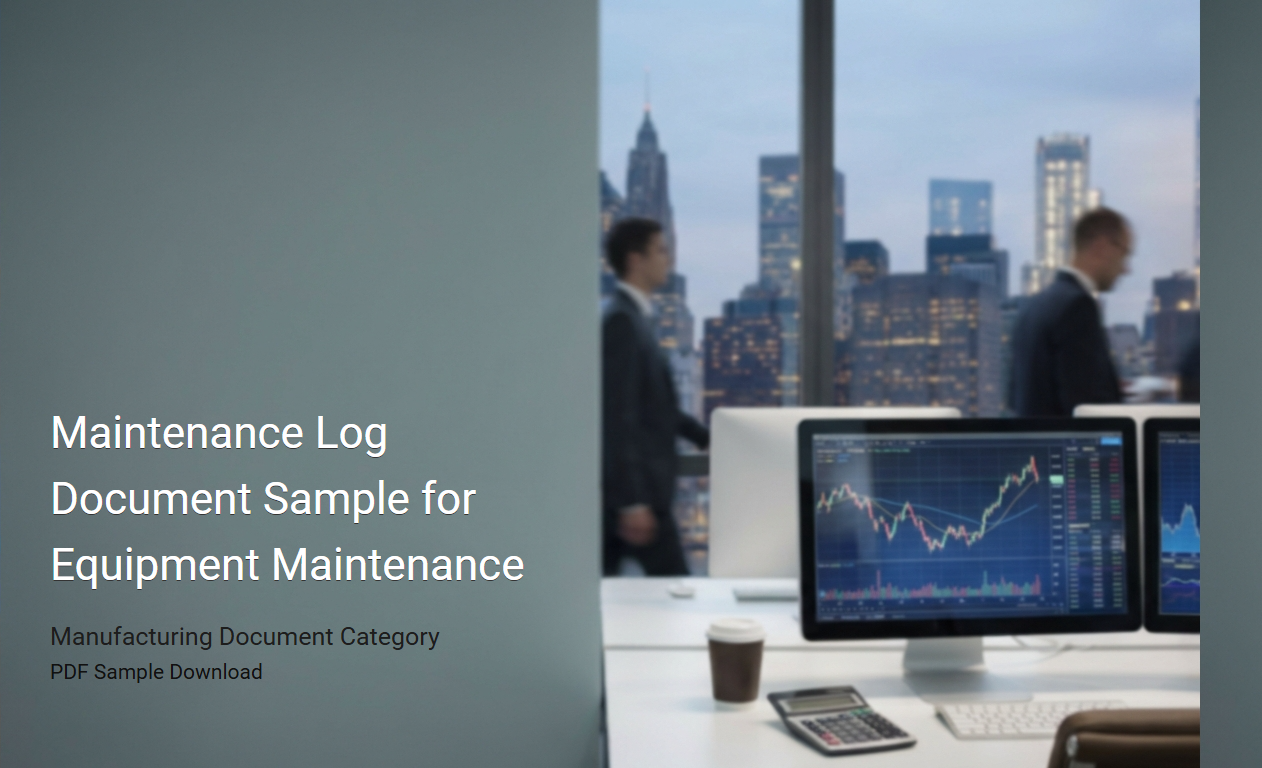

Preventive Maintenance Log Template for Industrial Equipment

A

Preventive Maintenance Log Template for industrial equipment is a structured document designed to systematically track and schedule routine maintenance activities. It helps in recording dates, inspection details, repairs, and parts replacements to ensure optimal performance and longevity of machinery. Utilizing this template reduces downtime, enhances safety, and supports compliance with industry maintenance standards.

