A Finished Goods Release Document Sample for Manufacturing ensures that all quality checks, inspections, and approvals are completed before products are dispatched. This document serves as a formal confirmation that finished goods meet required standards and specifications. It helps streamline inventory management and supports traceability throughout the supply chain.

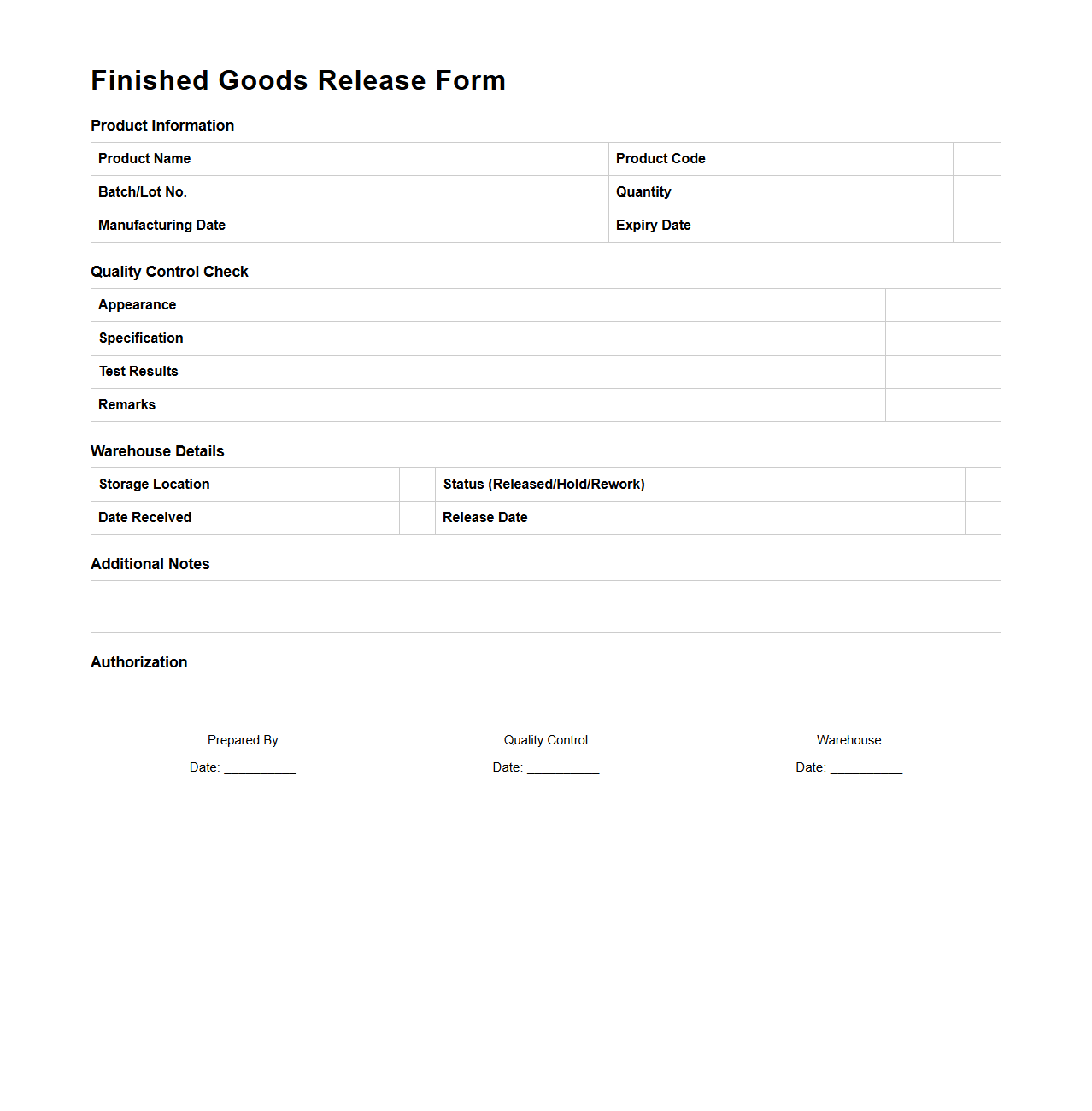

Finished Goods Release Form Template

A

Finished Goods Release Form Template is a standardized document used in manufacturing and inventory management to authorize the release of completed products from production to storage or shipment. It typically includes details such as product description, quantity, batch number, quality inspection results, and approval signatures to ensure compliance with quality control standards. This template streamlines communication between production and logistics teams, reducing errors and improving traceability in the supply chain.

