for an assembly line document serves as a critical tool to verify the quality, quantity, and specifications of raw materials before they proceed to the production process. It systematically records inspection criteria such as dimensions, material properties, and packaging integrity to prevent defects and ensure compliance with industry standards. This checklist enhances operational efficiency by minimizing production delays and reducing the risk of faulty products reaching the final assembly.

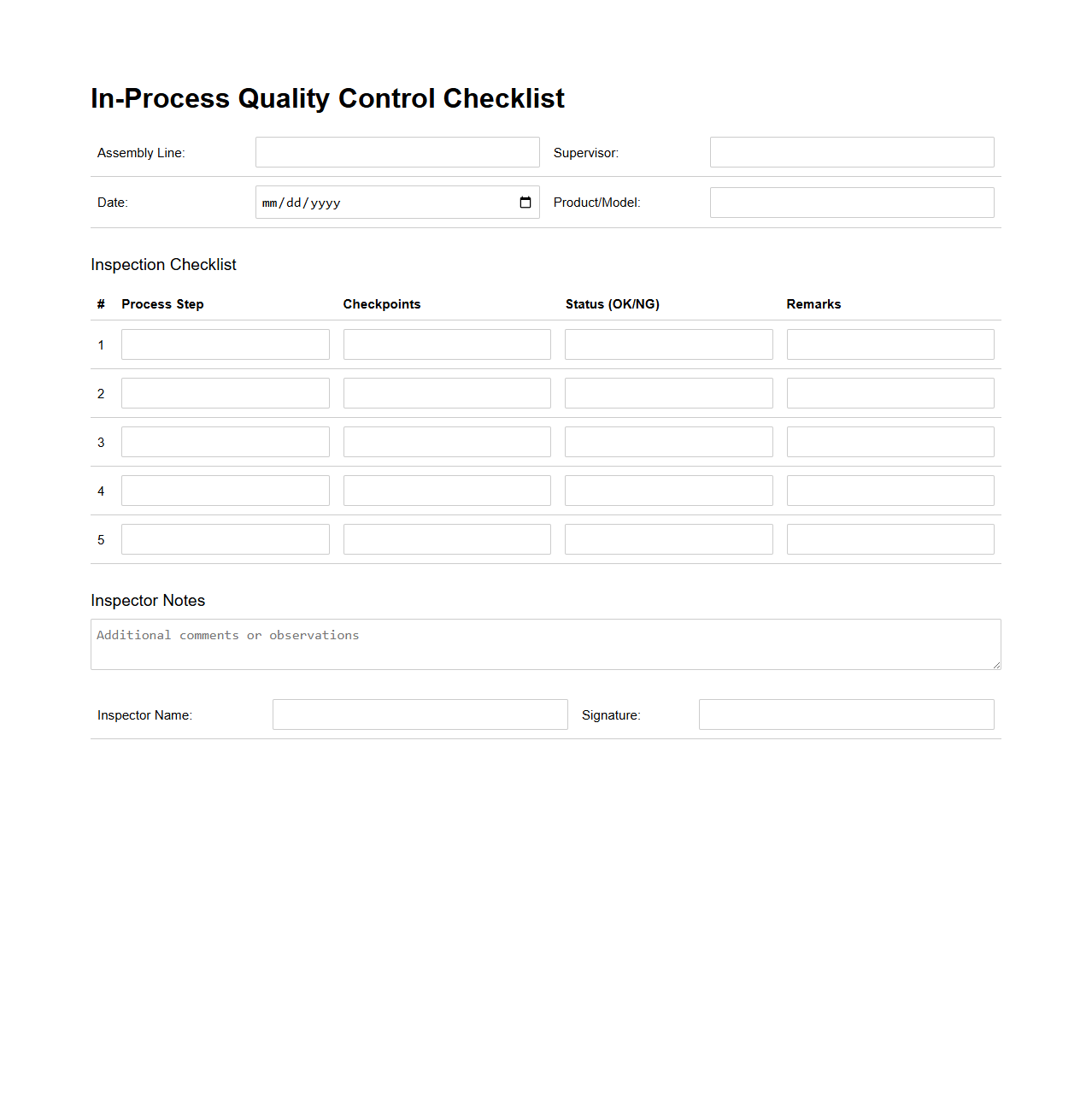

In-Process Quality Control Checklist for Assembly Line

The

In-Process Quality Control Checklist for Assembly Line document is a critical tool used to systematically verify that each stage of the assembly process meets predefined quality standards. It ensures consistent inspection of components, alignment, torque specifications, and functional tests, reducing defects and rework. This checklist helps maintain production efficiency while guaranteeing product reliability and compliance with industry regulations.

