A Process Change Notification Document Sample for Manufacturing Process serves as an essential tool to formally communicate modifications in production methods. It outlines specific changes, reasons, impact evaluation, and approval details to ensure consistency and maintain quality standards. Using this document helps streamline communication between engineering, quality, and production teams.

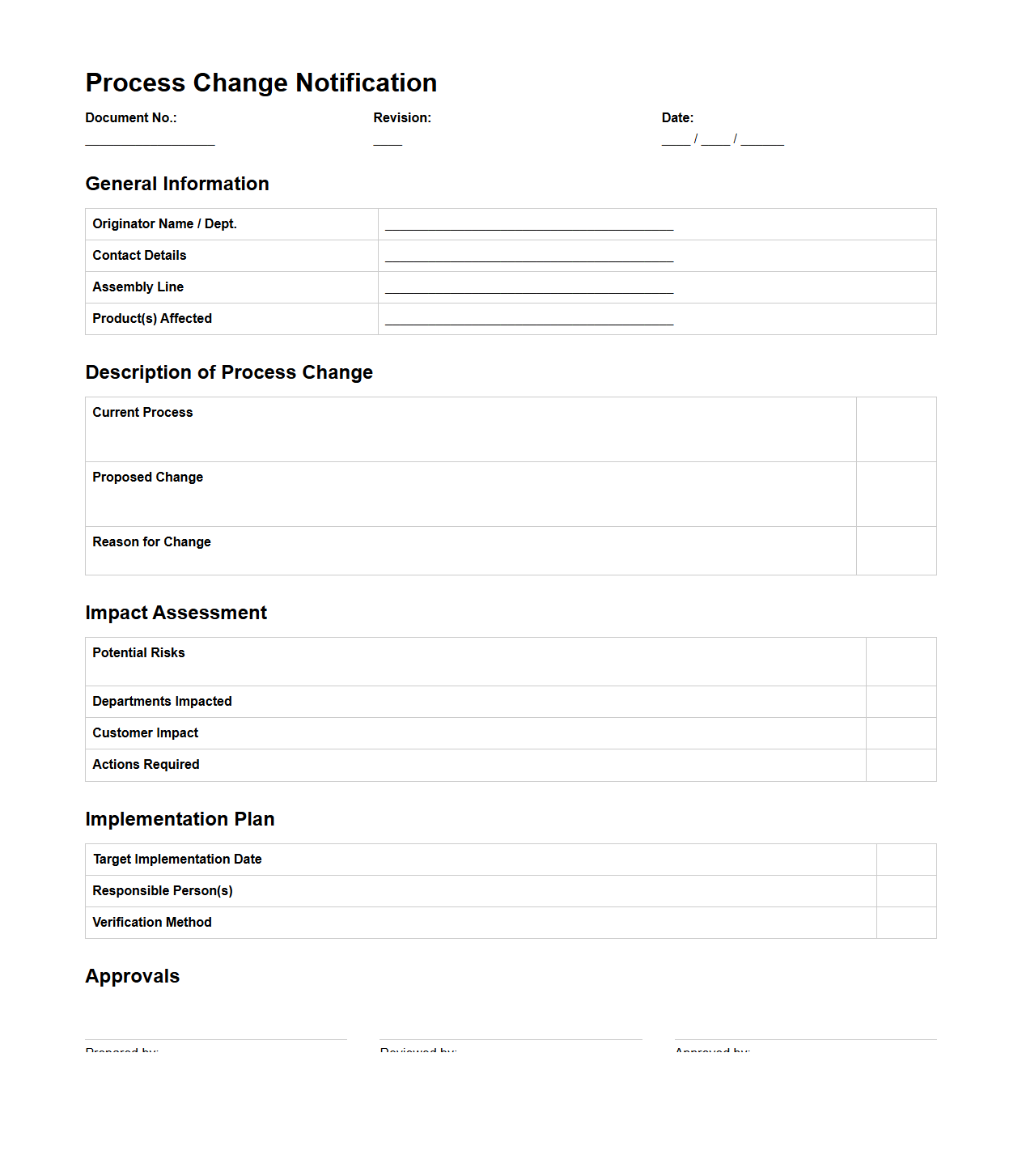

Process Change Notification Template for Assembly Line Adjustments

The

Process Change Notification Template for Assembly Line Adjustments is a structured document used to communicate modifications in production processes clearly and efficiently. It outlines the specific changes, their impact on workflow, and required actions to ensure smooth implementation on the assembly line. This template enhances coordination among teams, reduces errors, and supports continuous improvement in manufacturing operations.

