A Finished Goods Inspection Document Sample for Production Output provides a standardized template to systematically verify product quality before shipment. This document includes critical inspection criteria such as dimensions, appearance, functionality, and compliance with specifications. Utilizing this sample ensures consistent quality control and helps identify defects promptly, enhancing customer satisfaction and reducing returns.

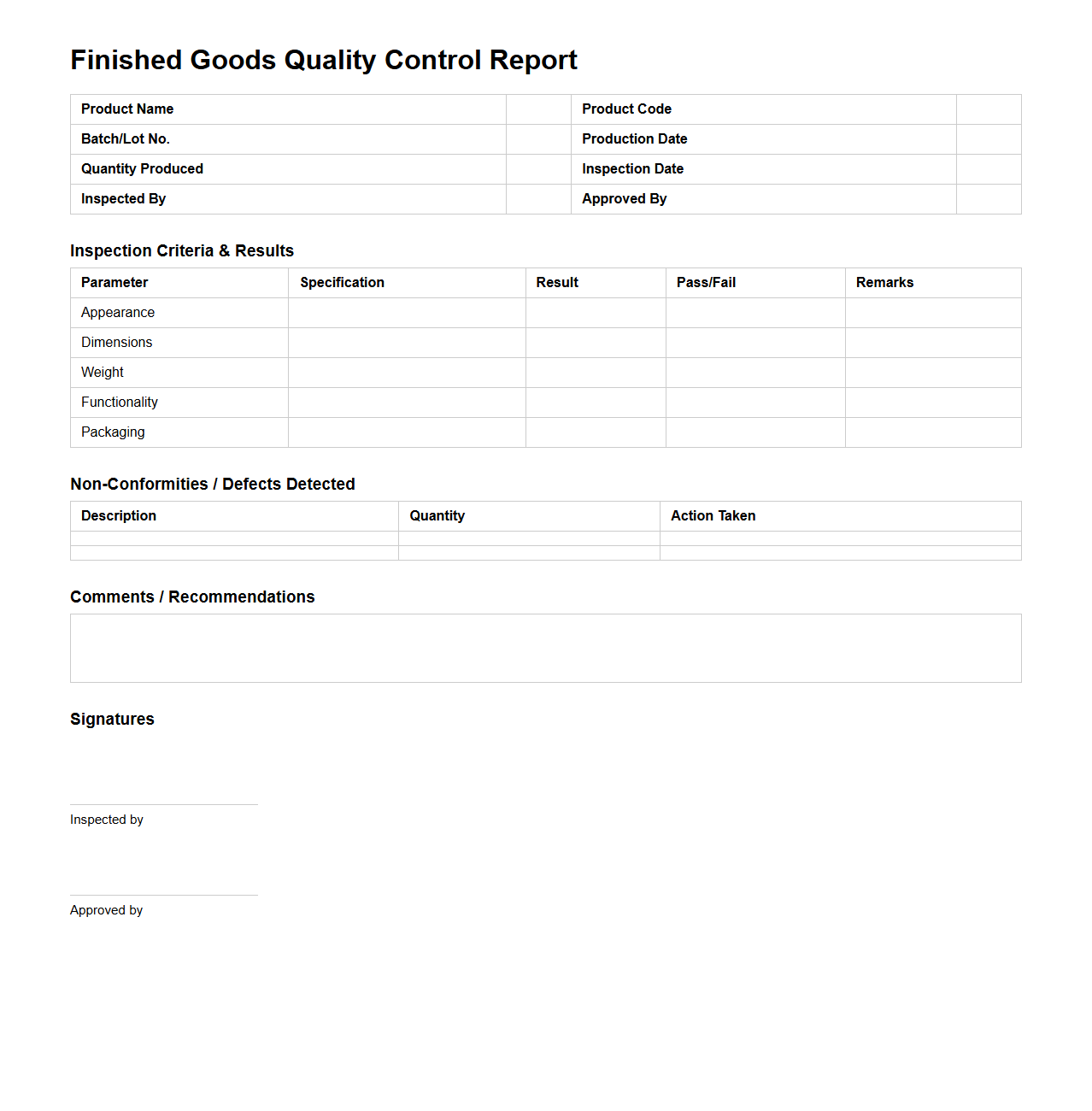

Finished Goods Quality Control Report Template

A

Finished Goods Quality Control Report Template is a standardized document designed to systematically record and assess the quality parameters of final products before shipment or distribution. It includes critical inspection data such as defect rates, compliance with specifications, and test results to ensure products meet regulatory and company standards. Utilizing this template helps maintain product consistency, reduce returns, and improve customer satisfaction through thorough quality verification.