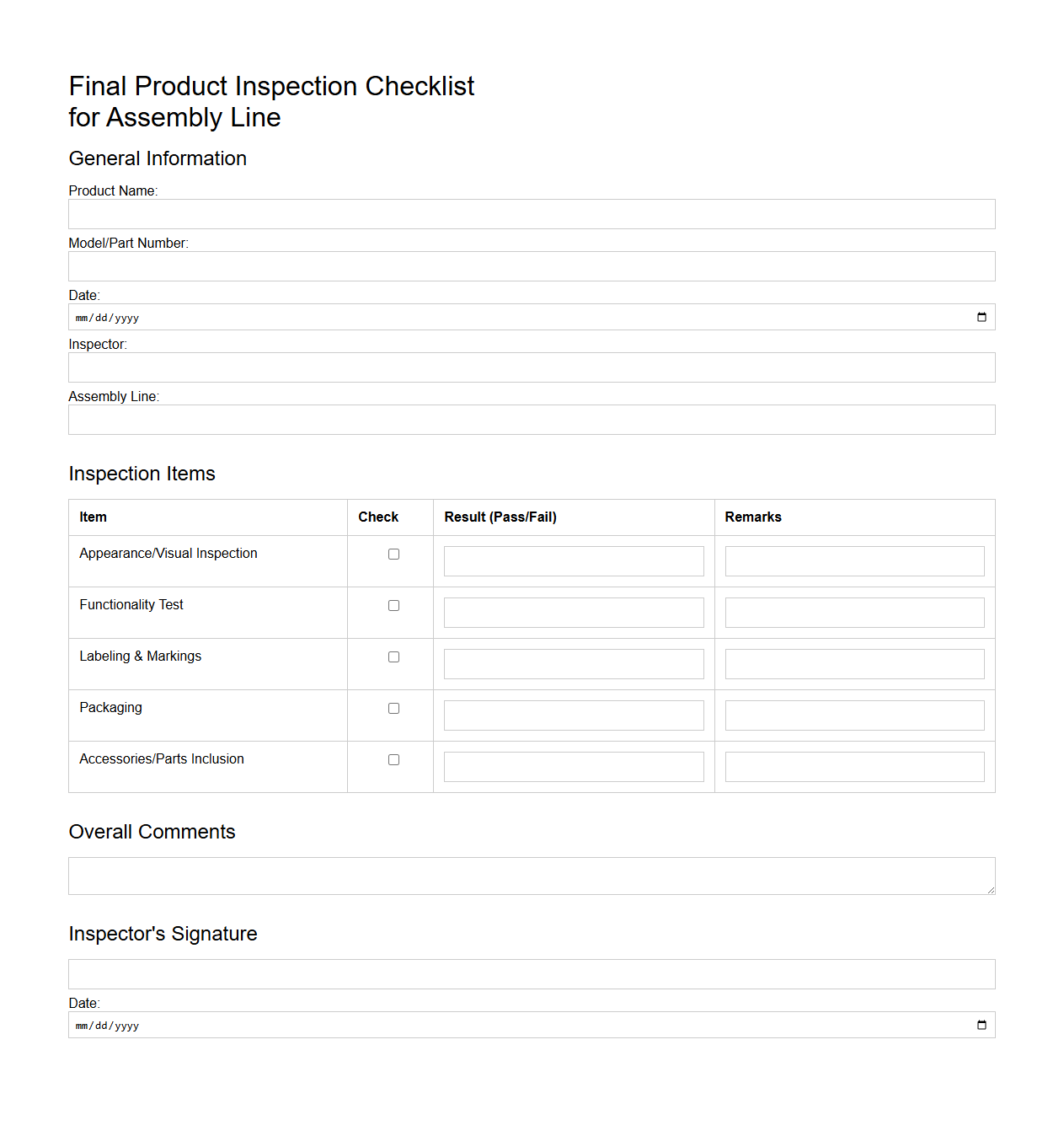

Final Product Inspection Checklist for Assembly Line

A

Final Product Inspection Checklist for Assembly Line document systematically verifies that each finished product meets predefined quality standards and specifications before shipment. It typically includes criteria such as dimensional accuracy, functionality, cosmetic appearance, and packaging integrity to ensure consistent product quality. This checklist helps reduce defects, enhance customer satisfaction, and maintain compliance with industry regulations.