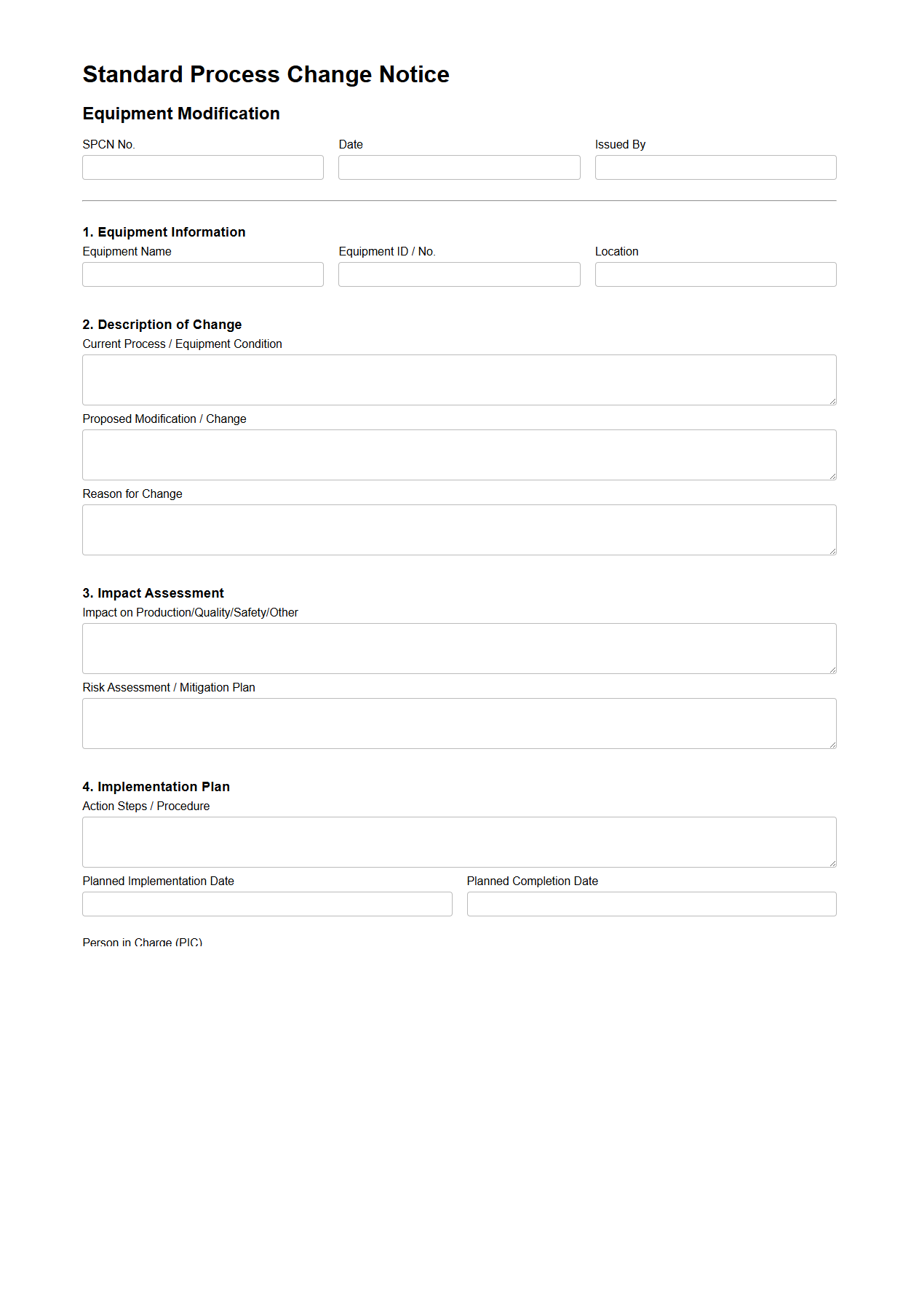

Standard Process Change Notice for Equipment Modification

The

Standard Process Change Notice for Equipment Modification document details the formal procedure for requesting, reviewing, and approving changes to existing equipment within a manufacturing or production environment. It ensures all modifications are systematically evaluated for impact on safety, compliance, and performance, maintaining operational integrity. This document serves as a critical control tool to track changes, communicate updates to relevant stakeholders, and uphold quality standards.