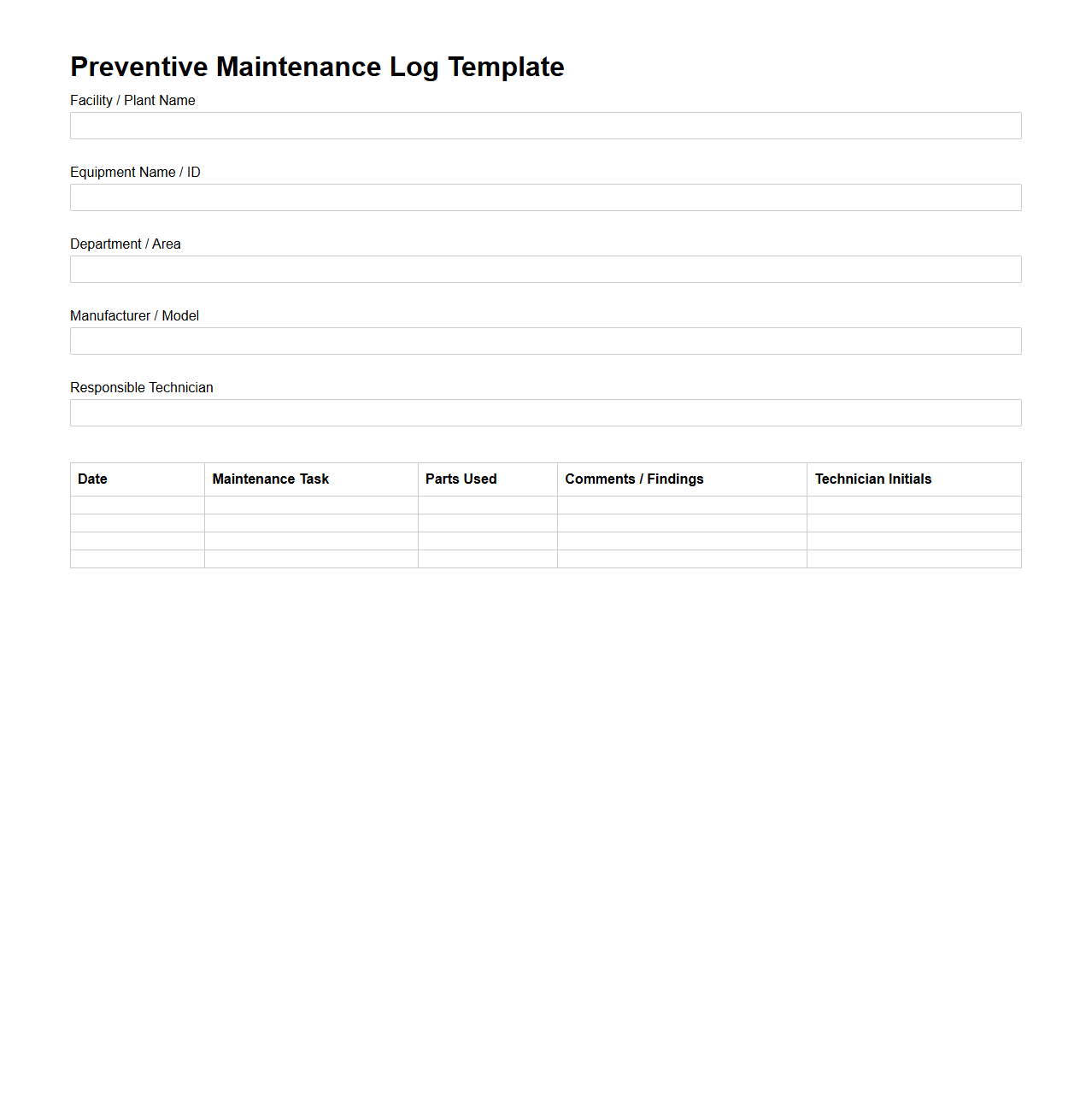

Monthly Equipment Maintenance Record Template

A

Monthly Equipment Maintenance Record Template document is designed to systematically track and document routine inspections, repairs, and servicing of machinery within a specific timeframe. It helps organizations maintain equipment efficiency, prevent unexpected breakdowns, and comply with safety regulations by recording dates, technician details, and maintenance activities. Consistent use of this template supports operational continuity and extends the lifespan of critical assets.

HVAC Maintenance Tracking Sheet

An HVAC Maintenance Tracking Sheet is a comprehensive document used to record and monitor routine servicing, inspections, and repairs of heating, ventilation, and air conditioning systems. This sheet ensures systematic tracking of maintenance activities, helping to extend equipment lifespan, improve energy efficiency, and prevent unexpected breakdowns. Utilizing a

HVAC Maintenance Tracking Sheet promotes organized scheduling and timely interventions, which are crucial for maintaining optimal performance and reducing operational costs.