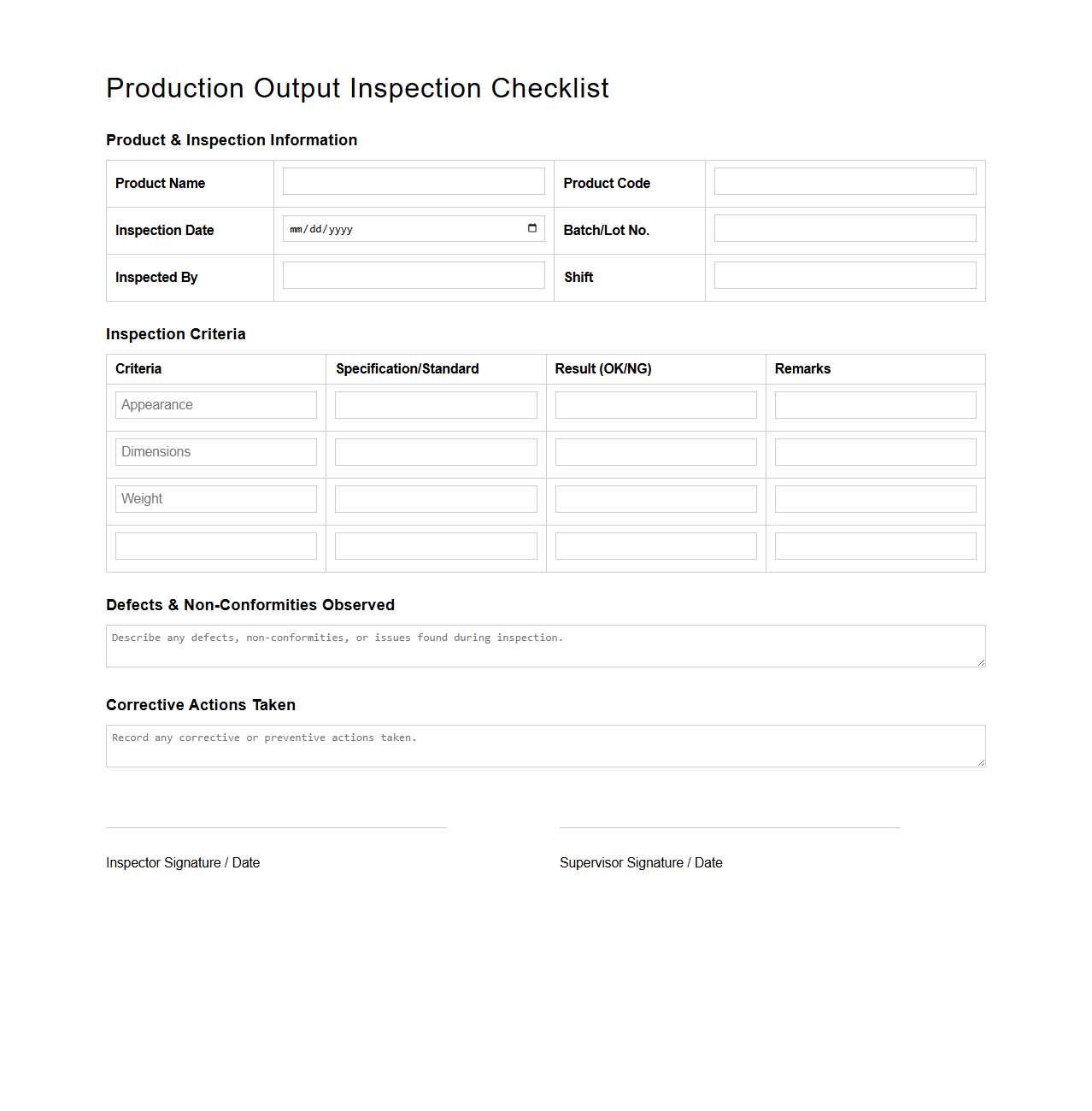

Production Output Inspection Checklist

The

Production Output Inspection Checklist document serves as a critical tool for verifying product quality and compliance during the manufacturing process. It outlines specific criteria and standards that each product must meet before proceeding to the next stage or final delivery. This checklist helps identify defects, ensures adherence to production specifications, and supports consistent quality control across all output units.

