A Production Planning Document Sample for Manufacturing outlines the detailed schedule, resource allocation, and workflow needed to efficiently manage the production process. It ensures all materials, labor, and equipment are properly coordinated to meet production goals and deadlines. This document serves as a critical tool for minimizing delays and optimizing manufacturing operations.

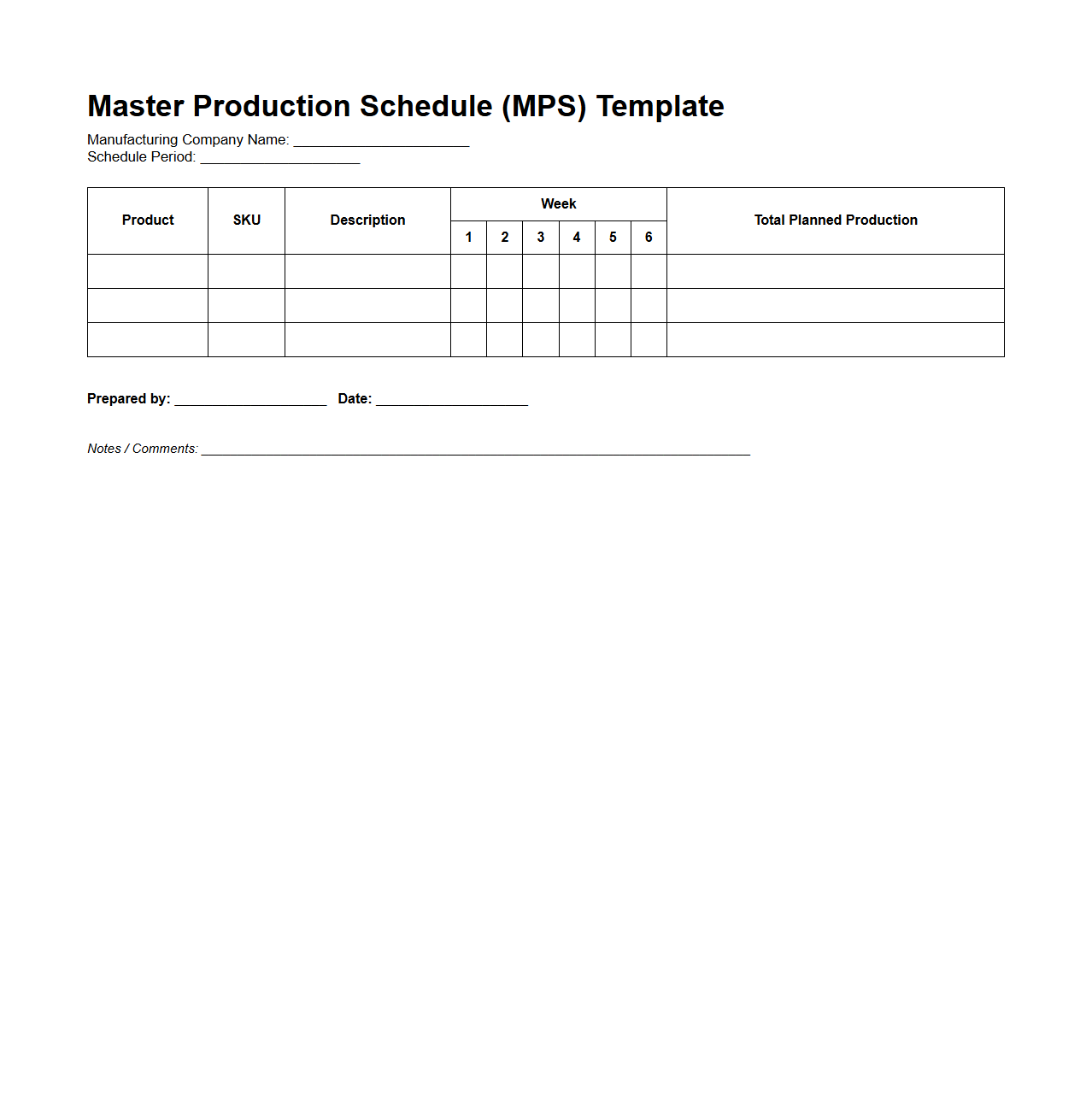

Master Production Schedule Template for Manufacturing

A

Master Production Schedule (MPS) Template for manufacturing is a structured document that outlines the planned production activities, quantities, and timelines for finished goods. It serves as a critical tool for synchronizing supply chain operations, inventory management, and labor allocation, ensuring timely delivery of products. By providing a clear production roadmap, the MPS template helps manufacturers optimize resource utilization and respond effectively to market demand fluctuations.