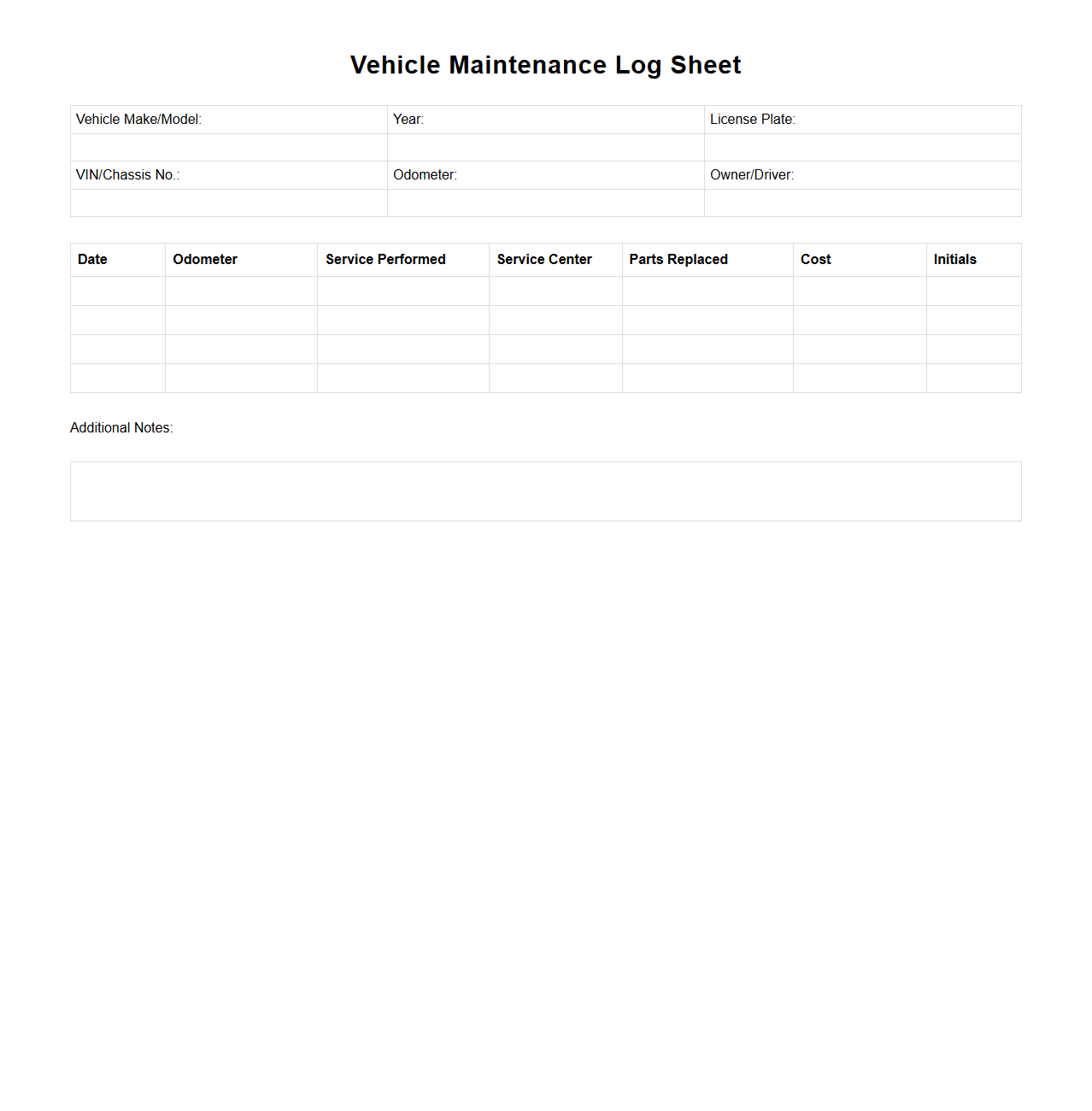

Vehicle Maintenance Log Sheet

A

Vehicle Maintenance Log Sheet is a detailed record document used to track all maintenance activities performed on a vehicle, including repairs, inspections, and routine services. It helps vehicle owners and fleet managers monitor the condition, performance history, and maintenance schedules, ensuring timely upkeep and preventing costly breakdowns. Keeping accurate log sheets supports compliance with safety regulations and extends the vehicle's lifespan.