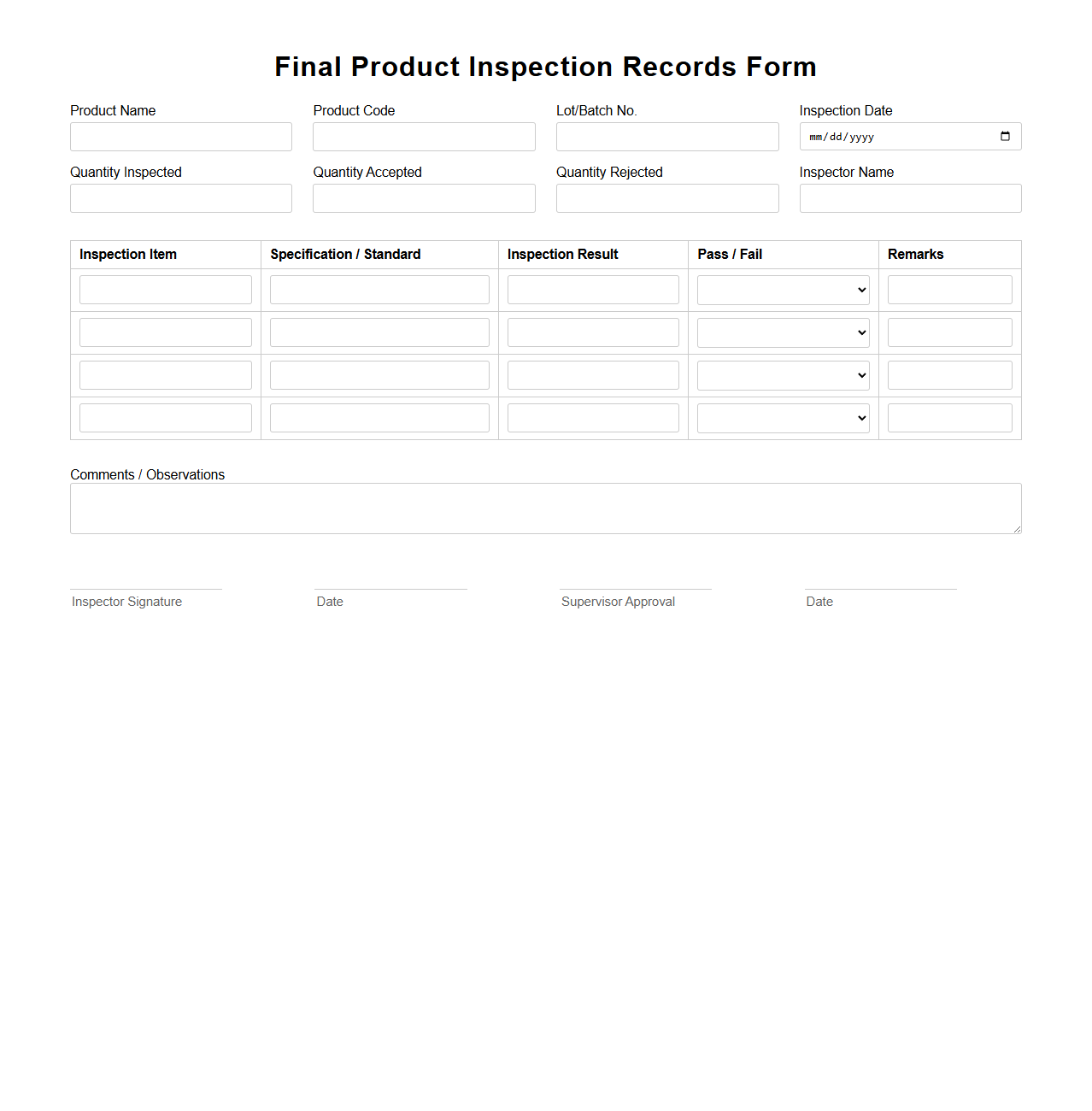

Final Product Inspection Records Form

The

Final Product Inspection Records Form document is a critical quality control tool used to verify that finished products meet specified standards before shipment or release. It systematically records inspection results, including measurements, defects, and compliance status, ensuring traceability and accountability in manufacturing processes. This form supports regulatory requirements and helps maintain product consistency by documenting all inspection findings in a standardized format.

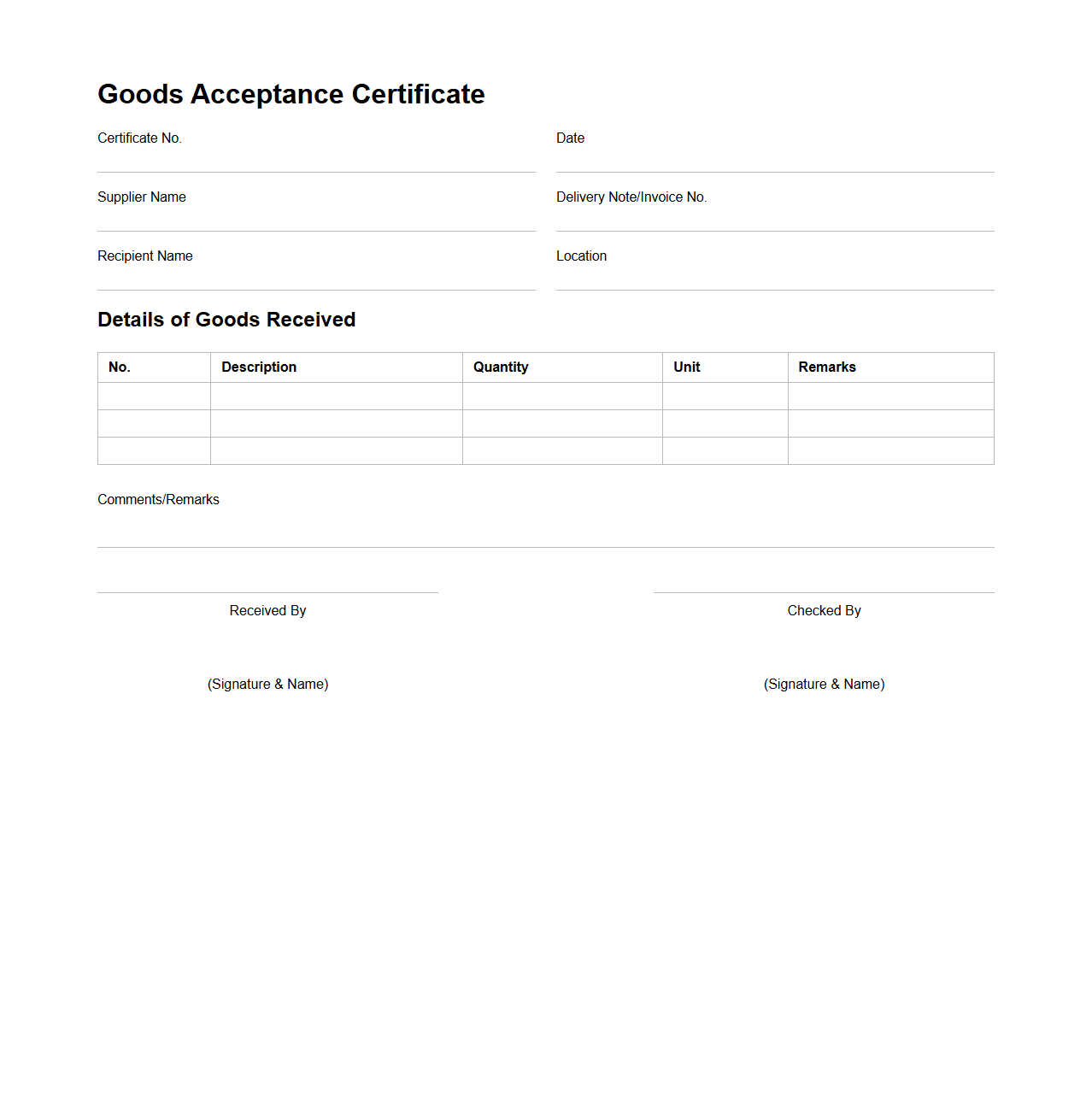

Goods Acceptance Certificate Sample

A

Goods Acceptance Certificate Sample document serves as official proof that delivered goods have been received in satisfactory condition and meet the specified requirements. It typically includes details such as the description of goods, quantity, delivery date, and signatures of both the supplier and receiver. This document is essential for maintaining accurate transaction records and facilitating smooth payment or warranty processes.