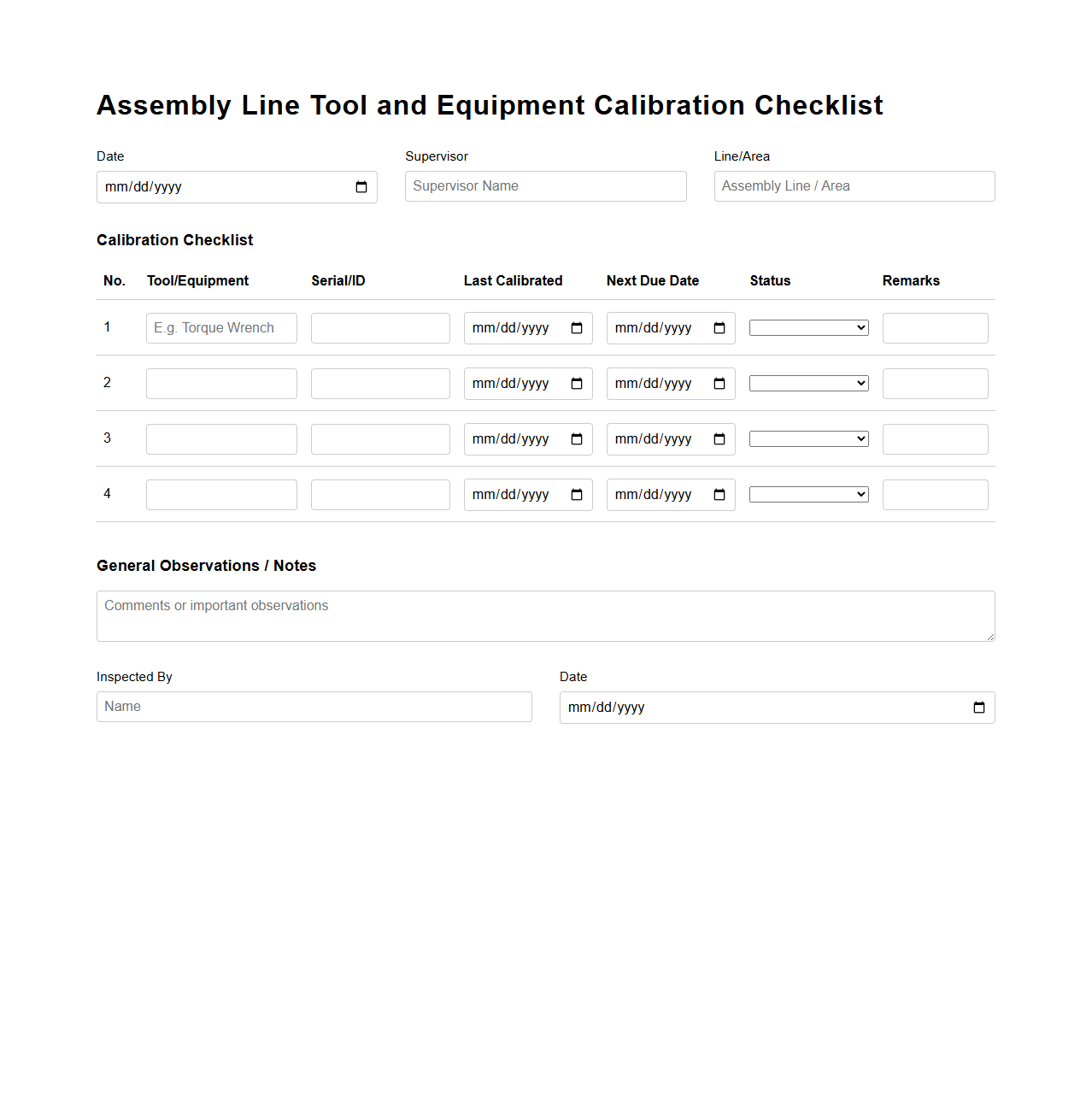

Assembly Line Tool and Equipment Calibration Checklist

The

Assembly Line Tool and Equipment Calibration Checklist document ensures that all tools and machinery used in the production process meet precise calibration standards, promoting accuracy and consistency. It details specific calibration intervals, verification methods, and acceptable tolerances for each piece of equipment, minimizing operational errors and downtime. Regular use of this checklist supports quality control, compliance with industry standards, and extends the lifespan of critical assembly line components.