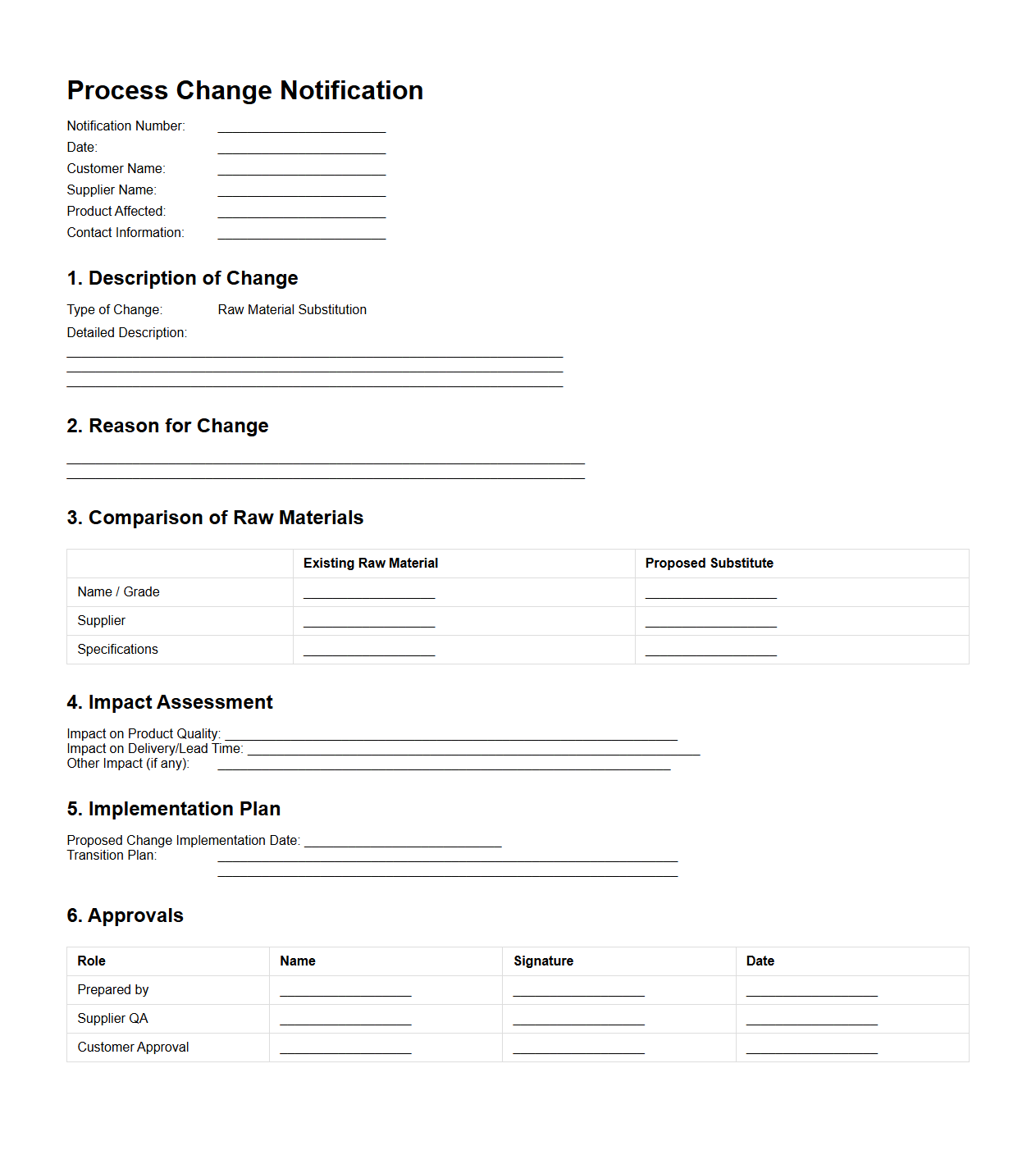

Process Change Notification Example for Raw Material Substitution

A

Process Change Notification (PCN) for Raw Material Substitution document serves as an official record detailing the replacement of one raw material with another in a manufacturing process. It includes critical information such as the reason for substitution, potential impacts on product quality, and updated compliance requirements. This document ensures all stakeholders are informed and aligned to maintain consistent production standards and regulatory adherence.

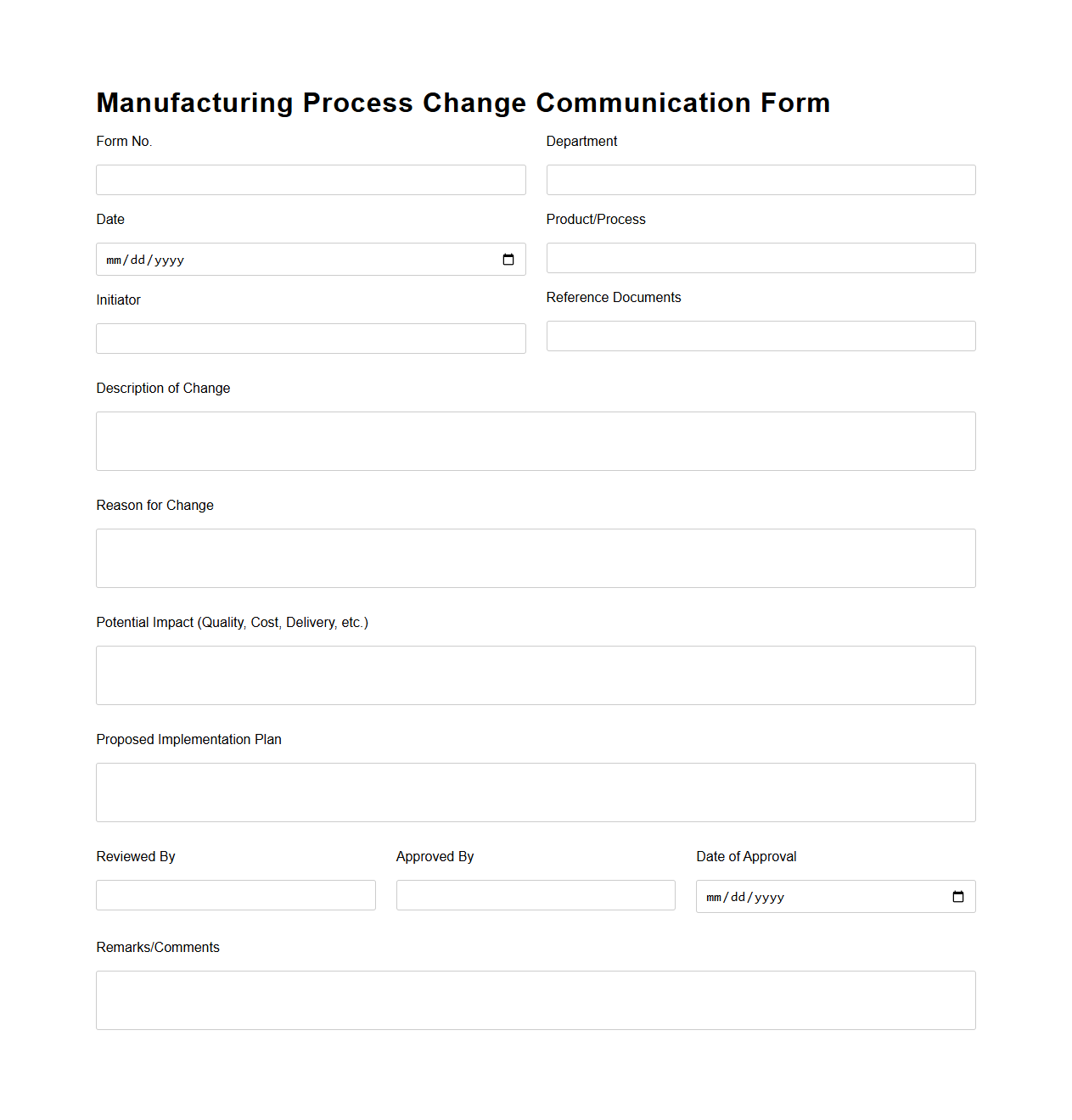

Manufacturing Process Change Communication Form

The

Manufacturing Process Change Communication Form is a critical document used to formally notify all relevant stakeholders of modifications in manufacturing methods, materials, or equipment. It ensures clear communication of process changes to maintain production quality, compliance with regulatory standards, and minimize disruptions. This form typically includes detailed descriptions of the change, reasons for implementation, affected products, and validation results to guarantee traceability and accountability.