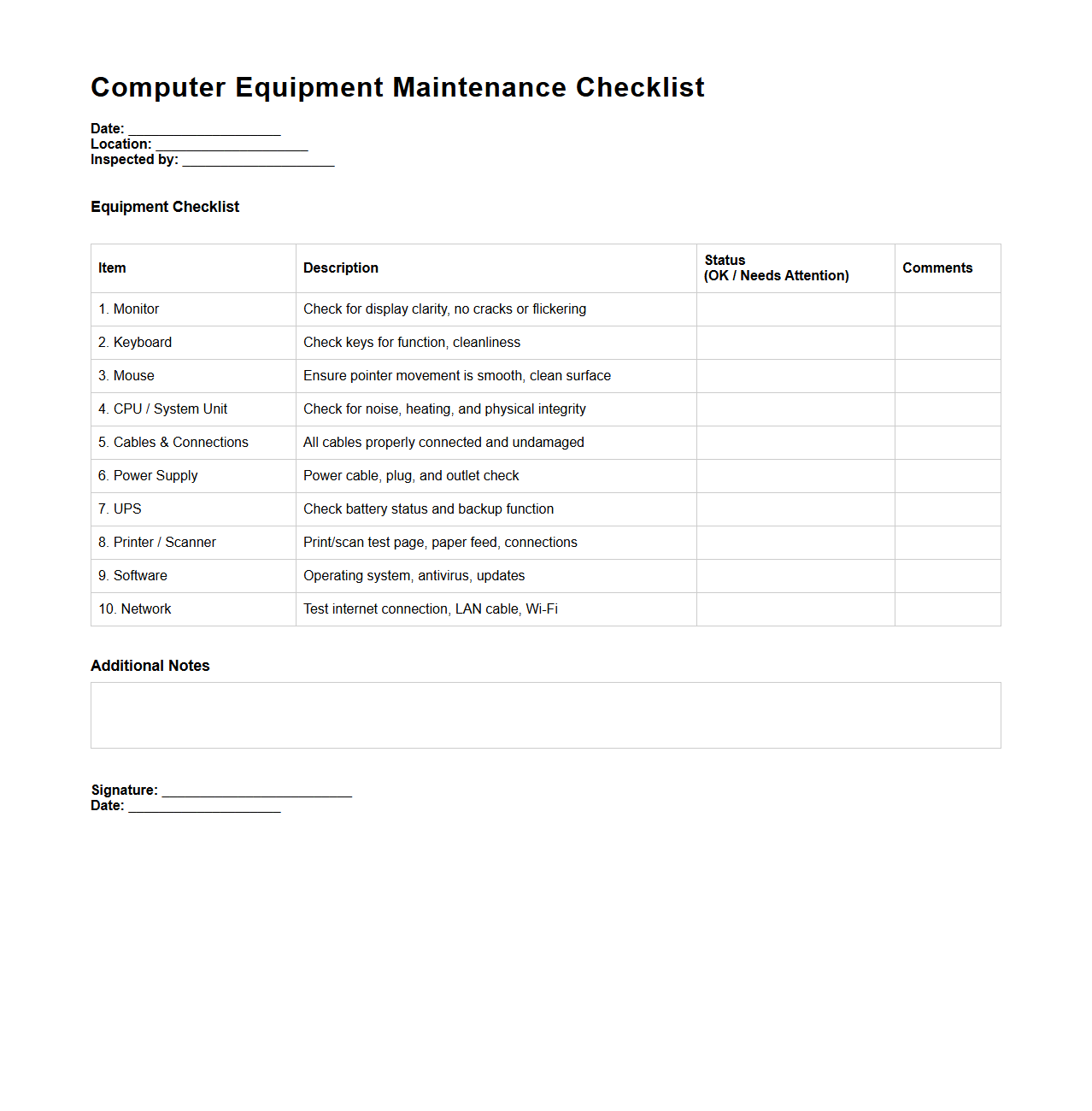

Computer Equipment Maintenance Checklist

A

Computer Equipment Maintenance Checklist document is a detailed guide used to systematically inspect, clean, and service computer hardware to ensure optimal performance and longevity. This checklist typically includes tasks such as checking for dust accumulation, verifying software updates, inspecting cables and connectors, and testing peripheral devices. Regular use of this document helps prevent equipment failures, reduces downtime, and extends the lifespan of critical computer systems.