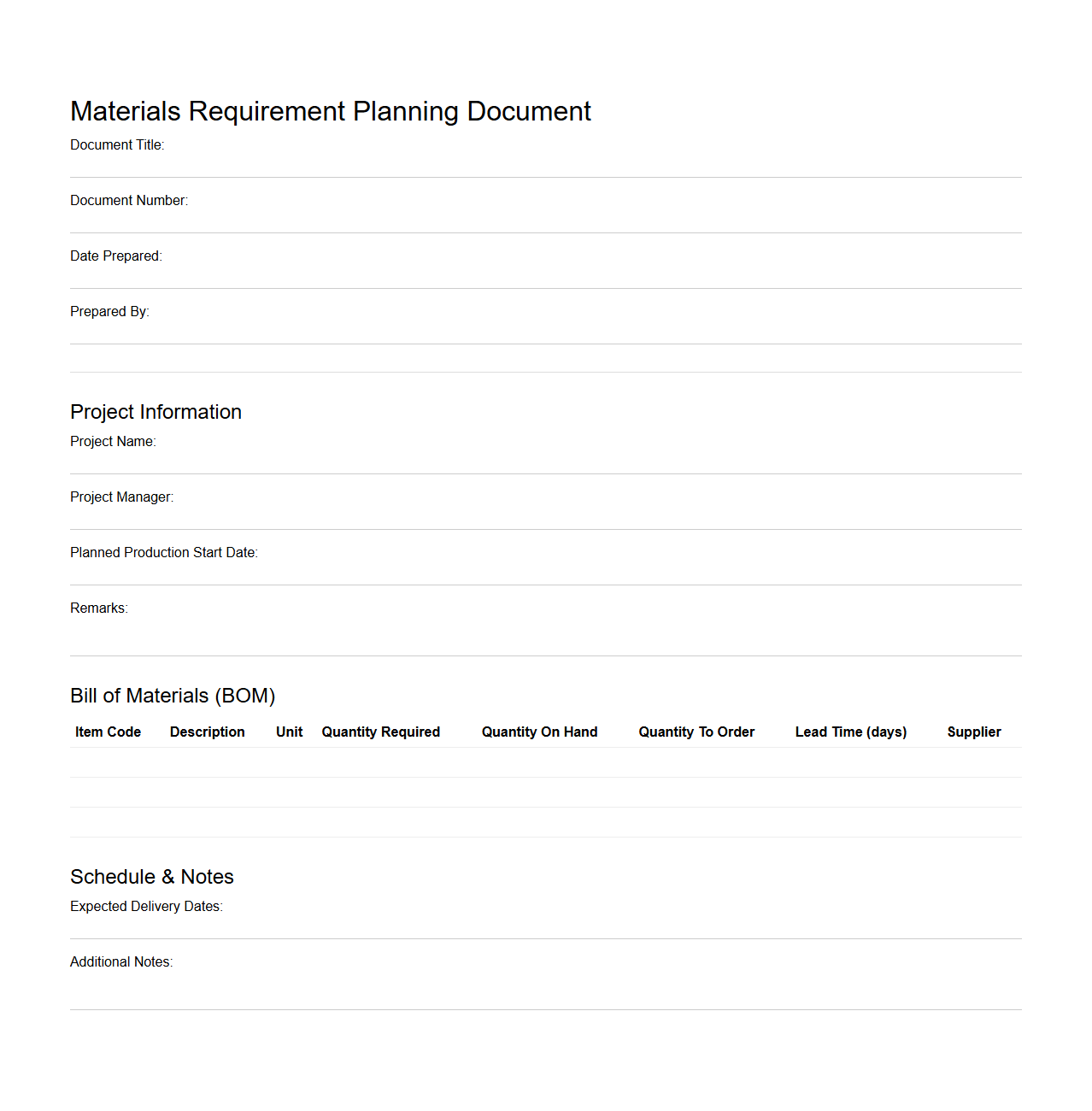

Materials Requirement Planning Document Template

A

Materials Requirement Planning Document Template is a structured tool used to organize and outline the materials needed for production processes efficiently. It helps in forecasting inventory requirements, scheduling procurement, and ensuring timely availability of raw materials to prevent production delays. This template is essential for supply chain management and optimizing manufacturing workflows.