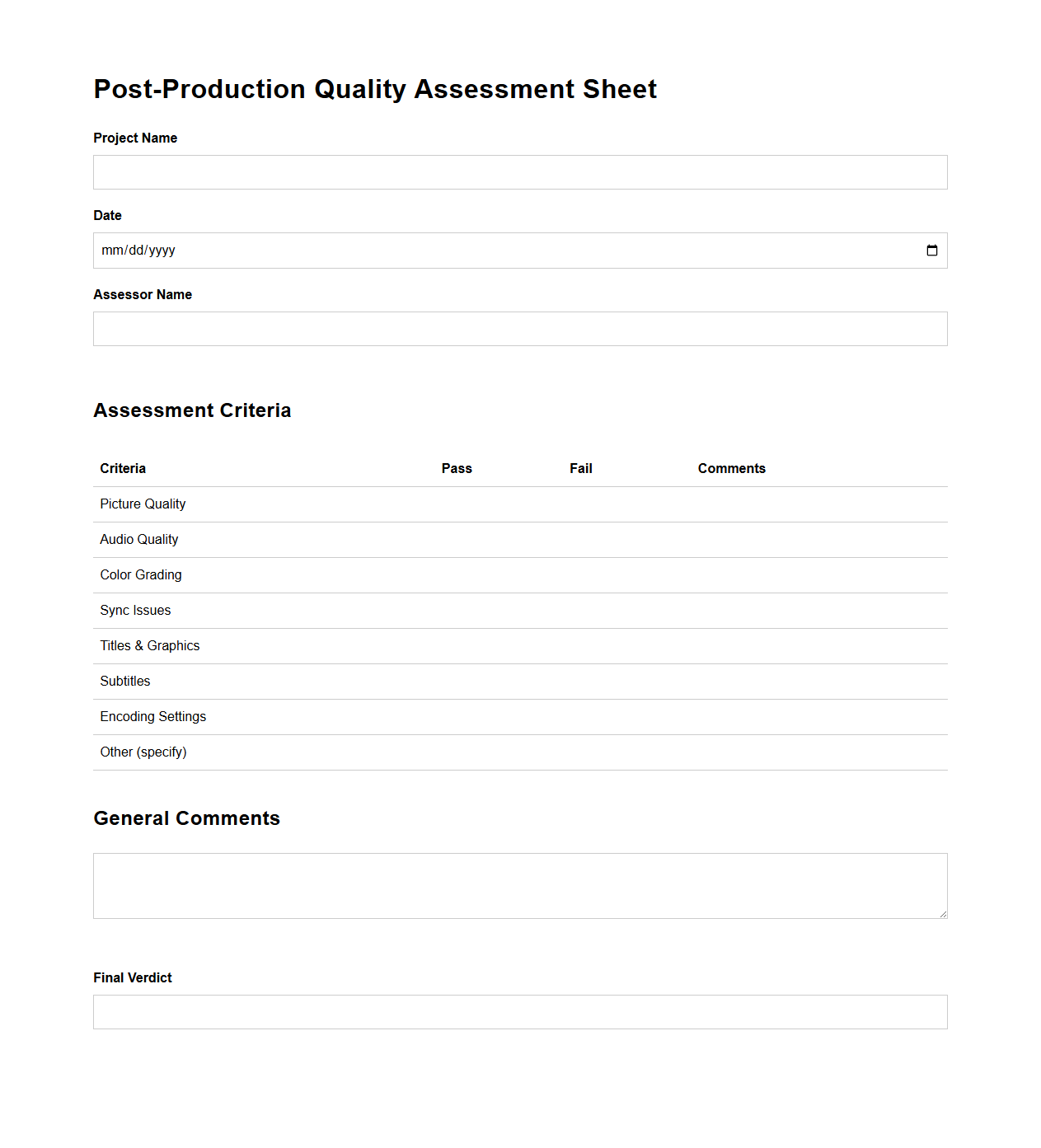

Post-Production Quality Assessment Sheet

The

Post-Production Quality Assessment Sheet document is a critical tool used to evaluate the final output of audio, video, or film projects, ensuring all technical and creative standards are met before release. It systematically records key quality metrics such as color grading accuracy, audio clarity, synchronization, and visual effects consistency. This document facilitates effective communication between production teams and quality controllers, helping to identify and correct any discrepancies promptly.