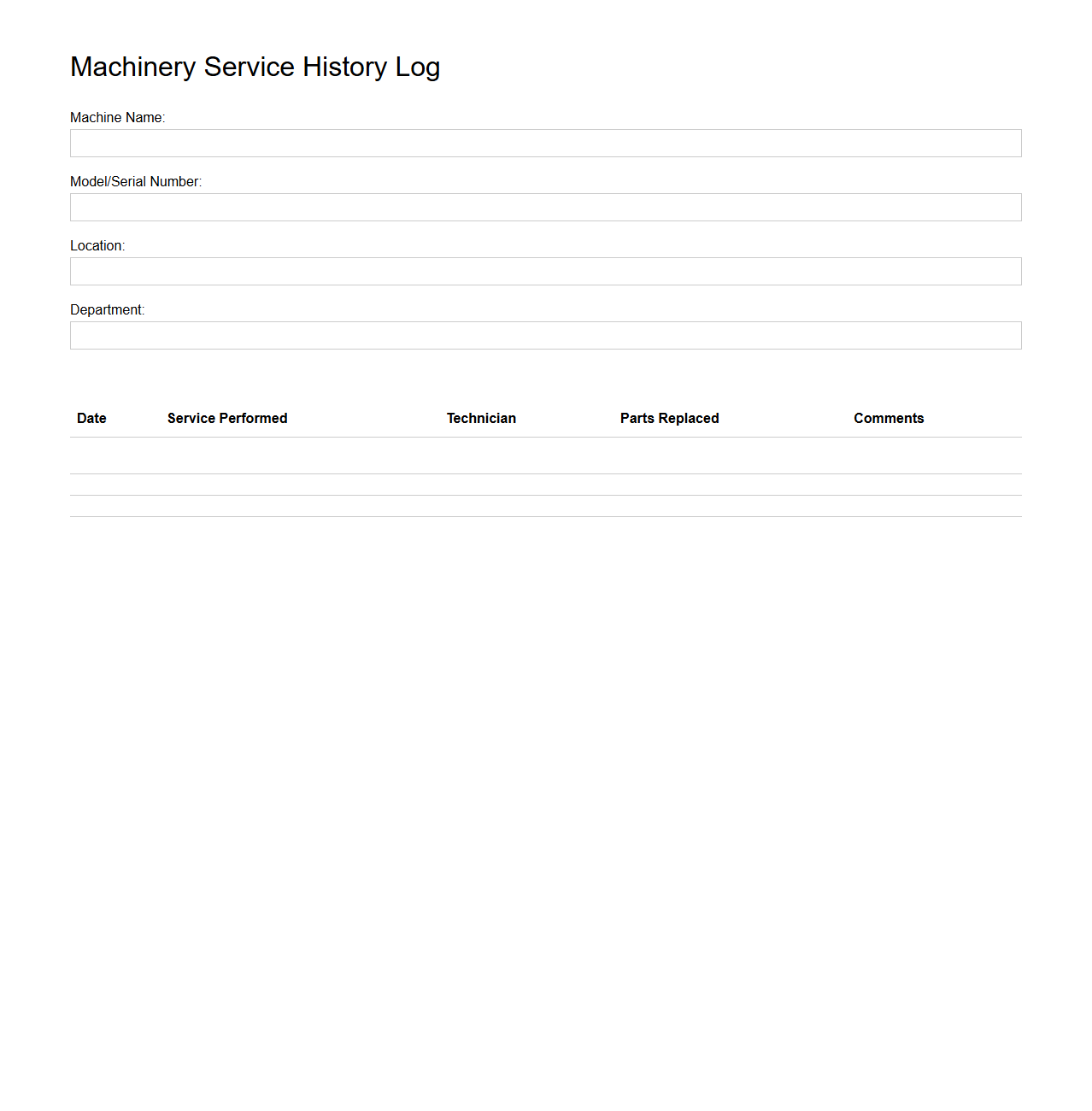

Machinery Service History Log

A

Machinery Service History Log document records detailed information about maintenance, repairs, and inspections performed on machinery over time. It helps track the lifecycle of equipment, ensuring timely servicing and minimizing downtime. This log is essential for warranty claims, compliance with safety regulations, and improving operational efficiency.

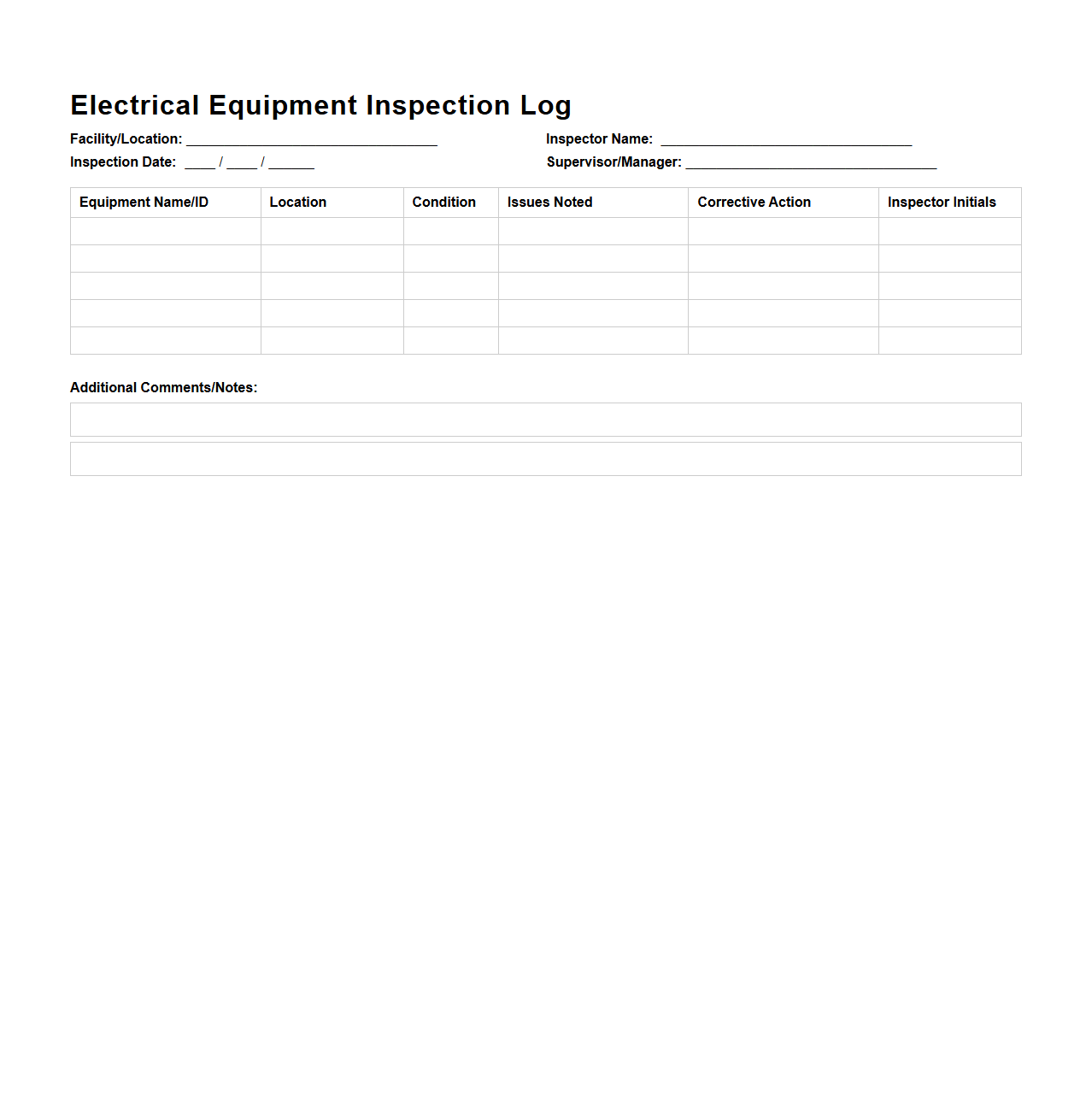

Electrical Equipment Inspection Log

An

Electrical Equipment Inspection Log document records detailed information about the regular inspection and maintenance of electrical devices, ensuring compliance with safety standards and operational efficiency. It typically includes data such as inspection dates, equipment condition, identified defects, and corrective actions taken. Maintaining this log is crucial for preventing electrical hazards, reducing downtime, and adhering to regulatory requirements.