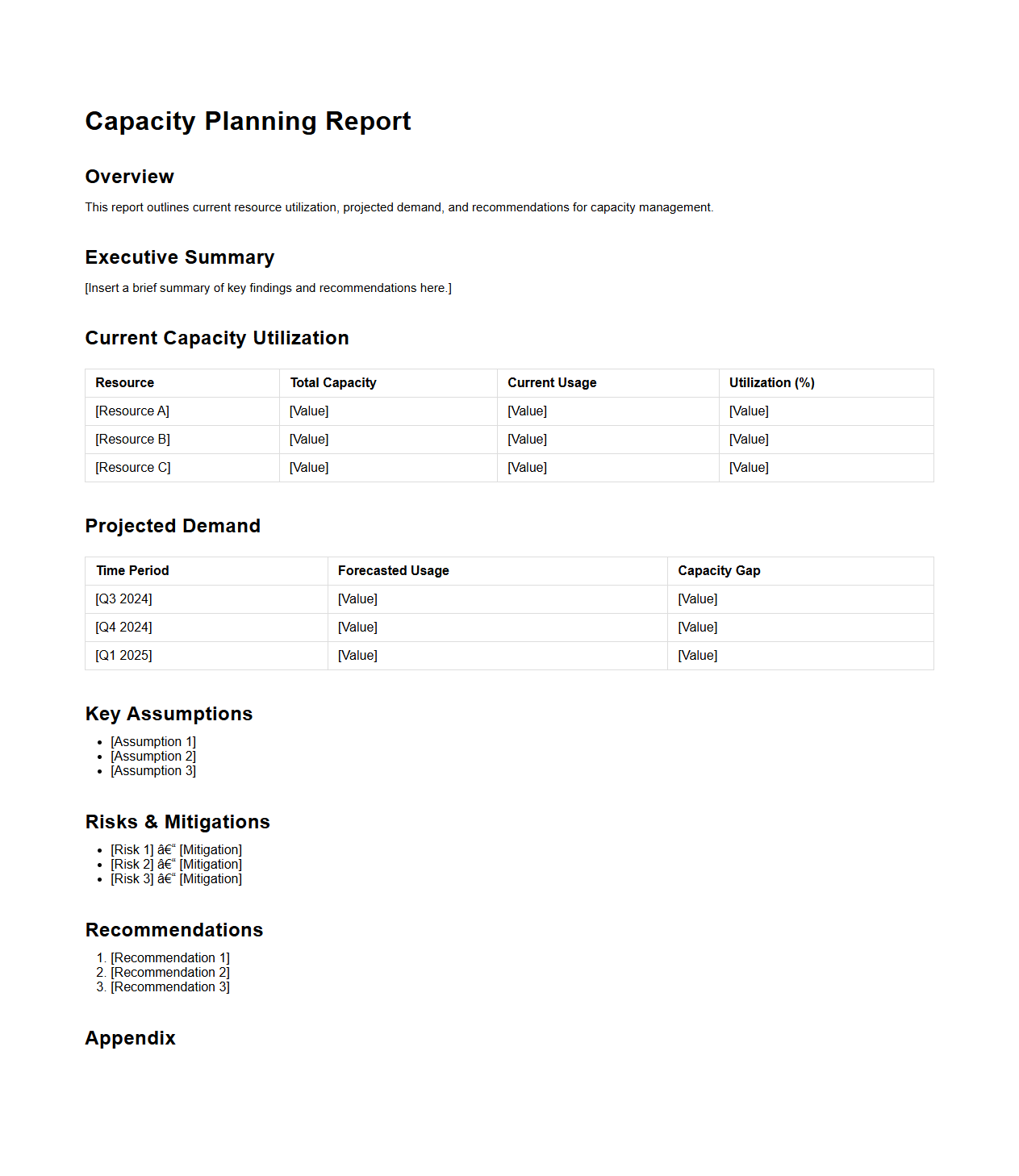

Capacity Planning Report Sample

A

Capacity Planning Report Sample document outlines the evaluation of current and future resource requirements to meet organizational demand efficiently. It includes data on workforce availability, equipment utilization, and production capabilities to ensure optimal allocation and prevent bottlenecks. Businesses use this report to forecast capacity needs, align operations with strategic goals, and improve overall productivity.

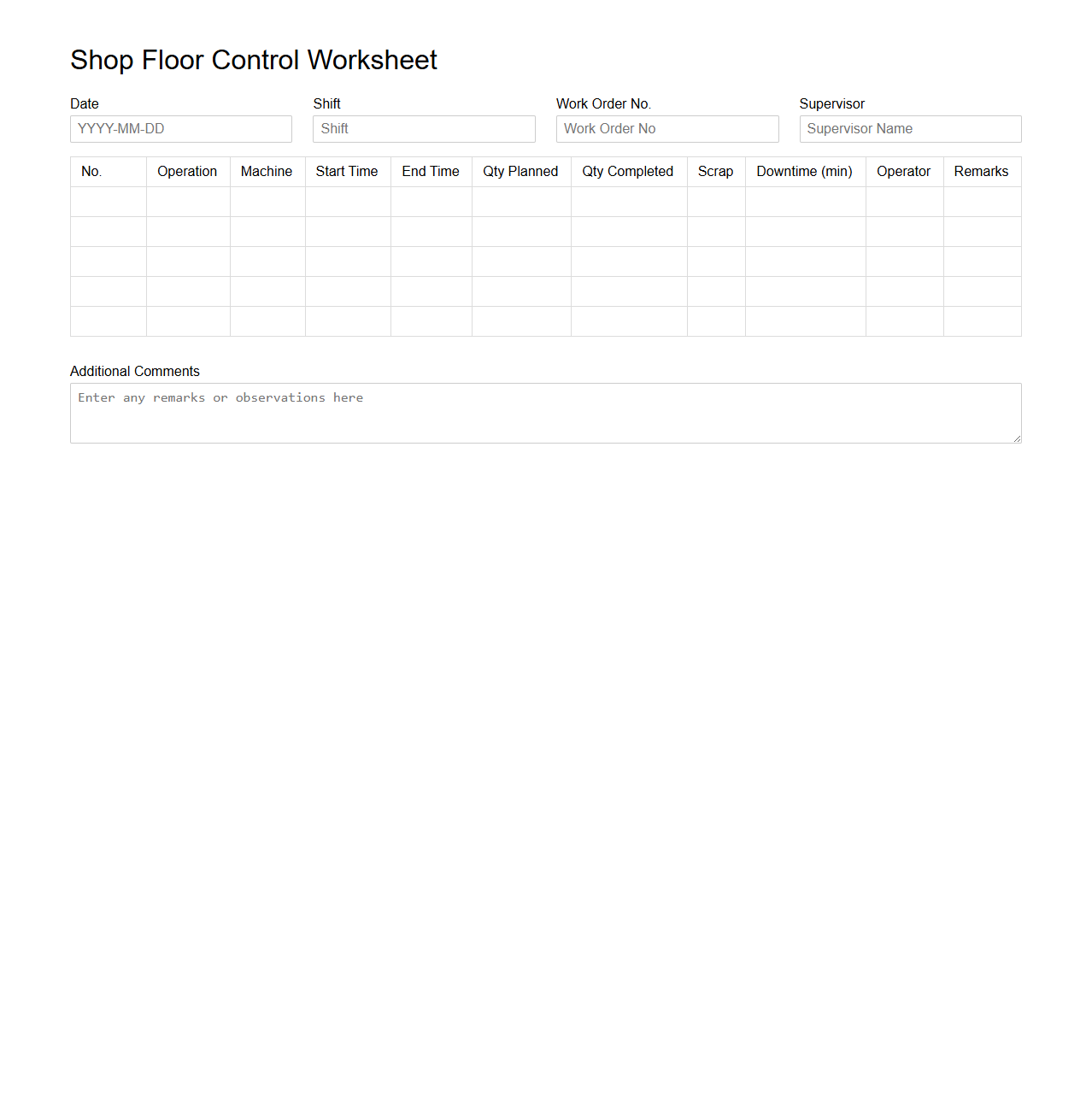

Shop Floor Control Worksheet

The

Shop Floor Control Worksheet is a vital document used in manufacturing to monitor and manage production activities on the shop floor. It details job orders, work progress, labor hours, machine usage, and materials consumed to ensure accurate tracking and efficient workflow. This worksheet facilitates real-time decision-making and helps maintain production schedules and quality standards.