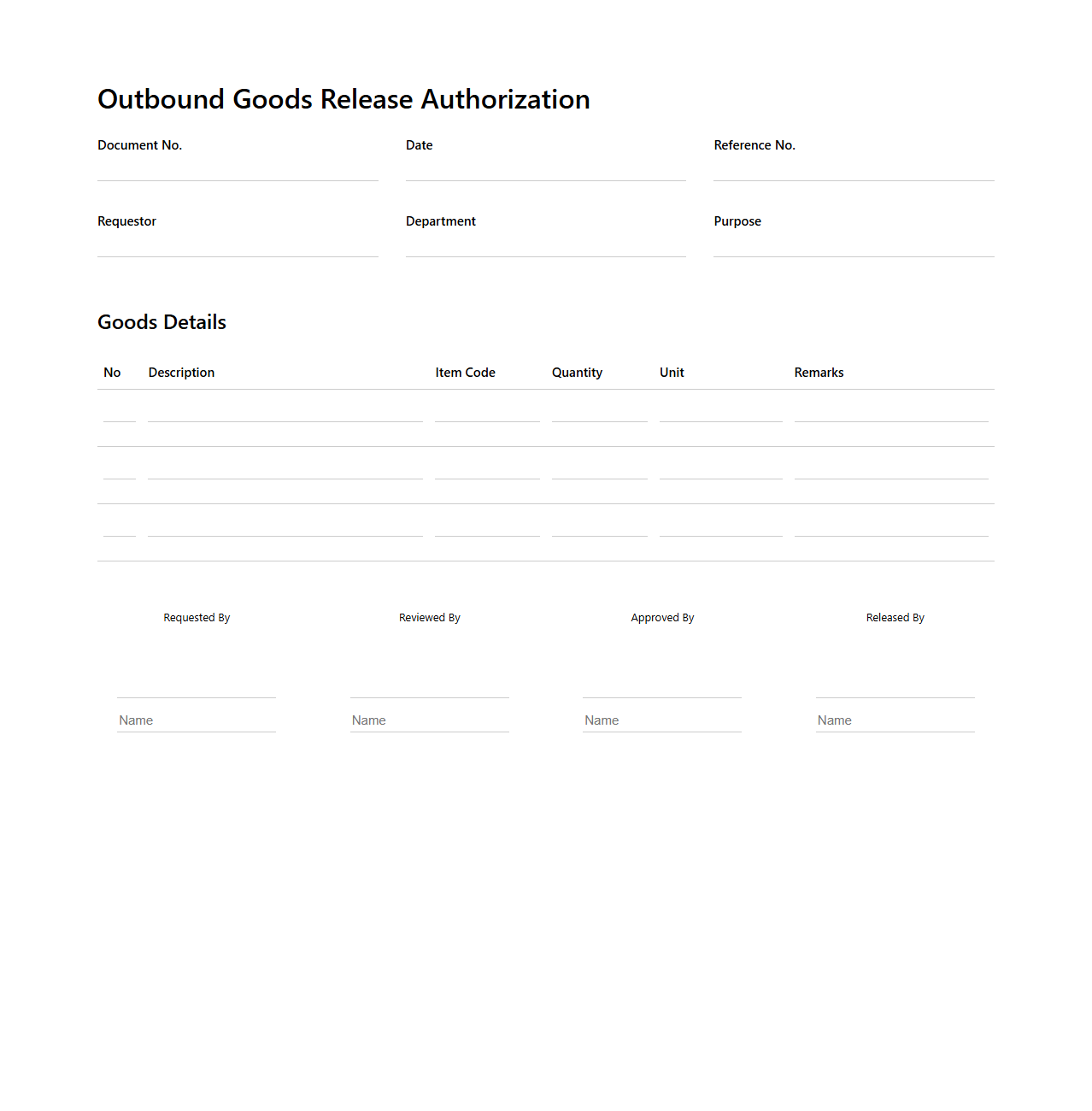

Outbound Goods Release Authorization

The

Outbound Goods Release Authorization document is a critical supply chain record that verifies permission to dispatch goods from a warehouse or production facility. It ensures all quality checks, inventory validation, and regulatory requirements have been met before shipment. This document streamlines logistics by providing clear authorization for transportation and delivery processes.