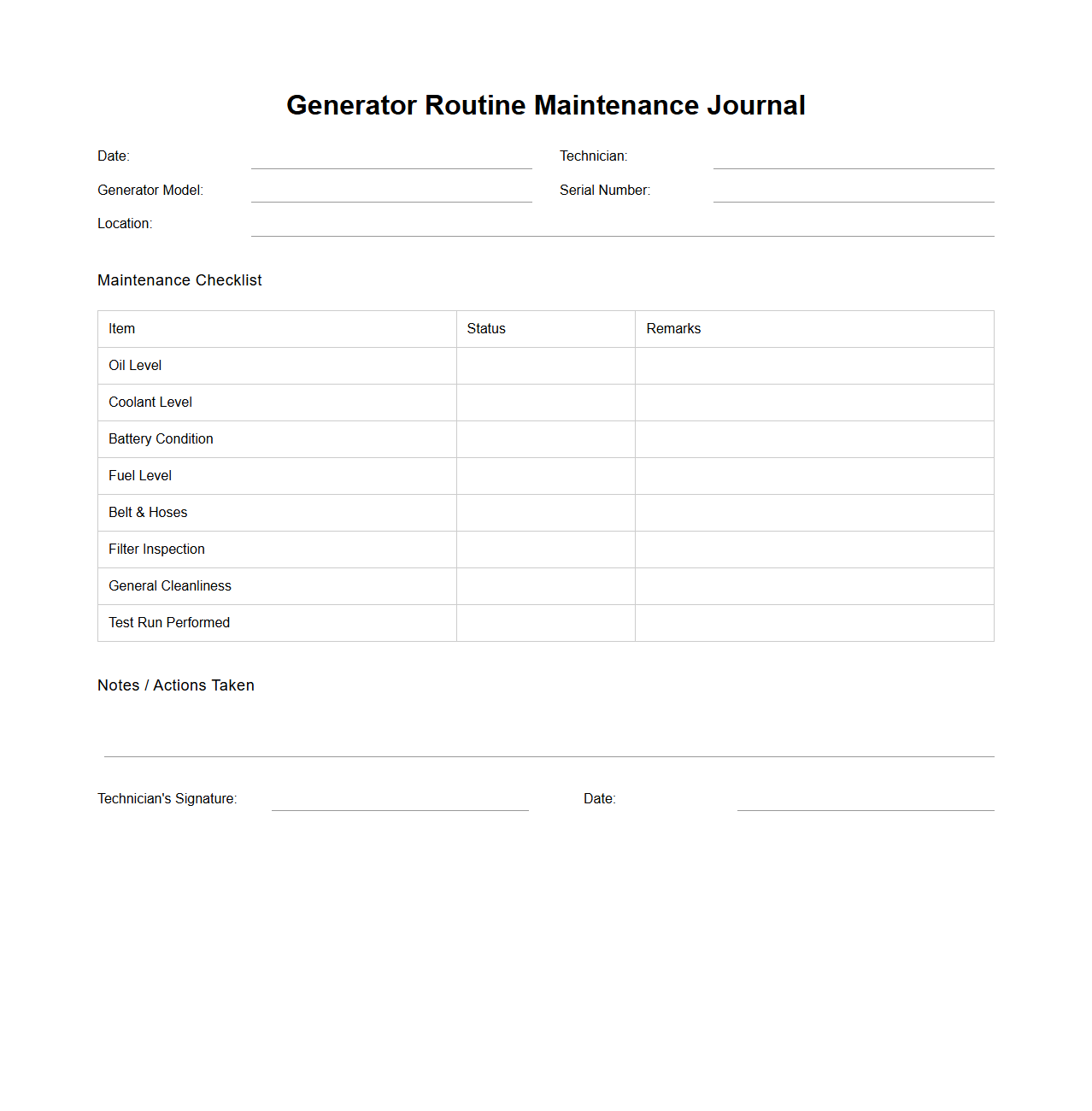

Generator Routine Maintenance Journal

A

Generator Routine Maintenance Journal document systematically records all scheduled inspections, servicing activities, and repairs performed on a generator to ensure its optimal operation and longevity. It includes detailed logs of operational hours, oil changes, filter replacements, battery tests, and any irregularities detected during maintenance checks. This document serves as a critical reference for maintenance teams and auditors to track equipment health and compliance with manufacturer guidelines.