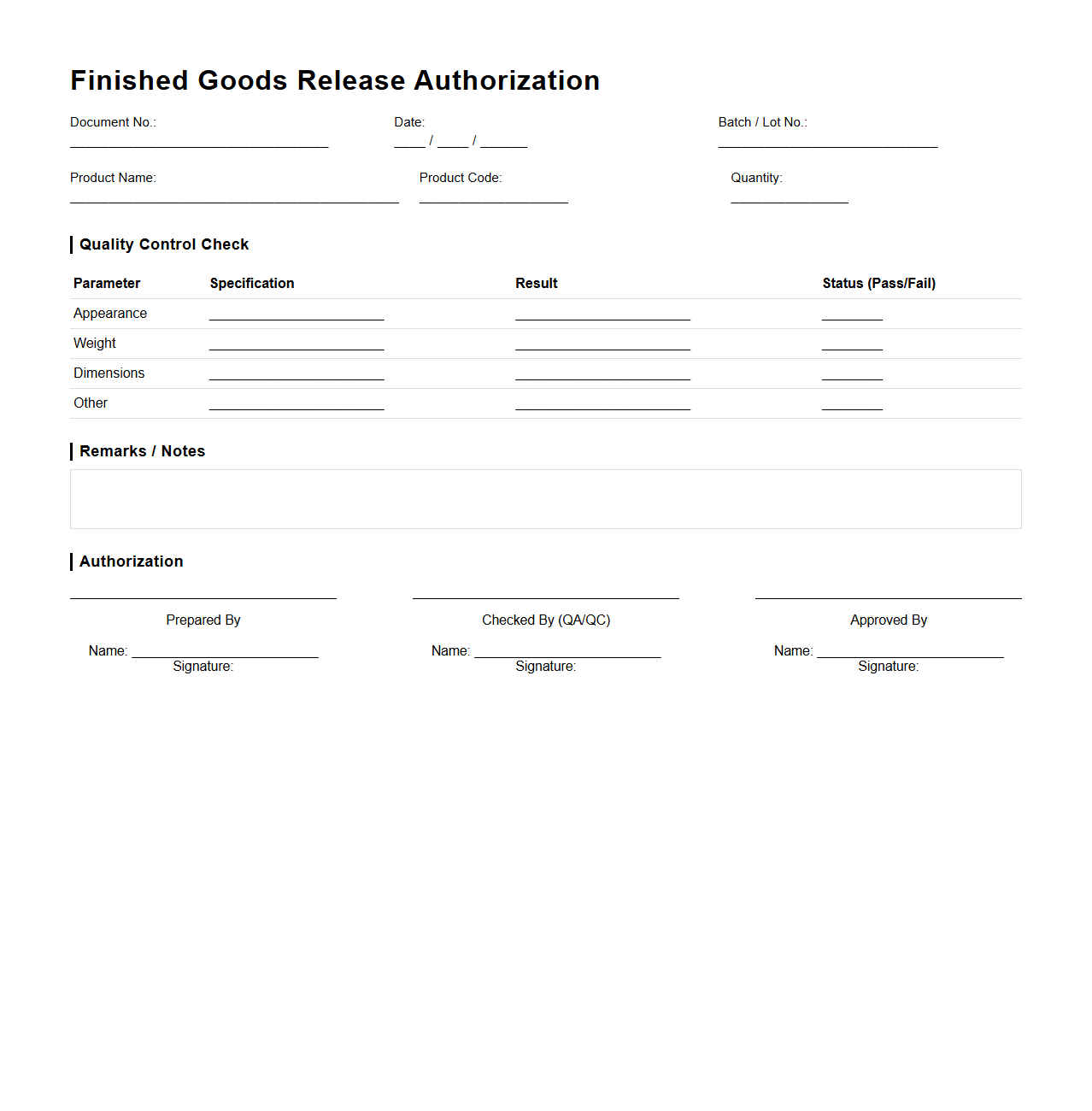

Finished Goods Release Authorization Document

The

Finished Goods Release Authorization Document is a critical component in the supply chain and quality control processes, ensuring that manufactured products meet all required specifications before they are shipped to customers. This document verifies that all production, inspection, and testing activities have been completed and authorized by designated personnel. It serves as formal approval to release the finished goods from inventory, confirming compliance with regulatory standards and company quality policies.