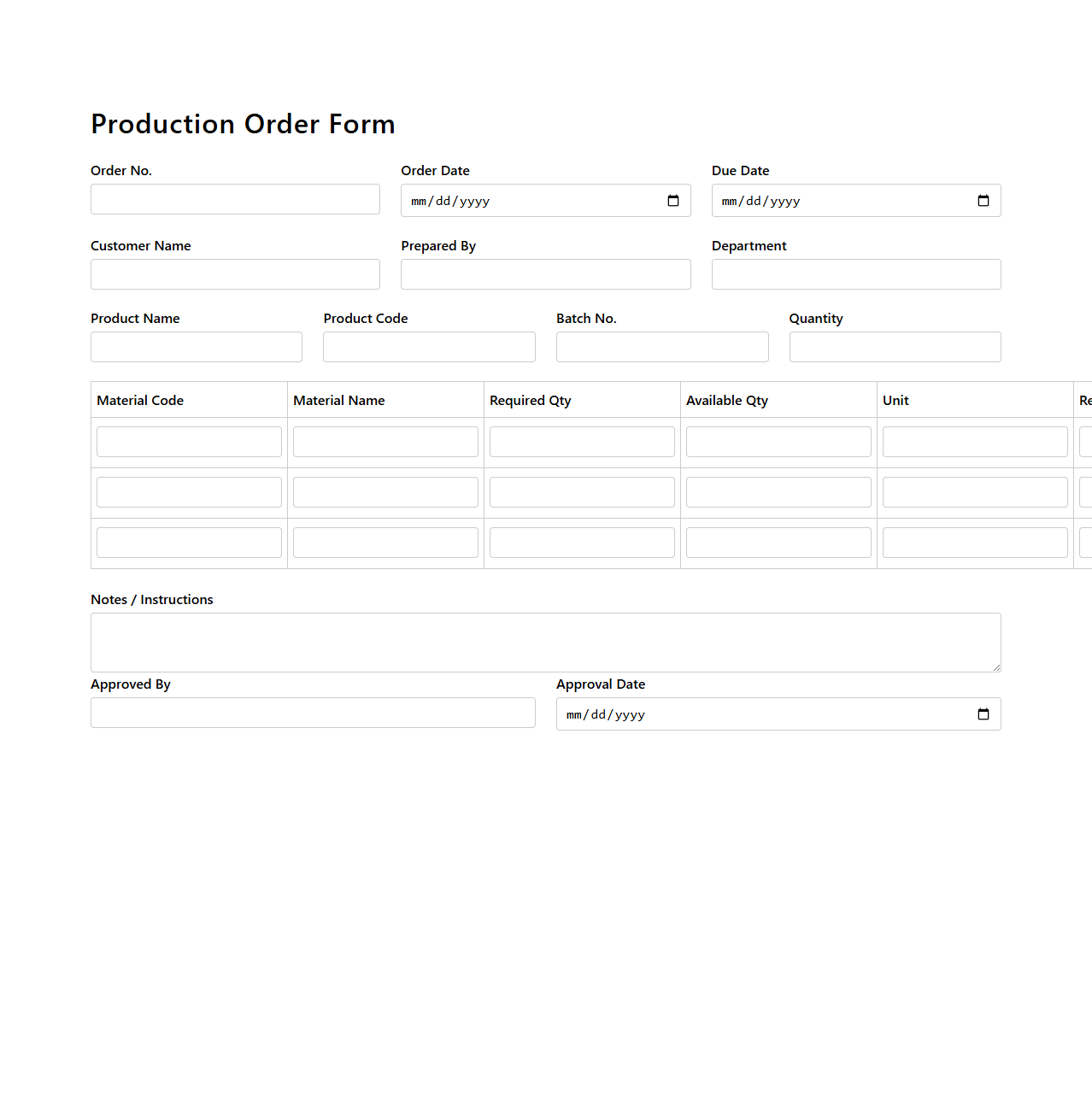

Production Order Form Template

A

Production Order Form Template is a standardized document used to outline the details necessary for manufacturing or production processes, including product specifications, quantities, deadlines, and resource allocation. It serves as a critical communication tool between planning and production teams to ensure accurate and efficient execution of orders. This template helps streamline workflow, monitor progress, and maintain quality control throughout the production cycle.