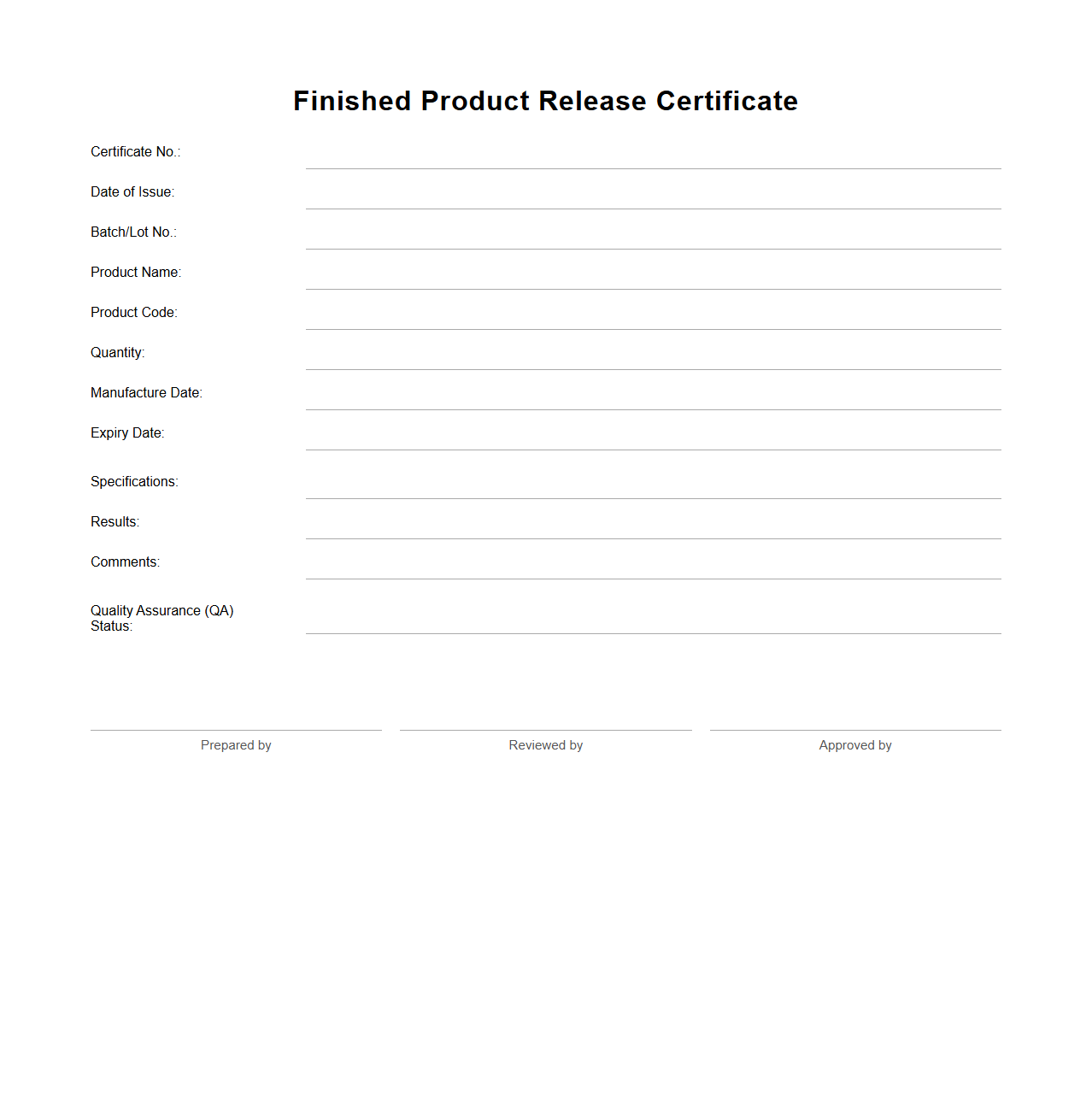

Finished Product Release Certificate

A

Finished Product Release Certificate is an official document issued by a quality control department confirming that a product has passed all required testing and quality standards before being distributed or sold. It includes detailed information such as batch number, manufacturing date, expiration date, and compliance with regulatory specifications. This certificate ensures product safety, efficacy, and consistency for both manufacturers and consumers.

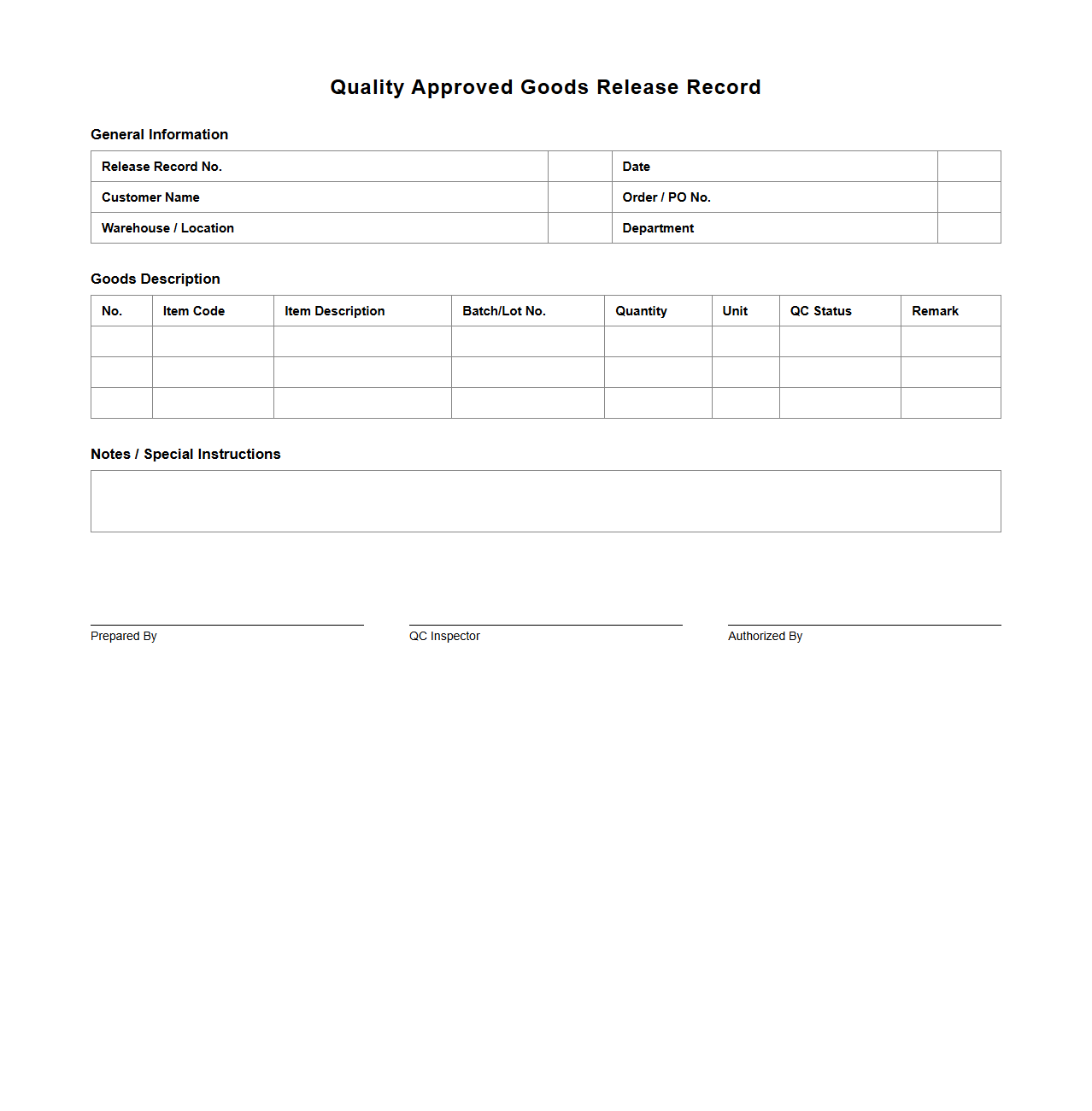

Quality Approved Goods Release Record

The

Quality Approved Goods Release Record document serves as formal evidence that products have met all specified quality standards and inspections before being released for distribution or sale. It typically includes detailed information such as batch numbers, inspection results, approval signatures, and dates, ensuring traceability and accountability. This record is crucial for maintaining compliance with regulatory requirements and supporting quality assurance processes.