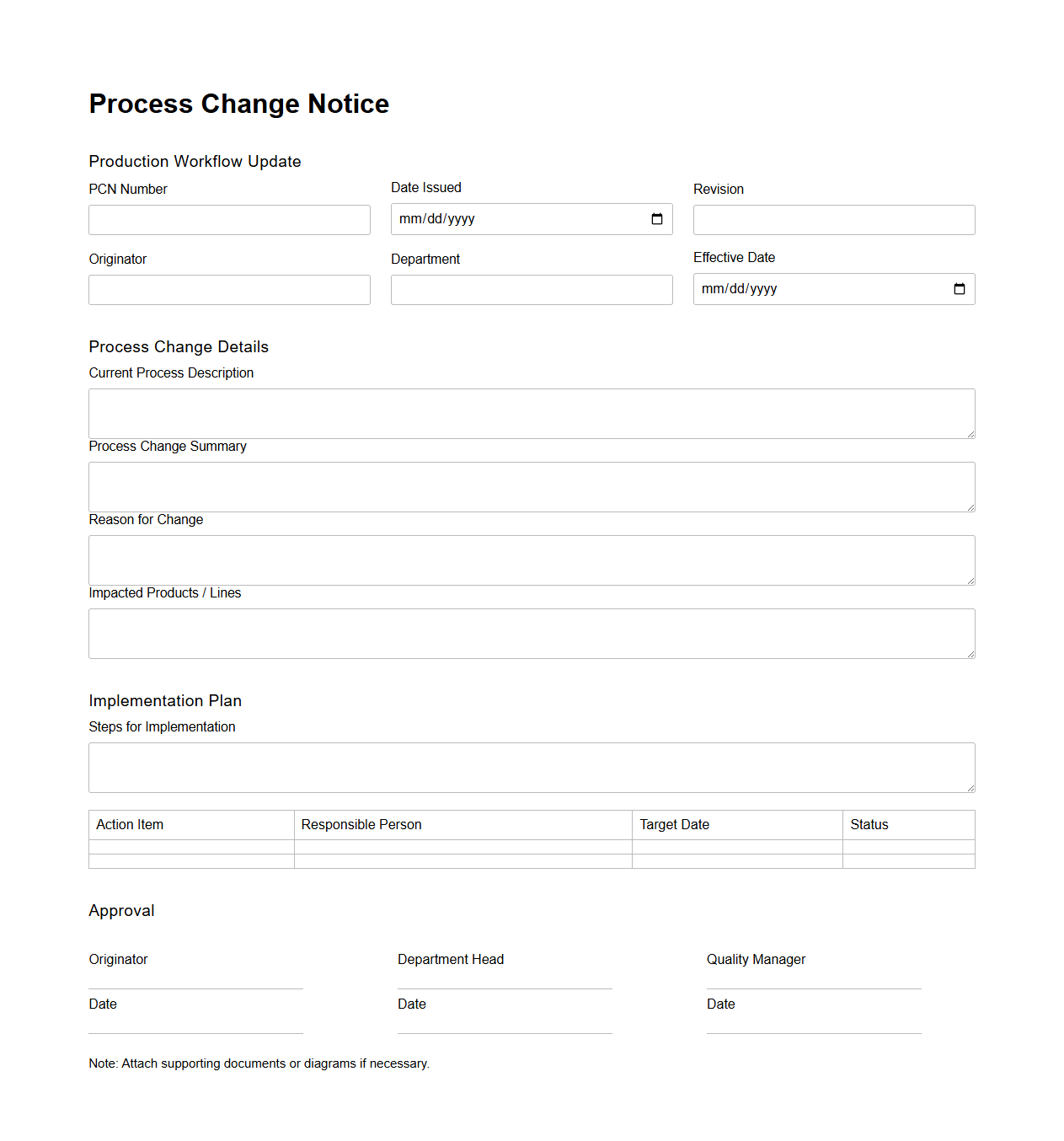

Process Change Notice Format for Production Workflow Updates

A

Process Change Notice Format for Production Workflow Updates document serves as a standardized template to formally communicate modifications in manufacturing procedures. It outlines detailed information such as the nature of the change, reasons behind the update, affected processes, implementation timeline, and responsible personnel. This document ensures clear, consistent communication across production teams, minimizing errors and facilitating smooth transitions during workflow adjustments.