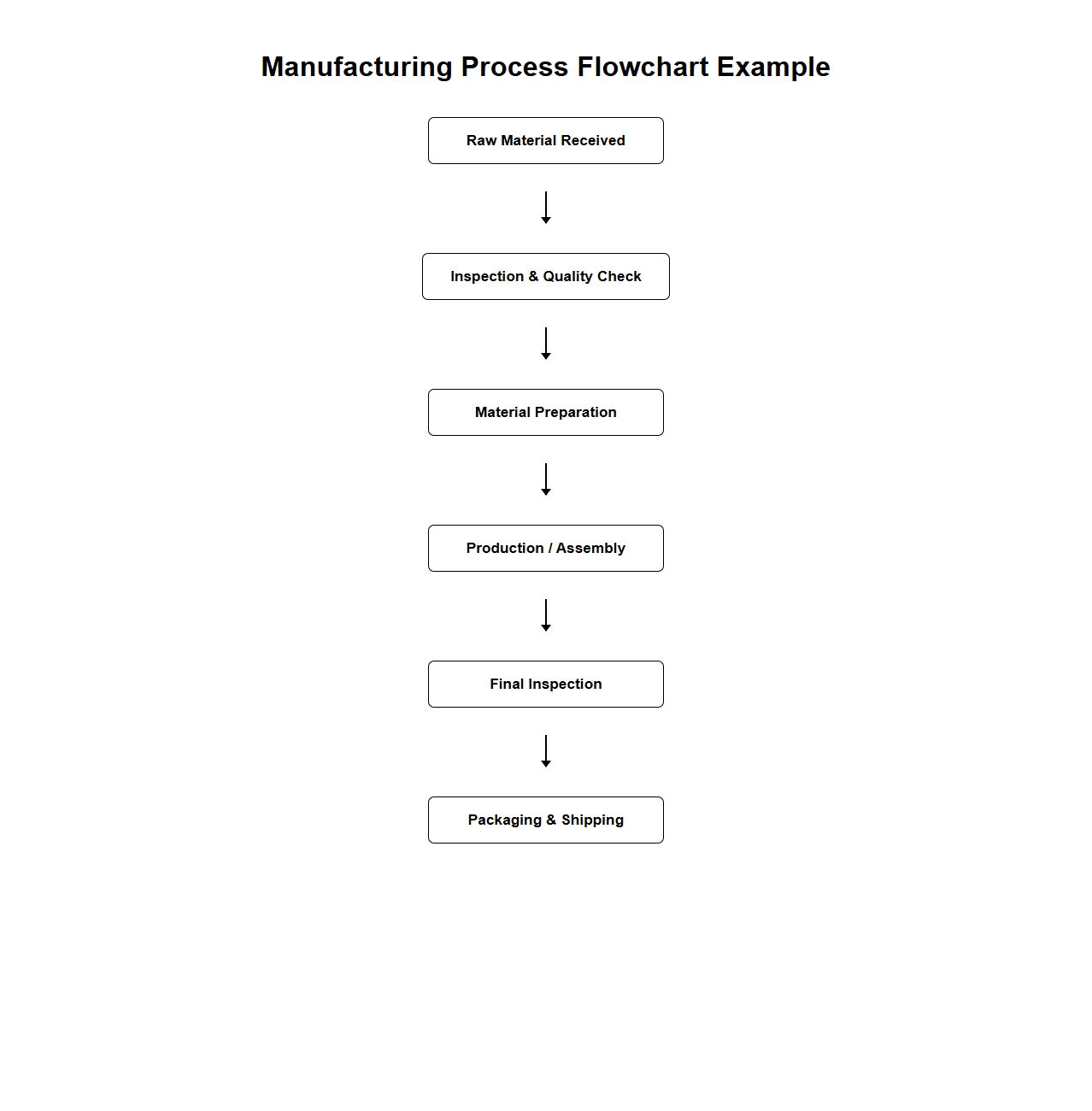

Manufacturing Process Flowchart Example

A

Manufacturing Process Flowchart Example document visually represents the sequential steps involved in a manufacturing operation, detailing each stage from raw material input to finished product output. It helps identify process inefficiencies, quality control checkpoints, and resource allocation for production optimization. This type of flowchart is essential for standardizing procedures, training employees, and facilitating continuous improvement in manufacturing workflows.