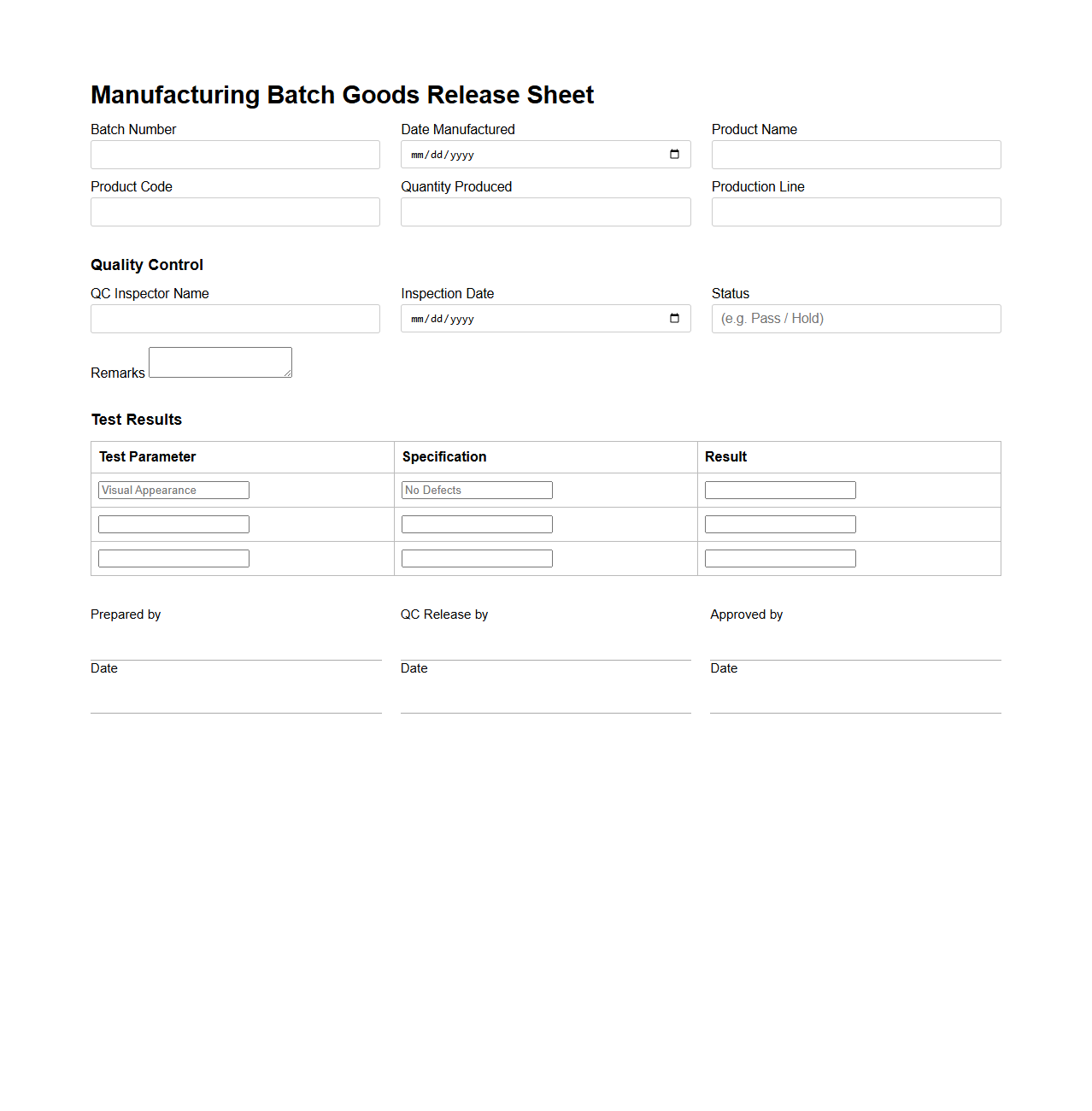

Manufacturing Batch Goods Release Sheet

The

Manufacturing Batch Goods Release Sheet is a critical quality control document used in production environments to verify that a specific batch of goods meets all required specifications before being released to the market. It includes detailed information such as batch number, production date, quality checks, test results, and approvals from authorized personnel. This document ensures compliance with industry standards and regulatory requirements, facilitating traceability and accountability in the manufacturing process.