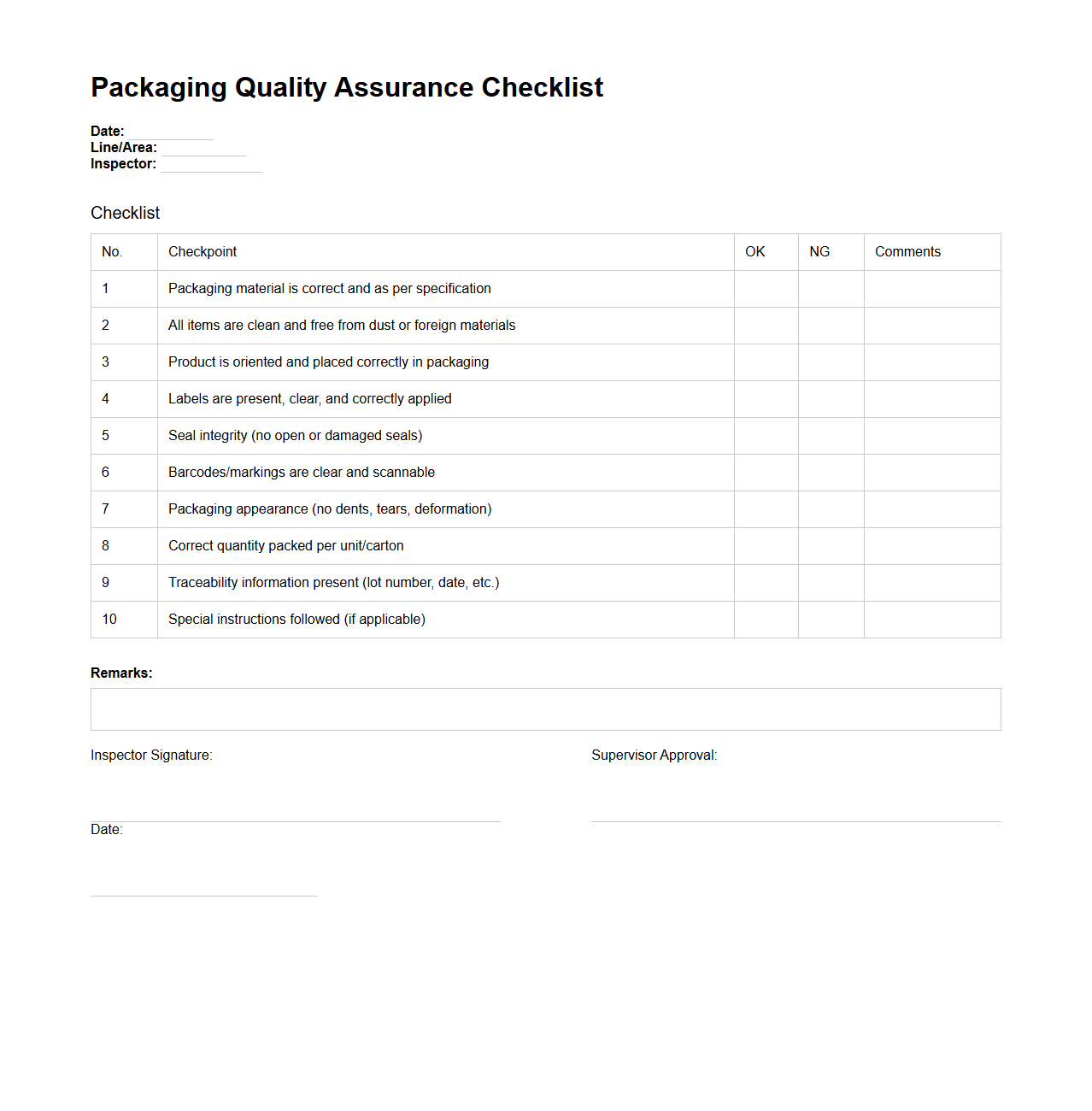

Packaging Quality Assurance Checklist for Assembly Line

The

Packaging Quality Assurance Checklist for an assembly line document serves as a critical tool to ensure all packaging processes meet defined standards and specifications. It systematically verifies packaging materials, seal integrity, labeling accuracy, and compliance with safety regulations to prevent defects and maintain product quality. This checklist facilitates consistent quality control, reduces errors, and enhances customer satisfaction by guaranteeing that finished products are packaged correctly before distribution.

Assembly Line Operator Performance Evaluation Checklist

The

Assembly Line Operator Performance Evaluation Checklist document is a structured tool designed to assess the efficiency, accuracy, and adherence to safety protocols of assembly line workers. It contains specific criteria related to task completion times, quality of work, equipment handling, and teamwork skills. This checklist helps supervisors objectively measure employee performance, identify areas for improvement, and enhance overall production line productivity.

Defect Tracking and Reporting Checklist for Assembly Line

The

Defect Tracking and Reporting Checklist for Assembly Line document is a vital tool used to systematically identify, record, and monitor defects during the manufacturing process. It ensures consistent documentation of defect types, occurrence times, and corrective actions, facilitating quality control and process improvement. This checklist enhances communication among assembly line teams and supports data-driven decision-making to reduce product flaws and increase operational efficiency.