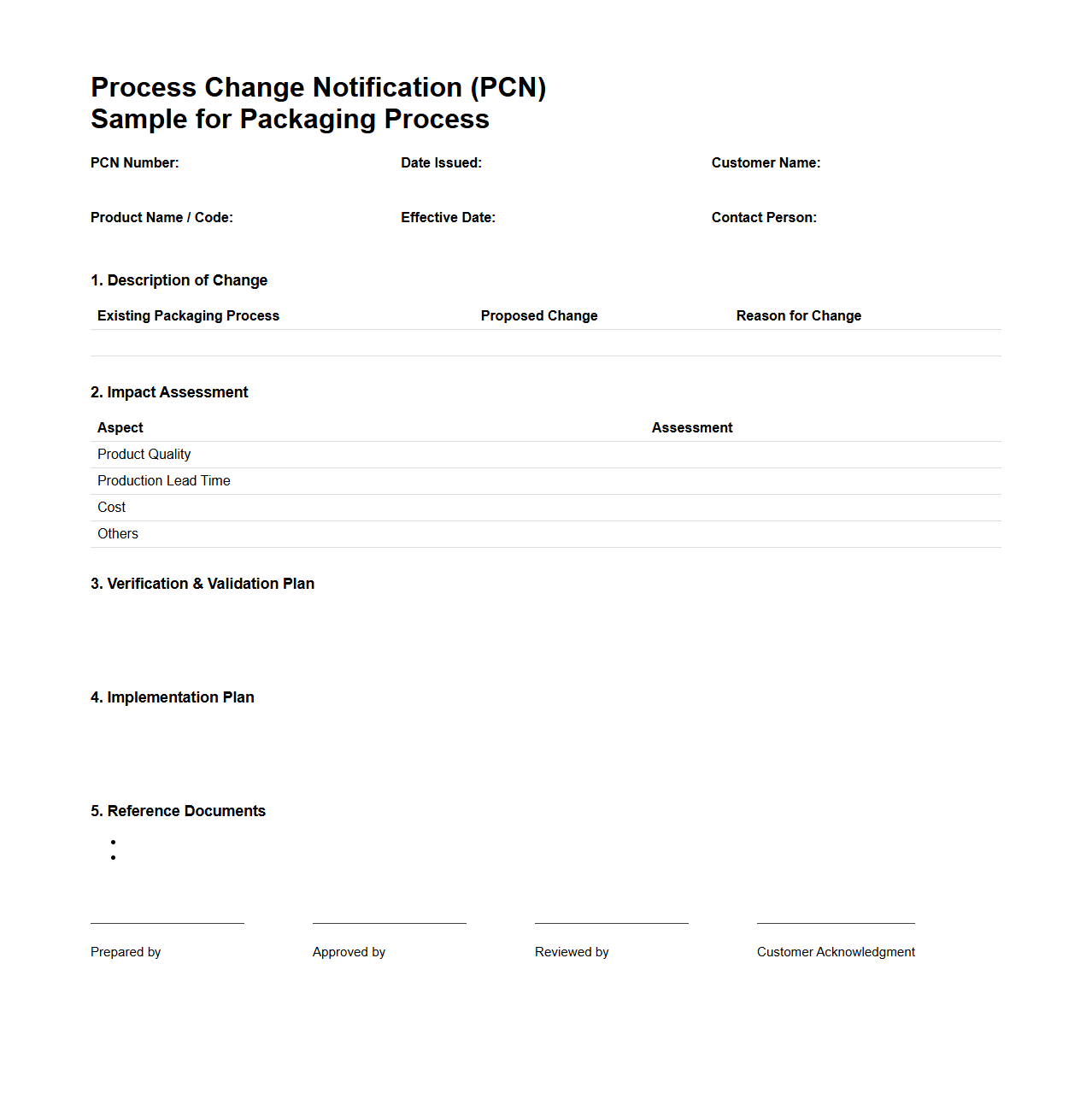

Process Change Notification Sample for Packaging Process

A

Process Change Notification Sample for Packaging Process document serves as a formal record to communicate modifications in packaging methods, materials, or equipment. It ensures stakeholders are informed about changes that may impact quality, compliance, or production timelines. This document helps maintain consistency and traceability within manufacturing and supply chain operations.