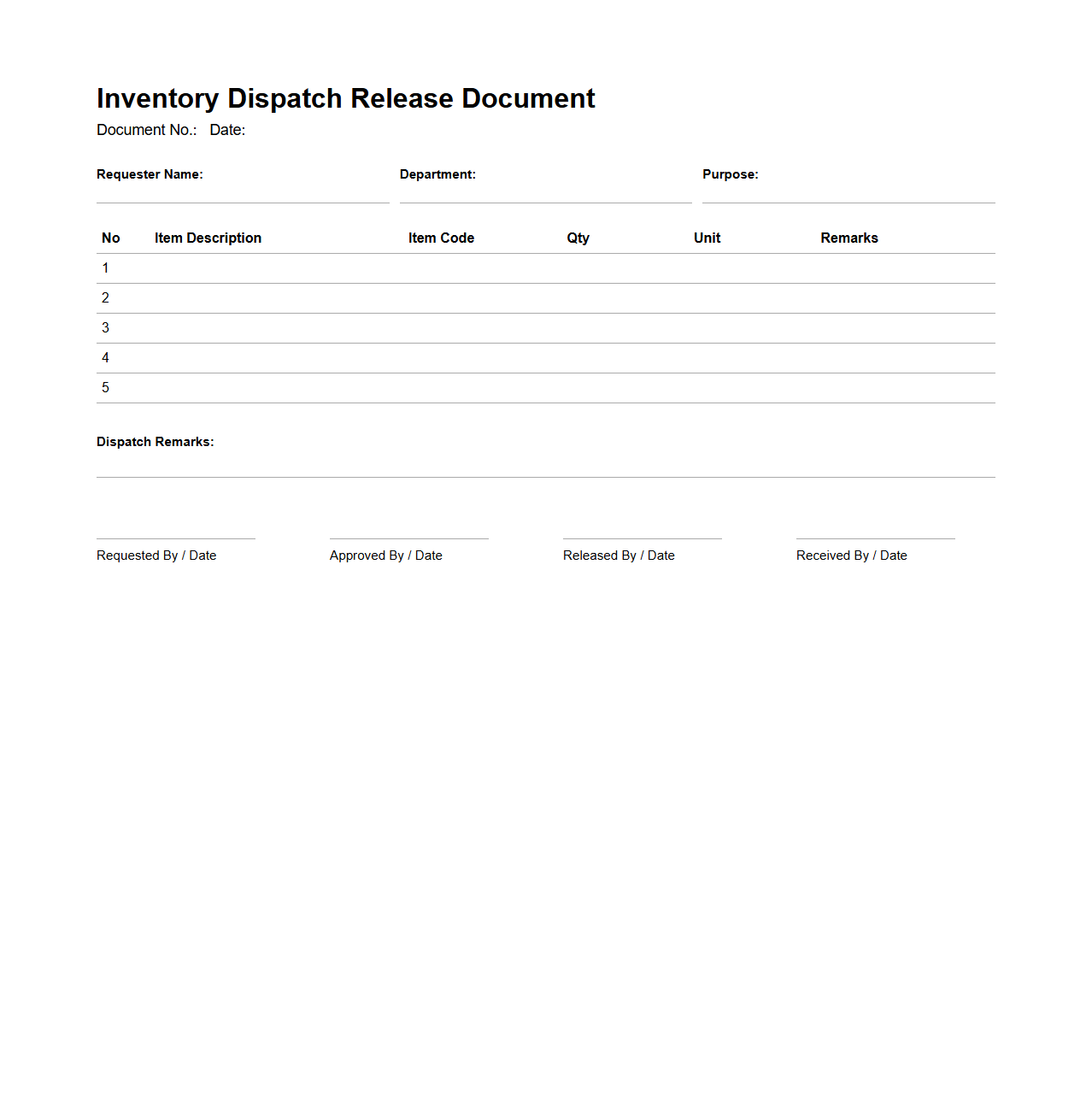

Inventory Dispatch Release Document

The

Inventory Dispatch Release Document serves as an official record authorizing the movement of goods from inventory to the shipping or dispatch area. It details the items, quantities, and destination, ensuring accurate tracking and accountability within supply chain operations. This document is essential for inventory control, preventing discrepancies and facilitating smooth order fulfillment.