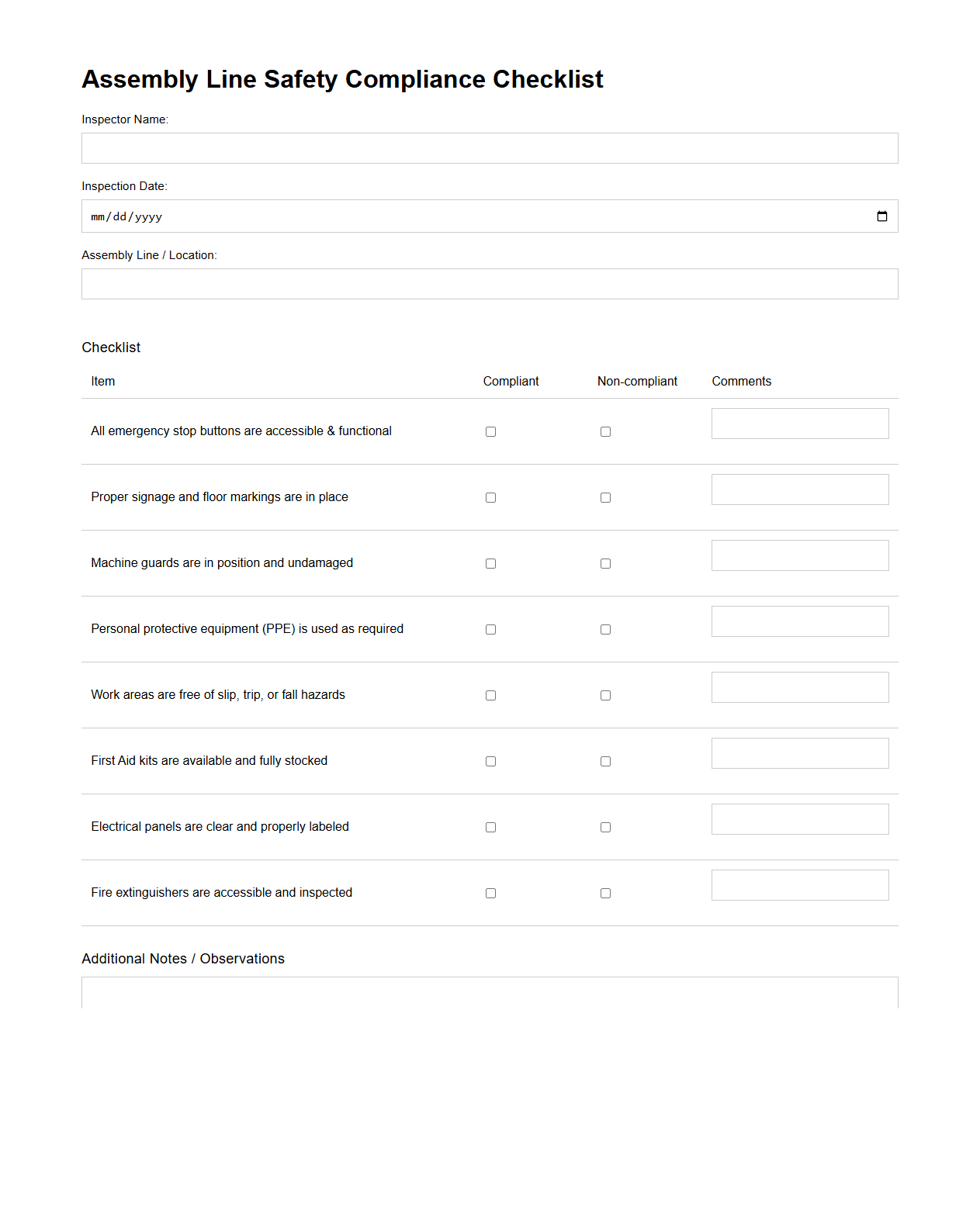

Assembly Line Safety Compliance Checklist

The

Assembly Line Safety Compliance Checklist document ensures all safety protocols and regulations are consistently followed on the production floor, reducing the risk of accidents and injuries. It outlines critical safety measures such as equipment inspections, worker protective gear, emergency procedures, and hazard identifications. This checklist serves as a vital tool for maintaining operational safety standards and fostering a secure working environment.