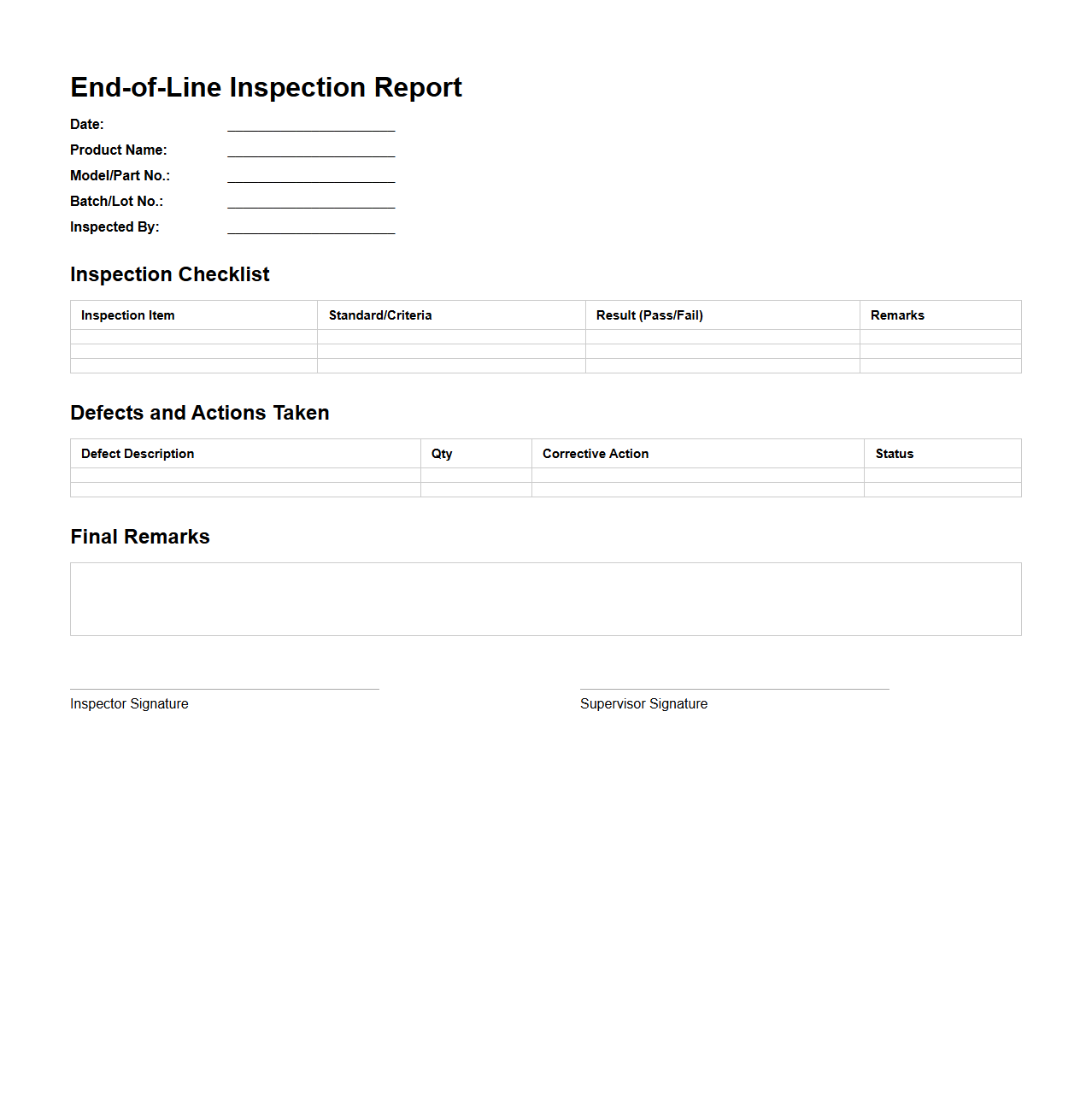

End-of-Line Inspection Report Format

The

End-of-Line Inspection Report Format document is a standardized template used to systematically record the final quality checks of products before they leave the production line. It ensures consistent documentation of inspection results, defects, and compliance with quality standards, facilitating traceability and accountability in manufacturing processes. This format typically includes fields for product identification, inspection criteria, defect categories, and inspector remarks to maintain thorough quality control.