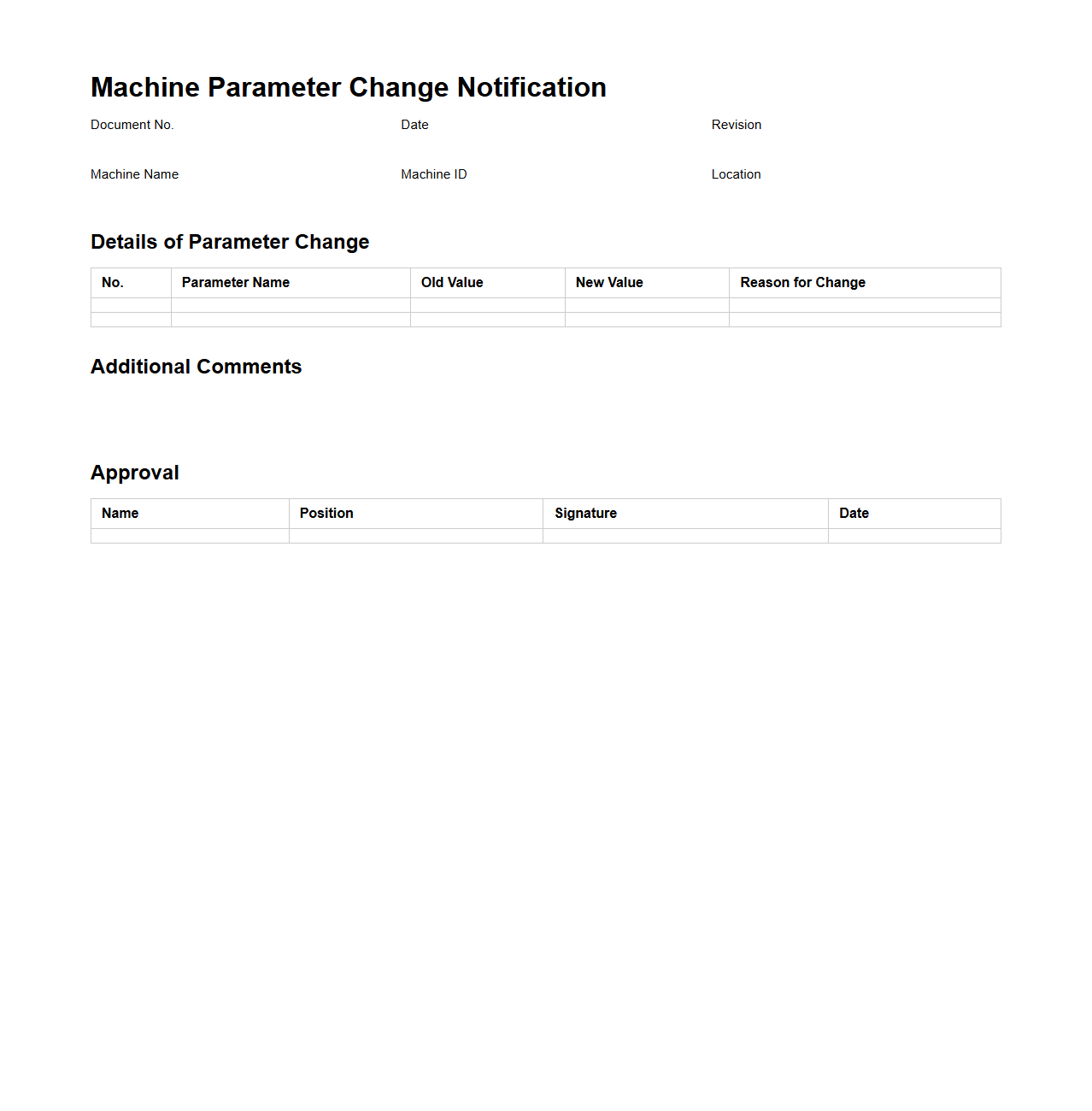

Document Sample for Machine Parameter Change Notification

A

Document Sample for Machine Parameter Change Notification outlines the formal communication template used to inform relevant personnel about modifications to machine settings. It includes detailed descriptions of parameter adjustments, the rationale behind changes, effective dates, and approval signatures to ensure traceability and accountability. This document is essential for maintaining operational consistency and minimizing downtime in manufacturing or industrial environments.