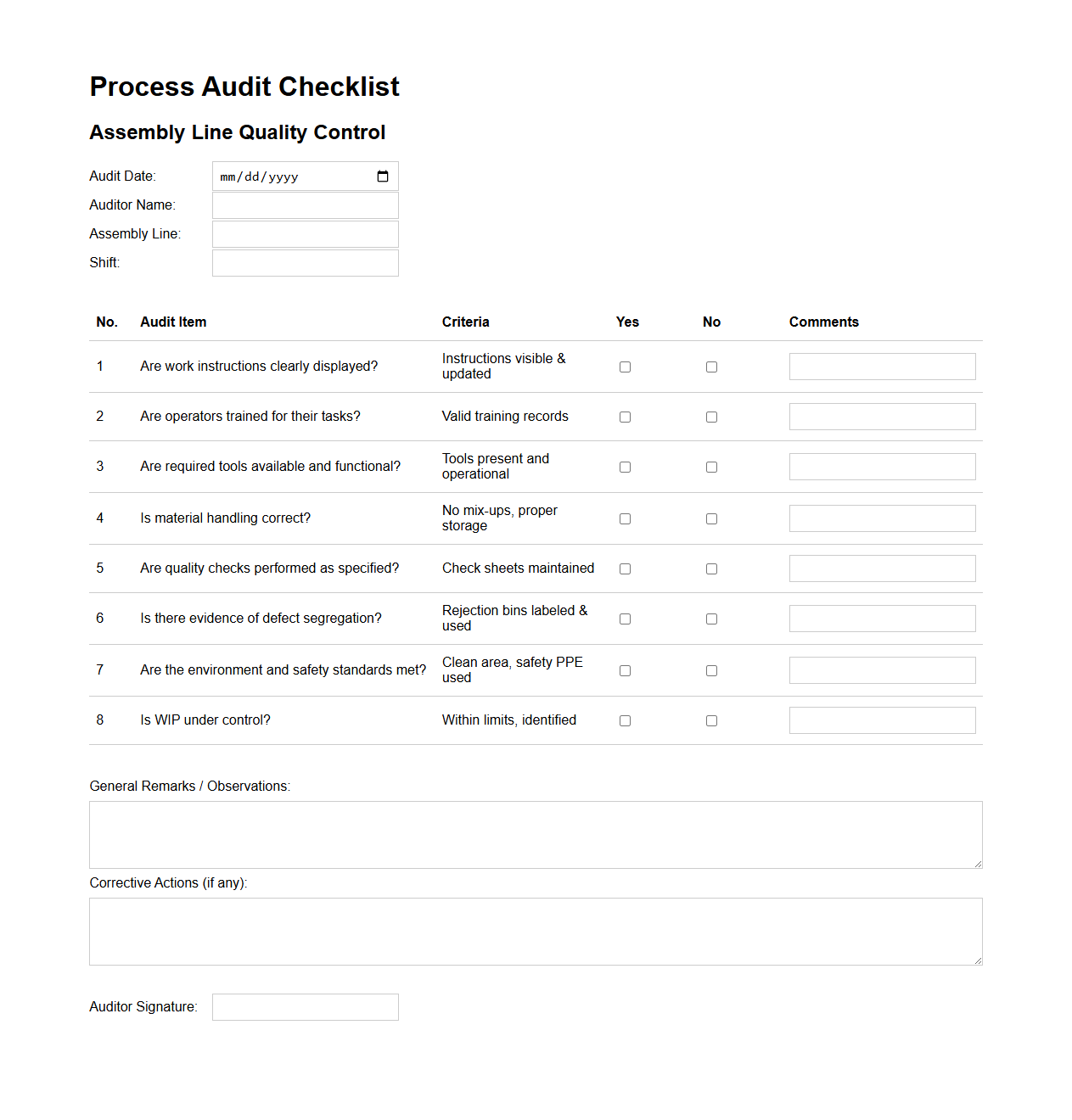

Process Audit Checklist for Assembly Line Quality Control

A

Process Audit Checklist for Assembly Line Quality Control document systematically verifies compliance with established production standards by evaluating assembly procedures, equipment functionality, and operator performance. It ensures consistent product quality by identifying deviations from specifications and facilitating corrective actions. This checklist is essential for maintaining efficiency, reducing defects, and supporting continuous improvement in manufacturing operations.