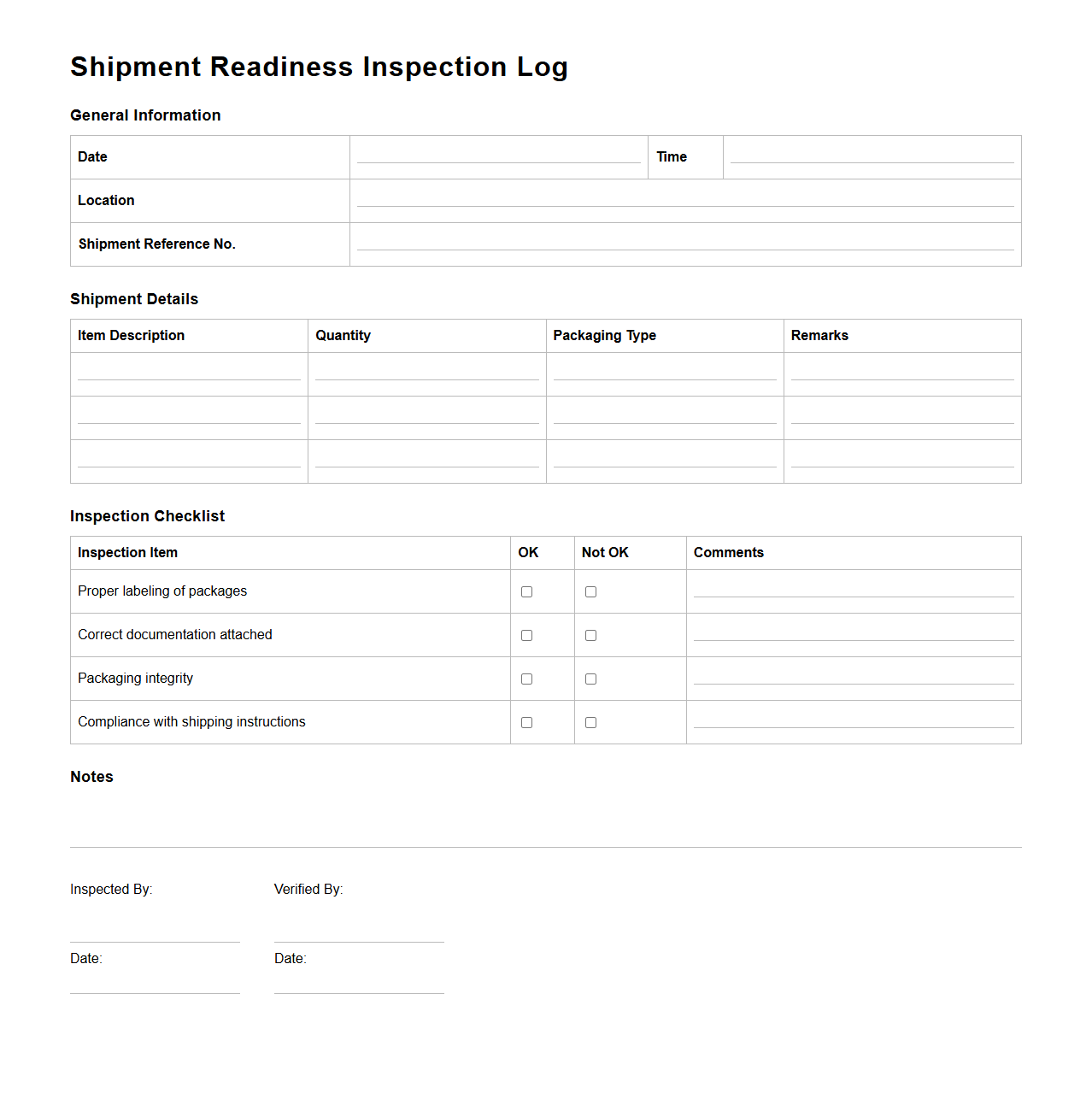

Shipment Readiness Inspection Log

The

Shipment Readiness Inspection Log document is a critical record used to verify that all shipment requirements and quality standards are met before dispatch. It includes detailed checks on packaging integrity, labeling accuracy, and compliance with regulatory guidelines to ensure products are shipment-ready. Maintaining this log helps prevent delays, damage, and non-compliance issues during transit.

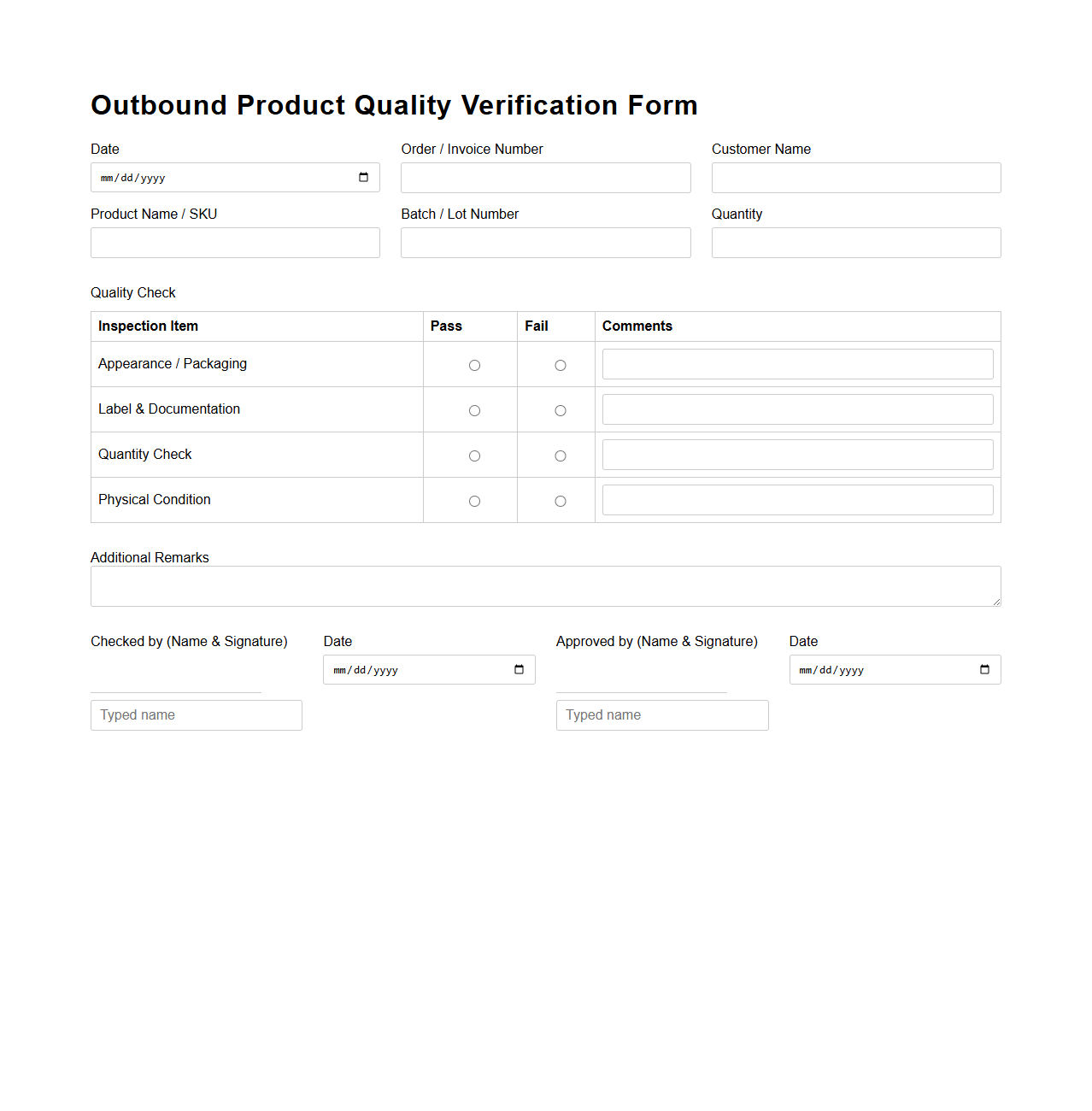

Outbound Product Quality Verification Form

The

Outbound Product Quality Verification Form is a critical document used to ensure that products leaving the manufacturing or warehouse facility meet predefined quality standards. It details specific inspection criteria such as packaging integrity, labeling accuracy, and product condition, helping to prevent customer dissatisfaction and returns. This form serves as a formal record that quality checks have been performed, supporting compliance with industry regulations and internal quality assurance policies.