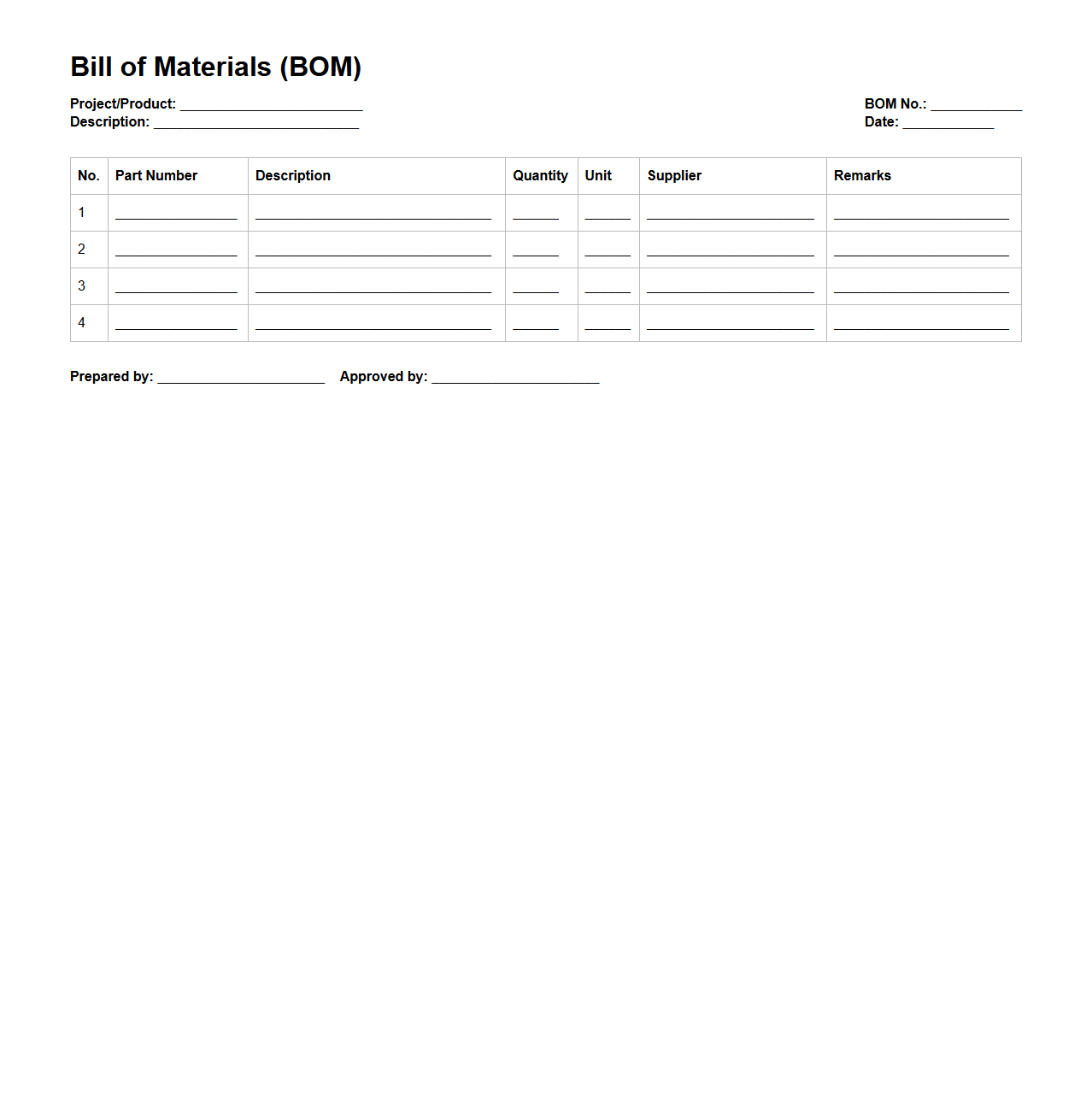

Bill of Materials (BOM) Sample

A

Bill of Materials (BOM) Sample document is a detailed list outlining the components, parts, and raw materials required to manufacture a product. It includes quantities, descriptions, part numbers, and specifications essential for production planning and inventory management. This document serves as a crucial reference for engineers, procurement teams, and manufacturers to ensure accurate assembly and cost control.