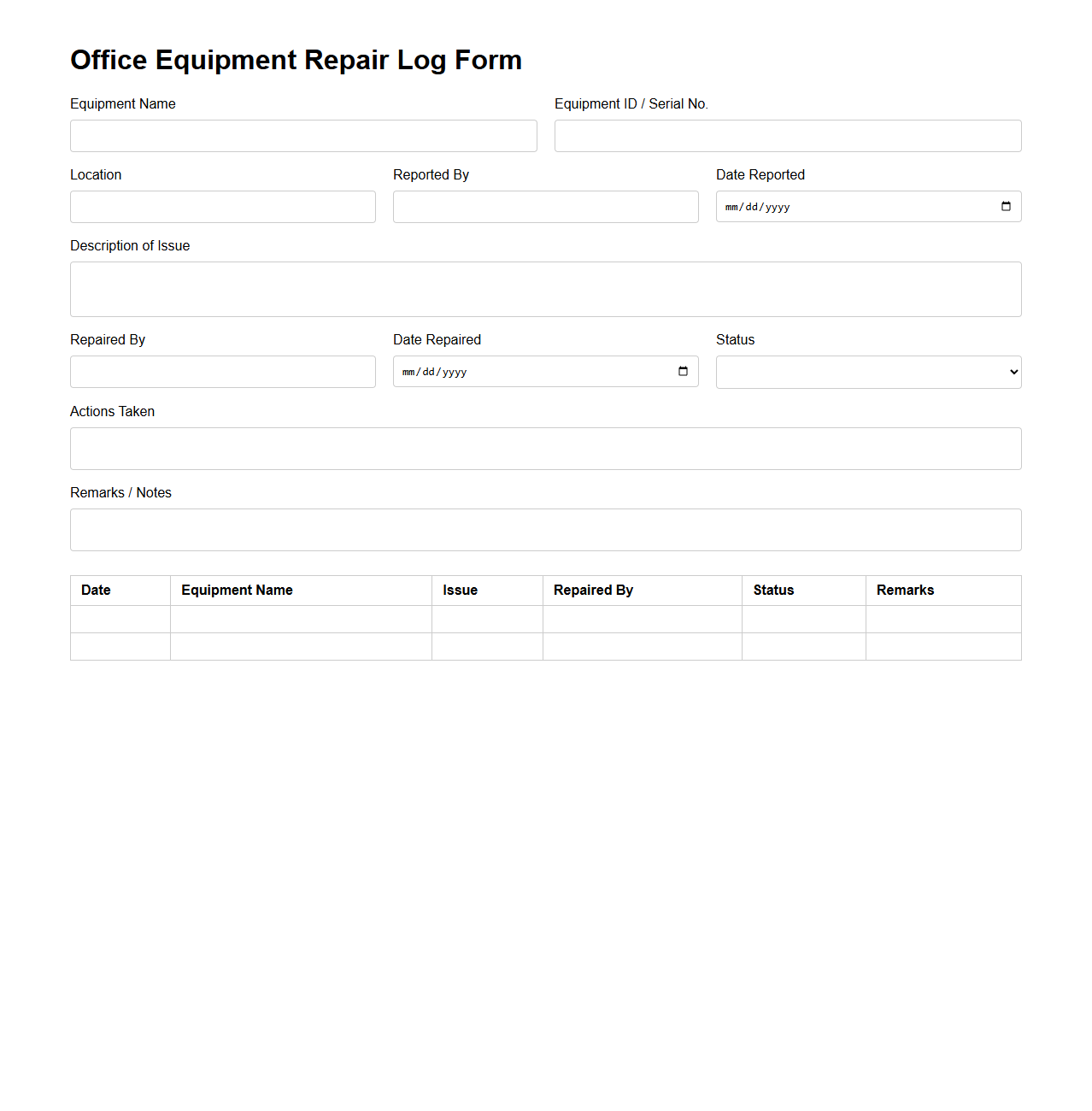

Office Equipment Repair Log Form

An

Office Equipment Repair Log Form document is a detailed record used to track the maintenance and repair activities of office devices such as printers, computers, and copiers. It includes fields for equipment identification, reported issues, dates of service, technician details, and repair outcomes to ensure timely and efficient resolution of technical problems. Maintaining this form helps organizations monitor equipment performance, plan preventive maintenance, and reduce downtime in the workplace.