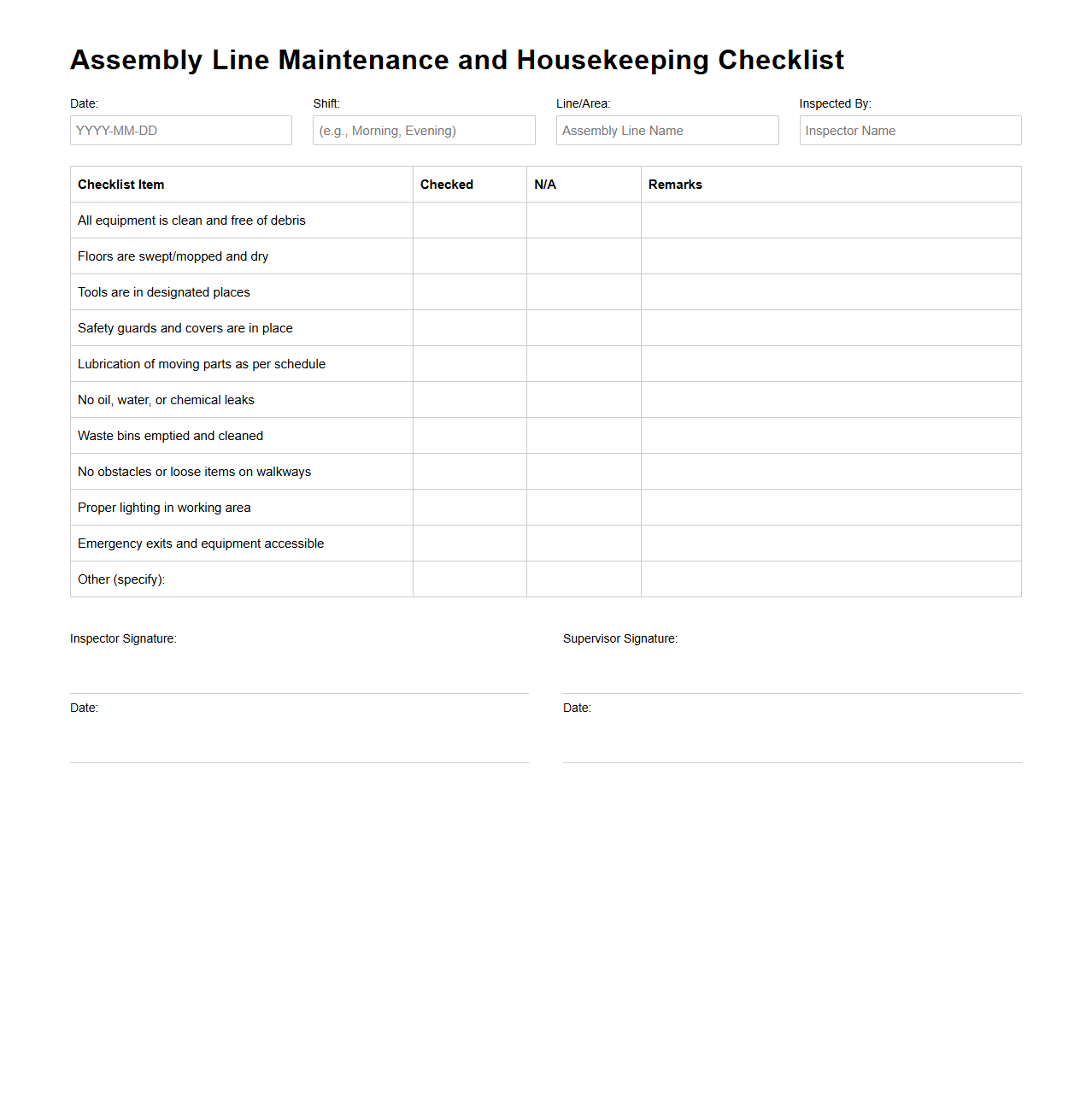

Assembly Line Maintenance and Housekeeping Checklist

The

Assembly Line Maintenance and Housekeeping Checklist document outlines systematic procedures for routine inspection, cleaning, and upkeep of assembly line equipment to ensure optimal performance and safety. It includes detailed tasks such as lubrication schedules, component wear assessments, and workspace organization to prevent downtime and maintain operational efficiency. Regular use of this checklist promotes a safe working environment, reduces equipment failures, and supports compliance with industry standards.

Critical Quality Checkpoints in the Quality Control Checklist Document

The critical quality checkpoints specified in the Quality Control Checklist Document focus on key assembly stages such as component fit, electrical connections, and functional testing. Each checkpoint ensures that specific quality standards are met before the product proceeds to the next stage. These checkpoints help identify defects early, minimizing rework and ensuring a consistent assembly process.

Definition of Acceptable Versus Unacceptable Product Conditions

The document clearly defines acceptable product conditions as those meeting predefined criteria such as dimensional accuracy, proper functionality, and surface finish. Conversely, unacceptable conditions include defects like misalignment, electrical failures, or physical damage that compromise product performance. Inspectors use these definitions to immediately classify products and determine necessary corrective actions.

Required Documentation and Evidence for Quality Control Steps

For each completed quality control step, the checklist mandates detailed documentation and evidence, including inspection reports, photographs, and measurement records. This documentation ensures traceability and accountability for every stage of the assembly process. Maintaining comprehensive records enables efficient audits and supports continuous improvement initiatives.