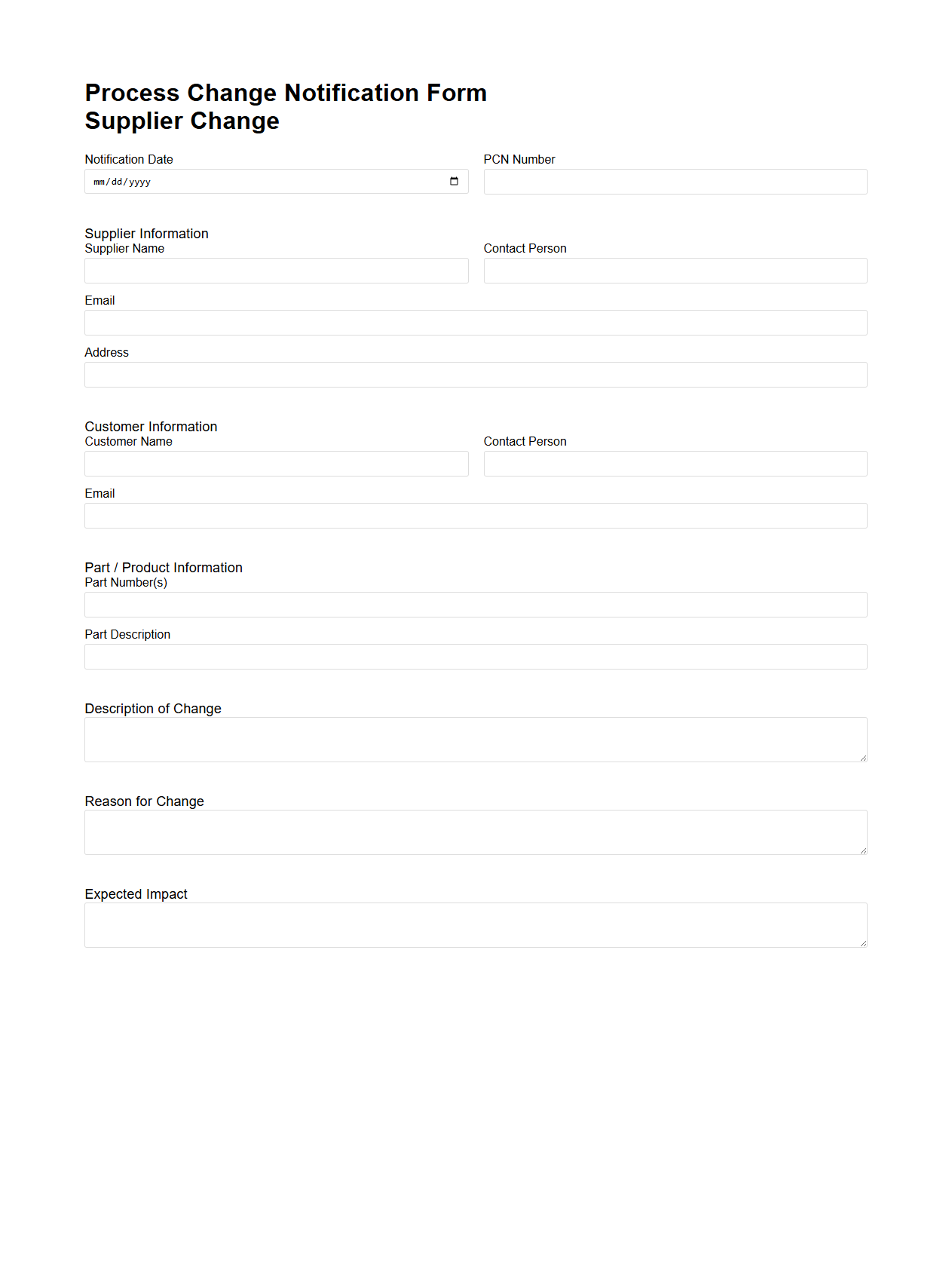

Process Change Notification Form for Supplier Change

A

Process Change Notification Form for Supplier Change document serves to formally communicate modifications in a supplier's processes that could impact product quality, delivery, or compliance. It ensures that all stakeholders are informed about changes such as new materials, altered production methods, or shifts in manufacturing locations. This document plays a crucial role in maintaining supply chain integrity and regulatory adherence by enabling timely review and approval of proposed changes.

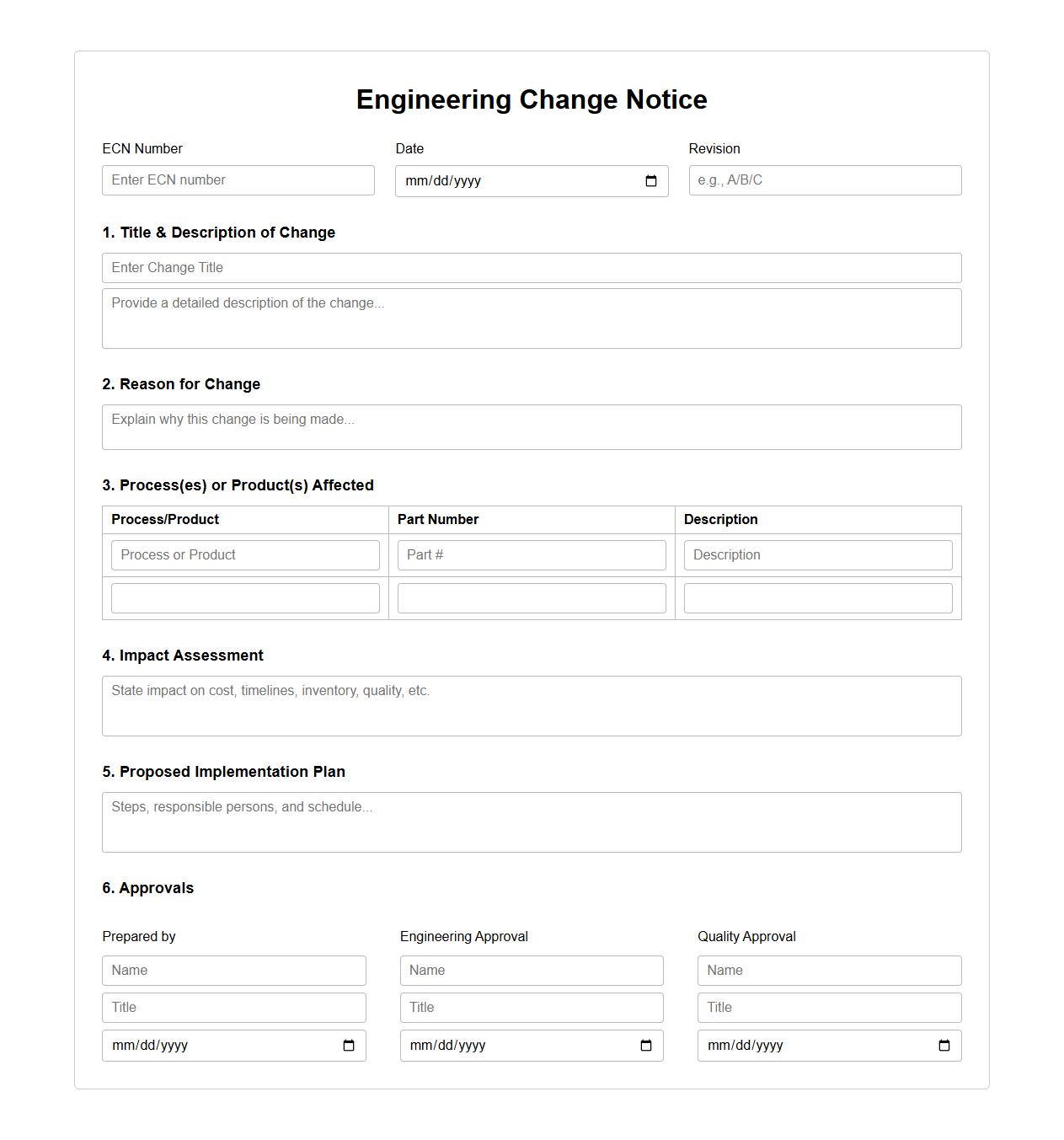

Engineering Change Notice Template for Manufacturing Processes

The

Engineering Change Notice (ECN) Template for manufacturing processes is a standardized document used to formally record and communicate modifications to product designs, materials, or production methods. This template ensures consistency, traceability, and clear authorization of changes, minimizing errors and disruptions in the manufacturing workflow. By capturing detailed information such as change justification, impact analysis, and approval signatures, the ECN template supports efficient implementation and quality control within production environments.