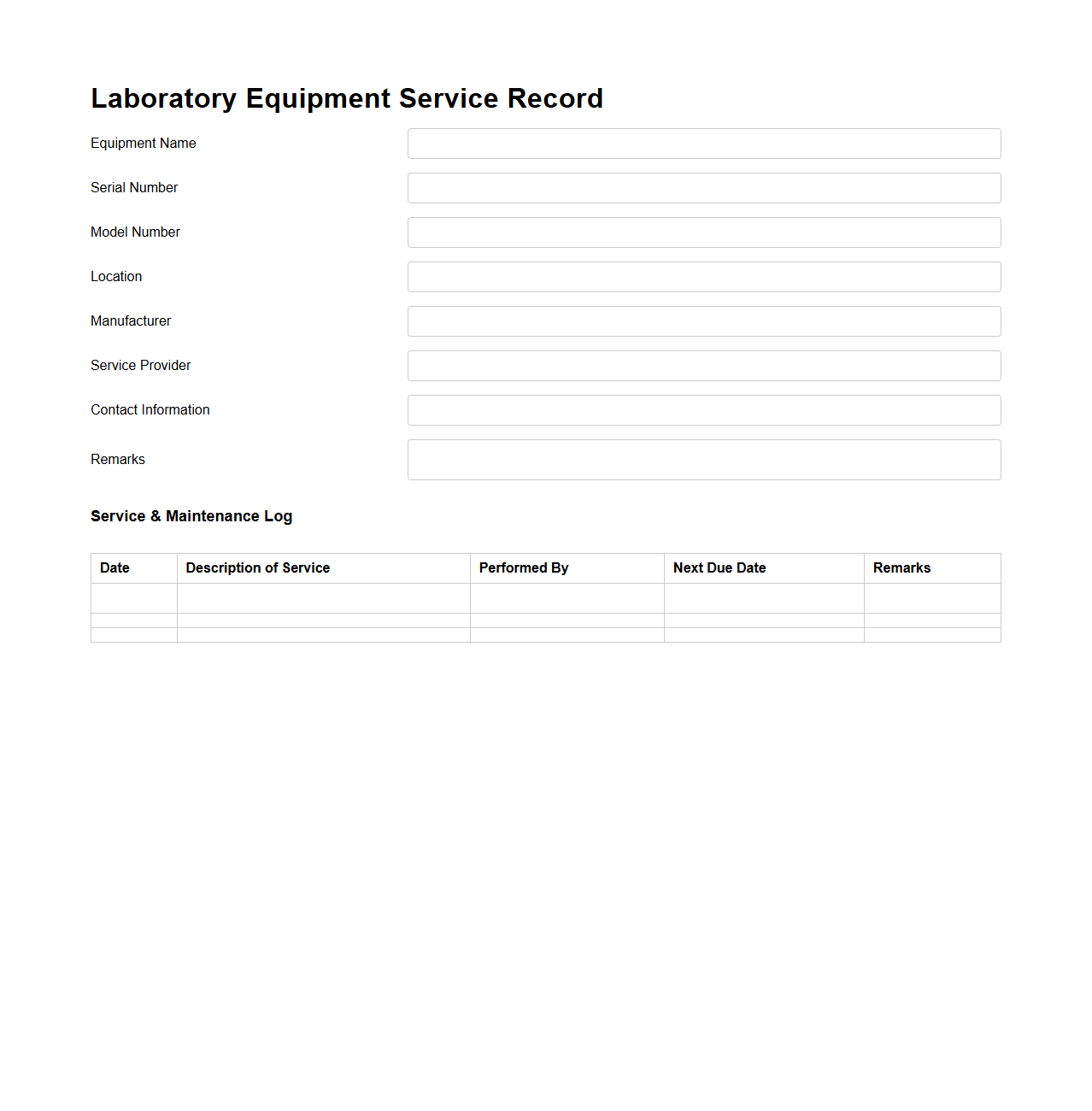

Laboratory Equipment Service Record

A

Laboratory Equipment Service Record document is a detailed log that tracks the maintenance, calibration, and repairs of laboratory instruments. It ensures equipment reliability, compliance with regulatory standards, and supports quality control by documenting service dates, technician details, and performed procedures. Properly maintained service records extend equipment lifespan and minimize operational downtime in scientific research and testing facilities.

What specific equipment or machinery is covered in this maintenance log document?

The maintenance log document covers all essential industrial equipment including conveyor belts, pumps, compressors, and HVAC systems. It also includes vehicles and specialized machinery used in production processes. This comprehensive inclusion ensures every critical asset is monitored for operational efficiency.

Which routine and corrective maintenance tasks must be documented for compliance?

Both routine inspections and corrective repairs must be documented to ensure compliance with safety and regulatory standards. Routine tasks include lubrication, calibration, and part replacements, while corrective maintenance covers unexpected repairs and troubleshooting. Proper documentation guarantees traceability and accountability of maintenance practices.

How frequently should maintenance activities be recorded for each equipment type?

Maintenance activities must be recorded based on the equipment manufacturer's recommendations and industry standards. Routine checks often require daily or weekly logging, while more extensive inspections might be monthly or quarterly. Adhering to these intervals helps prevent breakdowns and extends equipment lifespan.

What information should be included in each maintenance entry (e.g., date, technician, actions taken)?

Each maintenance entry must include the date of service, name of the technician, detailed actions performed, and any parts replaced. Additionally, noting the equipment's condition and any pending issues is critical for comprehensive record-keeping. This detailed information supports effective tracking and future maintenance planning.

Who is responsible for reviewing and verifying the accuracy of the maintenance log records?

The maintenance supervisor or designated quality control personnel are responsible for reviewing and verifying maintenance log entries. Their role ensures that records are accurate, complete, and compliant with company policies and regulatory requirements. Regular audits by these individuals uphold the integrity of the maintenance documentation process.