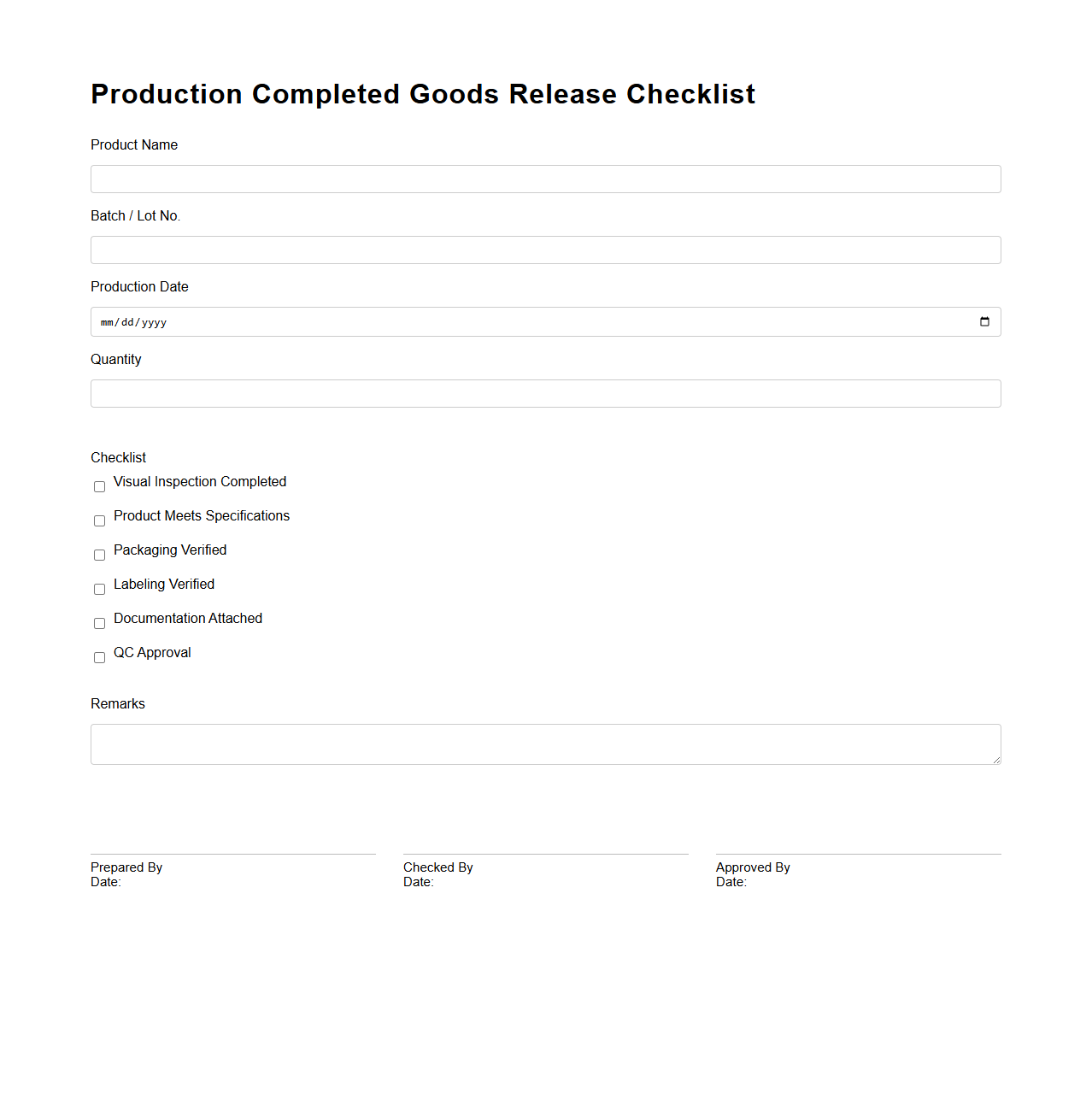

Production Completed Goods Release Checklist

The

Production Completed Goods Release Checklist document ensures that all finished products meet quality standards before shipment. It verifies compliance with production specifications, quality control tests, and packaging requirements. This checklist minimizes the risk of defects reaching customers and supports efficient inventory management.