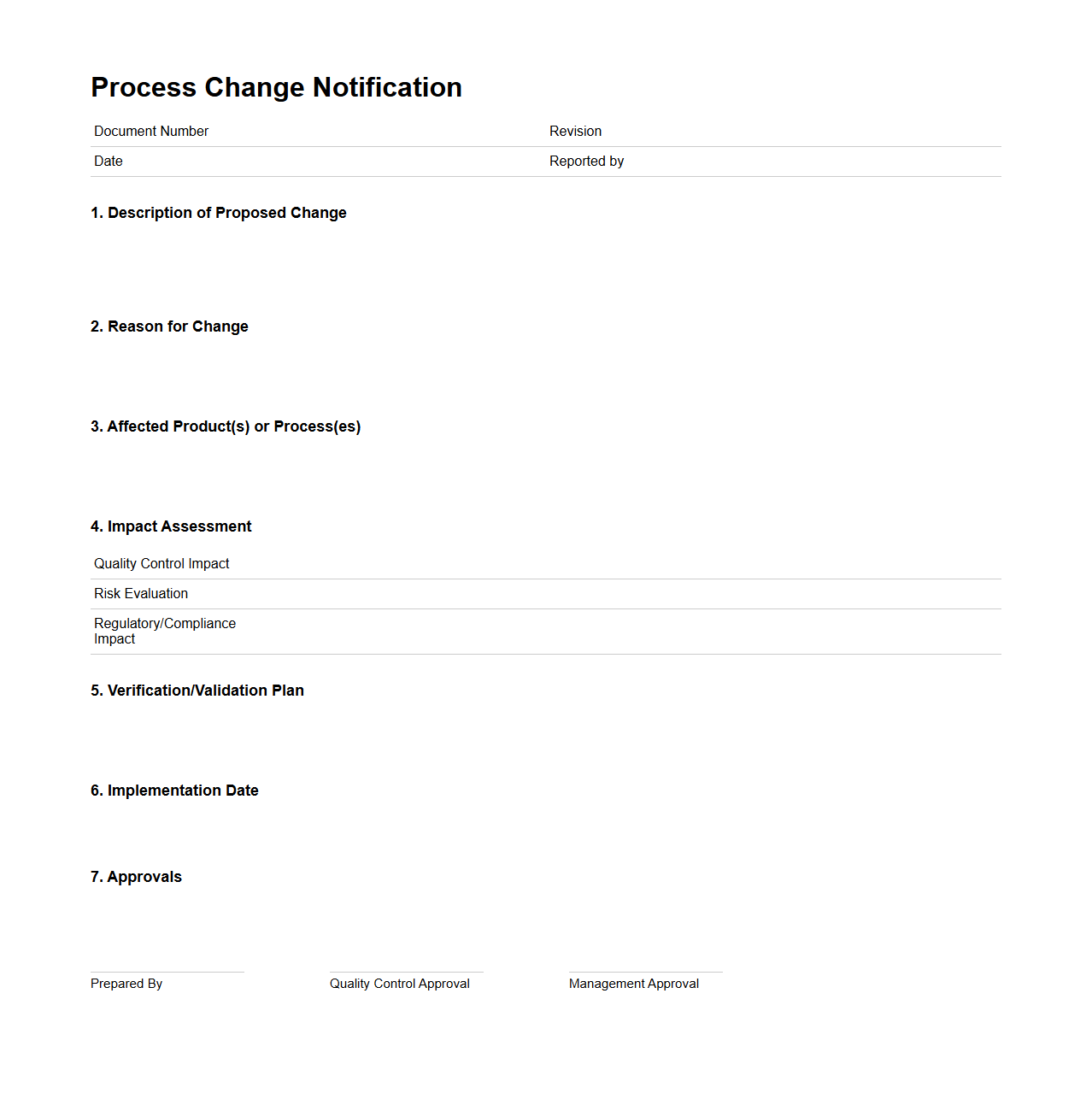

Process Change Notification Example for Quality Control Alterations

A

Process Change Notification (PCN) for Quality Control Alterations document details specific modifications in manufacturing or inspection procedures to maintain product consistency. It outlines the nature of the change, rationale, and the impact on quality standards, ensuring compliance and traceability. This document serves as a formal communication tool to inform stakeholders about adjustments that affect quality assurance measures.

What are the primary reasons for issuing a Process Change Notification (PCN) in manufacturing?

The primary reasons for issuing a Process Change Notification (PCN) include informing stakeholders about significant modifications in manufacturing that may affect product quality or reliability. PCNs ensure transparency and facilitate risk management by formally documenting changes in processes, materials, or equipment. This notification helps maintain compliance with industry standards and customer requirements.

Which specific process steps or parameters are being altered according to the sample PCN document?

The sample PCN document specifies changes to key process steps and parameters such as temperature settings, material sourcing, and assembly line configurations. These modifications aim to improve efficiency or adapt to new materials while maintaining product integrity. Detailed descriptions provide clarity on which exact stages of production will be affected by the update.

How does the PCN define the expected impact of the process change on product quality and performance?

The PCN clearly outlines the expected impact, stating that the process change will maintain or enhance product quality and performance. It includes data from testing or previous runs to support claims of stability and reliability post-change. Potential risks and mitigations are also discussed to reassure customers of continued product excellence.

What methods for verification or validation of the new process are described in the document?

The document describes verification methods such as process qualification, statistical analysis, and product testing to validate the new process. It emphasizes the use of control samples and trend monitoring to ensure consistent results. Validation plans include timelines and criteria for successful implementation before full production.

Who are the key stakeholders or departments required to review and approve the process change in the PCN sample?

The PCN sample identifies key stakeholders including the quality assurance, manufacturing, engineering, and supply chain departments. These groups collaborate to review technical, operational, and logistical aspects of the change. Final approval requires consensus from management and relevant regulatory bodies to ensure comprehensive oversight.

More Manufacturing Templates