Authorized Personnel for Verification and Sign-off

The checklist specifies that only certified quality control inspectors and assembly supervisors are authorized to verify and sign off on completed checklist items. These personnel undergo rigorous training to ensure competence in evaluating quality standards. Their approval validates that each assembly stage conforms to the company's quality requirements.

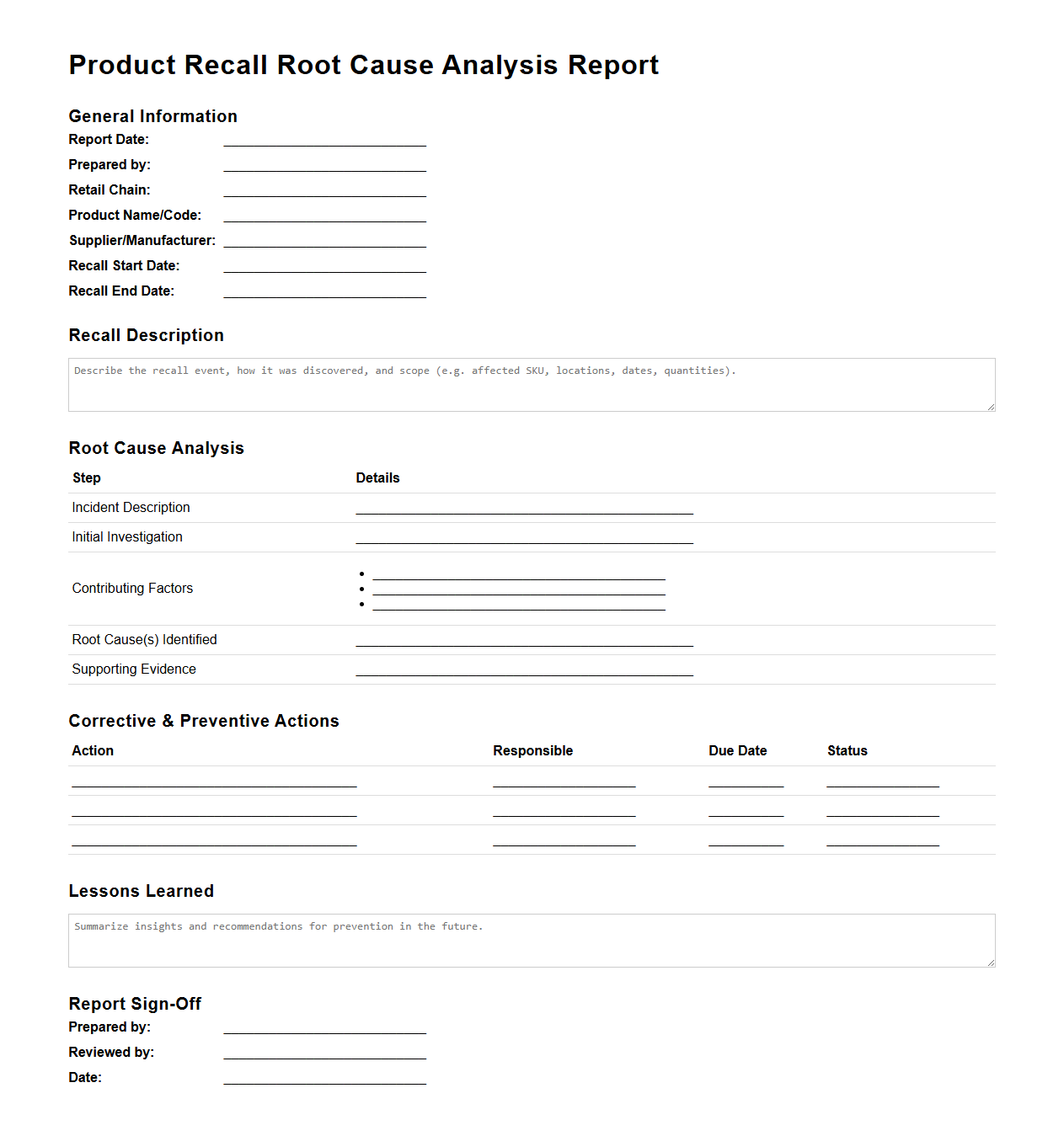

Procedures for Addressing and Resolving Defects or Nonconformities

The checklist outlines a standardized procedure for resolving detected defects, including immediate isolation of defective products, root cause analysis, and corrective action implementation. It emphasizes timely communication between quality control and production teams to prevent recurrence. Documenting all steps ensures transparency and supports continuous quality enhancement.

More Manufacturing Templates