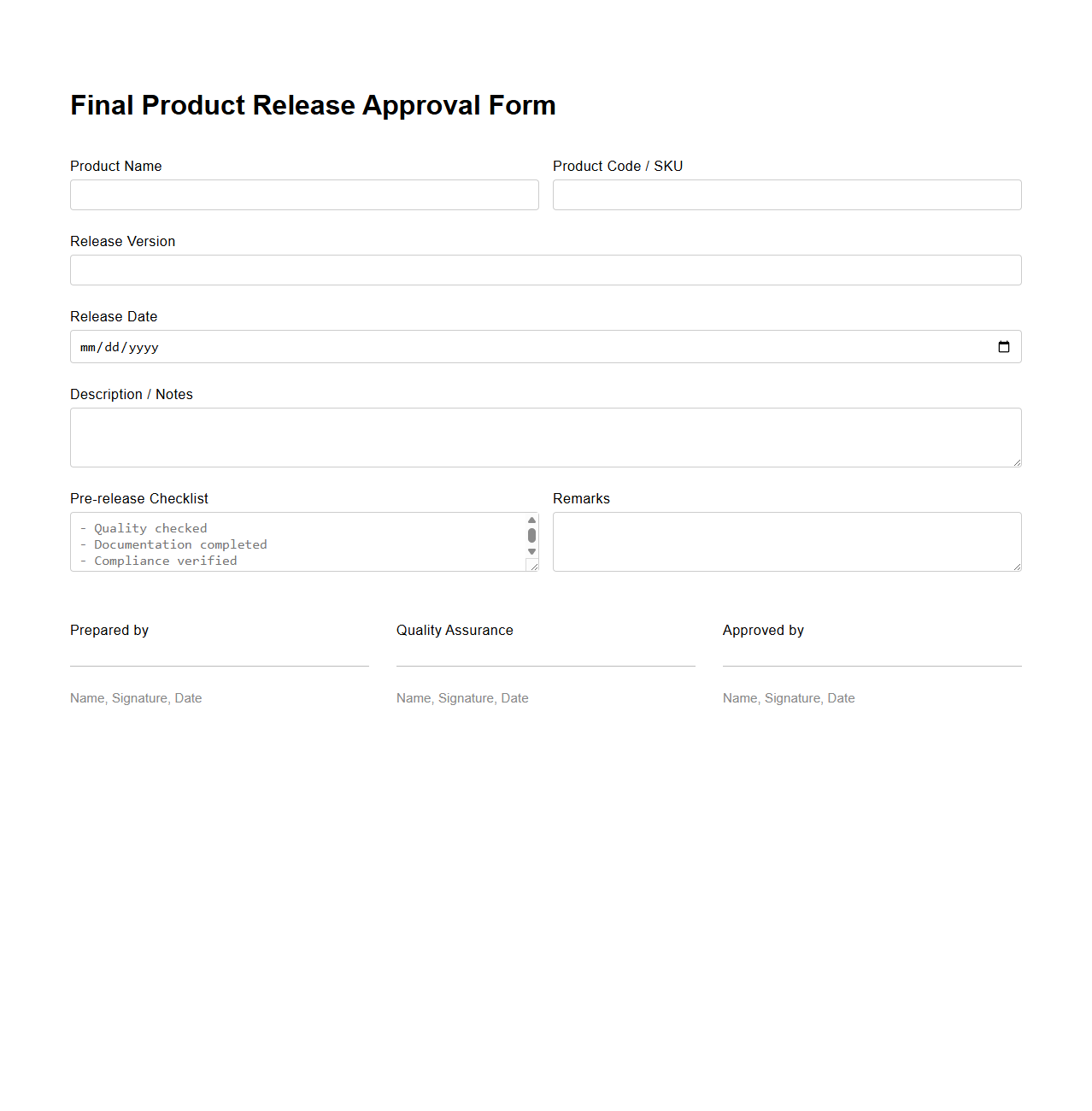

Final Product Release Approval Form

The

Final Product Release Approval Form is a critical document used to authorize the official launch or distribution of a product after meeting all quality and compliance standards. It typically includes key information such as inspection results, validation data, approval signatures from relevant departments, and confirmation that the product meets all regulatory and company requirements. This form ensures accountability and traceability in product release processes, minimizing risk and maintaining product integrity.

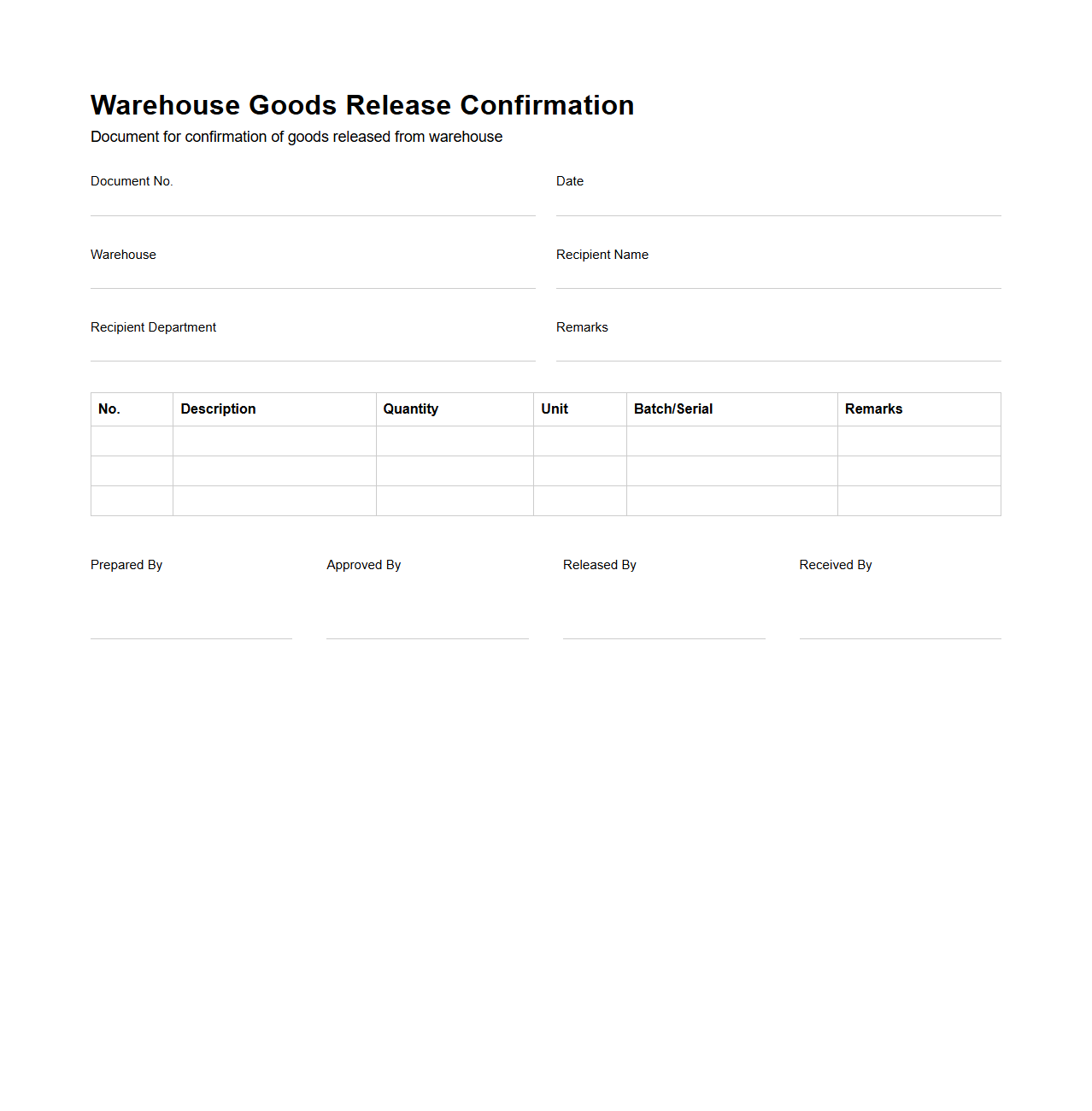

Warehouse Goods Release Confirmation

The

Warehouse Goods Release Confirmation document serves as an official record verifying that goods have been accurately dispatched from the warehouse to the designated recipient. It ensures inventory accuracy by confirming the release date, quantity, and condition of the items, facilitating seamless tracking and accountability. This document is crucial for maintaining transparent supply chain operations and preventing discrepancies in shipment delivery.