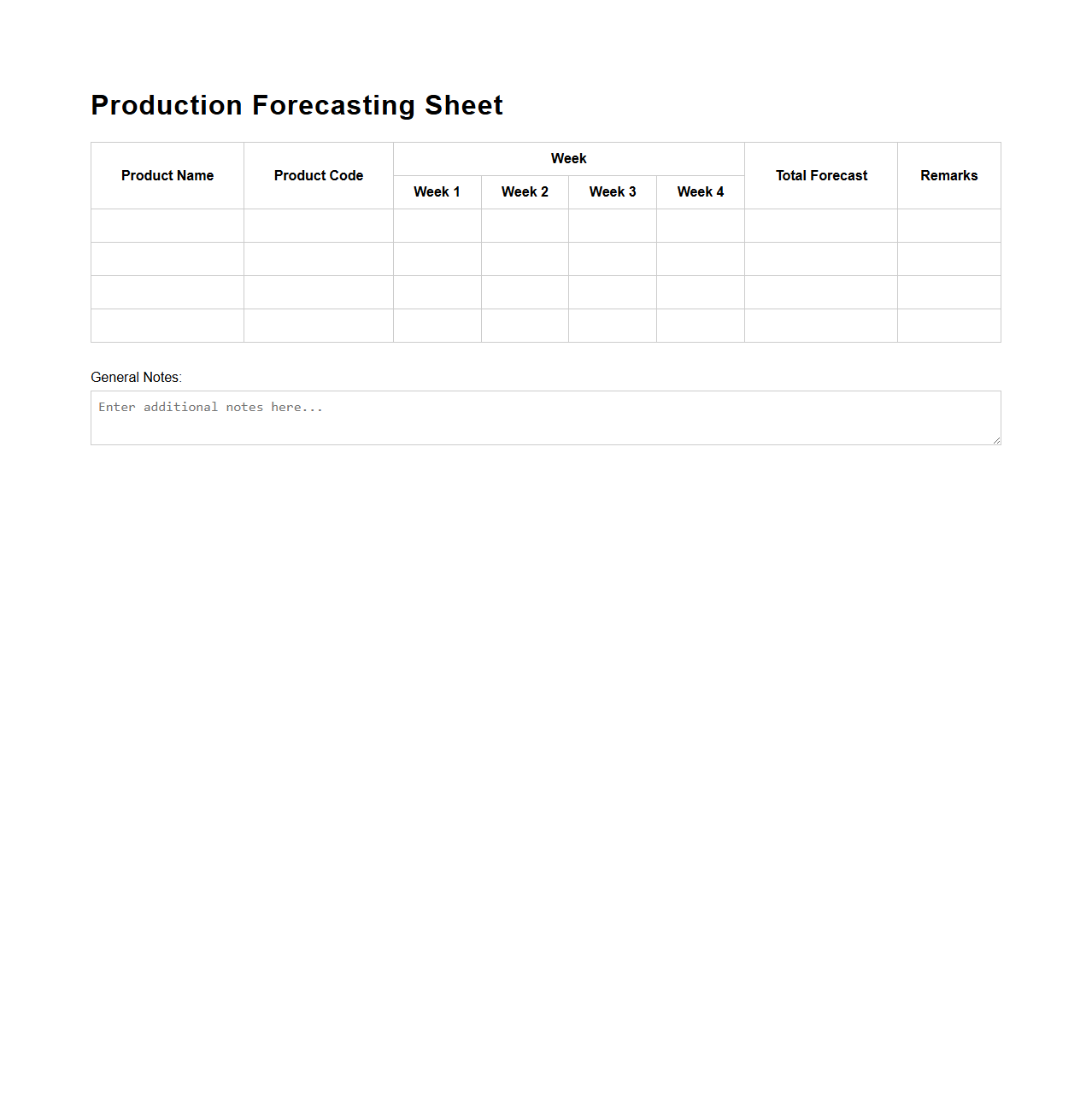

Production Forecasting Sheet for Factory Use

A

Production Forecasting Sheet for factory use is a detailed document that estimates future manufacturing output based on historical data, current orders, and market demand. It helps production managers allocate resources efficiently, schedule workforce shifts, and manage inventory levels to meet production targets. This tool enhances decision-making by providing a clear projection of production capacity and potential bottlenecks.

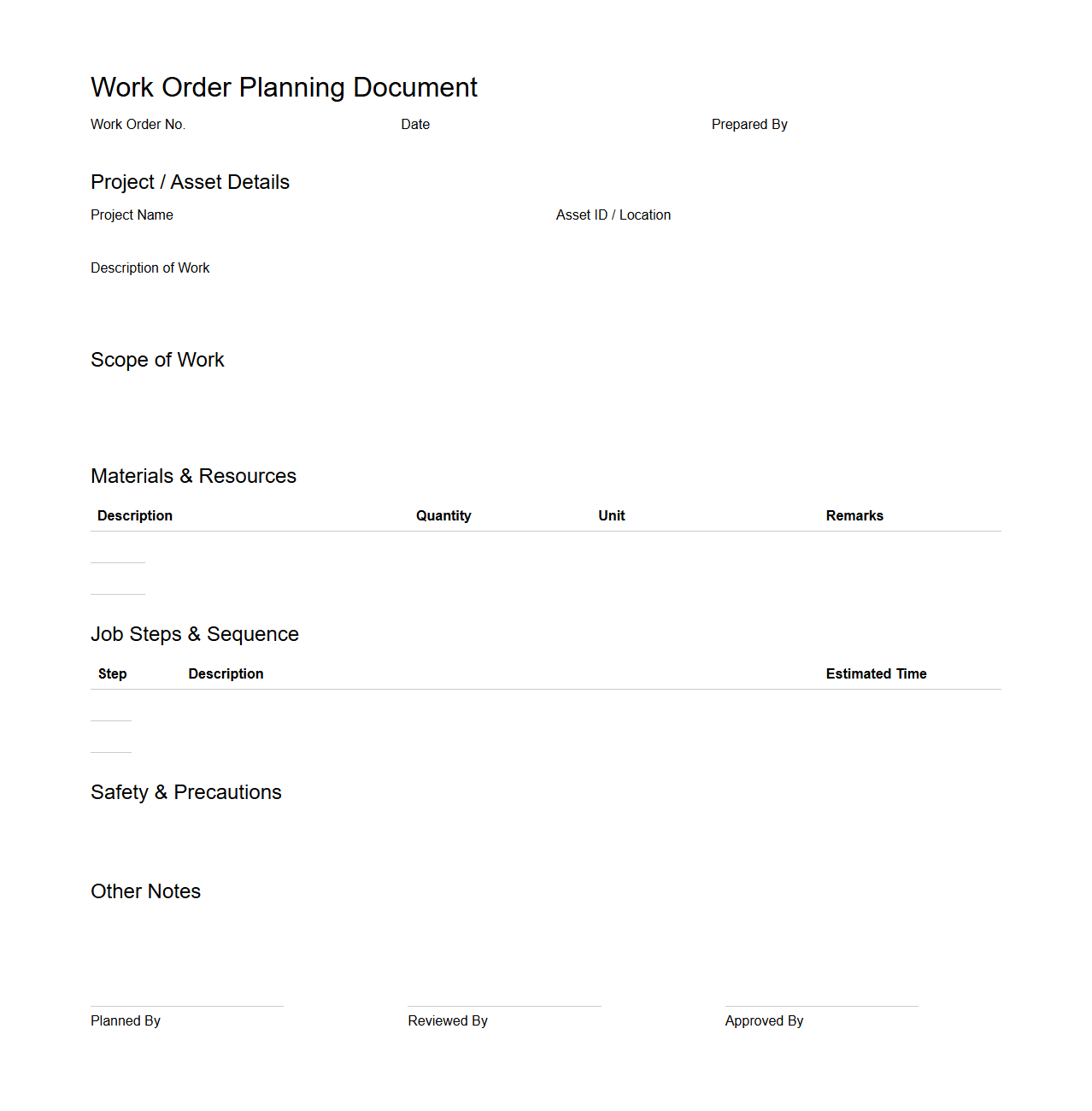

Work Order Planning Document Sample

A

Work Order Planning Document Sample serves as a template to systematically organize tasks, resources, and timelines for maintenance or project work. It outlines essential details such as scope, priority, required materials, assigned personnel, and estimated completion dates to ensure efficient execution. This document helps streamline workflows, improve communication, and reduce downtime in operational environments.