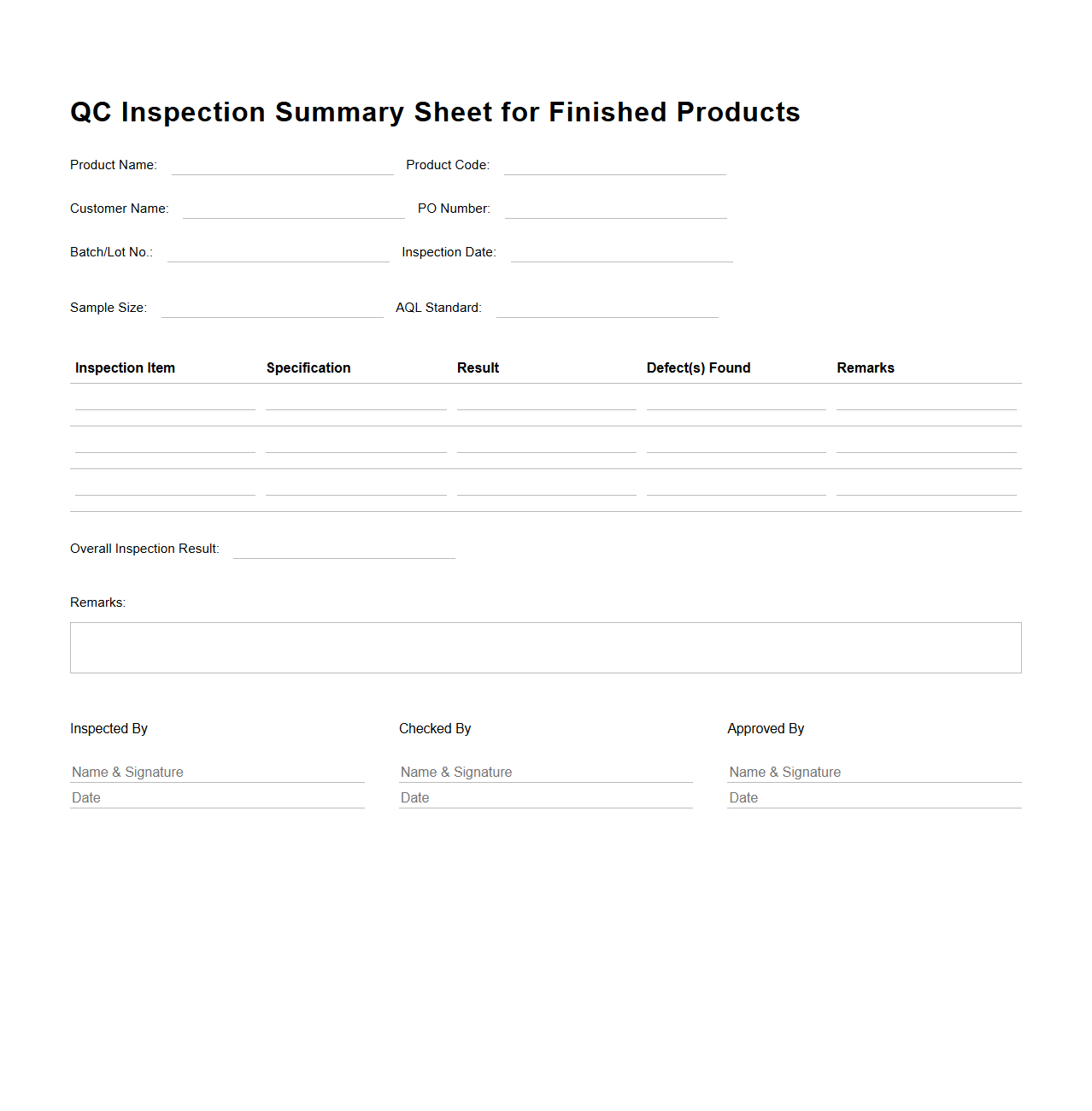

QC Inspection Summary Sheet for Finished Products

The

QC Inspection Summary Sheet for Finished Products is a critical document used to record and consolidate the results of quality control inspections conducted on final products before shipment. It includes key data such as product specifications, inspection criteria, defect types, and acceptance status to ensure compliance with quality standards. This summary facilitates quick assessment of product quality, enabling manufacturers to identify issues and maintain consistent production standards.

What essential information should be included in a Finished Goods Inspection Document for production output?

The Finished Goods Inspection Document must include product identification details such as batch or serial numbers. It should also capture the inspection date and location where the evaluation is performed. Additionally, relevant inspection criteria and acceptance standards are essential for clarity and traceability.

How does the document verify compliance with quality standards or specifications?

The document verifies compliance by recording detailed inspection results against predefined quality standards. It includes objective measurements and checks to confirm adherence to product specifications and regulatory requirements. This thorough comparison ensures the product meets all quality control benchmarks.

Which inspection results and findings must be clearly recorded on the document?

The document must clearly record quantitative test results, visual inspections, and functional performance outcomes. All findings, including pass/fail statuses and any anomalies, should be documented with precise details. This ensures transparency and supports effective quality analysis and decision-making.

How are non-conformities identified and addressed in the inspection documentation?

Non-conformities are explicitly highlighted and detailed within the inspection report. The document must include corrective actions or dispositions such as rework, rejection, or acceptance criteria deviations. Recording these steps is critical to maintaining quality assurance and continual improvement.

Who is responsible for reviewing, approving, and signing the finished goods inspection document?

The responsibility for reviewing and approving the document typically lies with qualified quality control personnel or supervisors. The inspector who conducts the examination usually performs the initial sign-off, ensuring accountability. Finally, a quality manager or authorized personnel provides final approval to certify product compliance before release.

More Manufacturing Templates