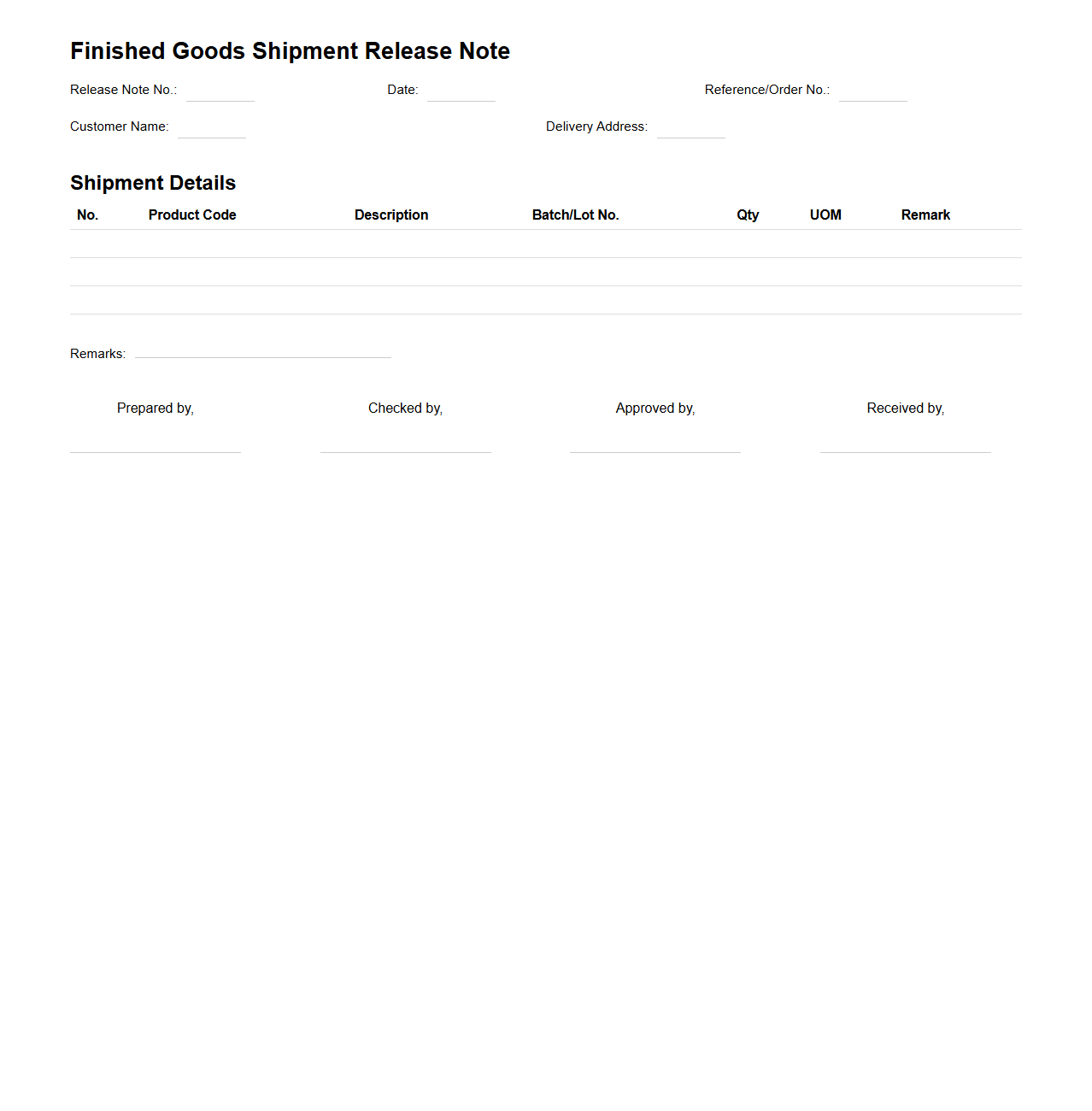

Finished Goods Shipment Release Note

The

Finished Goods Shipment Release Note document serves as an official record authorizing the dispatch of completed products from the warehouse to customers or distribution centers. It details crucial information such as product descriptions, quantities, shipment dates, and destination addresses to ensure accuracy and traceability throughout the supply chain. This document plays a vital role in inventory management, logistics coordination, and customer order fulfillment processes.

What critical information must be included in a Finished Goods Release Document for manufacturing compliance?

The Finished Goods Release Document must include product identification details such as batch or lot numbers to ensure precise tracking. It should also document manufacturing date, quantity, and specifications to confirm adherence to production standards. Additionally, the document needs to record quality assurance test results to validate product compliance with regulatory requirements.

How does the document ensure traceability and accountability for released finished goods?

The document ensures traceability by linking each finished product to its unique batch or serial numbers recorded during production. It maintains accountability by including signatures from responsible personnel involved in production, quality control, and release. This comprehensive record provides a clear audit trail for all released goods, facilitating recalls or investigations if necessary.

What quality control checkpoints are referenced or recorded within the release document?

The release document references critical quality control checkpoints such as in-process inspections, final product testing, and packaging integrity verification. It also records compliance with regulatory standards and internal quality specifications to ensure product safety and efficacy. These checkpoints validate that the finished goods meet all necessary quality requirements before release.

Which internal approvals and sign-offs are mandatory before finished goods are authorized for distribution?

Mandatory internal approvals include sign-offs from the production manager, quality assurance supervisor, and regulatory compliance officer. Each approver verifies that products meet established criteria and that documentation is complete. These formal endorsements are essential to authorize the finished goods for official release and distribution.

How does the document address handling of deviations or non-conformances in the released finished goods?

The document includes a section for recording any deviations or non-conformances identified during quality checks. It outlines the corrective actions taken, including investigations, root cause analyses, and remediation steps. This ensures that all issues are systematically managed before any compromised finished goods are considered for release.

More Manufacturing Templates