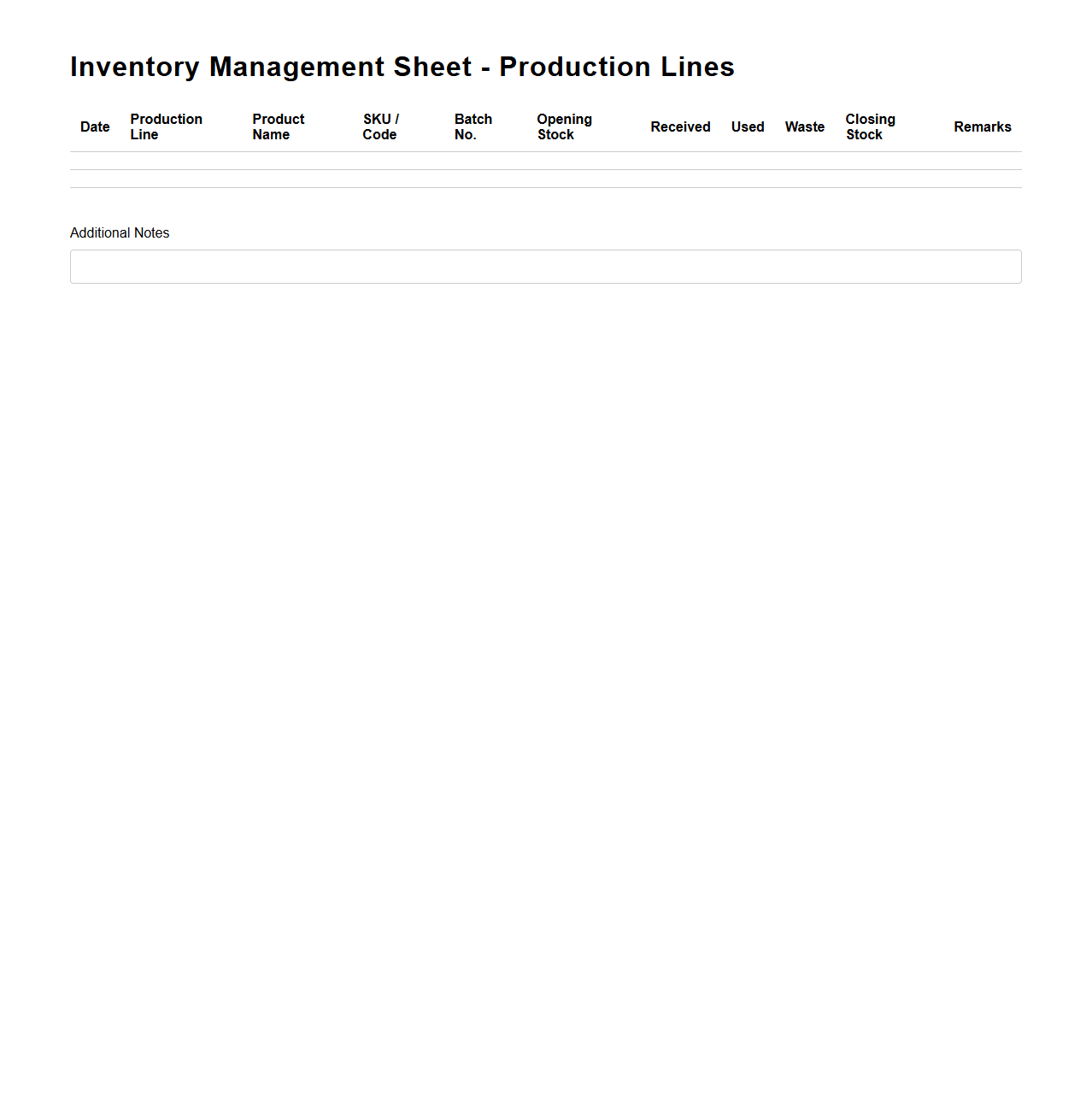

Inventory Management Sheet for Production Lines

An

Inventory Management Sheet for Production Lines is a crucial document used to track and control raw materials, work-in-progress, and finished goods within manufacturing processes. It enables efficient monitoring of stock levels, helps prevent production delays caused by shortages, and optimizes the ordering of supplies to maintain steady workflow. This sheet often includes columns for item names, quantities, batch numbers, and reorder points to ensure accurate and real-time inventory control.

What are the primary objectives outlined in the production planning document for manufacturing?

The production planning document primarily aims to optimize manufacturing efficiency by aligning resources with production goals. It focuses on reducing waste, minimizing delays, and ensuring timely delivery of products. These objectives help in maintaining a streamlined and cost-effective production process.

How does the document define the workflow and process sequencing for production tasks?

The document outlines a detailed workflow and process sequencing that ensures each production stage follows a logical order. It specifies task dependencies and the correct sequence to maximize productivity and avoid bottlenecks. This structured approach guarantees smooth transitions between different manufacturing phases.

What criteria are used in the document to establish inventory levels and material requirements?

Inventory levels and material requirements are established based on demand forecasts, production schedules, and safety stock considerations. The document uses just-in-time (JIT) principles to reduce excess inventory while avoiding stockouts. This ensures materials are available when needed without incurring unnecessary holding costs.

How does the production planning document address resource allocation and manpower scheduling?

The document details strategies for resource allocation and manpower scheduling to maximize workforce efficiency. It aligns staff shifts, machine availability, and skill sets with production needs to reduce downtime. Proper scheduling also enables flexibility to adapt to production changes or unexpected delays.

What key performance indicators (KPIs) are specified for monitoring production efficiency and output?

The production planning document identifies KPIs such as overall equipment effectiveness (OEE), production cycle time, and defect rates to track performance. These metrics provide insights into machine utilization, process efficiency, and product quality. Monitoring KPIs helps in continuous improvement and achieving production targets.

More Manufacturing Templates